Hybrid Piezoelectric-Electrochemical Sensing Platforms

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid Sensing Evolution

The evolution of hybrid sensing platforms, particularly those combining piezoelectric and electrochemical sensing technologies, represents a significant advancement in the field of sensor development. This integration has been driven by the need for more versatile, sensitive, and robust sensing systems capable of addressing complex analytical challenges across various domains.

The journey of hybrid piezoelectric-electrochemical sensing platforms began with the independent development of piezoelectric and electrochemical sensors. Piezoelectric sensors, based on the piezoelectric effect discovered by the Curie brothers in 1880, have been widely used for measuring pressure, acceleration, and force. Electrochemical sensors, on the other hand, have a rich history dating back to the invention of the glass pH electrode in the early 20th century.

The convergence of these two sensing modalities started gaining momentum in the late 1990s and early 2000s. Researchers recognized the potential synergies between piezoelectric and electrochemical techniques, particularly in enhancing sensitivity and selectivity. Early attempts at hybridization focused on using piezoelectric materials as substrates for electrochemical sensing elements, leveraging the mechanical stability and vibrational properties of piezoelectric materials.

A significant milestone in this evolution was the development of quartz crystal microbalance with dissipation monitoring (QCM-D) coupled with electrochemistry. This hybrid approach allowed for simultaneous measurement of mass changes and electrochemical reactions at electrode surfaces, opening new avenues for studying interfacial processes and biomolecular interactions.

The advent of nanomaterials and advanced fabrication techniques in the 2010s further accelerated the development of hybrid sensing platforms. Researchers began incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into hybrid designs, enhancing both piezoelectric and electrochemical properties. This led to the creation of highly sensitive and multifunctional sensors capable of detecting a wide range of analytes with improved performance.

Recent years have seen a shift towards miniaturization and integration of hybrid sensing platforms into portable and wearable devices. This trend has been driven by the growing demand for point-of-care diagnostics and real-time environmental monitoring. The integration of microfluidics with hybrid sensing elements has enabled the development of lab-on-a-chip devices that combine sample handling, sensing, and data processing in compact formats.

Looking forward, the evolution of hybrid piezoelectric-electrochemical sensing platforms is likely to continue towards greater integration with artificial intelligence and Internet of Things (IoT) technologies. This convergence promises to enhance data analysis, enable predictive capabilities, and facilitate the development of smart, interconnected sensing networks for applications in healthcare, environmental monitoring, and industrial process control.

The journey of hybrid piezoelectric-electrochemical sensing platforms began with the independent development of piezoelectric and electrochemical sensors. Piezoelectric sensors, based on the piezoelectric effect discovered by the Curie brothers in 1880, have been widely used for measuring pressure, acceleration, and force. Electrochemical sensors, on the other hand, have a rich history dating back to the invention of the glass pH electrode in the early 20th century.

The convergence of these two sensing modalities started gaining momentum in the late 1990s and early 2000s. Researchers recognized the potential synergies between piezoelectric and electrochemical techniques, particularly in enhancing sensitivity and selectivity. Early attempts at hybridization focused on using piezoelectric materials as substrates for electrochemical sensing elements, leveraging the mechanical stability and vibrational properties of piezoelectric materials.

A significant milestone in this evolution was the development of quartz crystal microbalance with dissipation monitoring (QCM-D) coupled with electrochemistry. This hybrid approach allowed for simultaneous measurement of mass changes and electrochemical reactions at electrode surfaces, opening new avenues for studying interfacial processes and biomolecular interactions.

The advent of nanomaterials and advanced fabrication techniques in the 2010s further accelerated the development of hybrid sensing platforms. Researchers began incorporating nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles into hybrid designs, enhancing both piezoelectric and electrochemical properties. This led to the creation of highly sensitive and multifunctional sensors capable of detecting a wide range of analytes with improved performance.

