How Smart Fabrics Integrate Piezoelectric Sensing

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Fabric Evolution

Smart fabrics have undergone a remarkable evolution since their inception, transforming from simple conductive textiles to sophisticated, multi-functional materials capable of sensing, actuating, and even computing. The journey of smart fabrics began in the late 20th century with the integration of conductive fibers into traditional textiles, primarily for anti-static and electromagnetic shielding purposes.

As technology advanced, the focus shifted towards creating fabrics with embedded electronic components. This phase saw the development of fabrics with integrated LEDs, heating elements, and basic sensors. However, these early iterations often suffered from issues of durability, washability, and comfort, limiting their practical applications.

The next significant leap came with the advent of nanotechnology and advanced material science. This enabled the creation of fibers and yarns with inherent smart properties, such as shape memory alloys and phase-change materials. These innovations allowed for the development of fabrics that could respond to environmental stimuli without the need for bulky electronic components.

The integration of piezoelectric materials into textiles marked a pivotal moment in smart fabric evolution. Piezoelectric sensing allowed fabrics to generate electrical signals in response to mechanical stress, opening up a wide range of applications in health monitoring, sports performance analysis, and human-machine interfaces.

Recent years have seen a convergence of multiple technologies in smart fabrics. The incorporation of flexible electronics, microfluidics, and advanced polymer science has led to the creation of truly multifunctional textiles. These fabrics can simultaneously sense multiple parameters, process data, and even harvest energy from the wearer's movements or the environment.

The latest frontier in smart fabric evolution is the development of self-powered textiles. By combining piezoelectric sensing with energy harvesting technologies, researchers are creating fabrics that can generate their own power, eliminating the need for external batteries and significantly enhancing the autonomy and longevity of smart textile systems.

Looking ahead, the evolution of smart fabrics is likely to focus on enhancing their seamless integration into everyday life. This includes improving their aesthetic appeal, washability, and overall durability while maintaining or expanding their functional capabilities. The ultimate goal is to create smart fabrics that are indistinguishable from traditional textiles in look and feel, yet possess advanced sensing and interactive capabilities.

As technology advanced, the focus shifted towards creating fabrics with embedded electronic components. This phase saw the development of fabrics with integrated LEDs, heating elements, and basic sensors. However, these early iterations often suffered from issues of durability, washability, and comfort, limiting their practical applications.

The next significant leap came with the advent of nanotechnology and advanced material science. This enabled the creation of fibers and yarns with inherent smart properties, such as shape memory alloys and phase-change materials. These innovations allowed for the development of fabrics that could respond to environmental stimuli without the need for bulky electronic components.

The integration of piezoelectric materials into textiles marked a pivotal moment in smart fabric evolution. Piezoelectric sensing allowed fabrics to generate electrical signals in response to mechanical stress, opening up a wide range of applications in health monitoring, sports performance analysis, and human-machine interfaces.

Recent years have seen a convergence of multiple technologies in smart fabrics. The incorporation of flexible electronics, microfluidics, and advanced polymer science has led to the creation of truly multifunctional textiles. These fabrics can simultaneously sense multiple parameters, process data, and even harvest energy from the wearer's movements or the environment.

The latest frontier in smart fabric evolution is the development of self-powered textiles. By combining piezoelectric sensing with energy harvesting technologies, researchers are creating fabrics that can generate their own power, eliminating the need for external batteries and significantly enhancing the autonomy and longevity of smart textile systems.

Looking ahead, the evolution of smart fabrics is likely to focus on enhancing their seamless integration into everyday life. This includes improving their aesthetic appeal, washability, and overall durability while maintaining or expanding their functional capabilities. The ultimate goal is to create smart fabrics that are indistinguishable from traditional textiles in look and feel, yet possess advanced sensing and interactive capabilities.

Piezoelectric Market Demand

The market demand for piezoelectric sensing in smart fabrics has been experiencing significant growth in recent years, driven by the increasing adoption of wearable technology and the growing interest in health monitoring devices. The integration of piezoelectric sensors into textiles offers a unique opportunity to create smart fabrics that can detect and measure various physical parameters, such as pressure, strain, and motion.

One of the primary drivers of market demand is the healthcare sector, where smart fabrics with piezoelectric sensing capabilities are being used to develop innovative medical devices and monitoring systems. These fabrics can be used to create garments that continuously monitor vital signs, detect falls, or track patient movement, providing valuable data for healthcare professionals and improving patient care.

