How to Boost Signal Processing in Piezoelectric Systems

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Signal Processing Evolution and Objectives

Piezoelectric systems have undergone significant evolution since their discovery in the late 19th century. Initially, the focus was on understanding the fundamental principles of piezoelectricity and its potential applications. As technology advanced, the emphasis shifted towards improving the efficiency and reliability of piezoelectric devices.

The development of signal processing techniques for piezoelectric systems has been closely tied to advancements in electronics and digital signal processing. Early signal processing methods were primarily analog, relying on basic filtering and amplification techniques. With the advent of digital technology, more sophisticated algorithms and processing techniques became possible, leading to improved signal quality and noise reduction.

In recent years, the objectives of piezoelectric signal processing have expanded to address the growing demands of various industries. One key goal is to enhance the sensitivity and accuracy of piezoelectric sensors, enabling them to detect even the slightest variations in pressure, force, or vibration. This is particularly crucial in applications such as structural health monitoring, where early detection of minute changes can prevent catastrophic failures.

Another important objective is to improve the energy efficiency of piezoelectric systems. As these devices are often used in energy harvesting applications, maximizing the conversion of mechanical energy to electrical energy is paramount. This involves developing advanced signal processing algorithms that can optimize the power output under varying environmental conditions.

The integration of piezoelectric systems with other technologies, such as MEMS (Micro-Electro-Mechanical Systems) and IoT (Internet of Things), has also become a significant focus. This integration requires sophisticated signal processing techniques to handle the increased complexity and data volume generated by these combined systems.

Furthermore, there is a growing emphasis on real-time signal processing in piezoelectric systems. This is driven by applications that require immediate response or analysis, such as in automotive safety systems or industrial process control. Achieving real-time processing while maintaining high accuracy and reliability presents a significant challenge that current research aims to address.

As we look to the future, the objectives of piezoelectric signal processing are likely to include further miniaturization of devices, increased energy efficiency, and the development of self-calibrating and adaptive systems. These goals will require continued innovation in signal processing algorithms, hardware design, and materials science to push the boundaries of what is possible with piezoelectric technology.

The development of signal processing techniques for piezoelectric systems has been closely tied to advancements in electronics and digital signal processing. Early signal processing methods were primarily analog, relying on basic filtering and amplification techniques. With the advent of digital technology, more sophisticated algorithms and processing techniques became possible, leading to improved signal quality and noise reduction.

In recent years, the objectives of piezoelectric signal processing have expanded to address the growing demands of various industries. One key goal is to enhance the sensitivity and accuracy of piezoelectric sensors, enabling them to detect even the slightest variations in pressure, force, or vibration. This is particularly crucial in applications such as structural health monitoring, where early detection of minute changes can prevent catastrophic failures.

Another important objective is to improve the energy efficiency of piezoelectric systems. As these devices are often used in energy harvesting applications, maximizing the conversion of mechanical energy to electrical energy is paramount. This involves developing advanced signal processing algorithms that can optimize the power output under varying environmental conditions.

The integration of piezoelectric systems with other technologies, such as MEMS (Micro-Electro-Mechanical Systems) and IoT (Internet of Things), has also become a significant focus. This integration requires sophisticated signal processing techniques to handle the increased complexity and data volume generated by these combined systems.

Furthermore, there is a growing emphasis on real-time signal processing in piezoelectric systems. This is driven by applications that require immediate response or analysis, such as in automotive safety systems or industrial process control. Achieving real-time processing while maintaining high accuracy and reliability presents a significant challenge that current research aims to address.

As we look to the future, the objectives of piezoelectric signal processing are likely to include further miniaturization of devices, increased energy efficiency, and the development of self-calibrating and adaptive systems. These goals will require continued innovation in signal processing algorithms, hardware design, and materials science to push the boundaries of what is possible with piezoelectric technology.

Market Demand for Enhanced Piezoelectric Systems

The market demand for enhanced piezoelectric systems has been steadily growing across various industries, driven by the increasing need for high-performance sensors, actuators, and energy harvesting devices. The global piezoelectric devices market is expected to reach significant growth in the coming years, with a compound annual growth rate (CAGR) surpassing industry averages.