Recent years have seen a shift towards miniaturization and integration of hybrid sensing platforms into portable and wearable devices. This trend has been driven by the growing demand for point-of-care diagnostics and real-time environmental monitoring. The integration of microfluidics with hybrid sensing elements has enabled the development of lab-on-a-chip devices that combine sample handling, sensing, and data processing in compact formats.

Looking forward, the evolution of hybrid piezoelectric-electrochemical sensing platforms is likely to continue towards greater integration with artificial intelligence and Internet of Things (IoT) technologies. This convergence promises to enhance data analysis, enable predictive capabilities, and facilitate the development of smart, interconnected sensing networks for applications in healthcare, environmental monitoring, and industrial process control.

Market Demand Analysis

The market demand for hybrid piezoelectric-electrochemical sensing platforms has been steadily growing, driven by the increasing need for advanced sensing technologies across various industries. These innovative platforms combine the advantages of piezoelectric and electrochemical sensing methods, offering enhanced sensitivity, selectivity, and real-time monitoring capabilities.

In the healthcare sector, there is a rising demand for point-of-care diagnostic devices that can provide rapid and accurate results. Hybrid piezoelectric-electrochemical sensors show great potential in this area, particularly for the detection of biomarkers, pathogens, and drug molecules. The global point-of-care diagnostics market is expected to experience significant growth in the coming years, creating opportunities for these advanced sensing platforms.

Environmental monitoring is another key application area driving market demand. With increasing concerns about air and water pollution, there is a growing need for sensitive and reliable sensors that can detect and measure various contaminants. Hybrid piezoelectric-electrochemical sensors offer the ability to detect multiple pollutants simultaneously, making them attractive for environmental agencies and industrial monitoring applications.

The food and beverage industry is also showing interest in these sensing platforms for quality control and safety assurance. The ability to detect food contaminants, adulterants, and pathogens quickly and accurately is crucial for ensuring consumer safety and maintaining regulatory compliance. Hybrid sensors can provide rapid on-site testing capabilities, addressing the industry's need for efficient quality control processes.

In the industrial sector, there is a growing demand for sensors that can operate in harsh environments and provide real-time monitoring of various parameters. Hybrid piezoelectric-electrochemical sensors offer robustness and versatility, making them suitable for applications such as structural health monitoring, corrosion detection, and process control in manufacturing.

The wearable technology market is another area where these sensing platforms are gaining traction. As consumers become more health-conscious, there is an increasing demand for wearable devices that can monitor various physiological parameters. Hybrid sensors can be integrated into wearable devices to provide continuous monitoring of vital signs, stress levels, and other health indicators.

Overall, the market for hybrid piezoelectric-electrochemical sensing platforms is expected to grow significantly in the coming years, driven by advancements in nanotechnology, materials science, and data analytics. The ability of these sensors to provide multi-parameter sensing with high sensitivity and selectivity positions them as a promising technology for addressing complex sensing challenges across various industries.

In the healthcare sector, there is a rising demand for point-of-care diagnostic devices that can provide rapid and accurate results. Hybrid piezoelectric-electrochemical sensors show great potential in this area, particularly for the detection of biomarkers, pathogens, and drug molecules. The global point-of-care diagnostics market is expected to experience significant growth in the coming years, creating opportunities for these advanced sensing platforms.

Environmental monitoring is another key application area driving market demand. With increasing concerns about air and water pollution, there is a growing need for sensitive and reliable sensors that can detect and measure various contaminants. Hybrid piezoelectric-electrochemical sensors offer the ability to detect multiple pollutants simultaneously, making them attractive for environmental agencies and industrial monitoring applications.

The food and beverage industry is also showing interest in these sensing platforms for quality control and safety assurance. The ability to detect food contaminants, adulterants, and pathogens quickly and accurately is crucial for ensuring consumer safety and maintaining regulatory compliance. Hybrid sensors can provide rapid on-site testing capabilities, addressing the industry's need for efficient quality control processes.

In the industrial sector, there is a growing demand for sensors that can operate in harsh environments and provide real-time monitoring of various parameters. Hybrid piezoelectric-electrochemical sensors offer robustness and versatility, making them suitable for applications such as structural health monitoring, corrosion detection, and process control in manufacturing.