The sports and fitness industry is another major contributor to the growing demand for piezoelectric smart fabrics. Athletes and fitness enthusiasts are increasingly seeking wearable technology that can provide real-time feedback on their performance, posture, and form. Smart fabrics with integrated piezoelectric sensors can offer precise measurements of muscle activity, joint angles, and body movements, enabling users to optimize their training and reduce the risk of injury.

In the automotive sector, there is a rising interest in incorporating piezoelectric smart fabrics into vehicle interiors. These fabrics can be used to create intelligent seating systems that monitor driver posture, fatigue levels, and even detect potential health issues. Additionally, piezoelectric sensors in car seats can enhance safety features by providing data for advanced airbag deployment systems.

The military and defense industry is also exploring the potential of piezoelectric smart fabrics for various applications. These include developing advanced combat uniforms that can monitor soldier health and performance, as well as creating smart textiles for use in protective gear and equipment.

Consumer electronics represent another significant market for piezoelectric smart fabrics. As the demand for wearable devices continues to grow, manufacturers are looking for ways to integrate sensing capabilities into everyday clothing and accessories. This has led to the development of smart garments that can control music playback, answer phone calls, or provide haptic feedback for navigation.

The industrial sector is showing increased interest in piezoelectric smart fabrics for applications such as worker safety monitoring, equipment maintenance, and process optimization. These fabrics can be used to create intelligent workwear that detects exposure to harmful substances, monitors worker fatigue, or provides early warning of potential safety hazards.

As the technology continues to advance and manufacturing costs decrease, the market for piezoelectric smart fabrics is expected to expand further. The growing emphasis on Internet of Things (IoT) and connected devices is likely to drive additional demand for these innovative textiles across various industries.

One of the primary drivers of market demand is the healthcare sector, where smart fabrics with piezoelectric sensing capabilities are being used to develop innovative medical devices and monitoring systems. These fabrics can be used to create garments that continuously monitor vital signs, detect falls, or track patient movement, providing valuable data for healthcare professionals and improving patient care.

The sports and fitness industry is another major contributor to the growing demand for piezoelectric smart fabrics. Athletes and fitness enthusiasts are increasingly seeking wearable technology that can provide real-time feedback on their performance, posture, and form. Smart fabrics with integrated piezoelectric sensors can offer precise measurements of muscle activity, joint angles, and body movements, enabling users to optimize their training and reduce the risk of injury.

In the automotive sector, there is a rising interest in incorporating piezoelectric smart fabrics into vehicle interiors. These fabrics can be used to create intelligent seating systems that monitor driver posture, fatigue levels, and even detect potential health issues. Additionally, piezoelectric sensors in car seats can enhance safety features by providing data for advanced airbag deployment systems.

The military and defense industry is also exploring the potential of piezoelectric smart fabrics for various applications. These include developing advanced combat uniforms that can monitor soldier health and performance, as well as creating smart textiles for use in protective gear and equipment.

Consumer electronics represent another significant market for piezoelectric smart fabrics. As the demand for wearable devices continues to grow, manufacturers are looking for ways to integrate sensing capabilities into everyday clothing and accessories. This has led to the development of smart garments that can control music playback, answer phone calls, or provide haptic feedback for navigation.

The industrial sector is showing increased interest in piezoelectric smart fabrics for applications such as worker safety monitoring, equipment maintenance, and process optimization. These fabrics can be used to create intelligent workwear that detects exposure to harmful substances, monitors worker fatigue, or provides early warning of potential safety hazards.

As the technology continues to advance and manufacturing costs decrease, the market for piezoelectric smart fabrics is expected to expand further. The growing emphasis on Internet of Things (IoT) and connected devices is likely to drive additional demand for these innovative textiles across various industries.

Piezo Integration Challenges

The integration of piezoelectric sensing into smart fabrics presents several significant challenges that researchers and engineers must overcome. One of the primary obstacles is the inherent rigidity of traditional piezoelectric materials, which contrasts sharply with the flexibility required for comfortable and wearable textiles. This mismatch in physical properties necessitates innovative approaches to material design and fabrication techniques.

Another major challenge lies in the durability and longevity of piezoelectric elements when incorporated into fabrics. Smart textiles are expected to withstand regular wear, washing, and environmental stresses, which can potentially damage or degrade the sensing capabilities of piezoelectric components. Developing robust encapsulation methods and protective layers that do not compromise the fabric's flexibility or breathability is crucial.

The integration process itself poses technical difficulties. Conventional textile manufacturing processes are not typically compatible with the precise placement and connection of piezoelectric sensors. New manufacturing techniques need to be developed to seamlessly incorporate these sensing elements into the fabric structure without compromising the textile's overall integrity or appearance.

