Flexible Electronics with Embedded Piezoelectric Sensors

JUL 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Electronics Evolution and Objectives

Flexible electronics have emerged as a revolutionary technology, transforming the landscape of electronic devices and systems. The evolution of this field can be traced back to the early 2000s when researchers began exploring the potential of creating electronic circuits on flexible substrates. The primary objective was to develop electronic components that could bend, stretch, and conform to various shapes without compromising functionality.

Over the past two decades, flexible electronics have progressed from simple proof-of-concept demonstrations to sophisticated, commercially viable products. The initial focus was on developing flexible displays and solar cells, which paved the way for more complex applications. As the technology matured, researchers began integrating various sensing capabilities into flexible platforms, with piezoelectric sensors emerging as a particularly promising avenue for exploration.

The integration of piezoelectric sensors into flexible electronics represents a significant milestone in the field. Piezoelectric materials generate an electric charge in response to mechanical stress, making them ideal for sensing applications in wearable devices, structural health monitoring, and human-machine interfaces. The combination of flexibility and sensing capabilities opens up new possibilities for creating smart, adaptable systems that can seamlessly interact with their environment.

The current research on flexible electronics with embedded piezoelectric sensors aims to address several key objectives. Firstly, there is a focus on improving the sensitivity and reliability of these sensors when integrated into flexible substrates. This involves developing new materials and fabrication techniques that can maintain the piezoelectric properties while ensuring mechanical flexibility.

Another important objective is to enhance the power efficiency of these systems. As flexible electronics often operate in resource-constrained environments, minimizing power consumption while maximizing sensor performance is crucial. This has led to research into energy harvesting techniques that can leverage the piezoelectric effect to power the flexible electronic systems themselves.

Researchers are also working on expanding the application areas for flexible electronics with embedded piezoelectric sensors. This includes developing new form factors for wearable health monitoring devices, creating smart textiles that can detect and respond to environmental changes, and designing flexible sensors for robotics and prosthetics to enable more natural and intuitive interactions.

As the field continues to evolve, there is an increasing emphasis on scalability and manufacturability. The ultimate goal is to transition these technologies from laboratory demonstrations to large-scale production, enabling widespread adoption across various industries. This requires overcoming challenges related to materials science, device engineering, and manufacturing processes to create reliable, cost-effective flexible electronic systems with integrated piezoelectric sensing capabilities.

Over the past two decades, flexible electronics have progressed from simple proof-of-concept demonstrations to sophisticated, commercially viable products. The initial focus was on developing flexible displays and solar cells, which paved the way for more complex applications. As the technology matured, researchers began integrating various sensing capabilities into flexible platforms, with piezoelectric sensors emerging as a particularly promising avenue for exploration.

The integration of piezoelectric sensors into flexible electronics represents a significant milestone in the field. Piezoelectric materials generate an electric charge in response to mechanical stress, making them ideal for sensing applications in wearable devices, structural health monitoring, and human-machine interfaces. The combination of flexibility and sensing capabilities opens up new possibilities for creating smart, adaptable systems that can seamlessly interact with their environment.

The current research on flexible electronics with embedded piezoelectric sensors aims to address several key objectives. Firstly, there is a focus on improving the sensitivity and reliability of these sensors when integrated into flexible substrates. This involves developing new materials and fabrication techniques that can maintain the piezoelectric properties while ensuring mechanical flexibility.

Another important objective is to enhance the power efficiency of these systems. As flexible electronics often operate in resource-constrained environments, minimizing power consumption while maximizing sensor performance is crucial. This has led to research into energy harvesting techniques that can leverage the piezoelectric effect to power the flexible electronic systems themselves.

Researchers are also working on expanding the application areas for flexible electronics with embedded piezoelectric sensors. This includes developing new form factors for wearable health monitoring devices, creating smart textiles that can detect and respond to environmental changes, and designing flexible sensors for robotics and prosthetics to enable more natural and intuitive interactions.

As the field continues to evolve, there is an increasing emphasis on scalability and manufacturability. The ultimate goal is to transition these technologies from laboratory demonstrations to large-scale production, enabling widespread adoption across various industries. This requires overcoming challenges related to materials science, device engineering, and manufacturing processes to create reliable, cost-effective flexible electronic systems with integrated piezoelectric sensing capabilities.