The wearable technology market is another area where these sensing platforms are gaining traction. As consumers become more health-conscious, there is an increasing demand for wearable devices that can monitor various physiological parameters. Hybrid sensors can be integrated into wearable devices to provide continuous monitoring of vital signs, stress levels, and other health indicators.

Overall, the market for hybrid piezoelectric-electrochemical sensing platforms is expected to grow significantly in the coming years, driven by advancements in nanotechnology, materials science, and data analytics. The ability of these sensors to provide multi-parameter sensing with high sensitivity and selectivity positions them as a promising technology for addressing complex sensing challenges across various industries.

Technical Challenges

The development of hybrid piezoelectric-electrochemical sensing platforms faces several significant technical challenges that require innovative solutions. One of the primary obstacles is the integration of piezoelectric and electrochemical components into a single, cohesive system. This integration process demands careful consideration of material compatibility, signal interference, and overall device performance.

Achieving optimal sensitivity and selectivity in these hybrid platforms remains a complex task. The piezoelectric element must be finely tuned to detect minute mechanical changes, while the electrochemical component needs to accurately measure specific chemical reactions. Balancing these two sensing modalities to work synergistically without compromising the performance of either is a delicate engineering challenge.

Another critical issue is the miniaturization of these hybrid sensing platforms. As the demand for portable and wearable devices increases, researchers must overcome the difficulties associated with scaling down the sensors while maintaining their functionality. This includes addressing issues related to power consumption, signal-to-noise ratio, and overall device robustness in compact form factors.

The long-term stability and reliability of hybrid piezoelectric-electrochemical sensors pose additional challenges. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can significantly impact sensor performance over time. Developing materials and designs that can withstand these external influences while maintaining consistent sensing capabilities is crucial for the widespread adoption of these technologies.

Signal processing and data interpretation present further complexities in hybrid sensing systems. The simultaneous acquisition and analysis of both piezoelectric and electrochemical signals require sophisticated algorithms and computational methods. Researchers must develop efficient data fusion techniques to extract meaningful information from the combined sensor outputs, ensuring accurate and reliable measurements.

Biocompatibility and fouling resistance are particularly important challenges for applications in biomedical and environmental monitoring. The sensors must be designed to operate effectively in complex biological environments without triggering adverse reactions or becoming compromised by biofouling. This necessitates the development of novel surface treatments and materials that can maintain sensor functionality in challenging conditions.

Lastly, the cost-effective manufacturing of these hybrid sensing platforms at scale remains a significant hurdle. Current fabrication processes for integrating piezoelectric and electrochemical components can be complex and expensive. Developing streamlined production methods that maintain high quality and reproducibility while reducing costs is essential for the commercial viability of these advanced sensing technologies.

Achieving optimal sensitivity and selectivity in these hybrid platforms remains a complex task. The piezoelectric element must be finely tuned to detect minute mechanical changes, while the electrochemical component needs to accurately measure specific chemical reactions. Balancing these two sensing modalities to work synergistically without compromising the performance of either is a delicate engineering challenge.

Another critical issue is the miniaturization of these hybrid sensing platforms. As the demand for portable and wearable devices increases, researchers must overcome the difficulties associated with scaling down the sensors while maintaining their functionality. This includes addressing issues related to power consumption, signal-to-noise ratio, and overall device robustness in compact form factors.

The long-term stability and reliability of hybrid piezoelectric-electrochemical sensors pose additional challenges. Environmental factors such as temperature fluctuations, humidity, and mechanical stress can significantly impact sensor performance over time. Developing materials and designs that can withstand these external influences while maintaining consistent sensing capabilities is crucial for the widespread adoption of these technologies.

Signal processing and data interpretation present further complexities in hybrid sensing systems. The simultaneous acquisition and analysis of both piezoelectric and electrochemical signals require sophisticated algorithms and computational methods. Researchers must develop efficient data fusion techniques to extract meaningful information from the combined sensor outputs, ensuring accurate and reliable measurements.

