Cross-material Compatibility in Piezoelectric Sensor Fabrication

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception in the early 20th century. Initially discovered by the Curie brothers in 1880, piezoelectricity's practical applications emerged in the 1950s with the development of synthetic piezoelectric materials. The technology has since progressed from simple quartz crystals to advanced ceramic compounds and polymer-based sensors.

The evolution of piezoelectric sensors has been driven by the demand for more sensitive, reliable, and versatile sensing devices across various industries. Early applications were primarily focused on sonar and ultrasound technologies. However, as manufacturing techniques improved and new materials were developed, piezoelectric sensors found their way into automotive, aerospace, medical, and consumer electronics sectors.

A significant milestone in piezoelectric sensor development was the introduction of lead zirconate titanate (PZT) in the 1950s. PZT's superior piezoelectric properties revolutionized the field, enabling the creation of more efficient and powerful sensors. This breakthrough paved the way for miniaturization and integration of piezoelectric sensors into complex systems.

In recent years, the focus has shifted towards developing lead-free alternatives due to environmental concerns. This has led to research into new piezoelectric materials such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). These materials aim to match or exceed the performance of PZT while eliminating the use of toxic lead.

The current objectives in piezoelectric sensor fabrication are multifaceted. Researchers are striving to enhance sensor sensitivity, broaden the operating temperature range, and improve long-term stability. There is also a growing emphasis on developing flexible and stretchable piezoelectric sensors for wearable technology and soft robotics applications.

Cross-material compatibility has emerged as a critical challenge in advancing piezoelectric sensor technology. As sensors become more integrated into complex systems, the need for seamless interaction between different materials – piezoelectric elements, substrates, electrodes, and packaging materials – has become paramount. The objective is to create sensors that maintain their performance while interfacing with a variety of materials, ensuring durability and reliability in diverse operating conditions.

Another key goal is to develop scalable and cost-effective manufacturing processes for advanced piezoelectric sensors. This includes exploring new deposition techniques, such as 3D printing and roll-to-roll processing, to enable mass production of high-performance sensors. Additionally, there is a push towards creating multifunctional sensors that can simultaneously measure multiple parameters, such as pressure, temperature, and acceleration.

The evolution of piezoelectric sensors has been driven by the demand for more sensitive, reliable, and versatile sensing devices across various industries. Early applications were primarily focused on sonar and ultrasound technologies. However, as manufacturing techniques improved and new materials were developed, piezoelectric sensors found their way into automotive, aerospace, medical, and consumer electronics sectors.

A significant milestone in piezoelectric sensor development was the introduction of lead zirconate titanate (PZT) in the 1950s. PZT's superior piezoelectric properties revolutionized the field, enabling the creation of more efficient and powerful sensors. This breakthrough paved the way for miniaturization and integration of piezoelectric sensors into complex systems.

In recent years, the focus has shifted towards developing lead-free alternatives due to environmental concerns. This has led to research into new piezoelectric materials such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). These materials aim to match or exceed the performance of PZT while eliminating the use of toxic lead.

The current objectives in piezoelectric sensor fabrication are multifaceted. Researchers are striving to enhance sensor sensitivity, broaden the operating temperature range, and improve long-term stability. There is also a growing emphasis on developing flexible and stretchable piezoelectric sensors for wearable technology and soft robotics applications.

Cross-material compatibility has emerged as a critical challenge in advancing piezoelectric sensor technology. As sensors become more integrated into complex systems, the need for seamless interaction between different materials – piezoelectric elements, substrates, electrodes, and packaging materials – has become paramount. The objective is to create sensors that maintain their performance while interfacing with a variety of materials, ensuring durability and reliability in diverse operating conditions.

Another key goal is to develop scalable and cost-effective manufacturing processes for advanced piezoelectric sensors. This includes exploring new deposition techniques, such as 3D printing and roll-to-roll processing, to enable mass production of high-performance sensors. Additionally, there is a push towards creating multifunctional sensors that can simultaneously measure multiple parameters, such as pressure, temperature, and acceleration.

