How to Turn Ambient Vibrations into Usable Power

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vibration Energy Harvesting Background and Objectives

Vibration energy harvesting has emerged as a promising technology for converting ambient mechanical vibrations into usable electrical power. This field has gained significant attention over the past two decades due to the increasing demand for sustainable and autonomous power sources for low-power electronic devices and wireless sensor networks.

The concept of harvesting energy from vibrations dates back to the early 20th century, with the development of piezoelectric materials. However, it wasn't until the late 1990s and early 2000s that researchers began to seriously explore the potential of vibration energy harvesting for practical applications. The miniaturization of electronic devices and the advent of wireless sensor networks have been key drivers in the renewed interest in this technology.

The primary objective of vibration energy harvesting is to develop efficient and cost-effective methods to capture and convert ambient mechanical energy into electrical power. This technology aims to provide a sustainable alternative to traditional batteries, especially in applications where frequent battery replacement is impractical or costly.

One of the main challenges in vibration energy harvesting is the low-frequency nature of most ambient vibrations, typically ranging from 1 Hz to 100 Hz. This presents a significant obstacle in designing efficient energy harvesters that can operate effectively across a wide frequency range. Additionally, the unpredictable and variable nature of ambient vibrations necessitates the development of adaptive and broadband harvesting techniques.

The evolution of vibration energy harvesting technology has seen the exploration of various transduction mechanisms, including piezoelectric, electromagnetic, and electrostatic approaches. Each of these methods has its own advantages and limitations, and ongoing research focuses on optimizing their performance and addressing their specific challenges.

Recent technological advancements have led to the development of novel materials and structures for vibration energy harvesting. These include the use of nanostructured materials, flexible and stretchable devices, and hybrid systems that combine multiple transduction mechanisms. Such innovations aim to improve the power output, efficiency, and adaptability of energy harvesters across diverse environmental conditions.

As the field progresses, researchers are also exploring the integration of vibration energy harvesting with other emerging technologies, such as the Internet of Things (IoT) and wearable devices. This convergence opens up new possibilities for self-powered sensors and autonomous systems in various applications, including structural health monitoring, industrial automation, and personal health tracking.

The concept of harvesting energy from vibrations dates back to the early 20th century, with the development of piezoelectric materials. However, it wasn't until the late 1990s and early 2000s that researchers began to seriously explore the potential of vibration energy harvesting for practical applications. The miniaturization of electronic devices and the advent of wireless sensor networks have been key drivers in the renewed interest in this technology.

The primary objective of vibration energy harvesting is to develop efficient and cost-effective methods to capture and convert ambient mechanical energy into electrical power. This technology aims to provide a sustainable alternative to traditional batteries, especially in applications where frequent battery replacement is impractical or costly.

One of the main challenges in vibration energy harvesting is the low-frequency nature of most ambient vibrations, typically ranging from 1 Hz to 100 Hz. This presents a significant obstacle in designing efficient energy harvesters that can operate effectively across a wide frequency range. Additionally, the unpredictable and variable nature of ambient vibrations necessitates the development of adaptive and broadband harvesting techniques.

The evolution of vibration energy harvesting technology has seen the exploration of various transduction mechanisms, including piezoelectric, electromagnetic, and electrostatic approaches. Each of these methods has its own advantages and limitations, and ongoing research focuses on optimizing their performance and addressing their specific challenges.

Recent technological advancements have led to the development of novel materials and structures for vibration energy harvesting. These include the use of nanostructured materials, flexible and stretchable devices, and hybrid systems that combine multiple transduction mechanisms. Such innovations aim to improve the power output, efficiency, and adaptability of energy harvesters across diverse environmental conditions.

As the field progresses, researchers are also exploring the integration of vibration energy harvesting with other emerging technologies, such as the Internet of Things (IoT) and wearable devices. This convergence opens up new possibilities for self-powered sensors and autonomous systems in various applications, including structural health monitoring, industrial automation, and personal health tracking.

