Piezoelectricity in High-speed Rail Integrity Surveillance

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Tech in Rail Monitoring: Background and Objectives

Piezoelectric technology has emerged as a promising solution for high-speed rail integrity surveillance, offering a novel approach to monitoring and maintaining the safety of rail infrastructure. The development of this technology can be traced back to the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880. Since then, piezoelectric materials have found applications in various fields, including sensors, actuators, and energy harvesting devices.

In the context of high-speed rail systems, the need for real-time, accurate, and non-intrusive monitoring techniques has become increasingly critical. Traditional methods of rail inspection, such as visual inspections and ultrasonic testing, often require service interruptions and may not provide continuous monitoring capabilities. This gap in monitoring technology has driven the exploration of piezoelectric-based solutions for rail integrity surveillance.

The primary objective of implementing piezoelectric technology in high-speed rail monitoring is to enhance safety, reliability, and efficiency of rail operations. By leveraging the unique properties of piezoelectric materials, researchers aim to develop advanced sensing systems capable of detecting and reporting structural defects, excessive vibrations, and other potential hazards in real-time.

One of the key advantages of piezoelectric sensors is their ability to convert mechanical stress into electrical signals, allowing for the continuous monitoring of rail conditions without the need for external power sources. This self-powered characteristic makes piezoelectric sensors particularly suitable for deployment in remote or hard-to-reach areas of rail networks.

The evolution of piezoelectric technology in rail monitoring has been driven by advancements in materials science, signal processing, and data analytics. Early applications focused on simple vibration detection, while current research explores more sophisticated techniques such as acoustic emission monitoring and impedance-based structural health assessment.

As the technology progresses, researchers are working towards developing integrated systems that combine multiple piezoelectric sensors with advanced data processing algorithms. These systems aim to provide comprehensive health monitoring of rail infrastructure, including track conditions, wheel-rail interactions, and potential structural weaknesses.

The implementation of piezoelectric technology in high-speed rail monitoring aligns with broader industry trends towards smart infrastructure and predictive maintenance. By enabling early detection of potential issues, this technology has the potential to significantly reduce maintenance costs, minimize service disruptions, and enhance overall safety in rail transportation.

Looking ahead, the continued development of piezoelectric technology in rail monitoring is expected to play a crucial role in supporting the expansion and modernization of high-speed rail networks worldwide. As research progresses, the focus will likely shift towards improving sensor durability, enhancing data interpretation capabilities, and integrating piezoelectric monitoring systems with other emerging technologies such as artificial intelligence and the Internet of Things.

In the context of high-speed rail systems, the need for real-time, accurate, and non-intrusive monitoring techniques has become increasingly critical. Traditional methods of rail inspection, such as visual inspections and ultrasonic testing, often require service interruptions and may not provide continuous monitoring capabilities. This gap in monitoring technology has driven the exploration of piezoelectric-based solutions for rail integrity surveillance.

The primary objective of implementing piezoelectric technology in high-speed rail monitoring is to enhance safety, reliability, and efficiency of rail operations. By leveraging the unique properties of piezoelectric materials, researchers aim to develop advanced sensing systems capable of detecting and reporting structural defects, excessive vibrations, and other potential hazards in real-time.

One of the key advantages of piezoelectric sensors is their ability to convert mechanical stress into electrical signals, allowing for the continuous monitoring of rail conditions without the need for external power sources. This self-powered characteristic makes piezoelectric sensors particularly suitable for deployment in remote or hard-to-reach areas of rail networks.

The evolution of piezoelectric technology in rail monitoring has been driven by advancements in materials science, signal processing, and data analytics. Early applications focused on simple vibration detection, while current research explores more sophisticated techniques such as acoustic emission monitoring and impedance-based structural health assessment.

As the technology progresses, researchers are working towards developing integrated systems that combine multiple piezoelectric sensors with advanced data processing algorithms. These systems aim to provide comprehensive health monitoring of rail infrastructure, including track conditions, wheel-rail interactions, and potential structural weaknesses.