Market Demand Analysis for Flexible Sensors

The market demand for flexible sensors with embedded piezoelectric technology is experiencing significant growth, driven by the increasing need for wearable devices, IoT applications, and advanced healthcare solutions. This technology offers unique advantages in creating thin, lightweight, and conformable sensors that can be integrated into various products and surfaces.

In the consumer electronics sector, flexible sensors are finding applications in smartphones, smartwatches, and other wearable devices. The global wearable technology market is projected to expand rapidly, creating a substantial demand for flexible sensors. These sensors enable more comfortable and less obtrusive wearable designs, enhancing user experience and adoption rates.

The healthcare industry represents another major market for flexible sensors with embedded piezoelectric technology. There is a growing demand for non-invasive, continuous health monitoring devices that can be worn comfortably for extended periods. Flexible sensors can be used in applications such as smart bandages for wound healing monitoring, wearable ECG monitors, and pressure-sensitive insoles for gait analysis.

In the automotive sector, flexible sensors are increasingly being integrated into vehicle interiors for enhanced safety and user interface applications. These sensors can be used in steering wheels, seats, and dashboards to detect driver alertness, adjust seating positions, or provide touch-sensitive controls.

The industrial and robotics sectors are also driving demand for flexible sensors. In manufacturing environments, these sensors can be used for precise force and pressure measurements in robotic systems, improving the accuracy and efficiency of automated processes.

The aerospace industry is another potential growth area for flexible sensors. These sensors can be integrated into aircraft structures for real-time structural health monitoring, enhancing safety and reducing maintenance costs.

As smart textiles and e-textiles continue to evolve, the demand for flexible sensors that can be seamlessly integrated into fabrics is expected to rise. This opens up opportunities in sports and fitness apparel, military applications, and even fashion-forward consumer products.

The market for flexible sensors is also being driven by advancements in printed electronics and roll-to-roll manufacturing processes. These technologies are enabling more cost-effective production of flexible sensors, making them increasingly accessible for a wider range of applications and industries.

Overall, the market demand for flexible sensors with embedded piezoelectric technology is poised for substantial growth across multiple sectors. As the technology continues to mature and new applications emerge, we can expect to see an expanding ecosystem of products and solutions leveraging these innovative sensors.

In the consumer electronics sector, flexible sensors are finding applications in smartphones, smartwatches, and other wearable devices. The global wearable technology market is projected to expand rapidly, creating a substantial demand for flexible sensors. These sensors enable more comfortable and less obtrusive wearable designs, enhancing user experience and adoption rates.

The healthcare industry represents another major market for flexible sensors with embedded piezoelectric technology. There is a growing demand for non-invasive, continuous health monitoring devices that can be worn comfortably for extended periods. Flexible sensors can be used in applications such as smart bandages for wound healing monitoring, wearable ECG monitors, and pressure-sensitive insoles for gait analysis.

In the automotive sector, flexible sensors are increasingly being integrated into vehicle interiors for enhanced safety and user interface applications. These sensors can be used in steering wheels, seats, and dashboards to detect driver alertness, adjust seating positions, or provide touch-sensitive controls.

The industrial and robotics sectors are also driving demand for flexible sensors. In manufacturing environments, these sensors can be used for precise force and pressure measurements in robotic systems, improving the accuracy and efficiency of automated processes.

The aerospace industry is another potential growth area for flexible sensors. These sensors can be integrated into aircraft structures for real-time structural health monitoring, enhancing safety and reducing maintenance costs.

As smart textiles and e-textiles continue to evolve, the demand for flexible sensors that can be seamlessly integrated into fabrics is expected to rise. This opens up opportunities in sports and fitness apparel, military applications, and even fashion-forward consumer products.

The market for flexible sensors is also being driven by advancements in printed electronics and roll-to-roll manufacturing processes. These technologies are enabling more cost-effective production of flexible sensors, making them increasingly accessible for a wider range of applications and industries.

Overall, the market demand for flexible sensors with embedded piezoelectric technology is poised for substantial growth across multiple sectors. As the technology continues to mature and new applications emerge, we can expect to see an expanding ecosystem of products and solutions leveraging these innovative sensors.