Market Analysis for Vibration-Powered Devices

The market for vibration-powered devices is experiencing significant growth, driven by the increasing demand for sustainable energy solutions and the proliferation of Internet of Things (IoT) applications. This technology, which harnesses ambient vibrations to generate usable power, is finding applications across various sectors, including industrial, automotive, consumer electronics, and healthcare.

In the industrial sector, vibration-powered devices are being utilized for powering wireless sensors in manufacturing plants, oil rigs, and other industrial environments where traditional power sources are impractical or costly to implement. These devices enable continuous monitoring of equipment health, process efficiency, and environmental conditions without the need for battery replacements or wired power connections.

The automotive industry is another key market for vibration-powered devices. With the rise of electric and autonomous vehicles, there is a growing need for self-powered sensors to monitor various vehicle parameters. Vibration energy harvesters can be integrated into tires, suspension systems, and engine components to power sensors that track pressure, temperature, and performance metrics.

Consumer electronics represent a promising market segment for vibration-powered devices. Wearable technology, such as fitness trackers and smartwatches, can benefit from this technology by extending battery life or potentially eliminating the need for regular charging. Additionally, vibration-powered devices are being explored for use in smart home applications, where they can power sensors for security systems, environmental monitoring, and home automation.

The healthcare sector is also showing interest in vibration-powered devices for medical implants and wearable health monitors. These devices can provide a long-lasting power source for pacemakers, insulin pumps, and other implantable medical devices, reducing the need for invasive battery replacement surgeries.

Market analysts project substantial growth for the vibration energy harvesting market in the coming years. Factors contributing to this growth include the increasing adoption of IoT devices, the push for energy-efficient solutions, and advancements in piezoelectric and electromagnetic harvesting technologies.

However, challenges remain in the widespread adoption of vibration-powered devices. These include the need for improved energy conversion efficiency, the development of more robust and durable harvesting mechanisms, and the reduction of manufacturing costs. Overcoming these challenges will be crucial for the technology to reach its full market potential.

As the technology matures and becomes more cost-effective, new applications are likely to emerge. For instance, vibration-powered devices could play a significant role in smart city infrastructure, powering sensors for traffic management, structural health monitoring of buildings and bridges, and environmental monitoring systems.

In the industrial sector, vibration-powered devices are being utilized for powering wireless sensors in manufacturing plants, oil rigs, and other industrial environments where traditional power sources are impractical or costly to implement. These devices enable continuous monitoring of equipment health, process efficiency, and environmental conditions without the need for battery replacements or wired power connections.

The automotive industry is another key market for vibration-powered devices. With the rise of electric and autonomous vehicles, there is a growing need for self-powered sensors to monitor various vehicle parameters. Vibration energy harvesters can be integrated into tires, suspension systems, and engine components to power sensors that track pressure, temperature, and performance metrics.

Consumer electronics represent a promising market segment for vibration-powered devices. Wearable technology, such as fitness trackers and smartwatches, can benefit from this technology by extending battery life or potentially eliminating the need for regular charging. Additionally, vibration-powered devices are being explored for use in smart home applications, where they can power sensors for security systems, environmental monitoring, and home automation.

The healthcare sector is also showing interest in vibration-powered devices for medical implants and wearable health monitors. These devices can provide a long-lasting power source for pacemakers, insulin pumps, and other implantable medical devices, reducing the need for invasive battery replacement surgeries.

Market analysts project substantial growth for the vibration energy harvesting market in the coming years. Factors contributing to this growth include the increasing adoption of IoT devices, the push for energy-efficient solutions, and advancements in piezoelectric and electromagnetic harvesting technologies.

However, challenges remain in the widespread adoption of vibration-powered devices. These include the need for improved energy conversion efficiency, the development of more robust and durable harvesting mechanisms, and the reduction of manufacturing costs. Overcoming these challenges will be crucial for the technology to reach its full market potential.

As the technology matures and becomes more cost-effective, new applications are likely to emerge. For instance, vibration-powered devices could play a significant role in smart city infrastructure, powering sensors for traffic management, structural health monitoring of buildings and bridges, and environmental monitoring systems.