Power management and energy harvesting present additional challenges. While piezoelectric materials can generate electricity from mechanical deformation, efficiently capturing and storing this energy for powering other smart fabric components requires sophisticated circuitry and energy storage solutions that are both miniaturized and flexible.

Signal processing and noise reduction are critical aspects that need addressing. The human body and surrounding environment generate various mechanical vibrations and electromagnetic interference that can affect the accuracy of piezoelectric sensors. Developing algorithms and hardware solutions to filter out noise and extract meaningful data is essential for reliable sensing performance.

Scalability and cost-effectiveness are also significant hurdles. For smart fabrics with integrated piezoelectric sensing to become commercially viable, manufacturing processes must be scalable to mass production while maintaining consistent quality and performance. Additionally, the cost of materials and production needs to be competitive with traditional textiles to ensure market adoption.

Lastly, standardization and interoperability pose challenges in the rapidly evolving field of smart textiles. The lack of industry-wide standards for piezoelectric integration in fabrics can lead to fragmentation in development approaches and hinder the widespread adoption of this technology. Establishing common protocols and interfaces for data communication and power management across different smart fabric systems is crucial for creating a cohesive ecosystem of wearable technologies.

Another major challenge lies in the durability and longevity of piezoelectric elements when incorporated into fabrics. Smart textiles are expected to withstand regular wear, washing, and environmental stresses, which can potentially damage or degrade the sensing capabilities of piezoelectric components. Developing robust encapsulation methods and protective layers that do not compromise the fabric's flexibility or breathability is crucial.

The integration process itself poses technical difficulties. Conventional textile manufacturing processes are not typically compatible with the precise placement and connection of piezoelectric sensors. New manufacturing techniques need to be developed to seamlessly incorporate these sensing elements into the fabric structure without compromising the textile's overall integrity or appearance.

Power management and energy harvesting present additional challenges. While piezoelectric materials can generate electricity from mechanical deformation, efficiently capturing and storing this energy for powering other smart fabric components requires sophisticated circuitry and energy storage solutions that are both miniaturized and flexible.

Signal processing and noise reduction are critical aspects that need addressing. The human body and surrounding environment generate various mechanical vibrations and electromagnetic interference that can affect the accuracy of piezoelectric sensors. Developing algorithms and hardware solutions to filter out noise and extract meaningful data is essential for reliable sensing performance.

Scalability and cost-effectiveness are also significant hurdles. For smart fabrics with integrated piezoelectric sensing to become commercially viable, manufacturing processes must be scalable to mass production while maintaining consistent quality and performance. Additionally, the cost of materials and production needs to be competitive with traditional textiles to ensure market adoption.

Lastly, standardization and interoperability pose challenges in the rapidly evolving field of smart textiles. The lack of industry-wide standards for piezoelectric integration in fabrics can lead to fragmentation in development approaches and hinder the widespread adoption of this technology. Establishing common protocols and interfaces for data communication and power management across different smart fabric systems is crucial for creating a cohesive ecosystem of wearable technologies.

Piezo Sensing Solutions

01 Piezoelectric fabric sensors for motion detection

Smart fabrics incorporating piezoelectric sensors can detect and measure various types of motion and deformation. These sensors convert mechanical stress into electrical signals, allowing for the monitoring of body movements, gestures, or external forces applied to the fabric. This technology has applications in wearable devices, sports performance analysis, and health monitoring.- Piezoelectric fabric sensors for wearable applications: Smart fabrics incorporating piezoelectric sensors are developed for wearable applications. These fabrics can detect and measure various physical parameters such as pressure, strain, and motion. The piezoelectric materials integrated into the fabric structure convert mechanical stress into electrical signals, enabling real-time monitoring of body movements and physiological parameters.

- Fabrication methods for piezoelectric smart textiles: Various fabrication techniques are employed to create piezoelectric smart textiles. These methods include coating or printing piezoelectric materials onto fabric substrates, incorporating piezoelectric fibers into the textile structure during weaving or knitting processes, and developing composite materials that combine piezoelectric properties with flexible textile characteristics.

- Signal processing and data analysis for piezoelectric fabric sensors: Advanced signal processing and data analysis techniques are developed to interpret the electrical signals generated by piezoelectric fabric sensors. These methods involve filtering, amplification, and pattern recognition algorithms to extract meaningful information from the sensor data, enabling accurate detection of gestures, movements, and physiological parameters.