Cross-material Demand Analysis

The demand for cross-material compatibility in piezoelectric sensor fabrication has been steadily increasing due to the growing complexity and miniaturization of electronic devices. This trend is driven by the need for sensors that can operate effectively in diverse environments and applications, ranging from consumer electronics to industrial monitoring systems.

In the consumer electronics sector, there is a significant demand for piezoelectric sensors that can be integrated seamlessly into smartphones, wearables, and other portable devices. These sensors need to be compatible with a variety of materials, including plastics, metals, and ceramics, to ensure optimal performance and durability. The market for such sensors is expected to grow as manufacturers seek to enhance user experience through improved haptic feedback and gesture recognition features.

The automotive industry represents another major market for cross-material compatible piezoelectric sensors. With the rise of electric and autonomous vehicles, there is an increasing need for sensors that can withstand harsh operating conditions while maintaining high sensitivity and reliability. These sensors must be able to interface with various materials used in vehicle construction, such as composites, alloys, and polymers, without compromising their performance or longevity.

In the healthcare sector, the demand for biocompatible piezoelectric sensors is on the rise. These sensors are crucial for developing advanced medical devices, implants, and diagnostic tools. The ability to fabricate sensors that are compatible with both biological tissues and synthetic materials is essential for applications such as smart prosthetics, continuous health monitoring systems, and minimally invasive surgical instruments.

The industrial sector also presents significant opportunities for cross-material compatible piezoelectric sensors. In manufacturing and process control, there is a growing need for sensors that can operate in diverse environments, including high-temperature, high-pressure, and corrosive conditions. These sensors must be able to interface with a wide range of industrial materials while maintaining their sensing capabilities and structural integrity.

Environmental monitoring and energy harvesting applications are driving demand for piezoelectric sensors that can be integrated into various structures and materials. This includes sensors for structural health monitoring in buildings and infrastructure, as well as energy harvesting devices that can be embedded in roads, bridges, and other structures to generate power from vibrations and mechanical stress.

The aerospace and defense industries also require piezoelectric sensors with cross-material compatibility for applications such as structural health monitoring of aircraft components, vibration sensing in spacecraft, and underwater acoustic sensing for naval operations. These sensors must be able to function reliably in extreme conditions while interfacing with advanced composite materials and alloys used in aerospace construction.

In the consumer electronics sector, there is a significant demand for piezoelectric sensors that can be integrated seamlessly into smartphones, wearables, and other portable devices. These sensors need to be compatible with a variety of materials, including plastics, metals, and ceramics, to ensure optimal performance and durability. The market for such sensors is expected to grow as manufacturers seek to enhance user experience through improved haptic feedback and gesture recognition features.

The automotive industry represents another major market for cross-material compatible piezoelectric sensors. With the rise of electric and autonomous vehicles, there is an increasing need for sensors that can withstand harsh operating conditions while maintaining high sensitivity and reliability. These sensors must be able to interface with various materials used in vehicle construction, such as composites, alloys, and polymers, without compromising their performance or longevity.

In the healthcare sector, the demand for biocompatible piezoelectric sensors is on the rise. These sensors are crucial for developing advanced medical devices, implants, and diagnostic tools. The ability to fabricate sensors that are compatible with both biological tissues and synthetic materials is essential for applications such as smart prosthetics, continuous health monitoring systems, and minimally invasive surgical instruments.

The industrial sector also presents significant opportunities for cross-material compatible piezoelectric sensors. In manufacturing and process control, there is a growing need for sensors that can operate in diverse environments, including high-temperature, high-pressure, and corrosive conditions. These sensors must be able to interface with a wide range of industrial materials while maintaining their sensing capabilities and structural integrity.

Environmental monitoring and energy harvesting applications are driving demand for piezoelectric sensors that can be integrated into various structures and materials. This includes sensors for structural health monitoring in buildings and infrastructure, as well as energy harvesting devices that can be embedded in roads, bridges, and other structures to generate power from vibrations and mechanical stress.