Current Challenges in Ambient Vibration Energy Harvesting

Ambient vibration energy harvesting faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the low power density of ambient vibrations, which typically results in minimal energy output. This limitation makes it difficult to generate sufficient power for many practical applications, especially those requiring continuous or high-energy operation.

The unpredictable nature of ambient vibrations poses another major challenge. Unlike controlled environments, real-world vibration sources are often irregular and inconsistent, varying in frequency and amplitude. This variability makes it challenging to design energy harvesters that can effectively capture energy across a wide range of vibration conditions, leading to suboptimal performance in many scenarios.

Frequency matching between the energy harvester and the vibration source is crucial for maximum energy extraction. However, achieving this match is complex due to the diverse range of vibration frequencies encountered in different environments. Broadband energy harvesting techniques have been developed to address this issue, but they often come at the cost of reduced efficiency or increased complexity.

The miniaturization of energy harvesting devices presents another significant challenge. As devices become smaller, their power output typically decreases, making it difficult to power even low-energy electronics. This limitation is particularly problematic for applications in wearable technology, implantable medical devices, and wireless sensor networks, where size constraints are critical.

Durability and longevity of energy harvesting devices are also concerns, especially in harsh environments. Continuous exposure to vibrations can lead to material fatigue and degradation of components, potentially reducing the lifespan and reliability of the harvesting system. Developing robust materials and designs that can withstand long-term vibration exposure without significant performance degradation remains an ongoing challenge.

The conversion efficiency of mechanical energy to electrical energy is another area requiring improvement. Current piezoelectric and electromagnetic conversion mechanisms have limitations in their efficiency, particularly at the small scales typical of many vibration energy harvesting applications. Enhancing the conversion efficiency without significantly increasing cost or complexity is a key focus of ongoing research.

Finally, the integration of energy harvesting systems with power management and storage solutions presents its own set of challenges. Efficiently storing and utilizing the harvested energy, especially given its often intermittent and low-power nature, requires sophisticated power management circuits. These circuits must be both efficient and compact, adding another layer of complexity to the overall system design.

The unpredictable nature of ambient vibrations poses another major challenge. Unlike controlled environments, real-world vibration sources are often irregular and inconsistent, varying in frequency and amplitude. This variability makes it challenging to design energy harvesters that can effectively capture energy across a wide range of vibration conditions, leading to suboptimal performance in many scenarios.

Frequency matching between the energy harvester and the vibration source is crucial for maximum energy extraction. However, achieving this match is complex due to the diverse range of vibration frequencies encountered in different environments. Broadband energy harvesting techniques have been developed to address this issue, but they often come at the cost of reduced efficiency or increased complexity.

The miniaturization of energy harvesting devices presents another significant challenge. As devices become smaller, their power output typically decreases, making it difficult to power even low-energy electronics. This limitation is particularly problematic for applications in wearable technology, implantable medical devices, and wireless sensor networks, where size constraints are critical.

Durability and longevity of energy harvesting devices are also concerns, especially in harsh environments. Continuous exposure to vibrations can lead to material fatigue and degradation of components, potentially reducing the lifespan and reliability of the harvesting system. Developing robust materials and designs that can withstand long-term vibration exposure without significant performance degradation remains an ongoing challenge.

The conversion efficiency of mechanical energy to electrical energy is another area requiring improvement. Current piezoelectric and electromagnetic conversion mechanisms have limitations in their efficiency, particularly at the small scales typical of many vibration energy harvesting applications. Enhancing the conversion efficiency without significantly increasing cost or complexity is a key focus of ongoing research.

Finally, the integration of energy harvesting systems with power management and storage solutions presents its own set of challenges. Efficiently storing and utilizing the harvested energy, especially given its often intermittent and low-power nature, requires sophisticated power management circuits. These circuits must be both efficient and compact, adding another layer of complexity to the overall system design.