The implementation of piezoelectric technology in high-speed rail monitoring aligns with broader industry trends towards smart infrastructure and predictive maintenance. By enabling early detection of potential issues, this technology has the potential to significantly reduce maintenance costs, minimize service disruptions, and enhance overall safety in rail transportation.

Looking ahead, the continued development of piezoelectric technology in rail monitoring is expected to play a crucial role in supporting the expansion and modernization of high-speed rail networks worldwide. As research progresses, the focus will likely shift towards improving sensor durability, enhancing data interpretation capabilities, and integrating piezoelectric monitoring systems with other emerging technologies such as artificial intelligence and the Internet of Things.

Market Analysis for Rail Integrity Monitoring Systems

The market for rail integrity monitoring systems has experienced significant growth in recent years, driven by the increasing demand for safer and more efficient rail transportation. This trend is particularly evident in the high-speed rail sector, where the need for advanced monitoring technologies is paramount. The global rail integrity monitoring systems market is expected to continue its upward trajectory, with a compound annual growth rate projected to remain strong over the next five years.

Several factors contribute to the expanding market demand for these systems. Firstly, the rapid expansion of high-speed rail networks worldwide, especially in countries like China, Japan, and various European nations, has created a substantial need for sophisticated monitoring solutions. These high-speed lines require more frequent and accurate inspections to ensure safety and prevent potential failures.

Secondly, the aging rail infrastructure in many developed countries necessitates more robust monitoring systems to detect and prevent structural issues before they lead to accidents or service disruptions. This has led to increased investment in modernizing existing rail networks, including the implementation of advanced monitoring technologies.

The market is also being driven by stringent safety regulations and standards imposed by government bodies and rail authorities. These regulations often mandate the use of advanced monitoring systems to ensure the integrity of rail infrastructure, further boosting market demand.

In terms of technology trends, there is a growing interest in real-time monitoring solutions that can provide continuous data on rail conditions. This shift from periodic inspections to constant surveillance is expected to revolutionize the industry, allowing for more proactive maintenance and reducing the risk of unexpected failures.

The integration of Internet of Things (IoT) and artificial intelligence (AI) technologies into rail integrity monitoring systems is another significant trend. These technologies enable more accurate data analysis, predictive maintenance, and automated decision-making processes, enhancing the overall efficiency of rail operations.

Geographically, Asia-Pacific is emerging as a key market for rail integrity monitoring systems, primarily due to extensive high-speed rail projects in countries like China and Japan. North America and Europe also represent substantial markets, driven by the need to upgrade aging rail infrastructure and improve safety standards.

Several factors contribute to the expanding market demand for these systems. Firstly, the rapid expansion of high-speed rail networks worldwide, especially in countries like China, Japan, and various European nations, has created a substantial need for sophisticated monitoring solutions. These high-speed lines require more frequent and accurate inspections to ensure safety and prevent potential failures.

Secondly, the aging rail infrastructure in many developed countries necessitates more robust monitoring systems to detect and prevent structural issues before they lead to accidents or service disruptions. This has led to increased investment in modernizing existing rail networks, including the implementation of advanced monitoring technologies.

The market is also being driven by stringent safety regulations and standards imposed by government bodies and rail authorities. These regulations often mandate the use of advanced monitoring systems to ensure the integrity of rail infrastructure, further boosting market demand.

In terms of technology trends, there is a growing interest in real-time monitoring solutions that can provide continuous data on rail conditions. This shift from periodic inspections to constant surveillance is expected to revolutionize the industry, allowing for more proactive maintenance and reducing the risk of unexpected failures.

The integration of Internet of Things (IoT) and artificial intelligence (AI) technologies into rail integrity monitoring systems is another significant trend. These technologies enable more accurate data analysis, predictive maintenance, and automated decision-making processes, enhancing the overall efficiency of rail operations.

Geographically, Asia-Pacific is emerging as a key market for rail integrity monitoring systems, primarily due to extensive high-speed rail projects in countries like China and Japan. North America and Europe also represent substantial markets, driven by the need to upgrade aging rail infrastructure and improve safety standards.