Piezoelectric Sensor Integration Challenges

The integration of piezoelectric sensors into flexible electronics presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving seamless integration without compromising the flexibility of the overall system. Piezoelectric materials are typically rigid and brittle, which can introduce stress points and reduce the overall flexibility of the device.

Another major challenge lies in maintaining the sensitivity and performance of piezoelectric sensors when embedded in flexible substrates. The mechanical properties of the flexible substrate can dampen or alter the piezoelectric response, potentially reducing the sensor's accuracy and reliability. This issue is particularly pronounced in applications requiring high precision measurements or continuous monitoring.

The fabrication process itself poses considerable difficulties. Traditional manufacturing techniques for piezoelectric sensors often involve high-temperature processes or harsh chemical treatments that are incompatible with many flexible substrates. Developing new fabrication methods that can effectively integrate piezoelectric materials into flexible platforms without degrading their performance or damaging the substrate is a critical area of research.

Durability and long-term stability represent another set of challenges. Flexible electronics are often subjected to repeated bending, stretching, and other mechanical stresses. Ensuring that the embedded piezoelectric sensors can withstand these stresses without delamination, cracking, or loss of functionality is crucial for the development of robust and reliable devices.

Electrical interconnections between the piezoelectric sensors and the flexible circuitry present additional integration challenges. Traditional wiring methods may not be suitable for flexible applications, necessitating the development of novel interconnect technologies that can maintain electrical connectivity under various deformation conditions.

Scalability and cost-effectiveness are also significant concerns in the integration process. While laboratory-scale demonstrations have shown promising results, scaling up the production of flexible electronics with embedded piezoelectric sensors for commercial applications remains challenging. Developing economically viable manufacturing processes that can produce these integrated systems at scale is essential for widespread adoption.

Lastly, the challenge of power management and energy harvesting must be addressed. Piezoelectric sensors in flexible electronics often need to operate in low-power or self-powered configurations. Integrating energy harvesting capabilities and efficient power management systems into the flexible platform without adding bulk or reducing flexibility is a complex task that requires innovative solutions.

Another major challenge lies in maintaining the sensitivity and performance of piezoelectric sensors when embedded in flexible substrates. The mechanical properties of the flexible substrate can dampen or alter the piezoelectric response, potentially reducing the sensor's accuracy and reliability. This issue is particularly pronounced in applications requiring high precision measurements or continuous monitoring.

The fabrication process itself poses considerable difficulties. Traditional manufacturing techniques for piezoelectric sensors often involve high-temperature processes or harsh chemical treatments that are incompatible with many flexible substrates. Developing new fabrication methods that can effectively integrate piezoelectric materials into flexible platforms without degrading their performance or damaging the substrate is a critical area of research.

Durability and long-term stability represent another set of challenges. Flexible electronics are often subjected to repeated bending, stretching, and other mechanical stresses. Ensuring that the embedded piezoelectric sensors can withstand these stresses without delamination, cracking, or loss of functionality is crucial for the development of robust and reliable devices.

Electrical interconnections between the piezoelectric sensors and the flexible circuitry present additional integration challenges. Traditional wiring methods may not be suitable for flexible applications, necessitating the development of novel interconnect technologies that can maintain electrical connectivity under various deformation conditions.

Scalability and cost-effectiveness are also significant concerns in the integration process. While laboratory-scale demonstrations have shown promising results, scaling up the production of flexible electronics with embedded piezoelectric sensors for commercial applications remains challenging. Developing economically viable manufacturing processes that can produce these integrated systems at scale is essential for widespread adoption.

Lastly, the challenge of power management and energy harvesting must be addressed. Piezoelectric sensors in flexible electronics often need to operate in low-power or self-powered configurations. Integrating energy harvesting capabilities and efficient power management systems into the flexible platform without adding bulk or reducing flexibility is a complex task that requires innovative solutions.

Current Flexible Piezoelectric Sensor Solutions

01 Flexible substrate materials for piezoelectric sensors

Utilizing flexible substrate materials such as polymers or thin films to create a bendable base for piezoelectric sensors. This allows for the integration of sensors into curved or non-planar surfaces, enhancing the adaptability of the electronic devices to various shapes and forms.- Flexible substrate materials for piezoelectric sensors: Utilizing flexible substrate materials such as polymers or thin films to create a bendable base for piezoelectric sensors. This allows for the integration of sensors into curved or non-planar surfaces, enhancing the adaptability of the electronic devices to various form factors.