The aerospace and defense industries also require piezoelectric sensors with cross-material compatibility for applications such as structural health monitoring of aircraft components, vibration sensing in spacecraft, and underwater acoustic sensing for naval operations. These sensors must be able to function reliably in extreme conditions while interfacing with advanced composite materials and alloys used in aerospace construction.

Current Challenges in Material Compatibility

The fabrication of piezoelectric sensors faces significant challenges in material compatibility, particularly when integrating diverse materials with varying properties. One of the primary issues is the mismatch in thermal expansion coefficients between different layers, which can lead to residual stresses and potential delamination during thermal processing or operation. This problem is especially pronounced when combining rigid piezoelectric ceramics with flexible polymer substrates or electrodes.

Another critical challenge is the chemical compatibility between materials. The interaction between piezoelectric materials, electrodes, and encapsulation layers can result in unwanted chemical reactions or diffusion processes. These interactions may degrade the piezoelectric properties, alter the electrical characteristics, or compromise the long-term stability of the sensor. For instance, the migration of metal ions from electrodes into the piezoelectric layer can significantly impact the sensor's performance and reliability.

The adhesion between different material layers presents a persistent challenge in sensor fabrication. Poor adhesion can lead to mechanical failure, reduced sensitivity, and compromised durability of the sensor. This issue is particularly evident when attempting to bond materials with vastly different surface energies or when dealing with inert surfaces that resist conventional bonding techniques.

Interfacial effects at the boundaries between different materials pose another significant hurdle. These effects can include charge accumulation, band alignment issues, and the formation of interfacial defects. Such phenomena can alter the local electric field distribution, affecting the overall piezoelectric response and potentially introducing non-linear behaviors that complicate sensor calibration and operation.

The integration of nanomaterials, such as carbon nanotubes or graphene, into piezoelectric sensors introduces additional compatibility challenges. While these materials offer enhanced properties, their incorporation often requires specialized processing techniques that may not be compatible with traditional piezoelectric materials or fabrication methods. Achieving uniform dispersion and maintaining the integrity of these nanomaterials throughout the fabrication process remains a significant technical challenge.

Lastly, the scalability of fabrication processes that maintain material compatibility across different production volumes is a persistent issue. Techniques that work well in laboratory settings may face significant hurdles when scaled up to industrial production levels, particularly in maintaining consistent material properties and interfaces across larger areas or in high-throughput manufacturing environments.

Another critical challenge is the chemical compatibility between materials. The interaction between piezoelectric materials, electrodes, and encapsulation layers can result in unwanted chemical reactions or diffusion processes. These interactions may degrade the piezoelectric properties, alter the electrical characteristics, or compromise the long-term stability of the sensor. For instance, the migration of metal ions from electrodes into the piezoelectric layer can significantly impact the sensor's performance and reliability.

The adhesion between different material layers presents a persistent challenge in sensor fabrication. Poor adhesion can lead to mechanical failure, reduced sensitivity, and compromised durability of the sensor. This issue is particularly evident when attempting to bond materials with vastly different surface energies or when dealing with inert surfaces that resist conventional bonding techniques.

Interfacial effects at the boundaries between different materials pose another significant hurdle. These effects can include charge accumulation, band alignment issues, and the formation of interfacial defects. Such phenomena can alter the local electric field distribution, affecting the overall piezoelectric response and potentially introducing non-linear behaviors that complicate sensor calibration and operation.

The integration of nanomaterials, such as carbon nanotubes or graphene, into piezoelectric sensors introduces additional compatibility challenges. While these materials offer enhanced properties, their incorporation often requires specialized processing techniques that may not be compatible with traditional piezoelectric materials or fabrication methods. Achieving uniform dispersion and maintaining the integrity of these nanomaterials throughout the fabrication process remains a significant technical challenge.

Lastly, the scalability of fabrication processes that maintain material compatibility across different production volumes is a persistent issue. Techniques that work well in laboratory settings may face significant hurdles when scaled up to industrial production levels, particularly in maintaining consistent material properties and interfaces across larger areas or in high-throughput manufacturing environments.