Current Challenges in High-speed Rail Surveillance

High-speed rail surveillance faces several critical challenges in ensuring the integrity and safety of rail systems. One of the primary concerns is the detection and monitoring of structural defects in real-time. As trains operate at increasingly higher speeds, the potential for rapid deterioration of rail infrastructure increases, necessitating more advanced and responsive monitoring systems.

The current surveillance methods often struggle to provide continuous, real-time data on the structural health of rails, bridges, and other critical components. Traditional inspection techniques, such as visual inspections and periodic maintenance checks, are becoming insufficient in the face of the demanding operational conditions of high-speed rail systems.

Another significant challenge is the integration of various sensor technologies to create a comprehensive monitoring system. While individual sensors can provide valuable data, the true power of surveillance lies in the ability to synthesize information from multiple sources. This integration is complicated by the need for compatibility between different sensor types and the requirement for robust data transmission in harsh railway environments.

The vast amount of data generated by modern surveillance systems presents its own set of challenges. Processing and analyzing this data in real-time to identify potential issues before they become critical failures is a complex task that requires advanced algorithms and significant computational power. The development of efficient data management and analysis systems is crucial for effective high-speed rail surveillance.

Environmental factors also pose significant challenges to surveillance systems. Extreme weather conditions, electromagnetic interference from the rail system itself, and the physical stresses of high-speed operations can all affect the reliability and accuracy of monitoring equipment. Designing surveillance systems that can operate consistently under these conditions is a major technical hurdle.

Furthermore, the implementation of new surveillance technologies must be balanced with the need to minimize disruptions to existing rail operations. Retrofitting existing infrastructure with advanced monitoring systems without causing significant downtime is a logistical and engineering challenge that requires careful planning and execution.

Lastly, there is the ongoing challenge of cost-effectiveness. While the importance of robust surveillance systems is clear, the implementation and maintenance of advanced technologies across extensive rail networks represent a significant investment. Balancing the need for comprehensive monitoring with budgetary constraints is a constant consideration for rail operators and infrastructure managers.

The current surveillance methods often struggle to provide continuous, real-time data on the structural health of rails, bridges, and other critical components. Traditional inspection techniques, such as visual inspections and periodic maintenance checks, are becoming insufficient in the face of the demanding operational conditions of high-speed rail systems.

Another significant challenge is the integration of various sensor technologies to create a comprehensive monitoring system. While individual sensors can provide valuable data, the true power of surveillance lies in the ability to synthesize information from multiple sources. This integration is complicated by the need for compatibility between different sensor types and the requirement for robust data transmission in harsh railway environments.

The vast amount of data generated by modern surveillance systems presents its own set of challenges. Processing and analyzing this data in real-time to identify potential issues before they become critical failures is a complex task that requires advanced algorithms and significant computational power. The development of efficient data management and analysis systems is crucial for effective high-speed rail surveillance.

Environmental factors also pose significant challenges to surveillance systems. Extreme weather conditions, electromagnetic interference from the rail system itself, and the physical stresses of high-speed operations can all affect the reliability and accuracy of monitoring equipment. Designing surveillance systems that can operate consistently under these conditions is a major technical hurdle.

Furthermore, the implementation of new surveillance technologies must be balanced with the need to minimize disruptions to existing rail operations. Retrofitting existing infrastructure with advanced monitoring systems without causing significant downtime is a logistical and engineering challenge that requires careful planning and execution.

Lastly, there is the ongoing challenge of cost-effectiveness. While the importance of robust surveillance systems is clear, the implementation and maintenance of advanced technologies across extensive rail networks represent a significant investment. Balancing the need for comprehensive monitoring with budgetary constraints is a constant consideration for rail operators and infrastructure managers.

Existing Piezoelectric Solutions for Rail Integrity

01 Piezoelectric sensor integrity monitoring

Techniques for monitoring the integrity of piezoelectric sensors in various applications. This includes methods for detecting faults, damage, or degradation in piezoelectric elements to ensure reliable operation and accurate measurements. Integrity monitoring systems may incorporate self-diagnostic features and real-time analysis of sensor performance.- Piezoelectric sensor integrity monitoring: Techniques for monitoring the integrity of piezoelectric sensors in various applications. This includes methods for detecting faults, damage, or degradation in piezoelectric elements to ensure reliable operation and accurate measurements. Integrity monitoring systems may involve continuous assessment of sensor performance and early warning mechanisms for potential failures.