- Stretchable piezoelectric materials: Developing stretchable piezoelectric materials that can maintain their sensing capabilities under deformation. These materials can be incorporated into flexible electronics to create sensors that can withstand bending, twisting, and stretching without losing functionality.

- Integration of piezoelectric sensors with flexible circuits: Techniques for seamlessly integrating piezoelectric sensors with flexible printed circuits or thin-film transistors. This integration allows for the creation of complete flexible electronic systems with sensing capabilities embedded directly into the circuitry.

- Encapsulation methods for flexible piezoelectric sensors: Developing encapsulation techniques to protect flexible piezoelectric sensors from environmental factors while maintaining their flexibility. This includes using soft, stretchable polymers or thin protective layers that do not impede the sensor's performance or flexibility.

- Novel piezoelectric structures for enhanced flexibility: Creating innovative piezoelectric structures, such as nanofibers, nanowires, or 3D-printed architectures, that inherently possess high flexibility. These structures can be designed to optimize both sensing performance and mechanical flexibility in electronic devices.

02 Stretchable electrode designs

Developing stretchable electrode configurations that maintain conductivity under deformation. These designs may include serpentine patterns, mesh structures, or liquid metal conductors that can withstand bending and stretching while preserving electrical connections to the piezoelectric elements.Expand Specific Solutions03 Integration of piezoelectric materials in flexible forms

Incorporating piezoelectric materials such as PVDF or piezoelectric ceramics in thin-film or nanofiber forms to achieve flexibility. These materials can be deposited or embedded within the flexible substrate to create sensors that can detect pressure, vibration, or deformation while maintaining overall device flexibility.Expand Specific Solutions04 Encapsulation techniques for flexibility and protection

Developing encapsulation methods that protect the piezoelectric sensors and associated electronics while preserving flexibility. This may involve using soft, stretchable polymers or elastomers to encase the components, allowing for bending and folding while shielding against environmental factors.Expand Specific Solutions05 Interconnect strategies for flexible sensor arrays

Designing flexible interconnect systems that allow multiple piezoelectric sensors to be connected in arrays while maintaining overall device flexibility. This may include using stretchable conductive materials or innovative wiring layouts that can accommodate bending and folding without compromising electrical connections.Expand Specific Solutions

Key Players in Flexible Electronics Industry

The research on flexible electronics with embedded piezoelectric sensors is in a rapidly evolving phase, with significant market potential and technological advancements. The industry is transitioning from early-stage development to commercial applications, driven by growing demand in sectors like healthcare, consumer electronics, and automotive. Market size is expanding, with projections indicating substantial growth in the coming years. Technologically, while progress has been made, challenges remain in areas such as scalability and integration. Key players like Massachusetts Institute of Technology, Tsinghua University, and SABIC Global Technologies BV are at the forefront, pushing boundaries in material science and sensor technology. Companies like Sony Group Corp. and Lockheed Martin Corp. are also contributing to advancements, indicating a diverse and competitive landscape.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a groundbreaking approach to flexible electronics with embedded piezoelectric sensors. Their research focuses on creating ultrathin, conformable piezoelectric devices that can be seamlessly integrated into various surfaces. The team has successfully fabricated flexible piezoelectric nanoribbons using lead zirconate titanate (PZT) on plastic substrates[1]. These devices demonstrate excellent mechanical flexibility and high piezoelectric performance, capable of detecting minute strains and generating electrical signals. MIT's technology enables the creation of large-area sensor arrays that can be applied to curved or irregular surfaces, opening up possibilities for applications in wearable electronics, structural health monitoring, and biomedical devices[2]. The fabrication process involves transfer printing techniques that allow for precise positioning of the piezoelectric elements, ensuring optimal performance and reliability[3].

Strengths: Highly flexible and conformable sensors, excellent piezoelectric performance, and scalability for large-area applications. Weaknesses: Potential challenges in mass production and integration with existing manufacturing processes.