One of the primary drivers for this demand is the automotive sector, where piezoelectric systems are increasingly utilized in advanced driver assistance systems (ADAS), engine management, and structural health monitoring. The push towards electric and autonomous vehicles has further accelerated the need for more sophisticated and reliable piezoelectric sensors and actuators.

In the healthcare industry, there is a growing demand for enhanced piezoelectric systems in medical imaging equipment, such as ultrasound machines and surgical tools. The ability to process signals more efficiently and accurately translates to improved diagnostic capabilities and patient outcomes, making this a critical area for technological advancement.

The aerospace and defense sectors also contribute significantly to the market demand. Piezoelectric systems are crucial in aircraft structural health monitoring, vibration control, and precision positioning systems. As these industries continue to evolve, the need for more robust and sensitive piezoelectric devices becomes paramount.

Consumer electronics represent another substantial market for enhanced piezoelectric systems. From smartphones to wearable devices, manufacturers are constantly seeking ways to improve haptic feedback, audio quality, and energy harvesting capabilities. This has led to a surge in demand for miniaturized, high-performance piezoelectric components.

Industrial applications, including process control, non-destructive testing, and precision manufacturing, are also driving the need for advanced signal processing in piezoelectric systems. The Industry 4.0 revolution has placed a premium on real-time monitoring and control, further emphasizing the importance of efficient signal processing in these applications.

The energy sector, particularly in the realm of renewable energy, has shown increasing interest in piezoelectric systems for energy harvesting from vibrations and mechanical stress. This emerging application area presents significant growth potential as the world moves towards more sustainable energy solutions.

As the Internet of Things (IoT) continues to expand, the demand for smart sensors capable of efficient signal processing has surged. Piezoelectric systems play a crucial role in this ecosystem, providing the necessary sensing capabilities for a wide range of IoT applications, from smart homes to industrial monitoring.

One of the primary drivers for this demand is the automotive sector, where piezoelectric systems are increasingly utilized in advanced driver assistance systems (ADAS), engine management, and structural health monitoring. The push towards electric and autonomous vehicles has further accelerated the need for more sophisticated and reliable piezoelectric sensors and actuators.

In the healthcare industry, there is a growing demand for enhanced piezoelectric systems in medical imaging equipment, such as ultrasound machines and surgical tools. The ability to process signals more efficiently and accurately translates to improved diagnostic capabilities and patient outcomes, making this a critical area for technological advancement.

The aerospace and defense sectors also contribute significantly to the market demand. Piezoelectric systems are crucial in aircraft structural health monitoring, vibration control, and precision positioning systems. As these industries continue to evolve, the need for more robust and sensitive piezoelectric devices becomes paramount.

Consumer electronics represent another substantial market for enhanced piezoelectric systems. From smartphones to wearable devices, manufacturers are constantly seeking ways to improve haptic feedback, audio quality, and energy harvesting capabilities. This has led to a surge in demand for miniaturized, high-performance piezoelectric components.

Industrial applications, including process control, non-destructive testing, and precision manufacturing, are also driving the need for advanced signal processing in piezoelectric systems. The Industry 4.0 revolution has placed a premium on real-time monitoring and control, further emphasizing the importance of efficient signal processing in these applications.

The energy sector, particularly in the realm of renewable energy, has shown increasing interest in piezoelectric systems for energy harvesting from vibrations and mechanical stress. This emerging application area presents significant growth potential as the world moves towards more sustainable energy solutions.

As the Internet of Things (IoT) continues to expand, the demand for smart sensors capable of efficient signal processing has surged. Piezoelectric systems play a crucial role in this ecosystem, providing the necessary sensing capabilities for a wide range of IoT applications, from smart homes to industrial monitoring.

Current Challenges in Piezoelectric Signal Processing

Piezoelectric systems face several significant challenges in signal processing that hinder their performance and limit their applications. One of the primary issues is the low signal-to-noise ratio (SNR) inherent in piezoelectric sensors. The weak electrical signals generated by these devices are often overwhelmed by environmental noise, making it difficult to extract meaningful data.