- Structural health monitoring using piezoelectric materials: Application of piezoelectric materials in structural health monitoring systems. These systems utilize piezoelectric sensors to detect and assess damage or changes in structural integrity. The approach enables real-time monitoring of structures such as buildings, bridges, and aerospace components, allowing for early detection of potential issues and preventive maintenance.

- Piezoelectric energy harvesting device reliability: Methods and designs to enhance the reliability and integrity of piezoelectric energy harvesting devices. This includes improving the durability of piezoelectric materials, optimizing device structures to withstand environmental stresses, and developing protective measures to ensure long-term performance in energy harvesting applications.

- Piezoelectric transducer quality assurance: Techniques for ensuring the quality and integrity of piezoelectric transducers during manufacturing and operation. This involves developing testing protocols, implementing quality control measures, and creating standards for evaluating the performance and reliability of piezoelectric transducers used in various industries.

- Piezoelectric material characterization and testing: Methods and systems for characterizing and testing piezoelectric materials to ensure their integrity and performance. This includes developing advanced measurement techniques, creating standardized testing procedures, and establishing criteria for evaluating the quality and reliability of piezoelectric materials used in sensors, actuators, and other applications.

02 Structural health monitoring using piezoelectric materials

Application of piezoelectric materials in structural health monitoring systems. These systems utilize piezoelectric sensors to detect and assess damage or changes in structural integrity. The approach enables continuous monitoring of structures such as buildings, bridges, and aerospace components for improved safety and maintenance planning.Expand Specific Solutions03 Piezoelectric energy harvesting device reliability

Methods and designs to enhance the reliability and durability of piezoelectric energy harvesting devices. This includes techniques to improve the mechanical integrity of the piezoelectric elements, protective packaging, and strategies to maintain consistent performance over extended periods of operation in various environmental conditions.Expand Specific Solutions04 Integration of piezoelectric components in electronic systems

Approaches for integrating piezoelectric components into electronic systems while maintaining system integrity. This involves addressing challenges related to electrical connections, signal processing, and compatibility with other electronic components. Techniques may include specialized mounting methods and interface designs to ensure reliable operation within complex electronic assemblies.Expand Specific Solutions05 Quality control and testing of piezoelectric materials

Methods and systems for quality control and testing of piezoelectric materials and devices to ensure their integrity and performance. This includes techniques for characterizing piezoelectric properties, detecting defects or inconsistencies in material composition, and evaluating the overall quality of piezoelectric components during manufacturing and assembly processes.Expand Specific Solutions

Key Players in Rail Monitoring and Piezoelectric Tech

The research on piezoelectricity in high-speed rail integrity surveillance is in a developing stage, with growing market potential as rail networks expand globally. The technology's maturity varies among key players, with academic institutions like Southwest Jiaotong University and the University of Bologna leading fundamental research. Industry giants such as Siemens, Bosch, and China State Railway Group are advancing practical applications. Specialized companies like Kistler Holding AG and Indtact GmbH are focusing on sensor technologies. The competitive landscape is diverse, involving collaboration between academia, state-owned enterprises, and private sector companies, reflecting the interdisciplinary nature of this field and its strategic importance in railway safety and efficiency.

China Academy of Railway Sciences Group Co. Ltd.

Technical Solution: China Academy of Railway Sciences Group Co. Ltd. has developed a comprehensive piezoelectric-based integrity surveillance system for high-speed rail. Their approach integrates piezoelectric sensors along the rail tracks to detect and monitor structural changes, vibrations, and potential defects in real-time. The system utilizes advanced signal processing algorithms to filter out noise and identify critical anomalies. They have implemented a distributed sensor network that can cover extensive rail sections, allowing for continuous monitoring of rail integrity[1]. The company has also developed specialized piezoelectric materials optimized for the harsh railway environment, ensuring long-term reliability and sensitivity[3]. Their solution includes a centralized data analysis platform that uses machine learning algorithms to predict potential failures and optimize maintenance schedules[5].