Tsinghua University

Technical Solution: Tsinghua University has made significant contributions to the field of flexible electronics with embedded piezoelectric sensors. Their research focuses on developing novel materials and fabrication techniques for highly sensitive and flexible piezoelectric devices. The team has successfully created nanocomposite-based flexible piezoelectric sensors using a combination of piezoelectric nanoparticles and polymer matrices[7]. This approach allows for tunable mechanical and electrical properties, enabling the sensors to be customized for specific applications. Tsinghua's researchers have also developed innovative printing techniques for depositing piezoelectric materials onto flexible substrates, including screen printing and inkjet printing methods[8]. These techniques enable the fabrication of large-area sensor arrays with precise control over sensor placement and properties. Additionally, the university has explored the integration of these flexible piezoelectric sensors with other electronic components, such as flexible transistors and energy harvesters, to create fully integrated flexible electronic systems[9].

Strengths: Advanced materials research, innovative fabrication techniques, and integration with other flexible electronic components. Weaknesses: Potential challenges in scaling up production and ensuring long-term stability of nanocomposite-based sensors.

Core Innovations in Flexible Piezoelectric Materials

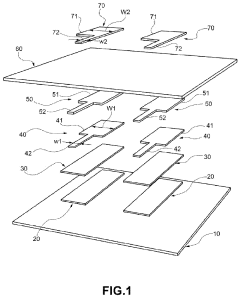

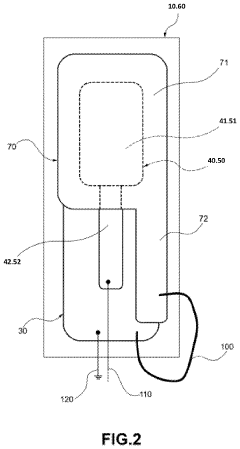

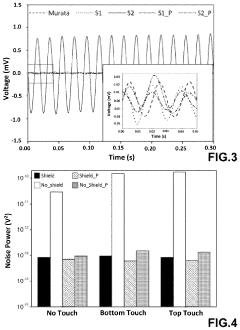

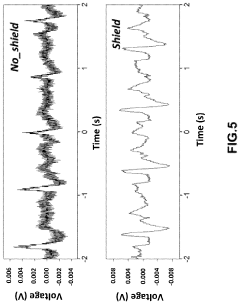

Flexible piezoelectric sensor with integrated electromagnetic shield

PatentPendingUS20220416148A1

Innovation

- A flexible piezoelectric sensor design integrating a thin metal layer as an electromagnetic shield, short-circuited to the bottom electrode, which is manufactured using standard microfabrication techniques and encapsulated in a polymeric matrix to provide effective shielding without compromising mechanical properties.

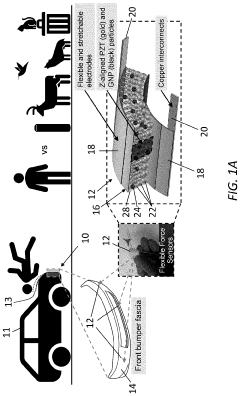

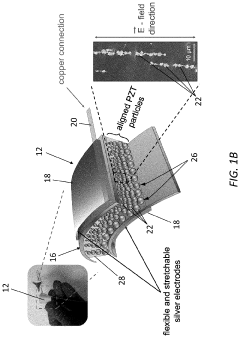

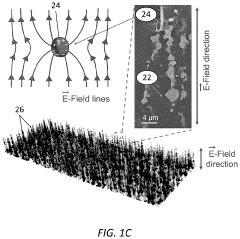

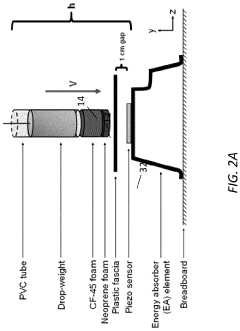

Flexible piezoelectric composite films, flexible piezoelectric impact sensors, pedestrian protection systems, and related methods

PatentPendingUS20240174197A1

Innovation

- The development of flexible piezoelectric composite films and sensors, aligned with an electric field to form anisotropic structures, are integrated into bumper assemblies to provide rapid and discriminative impact sensing, capable of differentiating between pedestrian and non-pedestrian impacts by generating distinct voltage signals.