Another major challenge is the nonlinear behavior of piezoelectric materials. This nonlinearity introduces distortions in the signal, complicating the interpretation and analysis of the output. As a result, traditional linear signal processing techniques may not be sufficient for accurate data extraction and interpretation.

Frequency response limitations also pose a significant hurdle in piezoelectric signal processing. Many piezoelectric systems exhibit resonant frequencies that can interfere with the desired signal bandwidth, leading to distortions and reduced sensitivity in certain frequency ranges. This limitation can be particularly problematic in applications requiring a wide frequency range of operation.

Temperature sensitivity is another critical issue affecting piezoelectric systems. The properties of piezoelectric materials can change significantly with temperature variations, leading to drift in sensor output and reduced accuracy. Compensating for these temperature-induced effects is crucial but often challenging, especially in environments with fluctuating temperatures.

Cross-axis sensitivity presents yet another challenge in multi-axis piezoelectric systems. Ideally, each axis should respond only to forces or vibrations along its designated direction. However, in practice, there is often unwanted coupling between axes, leading to measurement errors and reduced precision in multi-dimensional sensing applications.

The issue of charge leakage in piezoelectric sensors is also a significant concern, particularly for low-frequency or quasi-static measurements. This leakage can result in signal drift over time, making it difficult to maintain accurate long-term measurements without frequent recalibration.

Finally, the integration of piezoelectric systems with modern digital signal processing (DSP) technologies presents its own set of challenges. The need for high-resolution analog-to-digital converters (ADCs) and efficient digital filtering algorithms to handle the unique characteristics of piezoelectric signals adds complexity to system design and increases power consumption.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, signal processing algorithms, and system-level design. Innovations in these areas are crucial for expanding the capabilities and applications of piezoelectric systems across various industries, from healthcare and aerospace to consumer electronics and industrial monitoring.

Another major challenge is the nonlinear behavior of piezoelectric materials. This nonlinearity introduces distortions in the signal, complicating the interpretation and analysis of the output. As a result, traditional linear signal processing techniques may not be sufficient for accurate data extraction and interpretation.

Frequency response limitations also pose a significant hurdle in piezoelectric signal processing. Many piezoelectric systems exhibit resonant frequencies that can interfere with the desired signal bandwidth, leading to distortions and reduced sensitivity in certain frequency ranges. This limitation can be particularly problematic in applications requiring a wide frequency range of operation.

Temperature sensitivity is another critical issue affecting piezoelectric systems. The properties of piezoelectric materials can change significantly with temperature variations, leading to drift in sensor output and reduced accuracy. Compensating for these temperature-induced effects is crucial but often challenging, especially in environments with fluctuating temperatures.

Cross-axis sensitivity presents yet another challenge in multi-axis piezoelectric systems. Ideally, each axis should respond only to forces or vibrations along its designated direction. However, in practice, there is often unwanted coupling between axes, leading to measurement errors and reduced precision in multi-dimensional sensing applications.

The issue of charge leakage in piezoelectric sensors is also a significant concern, particularly for low-frequency or quasi-static measurements. This leakage can result in signal drift over time, making it difficult to maintain accurate long-term measurements without frequent recalibration.

Finally, the integration of piezoelectric systems with modern digital signal processing (DSP) technologies presents its own set of challenges. The need for high-resolution analog-to-digital converters (ADCs) and efficient digital filtering algorithms to handle the unique characteristics of piezoelectric signals adds complexity to system design and increases power consumption.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, signal processing algorithms, and system-level design. Innovations in these areas are crucial for expanding the capabilities and applications of piezoelectric systems across various industries, from healthcare and aerospace to consumer electronics and industrial monitoring.