Biocompatibility and fouling resistance are particularly important challenges for applications in biomedical and environmental monitoring. The sensors must be designed to operate effectively in complex biological environments without triggering adverse reactions or becoming compromised by biofouling. This necessitates the development of novel surface treatments and materials that can maintain sensor functionality in challenging conditions.

Lastly, the cost-effective manufacturing of these hybrid sensing platforms at scale remains a significant hurdle. Current fabrication processes for integrating piezoelectric and electrochemical components can be complex and expensive. Developing streamlined production methods that maintain high quality and reproducibility while reducing costs is essential for the commercial viability of these advanced sensing technologies.

Current Hybrid Solutions

01 Integration of piezoelectric and electrochemical sensing elements

Hybrid sensing platforms combine piezoelectric and electrochemical sensing elements to enhance sensitivity and selectivity. These platforms utilize the mechanical-to-electrical conversion properties of piezoelectric materials alongside electrochemical detection methods, allowing for multi-modal sensing capabilities in a single device.- Integration of piezoelectric and electrochemical sensing elements: Hybrid sensing platforms combine piezoelectric and electrochemical components to create multifunctional sensors. These integrated systems leverage the strengths of both sensing mechanisms, allowing for simultaneous detection of mechanical and chemical stimuli. The combination enhances sensitivity, selectivity, and versatility in various sensing applications.

- Nanomaterial-based hybrid sensors: Incorporation of nanomaterials such as nanoparticles, nanotubes, or nanowires in hybrid piezoelectric-electrochemical sensors. These nanomaterials enhance the surface area and electrical properties, leading to improved sensitivity and faster response times. The synergy between nanomaterials and hybrid sensing mechanisms enables detection of trace amounts of analytes.

- Microfluidic integration for sample handling: Integration of microfluidic systems with hybrid piezoelectric-electrochemical sensors for efficient sample handling and analysis. Microfluidic channels enable precise control of sample flow, reagent mixing, and waste removal. This integration enhances the overall performance and automation capabilities of the sensing platform.

- Energy harvesting and self-powered sensors: Development of self-powered hybrid sensing platforms by utilizing the piezoelectric effect for energy harvesting. The generated electrical energy from mechanical stimuli can power the electrochemical sensing components, enabling autonomous operation in remote or inaccessible locations. This approach reduces the need for external power sources and extends the sensor's operational lifetime.

- Signal processing and data fusion techniques: Implementation of advanced signal processing and data fusion algorithms to interpret and combine data from piezoelectric and electrochemical sensing elements. These techniques enable noise reduction, signal amplification, and correlation of multiple sensor outputs. The integrated data analysis enhances the overall accuracy and reliability of the hybrid sensing platform.

02 Nanomaterial-based hybrid sensors

Incorporation of nanomaterials such as carbon nanotubes, graphene, or metal nanoparticles in hybrid piezoelectric-electrochemical sensors. These nanomaterials enhance the surface area and conductivity, leading to improved sensitivity and faster response times in detecting various analytes.Expand Specific Solutions03 Microfluidic integration for sample handling

Integration of microfluidic channels or chambers with hybrid sensing platforms for efficient sample handling and analysis. This approach allows for precise control of sample volume, flow rate, and reaction conditions, enhancing the overall performance and reproducibility of the sensing system.Expand Specific Solutions04 Energy harvesting and self-powered sensors

Development of self-powered hybrid sensing platforms that utilize the piezoelectric effect for energy harvesting. These sensors can generate their own power from mechanical vibrations or fluid flow, enabling long-term, autonomous operation in various applications.Expand Specific Solutions05 Signal processing and data fusion techniques

Implementation of advanced signal processing algorithms and data fusion techniques to combine and analyze the outputs from piezoelectric and electrochemical sensing elements. These methods improve the accuracy, reliability, and interpretability of the sensor data, enabling more robust detection and quantification of target analytes.Expand Specific Solutions