Manufacturability and Scalability Assessment

The manufacturability and scalability of flexible electronics with embedded piezoelectric sensors present both challenges and opportunities in the realm of advanced manufacturing. Current production methods primarily rely on traditional microfabrication techniques adapted for flexible substrates. These include photolithography, etching, and deposition processes modified to accommodate the unique properties of flexible materials.

One of the key challenges in manufacturing these devices is maintaining precise alignment and uniformity across large areas of flexible substrates. Thermal expansion mismatches between different layers can lead to warping or delamination during fabrication. To address this, advanced tension control systems and temperature-compensated alignment tools have been developed, allowing for improved yield and consistency in production.

Roll-to-roll (R2R) manufacturing has emerged as a promising approach for scaling up the production of flexible electronics with embedded sensors. This continuous process allows for high-throughput fabrication of large-area devices, potentially reducing costs and increasing production capacity. However, R2R manufacturing requires careful optimization of each process step to ensure compatibility with flexible substrates and maintain the functionality of embedded piezoelectric sensors.

The integration of piezoelectric materials into flexible electronics poses additional manufacturing challenges. Traditional piezoelectric ceramics are brittle and not inherently compatible with flexible substrates. Recent advancements in piezoelectric polymers and nanocomposites have opened new avenues for integration, but these materials often require specialized deposition and patterning techniques to achieve optimal performance.

Scalability of production is closely tied to the availability and cost of materials. While flexible substrates like polyimide are readily available, high-performance piezoelectric materials may face supply chain constraints as demand increases. Developing alternative materials or improving the efficiency of existing ones will be crucial for large-scale adoption.

Quality control and testing procedures for flexible electronics with embedded sensors require adaptation from traditional rigid electronics manufacturing. In-line monitoring systems capable of assessing the performance of piezoelectric elements on flexible substrates are being developed to ensure consistent product quality at scale.

As the technology matures, standardization of manufacturing processes and materials will play a critical role in improving scalability. Industry consortia and research institutions are working towards establishing common standards and best practices for the production of flexible electronics with embedded sensors, which will facilitate broader adoption and interoperability across different manufacturers and applications.

One of the key challenges in manufacturing these devices is maintaining precise alignment and uniformity across large areas of flexible substrates. Thermal expansion mismatches between different layers can lead to warping or delamination during fabrication. To address this, advanced tension control systems and temperature-compensated alignment tools have been developed, allowing for improved yield and consistency in production.

Roll-to-roll (R2R) manufacturing has emerged as a promising approach for scaling up the production of flexible electronics with embedded sensors. This continuous process allows for high-throughput fabrication of large-area devices, potentially reducing costs and increasing production capacity. However, R2R manufacturing requires careful optimization of each process step to ensure compatibility with flexible substrates and maintain the functionality of embedded piezoelectric sensors.

The integration of piezoelectric materials into flexible electronics poses additional manufacturing challenges. Traditional piezoelectric ceramics are brittle and not inherently compatible with flexible substrates. Recent advancements in piezoelectric polymers and nanocomposites have opened new avenues for integration, but these materials often require specialized deposition and patterning techniques to achieve optimal performance.

Scalability of production is closely tied to the availability and cost of materials. While flexible substrates like polyimide are readily available, high-performance piezoelectric materials may face supply chain constraints as demand increases. Developing alternative materials or improving the efficiency of existing ones will be crucial for large-scale adoption.

Quality control and testing procedures for flexible electronics with embedded sensors require adaptation from traditional rigid electronics manufacturing. In-line monitoring systems capable of assessing the performance of piezoelectric elements on flexible substrates are being developed to ensure consistent product quality at scale.

As the technology matures, standardization of manufacturing processes and materials will play a critical role in improving scalability. Industry consortia and research institutions are working towards establishing common standards and best practices for the production of flexible electronics with embedded sensors, which will facilitate broader adoption and interoperability across different manufacturers and applications.

Environmental Impact and Sustainability Considerations

The development of flexible electronics with embedded piezoelectric sensors brings significant environmental and sustainability considerations to the forefront. These innovative devices offer potential benefits in terms of resource efficiency and energy harvesting, but also present challenges related to material selection, manufacturing processes, and end-of-life management.