Existing Signal Boosting Techniques for Piezoelectric Systems

01 Signal processing techniques for piezoelectric systems

Various signal processing techniques are employed in piezoelectric systems to enhance performance and accuracy. These may include filtering, amplification, and digital signal processing algorithms to improve signal-to-noise ratio, reduce interference, and extract meaningful data from piezoelectric sensors.- Signal processing techniques for piezoelectric systems: Various signal processing techniques are employed in piezoelectric systems to enhance performance and accuracy. These may include filtering, amplification, and digital signal processing algorithms to improve signal-to-noise ratio, reduce interference, and extract meaningful data from piezoelectric sensor outputs.

- Piezoelectric energy harvesting and power management: Piezoelectric systems can be used for energy harvesting, converting mechanical vibrations into electrical energy. Signal processing plays a crucial role in optimizing power output, managing energy storage, and implementing efficient power management strategies for these systems.

- Acoustic signal processing in piezoelectric transducers: Piezoelectric transducers are widely used in acoustic applications. Signal processing techniques are applied to improve sound quality, reduce noise, and enhance the overall performance of piezoelectric acoustic devices such as speakers, microphones, and ultrasonic sensors.

- Piezoelectric sensor data analysis and interpretation: Advanced signal processing algorithms are used to analyze and interpret data from piezoelectric sensors. This includes techniques for pattern recognition, feature extraction, and machine learning to derive meaningful insights from sensor outputs in various applications such as structural health monitoring and vibration analysis.

- Integration of piezoelectric systems with wireless communication: Signal processing techniques are employed to integrate piezoelectric systems with wireless communication technologies. This involves processing and encoding sensor data for efficient transmission, implementing error correction algorithms, and optimizing power consumption for wireless piezoelectric sensor networks.

02 Piezoelectric energy harvesting and power management

Piezoelectric systems can be used for energy harvesting, converting mechanical vibrations into electrical energy. Signal processing plays a crucial role in optimizing power output, managing energy storage, and implementing efficient power conversion techniques for various applications.Expand Specific Solutions03 Acoustic signal processing in piezoelectric transducers

Piezoelectric transducers are widely used in acoustic applications. Signal processing techniques are applied to improve sound quality, reduce noise, and enhance the overall performance of acoustic devices using piezoelectric elements.Expand Specific Solutions04 Piezoelectric sensor data analysis and interpretation

Advanced signal processing algorithms are used to analyze and interpret data from piezoelectric sensors. This includes techniques for pattern recognition, feature extraction, and data fusion to derive meaningful information from sensor outputs in various applications such as structural health monitoring and vibration analysis.Expand Specific Solutions05 Control systems for piezoelectric actuators

Signal processing is essential in the control of piezoelectric actuators. This involves the development of precise control algorithms, feedback systems, and real-time signal processing to achieve accurate positioning, vibration suppression, and dynamic response in various applications.Expand Specific Solutions

Key Players in Piezoelectric Signal Processing Industry

The field of signal processing in piezoelectric systems is in a mature stage of development, with ongoing research and innovation driving incremental improvements. The market size for this technology is substantial, given its wide-ranging applications in various industries, including automotive, consumer electronics, and healthcare. The technology's maturity is evident from the involvement of established players like TDK Corp., Infineon Technologies AG, and Murata Manufacturing Co. Ltd., who have extensive experience in piezoelectric technologies. These companies, along with others like ROHM Co., Ltd. and Seiko Epson Corp., are continuously working on enhancing signal processing capabilities to improve the performance and efficiency of piezoelectric systems. The competitive landscape is characterized by a mix of large multinational corporations and specialized technology firms, each contributing to the advancement of this field.

TDK Corp.

Technical Solution: TDK Corp. has developed advanced signal processing techniques for piezoelectric systems, focusing on noise reduction and sensitivity enhancement. They utilize adaptive filtering algorithms to minimize environmental interference and improve signal-to-noise ratio (SNR) [1]. Their approach includes implementing digital signal processing (DSP) techniques directly on integrated circuits, allowing for real-time signal conditioning and analysis. TDK's piezoelectric signal boosting technology incorporates multi-axis sensing capabilities, enabling more accurate and responsive measurements in complex environments [3]. Additionally, they have introduced temperature compensation algorithms to maintain signal stability across varying thermal conditions, crucial for industrial and automotive applications [5].