Industry Leaders

The research on hybrid piezoelectric-electrochemical sensing platforms is in an emerging stage, with growing market potential due to increasing demand for advanced sensing technologies. The global market for these platforms is expected to expand significantly in the coming years, driven by applications in healthcare, environmental monitoring, and industrial processes. While the technology is still evolving, several key players are making notable advancements. Companies like State Grid Corp. of China and Vanderbilt University are investing in research and development, while established firms such as Kuraray Co., Ltd. and STMicroelectronics are leveraging their expertise in materials and electronics to develop innovative solutions. The involvement of diverse organizations, from academic institutions to major corporations, indicates a competitive landscape with opportunities for both breakthrough innovations and incremental improvements.

Vanderbilt University

Technical Solution: Vanderbilt University has developed a hybrid piezoelectric-electrochemical sensing platform that combines the advantages of both piezoelectric and electrochemical sensing mechanisms. Their approach utilizes a piezoelectric substrate coated with an electrochemically active material, allowing for simultaneous mechanical and chemical detection. The platform demonstrates enhanced sensitivity and selectivity compared to traditional single-mode sensors[1]. The researchers have successfully applied this technology to detect various biomolecules and environmental pollutants with high accuracy and low detection limits[2]. Furthermore, they have integrated microfluidic channels into the design, enabling real-time, continuous monitoring capabilities[3].

Strengths: High sensitivity and selectivity, multi-modal sensing capabilities, potential for real-time monitoring. Weaknesses: Complexity in fabrication and signal processing, potential for cross-interference between sensing modes.

KIST Corp. (South Korea)

Technical Solution: KIST Corp. has developed an innovative hybrid piezoelectric-electrochemical sensing platform that leverages the synergistic effects of both sensing mechanisms. Their approach involves the use of nanostructured materials, such as zinc oxide nanowires, which exhibit both piezoelectric and electrochemical properties[4]. The platform incorporates a unique electrode design that allows for simultaneous measurement of mechanical stress and electrochemical reactions. KIST's technology has shown remarkable performance in detecting trace amounts of heavy metals and organic pollutants in water samples[5]. Additionally, they have demonstrated the platform's potential for wearable health monitoring applications, integrating it into flexible substrates for non-invasive biosensing[6].

Strengths: Advanced nanostructured materials, high sensitivity for environmental and health monitoring, potential for wearable applications. Weaknesses: Scalability challenges, potential long-term stability issues of nanostructures.

Key Innovations

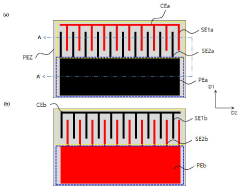

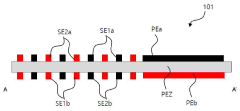

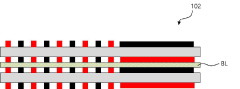

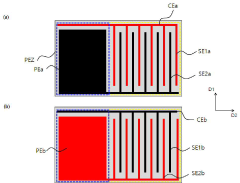

Hybrid type piezoelectric sensor

PatentActiveKR1020190063646A

Innovation

- A hybrid type piezoelectric sensor is designed with both 33 and 31 mode regions, featuring slit electrodes and electrodes patterns on the upper and lower surfaces of the piezoelectric body, polarized differently to enable simultaneous detection and conversion of forces in both directions.

Sensor Integration Methods

The integration of piezoelectric and electrochemical sensing technologies presents a promising approach for developing advanced hybrid sensing platforms. These platforms combine the strengths of both sensing modalities to achieve enhanced performance and functionality. The integration methods for such hybrid systems can be broadly categorized into three main approaches: physical integration, functional integration, and data integration.

Physical integration involves the direct combination of piezoelectric and electrochemical components within a single device structure. This can be achieved through various fabrication techniques, such as microfabrication, screen printing, or 3D printing. One common method is the deposition of piezoelectric materials onto electrochemical electrode surfaces, creating a layered structure that can simultaneously generate electrical signals from mechanical stress and detect electrochemical reactions. Another approach is the incorporation of piezoelectric nanostructures, such as nanowires or nanoparticles, into electrochemical sensing elements to create multifunctional sensing interfaces.