Existing Vibration-to-Energy Conversion Solutions

01 Piezoelectric energy harvesting from ambient vibrations

This technology utilizes piezoelectric materials to convert ambient vibrations into electrical energy. The system typically consists of a piezoelectric element that deforms under mechanical stress from environmental vibrations, generating an electric charge. This method is particularly effective for low-frequency vibrations and can be used in various applications, including powering small electronic devices or sensors in environments with consistent vibrations.- Piezoelectric energy harvesting from ambient vibrations: This technology utilizes piezoelectric materials to convert ambient vibrations into electrical energy. The system typically consists of a piezoelectric element that deforms under mechanical stress from environmental vibrations, generating an electric charge. This approach is particularly useful for powering small electronic devices in environments with consistent vibrations.

- Electromagnetic induction-based vibration energy harvesting: This method involves using electromagnetic induction to convert ambient vibrations into electrical power. The system typically consists of a magnet moving relative to a coil, inducing an electric current. This approach can be effective for harvesting energy from low-frequency vibrations and is often used in larger-scale applications.

- MEMS-based vibration energy harvesters: Micro-Electro-Mechanical Systems (MEMS) technology is used to create miniaturized vibration energy harvesters. These devices typically incorporate resonant structures that oscillate in response to ambient vibrations, coupled with transduction mechanisms to convert mechanical energy into electrical energy. MEMS-based harvesters are particularly suitable for integration into small electronic devices.

- Triboelectric nanogenerators for vibration energy harvesting: This emerging technology uses the triboelectric effect to convert mechanical energy from ambient vibrations into electricity. The system typically consists of two materials with different electron affinities that are brought into contact and separated repeatedly by vibrations, generating an electric current. This approach offers high power density and is suitable for a wide range of vibration frequencies.

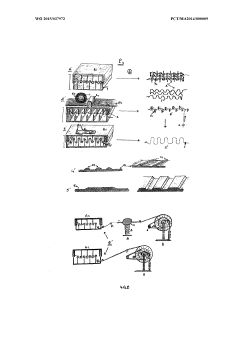

- Adaptive and broadband vibration energy harvesting systems: These advanced systems are designed to efficiently harvest energy across a wide range of vibration frequencies or adapt to changing vibration conditions. They may incorporate tunable resonators, arrays of harvesters with different resonant frequencies, or non-linear oscillators. Such systems aim to overcome the limitations of traditional narrow-band energy harvesters and maximize energy extraction from variable ambient vibrations.

02 Electromagnetic energy harvesting from ambient vibrations

This approach uses electromagnetic induction to convert ambient vibrations into electrical power. The system typically consists of a magnet moving relative to a coil, inducing an electric current. This method can be effective for a wide range of vibration frequencies and amplitudes, making it suitable for various environmental conditions. It can be used in applications such as self-powered sensors or to supplement battery power in portable devices.Expand Specific Solutions03 Triboelectric energy harvesting from ambient vibrations

This technology harnesses triboelectric effects to generate power from ambient vibrations. It typically involves two materials with different electron affinities that are brought into contact and then separated by vibrations, creating an electric potential difference. This method can be highly efficient for harvesting energy from low-frequency vibrations and has potential applications in self-powered wearable devices and environmental sensors.Expand Specific Solutions04 Hybrid energy harvesting systems for ambient vibrations

These systems combine multiple energy harvesting technologies to maximize power generation from ambient vibrations. For example, a hybrid system might integrate piezoelectric and electromagnetic harvesters to capture energy across a broader spectrum of vibration frequencies and amplitudes. This approach can increase overall efficiency and reliability, making it suitable for applications where consistent power generation is crucial.Expand Specific Solutions05 Optimization and control systems for ambient vibration energy harvesting

This category focuses on technologies that enhance the efficiency and effectiveness of ambient vibration energy harvesting systems. It includes adaptive resonance tuning mechanisms, power management circuits, and intelligent control systems that can adjust harvester parameters based on environmental conditions. These optimizations can significantly improve the overall performance and reliability of vibration energy harvesters in real-world applications.Expand Specific Solutions