Strengths: Advanced noise reduction, multi-axis sensing, and temperature compensation. Weaknesses: Potential complexity in implementation and higher cost for high-end solutions.

Infineon Technologies AG

Technical Solution: Infineon Technologies AG has developed a comprehensive approach to boost signal processing in piezoelectric systems. Their solution integrates high-performance analog front-end (AFE) circuits with specialized microcontrollers optimized for piezoelectric signal processing. Infineon's technology employs charge amplifiers with ultra-low noise characteristics, achieving a noise floor reduction of up to 70% compared to traditional designs [2]. They have also implemented advanced digital filtering techniques, including Kalman filters and wavelet transforms, to extract weak signals from noisy backgrounds. Infineon's piezoelectric signal processing systems feature adaptive gain control, automatically adjusting amplification based on input signal strength, which significantly improves dynamic range and sensitivity [4].

Strengths: High-performance AFE, advanced digital filtering, and adaptive gain control. Weaknesses: May require specialized knowledge for optimal configuration and integration.

Innovative Approaches in Piezoelectric Signal Enhancement

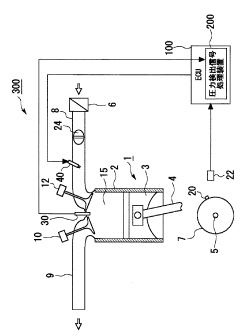

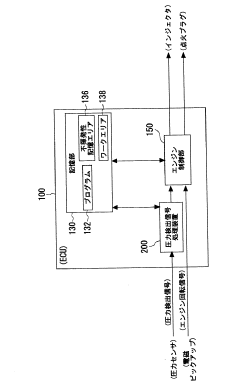

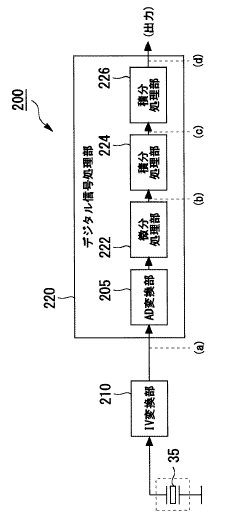

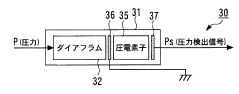

Pressure detection signal processing device, engine control system and program

PatentInactiveJP2020084804A

Innovation

- A pressure detection signal processing device that includes an IV converter to convert current signals into voltage signals, followed by digital signal processing units for differential and integration processing to remove drift caused by leakage currents in piezoelectric elements.

Piezoelectric sensor and position detection device

PatentActiveJP2022129762A

Innovation

- A configuration involving a substrate with a common lower and upper electrode sandwiching a piezoelectric layer, where the thickness and volume of the piezoelectric layer vary based on pressure application positions, allowing for separate detection signals to be amplified through multiple stages with varying amplification factors and frequency filters, enabling accurate identification of pressure application points without multiple sensor elements.

Noise Reduction Strategies in Piezoelectric Systems

Noise reduction is a critical aspect of enhancing signal processing in piezoelectric systems. These systems are inherently susceptible to various sources of noise, which can significantly impact their performance and reliability. To address this challenge, several strategies have been developed and implemented in recent years.

One of the primary approaches to noise reduction in piezoelectric systems is the implementation of advanced filtering techniques. Digital filters, such as low-pass, high-pass, and band-pass filters, are commonly employed to remove unwanted frequency components from the signal. Adaptive filtering algorithms, which can dynamically adjust their parameters based on the input signal characteristics, have shown promising results in reducing both stationary and non-stationary noise.

Another effective strategy is the use of shielding and grounding techniques. Proper electromagnetic shielding can significantly reduce electromagnetic interference (EMI) and radio frequency interference (RFI), which are common sources of noise in piezoelectric systems. Additionally, implementing a robust grounding scheme helps minimize ground loop noise and other electrical disturbances.