Existing Cross-material Fabrication Techniques

01 Material selection for piezoelectric sensors

The choice of materials for piezoelectric sensors is crucial for their performance and compatibility. Various materials, including ceramics, polymers, and composites, can be used to create piezoelectric sensors with different properties. The selection of materials depends on the specific application requirements, such as sensitivity, temperature range, and mechanical properties.- Material selection for piezoelectric sensors: Various materials can be used in piezoelectric sensors, including ceramics, polymers, and composites. The choice of material affects the sensor's performance, sensitivity, and compatibility with other components. Factors such as temperature stability, mechanical strength, and electrical properties are considered when selecting materials for specific applications.

- Compatibility with substrate materials: Piezoelectric sensors must be compatible with the substrate materials they are mounted on or integrated with. This includes considerations for thermal expansion coefficients, adhesion properties, and chemical interactions. Proper selection of materials and bonding techniques ensures long-term stability and performance of the sensor system.

- Electrode materials and interfaces: The choice of electrode materials and their interfaces with the piezoelectric element is crucial for sensor performance. Considerations include conductivity, durability, and compatibility with both the piezoelectric material and the surrounding environment. Proper electrode design and material selection can improve signal quality and sensor longevity.

- Encapsulation and packaging materials: Encapsulation and packaging materials protect piezoelectric sensors from environmental factors and ensure their proper functioning. These materials must be compatible with the sensor components and the intended operating conditions. Considerations include moisture resistance, thermal properties, and mechanical protection without interfering with the sensor's operation.

- Multi-material composite sensors: Composite structures combining different materials can enhance the performance and compatibility of piezoelectric sensors. These multi-material sensors can offer improved sensitivity, broader frequency response, or better integration with specific substrates. Careful design and material selection are required to optimize the properties of each component in the composite structure.

02 Substrate compatibility for piezoelectric sensors

The compatibility between the piezoelectric material and the substrate is essential for sensor performance. Different substrate materials, such as silicon, glass, or flexible polymers, can be used depending on the application. The choice of substrate affects the sensor's mechanical properties, thermal expansion, and overall integration with other components.Expand Specific Solutions03 Electrode material compatibility

The selection of electrode materials is critical for ensuring good electrical contact and compatibility with the piezoelectric material. Various metals and conductive materials can be used as electrodes, including gold, platinum, and conductive polymers. The electrode material must be chosen to minimize interfacial reactions and maintain long-term stability.Expand Specific Solutions04 Encapsulation and packaging materials

Proper encapsulation and packaging materials are essential for protecting piezoelectric sensors from environmental factors and ensuring their long-term reliability. The choice of encapsulation materials must be compatible with both the piezoelectric element and the substrate, while also providing the necessary protection against moisture, temperature variations, and mechanical stress.Expand Specific Solutions05 Interface layers for improved compatibility

Interface layers can be used to improve the compatibility between different materials in piezoelectric sensors. These layers can enhance adhesion, reduce stress, and prevent unwanted chemical reactions between the piezoelectric material, electrodes, and substrate. Various materials, such as thin metal films or oxide layers, can be used as interface layers to optimize sensor performance and reliability.Expand Specific Solutions

Key Players in Piezoelectric Sensor Industry

The research on cross-material compatibility in piezoelectric sensor fabrication is currently in a growth phase, with increasing market demand driven by applications in various industries. The global piezoelectric sensors market is expected to reach significant size in the coming years, fueled by technological advancements and expanding use cases. While the technology is relatively mature, ongoing research by key players aims to improve performance and expand applications. Companies like Sumitomo Riko, Mitsui Chemicals, and BOE Technology Group are actively developing new materials and fabrication techniques to enhance sensor compatibility and functionality. Academic institutions such as Tsinghua University and University of Electronic Science & Technology of China are also contributing to advancements in this field, fostering industry-academia collaborations to drive innovation.