Strengths: Extensive experience in railway systems, comprehensive solution covering large rail networks, advanced data analysis capabilities. Weaknesses: Potential high implementation costs, may require significant infrastructure changes for existing rail systems.

Kistler Holding AG

Technical Solution: Kistler Holding AG, a leader in dynamic measurement technology, has applied its expertise to develop a piezoelectric-based integrity surveillance system for high-speed rail. Their approach focuses on high-precision, high-frequency measurements to detect even the smallest changes in rail integrity. Kistler's system employs custom-designed piezoelectric sensors that can withstand the extreme conditions of high-speed rail environments while maintaining exceptional sensitivity. These sensors are strategically placed along the rail infrastructure to monitor vibrations, impacts, and structural stresses. The company has developed specialized charge amplifiers and data acquisition systems optimized for railway applications, ensuring accurate signal processing even in electromagnetically noisy environments[8]. Kistler's solution includes a sophisticated data analysis platform that uses advanced signal processing techniques, including wavelet analysis and machine learning algorithms, to identify patterns indicative of developing faults or structural weaknesses. The system can differentiate between normal operational variations and potential integrity issues, reducing false alarms and improving maintenance efficiency[10].

Strengths: High-precision measurement capabilities, robust sensors designed for harsh environments, advanced signal processing expertise. Weaknesses: May require more frequent calibration due to high sensitivity, potentially higher component costs.

Core Innovations in Piezoelectric Rail Sensors

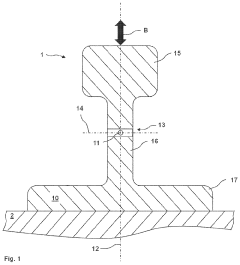

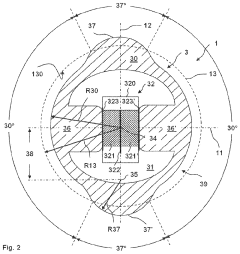

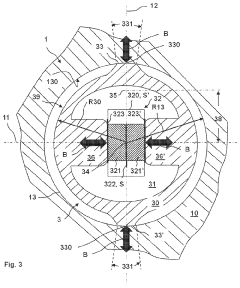

Device for Detecting a Rail Load and Method for Mounting Such Device in a Rail

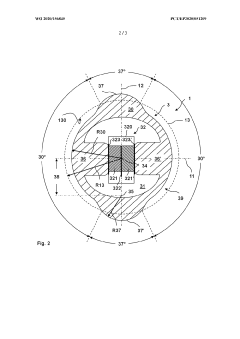

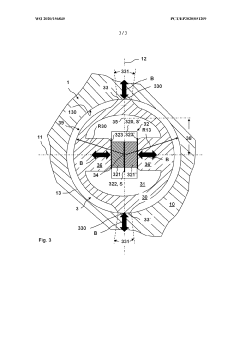

PatentActiveUS20220097740A1

Innovation

- A device using piezoelectric sensor elements that generate electric polarization charges proportional to the rail load, providing high accuracy and temperature independence, with a form-fit and force-fit connection for low-cost mounting and a service life matching that of the rail.

Device for detecting rail loading, and method for mounting such a device in a rail

PatentWO2020156845A1

Innovation

- A rail load detection device using piezoelectric sensor elements that generate electrical polarization charges proportional to the rail load, with a method of mounting that involves a sensor housing with a positive and non-positive fit into a bore in the rail, allowing for accurate detection of both static and dynamic components over a wide temperature range and extended service life.

Safety Standards and Regulations in Rail Industry

Safety standards and regulations play a crucial role in ensuring the integrity and reliability of high-speed rail systems. In the context of piezoelectric-based surveillance for rail integrity, adherence to these standards is paramount. The rail industry is governed by a complex network of international, national, and regional regulations that cover various aspects of rail operations, including infrastructure, rolling stock, and safety systems.

At the international level, organizations such as the International Union of Railways (UIC) and the International Electrotechnical Commission (IEC) provide guidelines and standards that are widely adopted across the global rail industry. These standards often serve as a foundation for national regulations and help ensure interoperability between different rail systems.