Signal averaging and oversampling are also valuable techniques for noise reduction. By acquiring multiple samples of the same signal and averaging them, random noise can be effectively suppressed while preserving the desired signal. Oversampling, combined with decimation, can improve the signal-to-noise ratio (SNR) by spreading quantization noise over a wider frequency range.

Active noise cancellation (ANC) has emerged as a powerful tool for noise reduction in piezoelectric systems. This technique involves generating an anti-noise signal that is equal in amplitude but opposite in phase to the unwanted noise, effectively canceling it out. ANC is particularly useful for reducing low-frequency noise and vibrations that are difficult to eliminate through passive methods.

Sensor fusion and data fusion techniques have also gained traction in noise reduction strategies. By combining data from multiple sensors or different types of sensors, it is possible to obtain a more accurate and noise-resistant representation of the measured phenomenon. This approach is especially beneficial in complex environments where single-sensor measurements may be prone to errors or interference.

Recent advancements in machine learning and artificial intelligence have opened up new possibilities for noise reduction in piezoelectric systems. Deep learning algorithms, such as convolutional neural networks (CNNs) and recurrent neural networks (RNNs), have demonstrated remarkable capabilities in separating signals from noise, even in challenging scenarios where traditional methods fall short.

In conclusion, noise reduction in piezoelectric systems requires a multi-faceted approach, combining various strategies to address different types of noise and interference. As technology continues to evolve, new and more sophisticated noise reduction techniques are likely to emerge, further enhancing the performance and reliability of piezoelectric systems across a wide range of applications.

One of the primary approaches to noise reduction in piezoelectric systems is the implementation of advanced filtering techniques. Digital filters, such as low-pass, high-pass, and band-pass filters, are commonly employed to remove unwanted frequency components from the signal. Adaptive filtering algorithms, which can dynamically adjust their parameters based on the input signal characteristics, have shown promising results in reducing both stationary and non-stationary noise.

Another effective strategy is the use of shielding and grounding techniques. Proper electromagnetic shielding can significantly reduce electromagnetic interference (EMI) and radio frequency interference (RFI), which are common sources of noise in piezoelectric systems. Additionally, implementing a robust grounding scheme helps minimize ground loop noise and other electrical disturbances.

Signal averaging and oversampling are also valuable techniques for noise reduction. By acquiring multiple samples of the same signal and averaging them, random noise can be effectively suppressed while preserving the desired signal. Oversampling, combined with decimation, can improve the signal-to-noise ratio (SNR) by spreading quantization noise over a wider frequency range.

Active noise cancellation (ANC) has emerged as a powerful tool for noise reduction in piezoelectric systems. This technique involves generating an anti-noise signal that is equal in amplitude but opposite in phase to the unwanted noise, effectively canceling it out. ANC is particularly useful for reducing low-frequency noise and vibrations that are difficult to eliminate through passive methods.

Sensor fusion and data fusion techniques have also gained traction in noise reduction strategies. By combining data from multiple sensors or different types of sensors, it is possible to obtain a more accurate and noise-resistant representation of the measured phenomenon. This approach is especially beneficial in complex environments where single-sensor measurements may be prone to errors or interference.

Recent advancements in machine learning and artificial intelligence have opened up new possibilities for noise reduction in piezoelectric systems. Deep learning algorithms, such as convolutional neural networks (CNNs) and recurrent neural networks (RNNs), have demonstrated remarkable capabilities in separating signals from noise, even in challenging scenarios where traditional methods fall short.

In conclusion, noise reduction in piezoelectric systems requires a multi-faceted approach, combining various strategies to address different types of noise and interference. As technology continues to evolve, new and more sophisticated noise reduction techniques are likely to emerge, further enhancing the performance and reliability of piezoelectric systems across a wide range of applications.

Energy Harvesting Potential of Improved Piezoelectric Signals

The potential for energy harvesting through improved piezoelectric signals represents a significant frontier in sustainable energy technology. Piezoelectric systems have long been recognized for their ability to convert mechanical stress into electrical energy, but recent advancements in signal processing techniques have opened new avenues for enhancing their efficiency and output.