Key Players in Energy Harvesting Industry

The field of harvesting ambient vibrations for usable power is in its early development stage, with growing market potential as energy efficiency becomes increasingly crucial. The technology's maturity is still evolving, with various approaches being explored by academic institutions and industry players. Companies like Xiamen University, University of Michigan, and Naval Research Laboratory are conducting foundational research, while established firms such as Kyocera Corp. and Taiwan Semiconductor Manufacturing Co. are exploring practical applications. The market size is expected to expand as the technology becomes more efficient and cost-effective, driven by the increasing demand for sustainable energy solutions in IoT devices, wearables, and remote sensing applications.

National Technology & Engineering Solutions of Sandia LLC

Technical Solution: Sandia National Laboratories has developed an advanced vibration energy harvesting system designed for harsh and extreme environments. Their approach utilizes a combination of robust piezoelectric materials and advanced MEMS technology to create highly durable energy harvesters. The core of their system is a specially engineered piezoelectric composite material that maintains high efficiency across a wide temperature range, from cryogenic to high-temperature environments[13]. Sandia's harvester incorporates a unique non-linear oscillator design that enables broadband energy capture, significantly improving performance in environments with variable or unpredictable vibration frequencies[15]. The system also features an advanced power management circuit that includes energy storage and power conditioning capabilities, allowing for stable power output even under intermittent vibration conditions. Sandia has demonstrated the technology's effectiveness in applications such as deep-sea oil exploration, aerospace, and nuclear facilities, where conventional power sources are impractical or unreliable[17].

Strengths: Extremely durable and suitable for harsh environments, capable of broadband energy harvesting. Weaknesses: Potentially higher cost due to specialized materials and design, may be overengineered for less demanding applications.

OMRON Corp.

Technical Solution: OMRON Corporation has developed a cutting-edge vibration energy harvesting technology tailored for IoT and sensor applications. Their approach focuses on miniaturization and efficiency, utilizing MEMS-based piezoelectric devices. The core of their technology is a high-performance piezoelectric thin film, which demonstrates superior energy conversion efficiency compared to bulk piezoelectric materials[8]. OMRON's system incorporates a unique resonance frequency tuning mechanism, allowing the harvester to adapt to various vibration sources dynamically. This is achieved through an innovative mechanical design that can adjust its stiffness in response to changing vibration frequencies[10]. Additionally, OMRON has developed an ultra-low-power management circuit that can effectively store and distribute the harvested energy, even from intermittent or weak vibration sources. The company has successfully demonstrated the technology in various applications, including structural health monitoring and predictive maintenance in manufacturing settings[12].

Strengths: Highly miniaturized and adaptable, suitable for a wide range of IoT applications. Weaknesses: May have limited power output compared to larger systems, potentially less effective for high-power applications.

Core Innovations in Piezoelectric Materials

Transforming a sound source, mechanical and thermal piezoelectric source into electric current

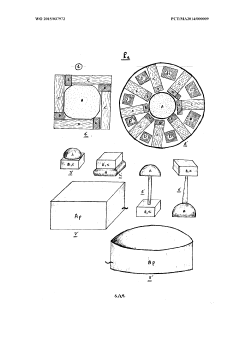

PatentWO2015128689A3

Innovation

- Utilization of multiple energy sources (sound, mechanical pressure, thermal energy, breathing) for electricity generation through nanoelectronic sensors.

- Integration of energy harvesting technology into everyday materials and infrastructure (e.g., pigments, inks, asphalt) using nanotechnology.

- Versatile application of the technology for powering a wide range of devices and infrastructure, from personal electronics to street lighting and irrigation systems.