Functional integration focuses on leveraging the complementary capabilities of piezoelectric and electrochemical sensing mechanisms to enhance overall sensor performance. This can involve using piezoelectric elements to induce mechanical perturbations or fluid flow in electrochemical systems, thereby improving mass transport and reaction kinetics. Alternatively, electrochemical reactions can be utilized to modulate the mechanical properties of piezoelectric materials, enabling novel sensing modalities. Functional integration often requires careful design of sensor architectures and operating protocols to optimize the synergistic effects between the two sensing mechanisms.

Data integration is a crucial aspect of hybrid sensing platforms, involving the fusion and analysis of signals from both piezoelectric and electrochemical components. This can be achieved through various signal processing techniques, such as multivariate analysis, machine learning algorithms, or artificial neural networks. Data integration enables the extraction of complementary information from the two sensing modalities, potentially leading to improved selectivity, sensitivity, and reliability in complex sensing environments. Advanced data integration methods may also incorporate real-time adaptive algorithms to optimize sensor performance based on changing environmental conditions or target analyte concentrations.

The successful implementation of these integration methods requires careful consideration of material compatibility, interface engineering, and system-level design. Researchers must address challenges such as signal interference, cross-sensitivity, and long-term stability to develop robust and reliable hybrid sensing platforms. As the field continues to advance, novel integration approaches are likely to emerge, further expanding the capabilities and applications of hybrid piezoelectric-electrochemical sensing systems.

Physical integration involves the direct combination of piezoelectric and electrochemical components within a single device structure. This can be achieved through various fabrication techniques, such as microfabrication, screen printing, or 3D printing. One common method is the deposition of piezoelectric materials onto electrochemical electrode surfaces, creating a layered structure that can simultaneously generate electrical signals from mechanical stress and detect electrochemical reactions. Another approach is the incorporation of piezoelectric nanostructures, such as nanowires or nanoparticles, into electrochemical sensing elements to create multifunctional sensing interfaces.

Functional integration focuses on leveraging the complementary capabilities of piezoelectric and electrochemical sensing mechanisms to enhance overall sensor performance. This can involve using piezoelectric elements to induce mechanical perturbations or fluid flow in electrochemical systems, thereby improving mass transport and reaction kinetics. Alternatively, electrochemical reactions can be utilized to modulate the mechanical properties of piezoelectric materials, enabling novel sensing modalities. Functional integration often requires careful design of sensor architectures and operating protocols to optimize the synergistic effects between the two sensing mechanisms.

Data integration is a crucial aspect of hybrid sensing platforms, involving the fusion and analysis of signals from both piezoelectric and electrochemical components. This can be achieved through various signal processing techniques, such as multivariate analysis, machine learning algorithms, or artificial neural networks. Data integration enables the extraction of complementary information from the two sensing modalities, potentially leading to improved selectivity, sensitivity, and reliability in complex sensing environments. Advanced data integration methods may also incorporate real-time adaptive algorithms to optimize sensor performance based on changing environmental conditions or target analyte concentrations.

The successful implementation of these integration methods requires careful consideration of material compatibility, interface engineering, and system-level design. Researchers must address challenges such as signal interference, cross-sensitivity, and long-term stability to develop robust and reliable hybrid sensing platforms. As the field continues to advance, novel integration approaches are likely to emerge, further expanding the capabilities and applications of hybrid piezoelectric-electrochemical sensing systems.

Performance Metrics

Performance metrics play a crucial role in evaluating the effectiveness and efficiency of hybrid piezoelectric-electrochemical sensing platforms. These metrics provide quantitative measures to assess the sensor's capabilities, reliability, and overall performance in various applications.

Sensitivity is a key performance metric for hybrid sensing platforms, indicating the minimum detectable change in the target analyte concentration. For piezoelectric-electrochemical sensors, sensitivity is typically expressed in terms of the change in electrical signal (e.g., current or voltage) per unit change in analyte concentration. Higher sensitivity allows for the detection of lower concentrations of target molecules, enhancing the sensor's applicability in trace analysis and early detection scenarios.