Tsinghua University

Technical Solution: Tsinghua University has conducted extensive research on cross-material compatibility in piezoelectric sensor fabrication, with a focus on nanostructured materials and interfaces. Their approach involves developing novel nanocomposite piezoelectric materials that combine the advantages of different material classes, such as ceramics and polymers. Tsinghua researchers have successfully fabricated hybrid nanostructures, including core-shell nanoparticles and nanofibers, that exhibit enhanced piezoelectric properties and improved compatibility with various substrate materials[10]. They have also explored the use of graphene and other 2D materials as interfacial layers to enhance adhesion and charge transfer between piezoelectric materials and electrodes[11]. Additionally, Tsinghua has developed innovative surface functionalization techniques to improve the compatibility of piezoelectric materials with biological tissues, enabling the creation of highly sensitive biosensors[12].

Strengths: Cutting-edge research in nanostructured piezoelectric materials, expertise in hybrid material systems, and focus on biocompatible sensor designs. Weaknesses: Potential challenges in scaling up production of complex nanostructures and the need for further long-term stability testing in diverse applications.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has made significant contributions to cross-material compatibility in piezoelectric sensor fabrication through their innovative research in materials science and engineering. Their approach focuses on developing multifunctional piezoelectric composites that combine different classes of materials to achieve enhanced performance and compatibility. Purdue researchers have successfully created hierarchical nanostructures that integrate piezoelectric ceramics with polymers and metals, resulting in sensors with improved flexibility, durability, and sensitivity[13]. They have also explored the use of novel fabrication techniques, such as 3D printing and self-assembly, to create complex piezoelectric structures with tailored properties and improved interfacial bonding[14]. Additionally, Purdue has developed advanced characterization methods to study the interactions between different materials at the nanoscale, enabling better control over sensor performance and reliability[15].

Strengths: Expertise in multifunctional piezoelectric composites, innovative fabrication techniques, and advanced characterization methods. Weaknesses: Potential challenges in scaling up production of complex hierarchical structures and the need for further optimization of 3D printing processes for certain material combinations.

Innovative Approaches to Material Integration

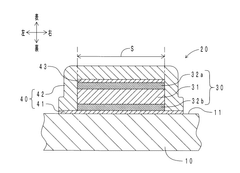

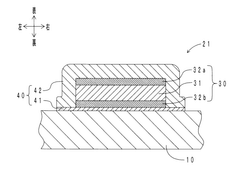

Piezoelectric sensor and method for manufacturing same

PatentActiveEP3726595A1

Innovation

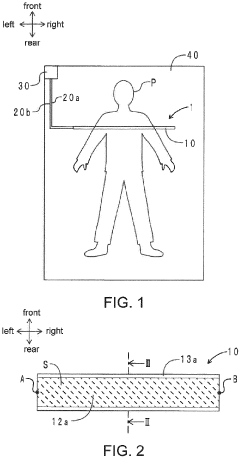

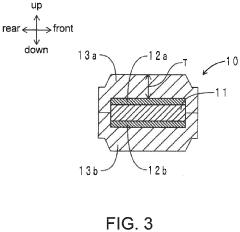

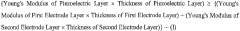

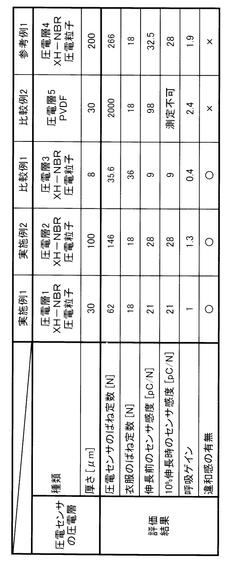

- A flexible piezoelectric sensor design featuring an elongated-sheet shape with a piezoelectric layer and electrode layers containing elastomers and flaky conductive materials, allowing for high conductivity and flexibility, with electrical resistance maintained below 3,000 Ω over a 500 mm pressure sensing region, ensuring accurate detection of weak vibrations and heartbeats without user discomfort.