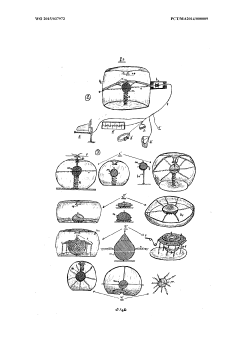

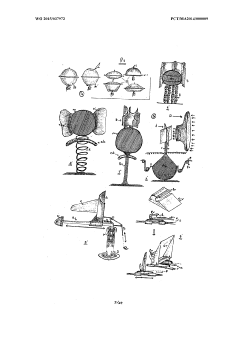

Apparatus for producing electrical energy from agitations and receivers

PatentWO2015037972A1

Innovation

- A device comprising a mass sensitive to agitations, articulated on springs or elastic bars, which transfers mechanical energy through a system of alternators and receivers to generate electrical energy, utilizing the weight and elasticity of the mass and agitation sources such as vehicles, wind, and human movement.

Environmental Impact of Energy Harvesting Technologies

Energy harvesting technologies, particularly those focused on converting ambient vibrations into usable power, have the potential to significantly impact the environment in both positive and negative ways. On the positive side, these technologies offer a sustainable alternative to traditional energy sources, reducing reliance on fossil fuels and decreasing greenhouse gas emissions. By harnessing energy from existing vibrations in the environment, such as those produced by machinery, traffic, or natural phenomena, these systems can generate clean electricity without additional fuel consumption or carbon emissions.

However, the environmental impact of energy harvesting technologies extends beyond their operational phase. The production and manufacturing processes of these devices may involve the use of rare earth elements and other materials with complex supply chains. The extraction and processing of these materials can lead to environmental degradation, including habitat destruction, water pollution, and increased energy consumption. Additionally, the disposal of these devices at the end of their lifecycle presents challenges, as they may contain components that are difficult to recycle or require special handling to prevent environmental contamination.

The implementation of vibration-based energy harvesting systems can also have indirect environmental effects. For instance, in urban environments, the widespread deployment of these technologies could potentially alter the acoustic landscape, affecting wildlife and human well-being. Conversely, by reducing the need for traditional power infrastructure, these systems could help minimize land use changes associated with power generation and transmission facilities.

The scalability of vibration energy harvesting technologies is another factor to consider when assessing their environmental impact. While small-scale applications may have minimal negative effects, large-scale implementation could lead to unforeseen consequences on local ecosystems. For example, extensive harvesting of vibrations from natural sources like ocean waves or wind could potentially disrupt natural energy flows and impact wildlife behavior.

It is crucial to conduct comprehensive life cycle assessments of these technologies to fully understand their environmental footprint. This includes evaluating the energy and resources required for production, the efficiency and longevity of the devices in operation, and the environmental costs of disposal or recycling. By considering these factors, researchers and policymakers can work towards optimizing the design and implementation of vibration energy harvesting technologies to maximize their positive environmental impact while minimizing potential drawbacks.

However, the environmental impact of energy harvesting technologies extends beyond their operational phase. The production and manufacturing processes of these devices may involve the use of rare earth elements and other materials with complex supply chains. The extraction and processing of these materials can lead to environmental degradation, including habitat destruction, water pollution, and increased energy consumption. Additionally, the disposal of these devices at the end of their lifecycle presents challenges, as they may contain components that are difficult to recycle or require special handling to prevent environmental contamination.

The implementation of vibration-based energy harvesting systems can also have indirect environmental effects. For instance, in urban environments, the widespread deployment of these technologies could potentially alter the acoustic landscape, affecting wildlife and human well-being. Conversely, by reducing the need for traditional power infrastructure, these systems could help minimize land use changes associated with power generation and transmission facilities.

The scalability of vibration energy harvesting technologies is another factor to consider when assessing their environmental impact. While small-scale applications may have minimal negative effects, large-scale implementation could lead to unforeseen consequences on local ecosystems. For example, extensive harvesting of vibrations from natural sources like ocean waves or wind could potentially disrupt natural energy flows and impact wildlife behavior.

It is crucial to conduct comprehensive life cycle assessments of these technologies to fully understand their environmental footprint. This includes evaluating the energy and resources required for production, the efficiency and longevity of the devices in operation, and the environmental costs of disposal or recycling. By considering these factors, researchers and policymakers can work towards optimizing the design and implementation of vibration energy harvesting technologies to maximize their positive environmental impact while minimizing potential drawbacks.