At the core of this potential lies the optimization of signal capture and conversion. Traditional piezoelectric systems often suffer from signal loss and inefficiencies in the energy conversion process. However, by implementing advanced signal processing algorithms, researchers have demonstrated substantial improvements in energy harvesting capabilities. These algorithms can effectively filter out noise, amplify weak signals, and maximize the conversion of mechanical vibrations into usable electrical energy.

One of the key areas of focus is the development of adaptive filtering techniques. These methods allow piezoelectric systems to dynamically adjust to varying environmental conditions, ensuring optimal performance across a wide range of operational scenarios. By continuously analyzing incoming signals and adjusting processing parameters in real-time, these systems can maintain high efficiency even in unpredictable or fluctuating environments.

Another promising approach involves the use of machine learning algorithms to predict and optimize energy harvesting patterns. By analyzing historical data and environmental factors, these systems can anticipate peak energy generation periods and adjust their operation accordingly. This predictive capability not only enhances overall energy output but also allows for more efficient energy storage and distribution.

The integration of advanced materials science with signal processing techniques has also yielded promising results. Novel piezoelectric materials with enhanced sensitivity and broader frequency response ranges have been developed, allowing for more effective energy harvesting across a wider spectrum of mechanical vibrations. When combined with sophisticated signal processing, these materials can significantly increase the amount of energy captured from even subtle environmental movements.

Furthermore, the miniaturization of piezoelectric systems, coupled with improved signal processing, has expanded the potential applications for energy harvesting. From powering small IoT devices to contributing to large-scale energy grids, the versatility of enhanced piezoelectric systems is becoming increasingly apparent. This scalability opens up new possibilities for sustainable energy generation in various sectors, including wearable technology, infrastructure monitoring, and automotive applications.

As research in this field continues to advance, the energy harvesting potential of improved piezoelectric signals is expected to play a crucial role in the development of self-powered systems and the broader transition towards more sustainable energy solutions. The ongoing refinement of signal processing techniques, combined with innovations in materials and system design, promises to unlock even greater efficiencies and applications in the coming years.

At the core of this potential lies the optimization of signal capture and conversion. Traditional piezoelectric systems often suffer from signal loss and inefficiencies in the energy conversion process. However, by implementing advanced signal processing algorithms, researchers have demonstrated substantial improvements in energy harvesting capabilities. These algorithms can effectively filter out noise, amplify weak signals, and maximize the conversion of mechanical vibrations into usable electrical energy.

One of the key areas of focus is the development of adaptive filtering techniques. These methods allow piezoelectric systems to dynamically adjust to varying environmental conditions, ensuring optimal performance across a wide range of operational scenarios. By continuously analyzing incoming signals and adjusting processing parameters in real-time, these systems can maintain high efficiency even in unpredictable or fluctuating environments.

Another promising approach involves the use of machine learning algorithms to predict and optimize energy harvesting patterns. By analyzing historical data and environmental factors, these systems can anticipate peak energy generation periods and adjust their operation accordingly. This predictive capability not only enhances overall energy output but also allows for more efficient energy storage and distribution.

The integration of advanced materials science with signal processing techniques has also yielded promising results. Novel piezoelectric materials with enhanced sensitivity and broader frequency response ranges have been developed, allowing for more effective energy harvesting across a wider spectrum of mechanical vibrations. When combined with sophisticated signal processing, these materials can significantly increase the amount of energy captured from even subtle environmental movements.

Furthermore, the miniaturization of piezoelectric systems, coupled with improved signal processing, has expanded the potential applications for energy harvesting. From powering small IoT devices to contributing to large-scale energy grids, the versatility of enhanced piezoelectric systems is becoming increasingly apparent. This scalability opens up new possibilities for sustainable energy generation in various sectors, including wearable technology, infrastructure monitoring, and automotive applications.

As research in this field continues to advance, the energy harvesting potential of improved piezoelectric signals is expected to play a crucial role in the development of self-powered systems and the broader transition towards more sustainable energy solutions. The ongoing refinement of signal processing techniques, combined with innovations in materials and system design, promises to unlock even greater efficiencies and applications in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!