In the European Union, the European Railway Agency (ERA) oversees the development and implementation of safety standards for the rail sector. The ERA's Technical Specifications for Interoperability (TSIs) provide detailed requirements for various components of the rail system, including those related to infrastructure monitoring and safety.

In the United States, the Federal Railroad Administration (FRA) is responsible for enforcing rail safety regulations. The FRA's Track Safety Standards outline specific requirements for track inspection and maintenance, which are relevant to the implementation of piezoelectric-based surveillance systems.

When implementing piezoelectric sensors for rail integrity surveillance, compliance with electromagnetic compatibility (EMC) standards is essential. These standards ensure that the sensors do not interfere with other electronic systems on the rail network and can function reliably in the electromagnetic environment of a high-speed rail system.

Safety integrity levels (SIL) are another critical consideration in the development of rail safety systems. The IEC 61508 standard provides a framework for determining the appropriate SIL for safety-related systems, including those used for rail integrity monitoring. Piezoelectric-based surveillance systems must be designed and implemented to meet the required SIL for their intended application.

Data protection and cybersecurity regulations also come into play when dealing with the information collected by piezoelectric sensors. As these systems gather and transmit data about the condition of rail infrastructure, they must comply with relevant data protection laws and implement robust cybersecurity measures to prevent unauthorized access or tampering.

The integration of piezoelectric sensors into existing rail infrastructure must also adhere to standards related to structural integrity and environmental resilience. These sensors must be able to withstand the harsh conditions of the rail environment, including vibrations, temperature fluctuations, and exposure to the elements, without compromising the safety or performance of the rail system.

As the technology for piezoelectric-based rail integrity surveillance continues to evolve, it is likely that new standards and regulations will emerge to address specific aspects of these systems. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions will be essential to ensure that safety standards keep pace with technological advancements in this field.

At the international level, organizations such as the International Union of Railways (UIC) and the International Electrotechnical Commission (IEC) provide guidelines and standards that are widely adopted across the global rail industry. These standards often serve as a foundation for national regulations and help ensure interoperability between different rail systems.

In the European Union, the European Railway Agency (ERA) oversees the development and implementation of safety standards for the rail sector. The ERA's Technical Specifications for Interoperability (TSIs) provide detailed requirements for various components of the rail system, including those related to infrastructure monitoring and safety.

In the United States, the Federal Railroad Administration (FRA) is responsible for enforcing rail safety regulations. The FRA's Track Safety Standards outline specific requirements for track inspection and maintenance, which are relevant to the implementation of piezoelectric-based surveillance systems.

When implementing piezoelectric sensors for rail integrity surveillance, compliance with electromagnetic compatibility (EMC) standards is essential. These standards ensure that the sensors do not interfere with other electronic systems on the rail network and can function reliably in the electromagnetic environment of a high-speed rail system.

Safety integrity levels (SIL) are another critical consideration in the development of rail safety systems. The IEC 61508 standard provides a framework for determining the appropriate SIL for safety-related systems, including those used for rail integrity monitoring. Piezoelectric-based surveillance systems must be designed and implemented to meet the required SIL for their intended application.

Data protection and cybersecurity regulations also come into play when dealing with the information collected by piezoelectric sensors. As these systems gather and transmit data about the condition of rail infrastructure, they must comply with relevant data protection laws and implement robust cybersecurity measures to prevent unauthorized access or tampering.

The integration of piezoelectric sensors into existing rail infrastructure must also adhere to standards related to structural integrity and environmental resilience. These sensors must be able to withstand the harsh conditions of the rail environment, including vibrations, temperature fluctuations, and exposure to the elements, without compromising the safety or performance of the rail system.

As the technology for piezoelectric-based rail integrity surveillance continues to evolve, it is likely that new standards and regulations will emerge to address specific aspects of these systems. Ongoing collaboration between industry stakeholders, regulatory bodies, and research institutions will be essential to ensure that safety standards keep pace with technological advancements in this field.