Piezoelectric sensor and bioinformation acquisition garment

PatentWO2021065085A1

Innovation

- A flexible piezoelectric sensor made from an elastomer and a piezoelectric sensor element with a piezoelectric layer containing particles, an electrode layer, and an elastic layer, which is laminated to match the elasticity of clothing, allowing it to deform with the garment and maintain sensitivity even when stretched by 10%, with a spring constant larger than the clothing to concentrate stress and improve output gain.

Environmental Impact of Sensor Materials

The environmental impact of sensor materials used in piezoelectric sensor fabrication is a critical consideration in the development and implementation of these devices. As the demand for sensors continues to grow across various industries, it becomes increasingly important to assess and mitigate the potential environmental consequences associated with their production and disposal.

Piezoelectric sensors typically incorporate a range of materials, including ceramics, polymers, and composites. The most commonly used piezoelectric materials are lead zirconate titanate (PZT), barium titanate, and quartz. While these materials offer excellent piezoelectric properties, their environmental footprint can be significant. The mining and processing of raw materials for these sensors often involve energy-intensive processes and can lead to habitat disruption and soil contamination.

Of particular concern is the use of lead-based piezoelectric materials, such as PZT. Lead is a toxic heavy metal that can accumulate in the environment and pose serious health risks to humans and wildlife. As a result, there is a growing push towards developing lead-free alternatives that can match or exceed the performance of traditional lead-based piezoelectric materials.

The manufacturing process of piezoelectric sensors also contributes to their environmental impact. The production of these sensors often requires high-temperature sintering, which consumes significant amounts of energy and can result in greenhouse gas emissions. Additionally, the use of various chemicals and solvents in the fabrication process may lead to air and water pollution if not properly managed.

End-of-life considerations for piezoelectric sensors are equally important. As these devices reach the end of their useful life, proper disposal and recycling become crucial to prevent the release of harmful substances into the environment. However, the complex nature of piezoelectric sensors, often involving multiple materials bonded together, can make recycling challenging and energy-intensive.

To address these environmental concerns, researchers and manufacturers are exploring several avenues. One approach is the development of more environmentally friendly piezoelectric materials, such as bismuth sodium titanate (BNT) and potassium sodium niobate (KNN), which offer lead-free alternatives. Another focus is on improving manufacturing processes to reduce energy consumption and minimize waste generation.

Furthermore, the concept of "green sensors" is gaining traction, emphasizing the use of biodegradable or easily recyclable materials in sensor fabrication. This approach not only reduces the environmental impact at the end of the sensor's life but also promotes the principles of circular economy in the electronics industry.

Piezoelectric sensors typically incorporate a range of materials, including ceramics, polymers, and composites. The most commonly used piezoelectric materials are lead zirconate titanate (PZT), barium titanate, and quartz. While these materials offer excellent piezoelectric properties, their environmental footprint can be significant. The mining and processing of raw materials for these sensors often involve energy-intensive processes and can lead to habitat disruption and soil contamination.

Of particular concern is the use of lead-based piezoelectric materials, such as PZT. Lead is a toxic heavy metal that can accumulate in the environment and pose serious health risks to humans and wildlife. As a result, there is a growing push towards developing lead-free alternatives that can match or exceed the performance of traditional lead-based piezoelectric materials.

The manufacturing process of piezoelectric sensors also contributes to their environmental impact. The production of these sensors often requires high-temperature sintering, which consumes significant amounts of energy and can result in greenhouse gas emissions. Additionally, the use of various chemicals and solvents in the fabrication process may lead to air and water pollution if not properly managed.

End-of-life considerations for piezoelectric sensors are equally important. As these devices reach the end of their useful life, proper disposal and recycling become crucial to prevent the release of harmful substances into the environment. However, the complex nature of piezoelectric sensors, often involving multiple materials bonded together, can make recycling challenging and energy-intensive.

To address these environmental concerns, researchers and manufacturers are exploring several avenues. One approach is the development of more environmentally friendly piezoelectric materials, such as bismuth sodium titanate (BNT) and potassium sodium niobate (KNN), which offer lead-free alternatives. Another focus is on improving manufacturing processes to reduce energy consumption and minimize waste generation.