Selectivity is another critical metric, measuring the sensor's ability to discriminate between the target analyte and potential interfering substances. In hybrid platforms, the combination of piezoelectric and electrochemical sensing mechanisms can often enhance selectivity by leveraging the unique advantages of each technique. Evaluating selectivity involves testing the sensor's response to various interfering compounds and comparing it to the response generated by the target analyte.

Response time is an essential performance metric that quantifies how quickly the sensor can detect and report changes in analyte concentration. For hybrid piezoelectric-electrochemical platforms, this metric is particularly important in real-time monitoring applications. Faster response times enable more rapid detection of analyte fluctuations, which is crucial in fields such as environmental monitoring and medical diagnostics.

Stability and reproducibility are interconnected metrics that assess the sensor's ability to maintain consistent performance over time and across multiple measurements. Long-term stability is evaluated by monitoring the sensor's response to a fixed analyte concentration over extended periods, while reproducibility is determined by comparing results from multiple sensors or measurements under identical conditions. These metrics are essential for ensuring reliable and accurate sensing in practical applications.

Dynamic range is another key performance metric, defining the span of analyte concentrations over which the sensor can provide accurate measurements. A wide dynamic range is desirable as it allows the sensor to operate effectively across various concentration levels without the need for sample dilution or concentration. In hybrid platforms, the combination of piezoelectric and electrochemical sensing can potentially extend the dynamic range beyond what is achievable with single-mode sensors.

Power consumption and energy efficiency are increasingly important metrics, particularly for portable or remote sensing applications. These metrics evaluate the sensor's energy requirements during operation and standby modes. Lower power consumption enables longer battery life and enhances the sensor's suitability for deployment in resource-constrained environments.

Sensitivity is a key performance metric for hybrid sensing platforms, indicating the minimum detectable change in the target analyte concentration. For piezoelectric-electrochemical sensors, sensitivity is typically expressed in terms of the change in electrical signal (e.g., current or voltage) per unit change in analyte concentration. Higher sensitivity allows for the detection of lower concentrations of target molecules, enhancing the sensor's applicability in trace analysis and early detection scenarios.

Selectivity is another critical metric, measuring the sensor's ability to discriminate between the target analyte and potential interfering substances. In hybrid platforms, the combination of piezoelectric and electrochemical sensing mechanisms can often enhance selectivity by leveraging the unique advantages of each technique. Evaluating selectivity involves testing the sensor's response to various interfering compounds and comparing it to the response generated by the target analyte.

Response time is an essential performance metric that quantifies how quickly the sensor can detect and report changes in analyte concentration. For hybrid piezoelectric-electrochemical platforms, this metric is particularly important in real-time monitoring applications. Faster response times enable more rapid detection of analyte fluctuations, which is crucial in fields such as environmental monitoring and medical diagnostics.

Stability and reproducibility are interconnected metrics that assess the sensor's ability to maintain consistent performance over time and across multiple measurements. Long-term stability is evaluated by monitoring the sensor's response to a fixed analyte concentration over extended periods, while reproducibility is determined by comparing results from multiple sensors or measurements under identical conditions. These metrics are essential for ensuring reliable and accurate sensing in practical applications.

Dynamic range is another key performance metric, defining the span of analyte concentrations over which the sensor can provide accurate measurements. A wide dynamic range is desirable as it allows the sensor to operate effectively across various concentration levels without the need for sample dilution or concentration. In hybrid platforms, the combination of piezoelectric and electrochemical sensing can potentially extend the dynamic range beyond what is achievable with single-mode sensors.

Power consumption and energy efficiency are increasingly important metrics, particularly for portable or remote sensing applications. These metrics evaluate the sensor's energy requirements during operation and standby modes. Lower power consumption enables longer battery life and enhances the sensor's suitability for deployment in resource-constrained environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!