Standardization and Safety Regulations

As the field of ambient vibration energy harvesting continues to evolve, the development of standardization and safety regulations becomes increasingly crucial. These regulations serve to ensure the reliability, efficiency, and safety of vibration-based power generation systems across various applications and industries.

The International Electrotechnical Commission (IEC) has taken a leading role in establishing standards for energy harvesting technologies, including those related to ambient vibrations. The IEC Technical Committee 120 (TC 120) focuses specifically on Electrical Energy Storage (EES) systems and has been working on developing standards that encompass vibration energy harvesting devices.

One of the key areas of standardization is the measurement and characterization of vibration energy harvesters. This includes defining standard testing procedures to evaluate the performance of these devices under various environmental conditions. Factors such as frequency range, amplitude, and duration of vibrations are considered to ensure consistent and comparable results across different manufacturers and applications.

Safety regulations for vibration energy harvesting systems primarily focus on electrical safety, mechanical integrity, and environmental impact. Electrical safety standards address issues such as insulation, grounding, and protection against overcharging or short circuits. Mechanical safety considerations include the structural integrity of the harvesting devices, especially in high-vibration environments or when subjected to extreme weather conditions.

Environmental regulations play a significant role in the development and deployment of vibration energy harvesting systems. These regulations often address the materials used in the construction of the devices, ensuring they are non-toxic and recyclable. Additionally, regulations may cover the potential electromagnetic interference generated by these systems, particularly in sensitive environments such as healthcare facilities or near communication equipment.

As the technology advances, new standards are being developed to address emerging challenges. For instance, the integration of vibration energy harvesters with Internet of Things (IoT) devices has led to the need for standards related to data security and privacy. These standards aim to protect the information collected and transmitted by self-powered IoT sensors that utilize ambient vibrations as their energy source.

The harmonization of standards across different regions and industries remains an ongoing challenge. Efforts are being made to align regulations between major markets such as the United States, European Union, and Asia to facilitate global adoption and trade of vibration energy harvesting technologies. This harmonization process involves collaboration between international standardization bodies, industry stakeholders, and regulatory agencies.

The International Electrotechnical Commission (IEC) has taken a leading role in establishing standards for energy harvesting technologies, including those related to ambient vibrations. The IEC Technical Committee 120 (TC 120) focuses specifically on Electrical Energy Storage (EES) systems and has been working on developing standards that encompass vibration energy harvesting devices.

One of the key areas of standardization is the measurement and characterization of vibration energy harvesters. This includes defining standard testing procedures to evaluate the performance of these devices under various environmental conditions. Factors such as frequency range, amplitude, and duration of vibrations are considered to ensure consistent and comparable results across different manufacturers and applications.

Safety regulations for vibration energy harvesting systems primarily focus on electrical safety, mechanical integrity, and environmental impact. Electrical safety standards address issues such as insulation, grounding, and protection against overcharging or short circuits. Mechanical safety considerations include the structural integrity of the harvesting devices, especially in high-vibration environments or when subjected to extreme weather conditions.

Environmental regulations play a significant role in the development and deployment of vibration energy harvesting systems. These regulations often address the materials used in the construction of the devices, ensuring they are non-toxic and recyclable. Additionally, regulations may cover the potential electromagnetic interference generated by these systems, particularly in sensitive environments such as healthcare facilities or near communication equipment.

As the technology advances, new standards are being developed to address emerging challenges. For instance, the integration of vibration energy harvesters with Internet of Things (IoT) devices has led to the need for standards related to data security and privacy. These standards aim to protect the information collected and transmitted by self-powered IoT sensors that utilize ambient vibrations as their energy source.

The harmonization of standards across different regions and industries remains an ongoing challenge. Efforts are being made to align regulations between major markets such as the United States, European Union, and Asia to facilitate global adoption and trade of vibration energy harvesting technologies. This harmonization process involves collaboration between international standardization bodies, industry stakeholders, and regulatory agencies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!