One of the primary environmental advantages of flexible electronics with piezoelectric sensors is their potential for energy harvesting. By converting mechanical stress into electrical energy, these devices can reduce reliance on traditional power sources, potentially decreasing overall energy consumption and associated carbon emissions. This self-powering capability is particularly valuable in applications such as wearable technology and remote sensing, where frequent battery replacement or wired power connections are impractical.

However, the production of flexible electronics often involves the use of specialized materials, some of which may have environmental implications. For instance, certain piezoelectric materials contain lead, which is toxic and can pose environmental risks if not properly managed. Research into lead-free alternatives, such as zinc oxide or polyvinylidene fluoride (PVDF), is ongoing to address these concerns and improve the overall sustainability profile of these devices.

The manufacturing processes for flexible electronics with embedded sensors also require careful consideration from an environmental perspective. While these technologies often allow for more efficient use of materials compared to traditional rigid electronics, the production of thin-film devices and the integration of sensors can involve energy-intensive processes and the use of potentially hazardous chemicals. Efforts to develop more sustainable manufacturing techniques, such as roll-to-roll processing and additive manufacturing, are crucial for minimizing the environmental footprint of production.

End-of-life management presents another significant challenge for flexible electronics. The integration of multiple materials and components in these devices can make recycling and disposal more complex. Developing effective strategies for disassembly, material recovery, and safe disposal is essential to prevent electronic waste and recover valuable resources. Design for recyclability and the use of biodegradable or easily separable materials are areas of active research to address these concerns.

The durability and repairability of flexible electronics with embedded sensors also play a role in their overall environmental impact. While flexibility can enhance durability in some applications, it may also introduce vulnerabilities that could shorten device lifespan. Designing for longevity and ease of repair can help extend the useful life of these devices, reducing waste and the need for frequent replacements.

As the field of flexible electronics with embedded piezoelectric sensors continues to evolve, it is crucial to prioritize sustainability considerations throughout the research, development, and commercialization processes. This includes exploring eco-friendly materials, optimizing manufacturing processes for energy and resource efficiency, and developing comprehensive lifecycle management strategies. By addressing these environmental challenges, the technology can maximize its potential benefits while minimizing negative impacts on the planet.

One of the primary environmental advantages of flexible electronics with piezoelectric sensors is their potential for energy harvesting. By converting mechanical stress into electrical energy, these devices can reduce reliance on traditional power sources, potentially decreasing overall energy consumption and associated carbon emissions. This self-powering capability is particularly valuable in applications such as wearable technology and remote sensing, where frequent battery replacement or wired power connections are impractical.

However, the production of flexible electronics often involves the use of specialized materials, some of which may have environmental implications. For instance, certain piezoelectric materials contain lead, which is toxic and can pose environmental risks if not properly managed. Research into lead-free alternatives, such as zinc oxide or polyvinylidene fluoride (PVDF), is ongoing to address these concerns and improve the overall sustainability profile of these devices.

The manufacturing processes for flexible electronics with embedded sensors also require careful consideration from an environmental perspective. While these technologies often allow for more efficient use of materials compared to traditional rigid electronics, the production of thin-film devices and the integration of sensors can involve energy-intensive processes and the use of potentially hazardous chemicals. Efforts to develop more sustainable manufacturing techniques, such as roll-to-roll processing and additive manufacturing, are crucial for minimizing the environmental footprint of production.

End-of-life management presents another significant challenge for flexible electronics. The integration of multiple materials and components in these devices can make recycling and disposal more complex. Developing effective strategies for disassembly, material recovery, and safe disposal is essential to prevent electronic waste and recover valuable resources. Design for recyclability and the use of biodegradable or easily separable materials are areas of active research to address these concerns.

The durability and repairability of flexible electronics with embedded sensors also play a role in their overall environmental impact. While flexibility can enhance durability in some applications, it may also introduce vulnerabilities that could shorten device lifespan. Designing for longevity and ease of repair can help extend the useful life of these devices, reducing waste and the need for frequent replacements.

As the field of flexible electronics with embedded piezoelectric sensors continues to evolve, it is crucial to prioritize sustainability considerations throughout the research, development, and commercialization processes. This includes exploring eco-friendly materials, optimizing manufacturing processes for energy and resource efficiency, and developing comprehensive lifecycle management strategies. By addressing these environmental challenges, the technology can maximize its potential benefits while minimizing negative impacts on the planet.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!