Environmental Impact of Piezoelectric Rail Sensors

The implementation of piezoelectric sensors in high-speed rail systems for integrity surveillance presents both environmental challenges and opportunities. These sensors, while offering advanced monitoring capabilities, also introduce new materials and electronic components into the rail infrastructure. The environmental impact of these sensors must be carefully considered throughout their lifecycle.

During the manufacturing process, the production of piezoelectric materials and associated electronics may involve the use of rare earth elements and potentially hazardous substances. This raises concerns about resource depletion and the need for responsible sourcing practices. Additionally, the manufacturing process itself may contribute to energy consumption and greenhouse gas emissions, necessitating the adoption of cleaner production methods.

The installation of piezoelectric sensors along rail tracks requires minimal disturbance to existing infrastructure, which is a positive aspect from an environmental perspective. However, the long-term presence of these sensors in outdoor environments raises questions about their durability and potential for leaching harmful substances into surrounding soil and water systems. Proper encapsulation and weatherproofing techniques are crucial to mitigate these risks.

On the positive side, the implementation of piezoelectric sensors can lead to significant environmental benefits. By enabling more precise and timely detection of rail integrity issues, these sensors can help prevent accidents and reduce the need for frequent manual inspections. This, in turn, can lower the carbon footprint associated with maintenance activities and improve the overall energy efficiency of rail operations.

Furthermore, the energy harvesting capabilities of piezoelectric sensors offer an exciting prospect for sustainable rail systems. By converting mechanical vibrations from passing trains into electrical energy, these sensors can potentially become self-powered, reducing the need for external power sources and associated environmental impacts.

End-of-life considerations for piezoelectric sensors are also important. The complex nature of these devices, combining electronic components with specialized materials, necessitates the development of proper recycling and disposal protocols. Efforts should be made to recover valuable materials and minimize waste sent to landfills.

In conclusion, while piezoelectric sensors in high-speed rail integrity surveillance systems do introduce some environmental concerns, their potential benefits in terms of improved safety, reduced maintenance needs, and energy harvesting capabilities may outweigh these drawbacks. Ongoing research and development should focus on enhancing the environmental performance of these sensors throughout their lifecycle, from production to disposal, to ensure their sustainable integration into modern rail infrastructure.

During the manufacturing process, the production of piezoelectric materials and associated electronics may involve the use of rare earth elements and potentially hazardous substances. This raises concerns about resource depletion and the need for responsible sourcing practices. Additionally, the manufacturing process itself may contribute to energy consumption and greenhouse gas emissions, necessitating the adoption of cleaner production methods.

The installation of piezoelectric sensors along rail tracks requires minimal disturbance to existing infrastructure, which is a positive aspect from an environmental perspective. However, the long-term presence of these sensors in outdoor environments raises questions about their durability and potential for leaching harmful substances into surrounding soil and water systems. Proper encapsulation and weatherproofing techniques are crucial to mitigate these risks.

On the positive side, the implementation of piezoelectric sensors can lead to significant environmental benefits. By enabling more precise and timely detection of rail integrity issues, these sensors can help prevent accidents and reduce the need for frequent manual inspections. This, in turn, can lower the carbon footprint associated with maintenance activities and improve the overall energy efficiency of rail operations.

Furthermore, the energy harvesting capabilities of piezoelectric sensors offer an exciting prospect for sustainable rail systems. By converting mechanical vibrations from passing trains into electrical energy, these sensors can potentially become self-powered, reducing the need for external power sources and associated environmental impacts.

End-of-life considerations for piezoelectric sensors are also important. The complex nature of these devices, combining electronic components with specialized materials, necessitates the development of proper recycling and disposal protocols. Efforts should be made to recover valuable materials and minimize waste sent to landfills.

In conclusion, while piezoelectric sensors in high-speed rail integrity surveillance systems do introduce some environmental concerns, their potential benefits in terms of improved safety, reduced maintenance needs, and energy harvesting capabilities may outweigh these drawbacks. Ongoing research and development should focus on enhancing the environmental performance of these sensors throughout their lifecycle, from production to disposal, to ensure their sustainable integration into modern rail infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!