Furthermore, the concept of "green sensors" is gaining traction, emphasizing the use of biodegradable or easily recyclable materials in sensor fabrication. This approach not only reduces the environmental impact at the end of the sensor's life but also promotes the principles of circular economy in the electronics industry.

Standardization of Compatibility Testing

Standardization of compatibility testing is crucial for ensuring the reliability and reproducibility of cross-material integration in piezoelectric sensor fabrication. The development of standardized testing protocols addresses the challenges associated with diverse material combinations and manufacturing processes. These protocols typically encompass a range of tests designed to evaluate the physical, chemical, and electrical compatibility of different materials used in sensor construction.

A comprehensive standardized testing framework often begins with material characterization, including surface analysis, chemical composition assessment, and mechanical property evaluation. This initial step provides a baseline understanding of the individual materials' properties before integration. Subsequent tests focus on the interface between different materials, examining aspects such as adhesion strength, interfacial reactions, and potential degradation mechanisms.

Electrical compatibility testing forms a critical component of the standardization process. This includes evaluating the piezoelectric response of the integrated system, assessing signal integrity, and measuring any potential interference or crosstalk between different sensor components. Standardized methods for measuring piezoelectric coefficients, frequency response, and sensitivity are essential for comparing different material combinations and fabrication techniques.

Environmental testing is another key aspect of standardized compatibility assessment. This involves subjecting the integrated sensor to various environmental conditions, such as temperature cycling, humidity exposure, and mechanical stress. These tests aim to simulate real-world operating conditions and assess the long-term stability and reliability of the cross-material interfaces.

The development of standardized compatibility testing also necessitates the establishment of accepted performance metrics and tolerance levels. This allows for objective comparison between different material combinations and fabrication methods, facilitating the selection of optimal solutions for specific applications. Additionally, standardized reporting formats ensure that test results are presented consistently across different research groups and manufacturers, enhancing transparency and facilitating knowledge sharing within the industry.

Efforts to standardize compatibility testing often involve collaboration between academic institutions, industry partners, and regulatory bodies. This collaborative approach ensures that the developed standards are both scientifically rigorous and practically applicable. As the field of piezoelectric sensor fabrication continues to evolve, these standards must be regularly reviewed and updated to incorporate new materials, manufacturing techniques, and application requirements.

A comprehensive standardized testing framework often begins with material characterization, including surface analysis, chemical composition assessment, and mechanical property evaluation. This initial step provides a baseline understanding of the individual materials' properties before integration. Subsequent tests focus on the interface between different materials, examining aspects such as adhesion strength, interfacial reactions, and potential degradation mechanisms.

Electrical compatibility testing forms a critical component of the standardization process. This includes evaluating the piezoelectric response of the integrated system, assessing signal integrity, and measuring any potential interference or crosstalk between different sensor components. Standardized methods for measuring piezoelectric coefficients, frequency response, and sensitivity are essential for comparing different material combinations and fabrication techniques.

Environmental testing is another key aspect of standardized compatibility assessment. This involves subjecting the integrated sensor to various environmental conditions, such as temperature cycling, humidity exposure, and mechanical stress. These tests aim to simulate real-world operating conditions and assess the long-term stability and reliability of the cross-material interfaces.

The development of standardized compatibility testing also necessitates the establishment of accepted performance metrics and tolerance levels. This allows for objective comparison between different material combinations and fabrication methods, facilitating the selection of optimal solutions for specific applications. Additionally, standardized reporting formats ensure that test results are presented consistently across different research groups and manufacturers, enhancing transparency and facilitating knowledge sharing within the industry.

Efforts to standardize compatibility testing often involve collaboration between academic institutions, industry partners, and regulatory bodies. This collaborative approach ensures that the developed standards are both scientifically rigorous and practically applicable. As the field of piezoelectric sensor fabrication continues to evolve, these standards must be regularly reviewed and updated to incorporate new materials, manufacturing techniques, and application requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!