- Energy harvesting capabilities of piezoelectric smart fabrics: Piezoelectric smart fabrics are designed to harvest energy from body movements and environmental vibrations. The piezoelectric materials in the fabric convert mechanical energy into electrical energy, which can be used to power small electronic devices or charge batteries, enhancing the self-sustainability of wearable technology systems.

- Applications of piezoelectric smart fabrics in healthcare and sports: Piezoelectric smart fabrics find applications in healthcare monitoring and sports performance analysis. These fabrics can be used to create garments that monitor vital signs, detect falls, analyze gait patterns, and provide feedback on athletic performance. The integration of piezoelectric sensing technology into everyday clothing enables continuous and non-invasive monitoring in various scenarios.

02 Integration of piezoelectric elements in textile structures

Techniques for seamlessly integrating piezoelectric elements into textile structures have been developed. These methods involve embedding piezoelectric fibers or films within the fabric during the manufacturing process, creating flexible and washable smart textiles. The resulting materials maintain their sensing capabilities while preserving the comfort and flexibility of traditional fabrics.Expand Specific Solutions03 Energy harvesting from piezoelectric smart fabrics

Piezoelectric smart fabrics can be designed to harvest energy from human motion or environmental vibrations. This energy can be used to power small electronic devices or sensors integrated into the fabric, reducing the need for external power sources. Applications include self-powered wearable electronics and energy-efficient smart clothing.Expand Specific Solutions04 Signal processing and data analysis for piezoelectric fabric sensors

Advanced signal processing and data analysis techniques have been developed to interpret the electrical signals generated by piezoelectric fabric sensors. These methods involve filtering, pattern recognition, and machine learning algorithms to extract meaningful information from the sensor data, enabling accurate interpretation of complex movements or gestures.Expand Specific Solutions05 Applications of piezoelectric smart fabrics in healthcare and sports

Piezoelectric smart fabrics find applications in healthcare and sports, including monitoring patient movements, assessing athletic performance, and providing real-time feedback on posture and form. These fabrics can be incorporated into clothing, bedding, or equipment to provide continuous, non-invasive monitoring and data collection for various physiological and biomechanical parameters.Expand Specific Solutions

Key Smart Fabric Players

The integration of piezoelectric sensing in smart fabrics is an emerging field in the early stages of development, with a growing market driven by increasing demand for wearable technology. The global smart textile market is projected to reach $5.55 billion by 2025, with piezoelectric sensors playing a crucial role. While the technology is still maturing, several key players are advancing its development. Universities like Wuhan Textile University, Chongqing University, and Qingdao University are conducting foundational research. Companies such as Asahi Kasei Trading Co. Ltd., Teijin Frontier Co., Ltd., and Sumitomo Riko Co. Ltd. are exploring commercial applications. The collaboration between academia and industry is accelerating progress, but challenges in scalability and durability remain.

National Taiwan University

Technical Solution: National Taiwan University has developed a novel approach to integrating piezoelectric sensing into smart fabrics using a combination of conductive polymers and piezoelectric nanoparticles. Their method involves creating a composite material that can be applied as a coating to existing textiles, effectively turning ordinary fabrics into smart, sensing materials. The university's research team has demonstrated that this coating can detect and differentiate between various types of mechanical stimuli, including stretching, bending, and pressure[6]. They have also developed a wireless data transmission system that allows these smart fabrics to communicate with external devices in real-time. The technology has shown promising results in applications such as gesture recognition for human-computer interaction and biomechanical analysis in sports science[7].

Strengths: Can be applied to existing fabrics, potentially reducing manufacturing complexity. Versatile sensing capabilities. Weaknesses: Durability of the coating may be a concern in long-term use or harsh conditions.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has developed a smart fabric technology that integrates piezoelectric sensing through a novel approach of embedding piezoelectric fibers directly into textile structures. Their method involves using a specialized coating process to create flexible, durable piezoelectric fibers that can be woven or knitted into fabrics. These fibers are capable of converting mechanical stress into electrical signals, allowing for real-time monitoring of pressure, strain, and movement[1]. The foundation has also developed advanced signal processing algorithms to interpret the complex data generated by these smart fabrics, enabling applications in healthcare monitoring, sports performance analysis, and human-machine interfaces[2]. Their technology has demonstrated a sensitivity capable of detecting subtle changes in body posture and even respiratory patterns[3].

Strengths: High sensitivity and versatility in applications. Integration directly into textile structures allows for seamless incorporation into everyday clothing. Weaknesses: May require specialized manufacturing processes, potentially increasing production costs.

Piezo-Fabric Innovations

Surface mountable piezoelectric sensor array fabric

PatentInactiveUS20170146493A1

Innovation

- A surface mountable piezoelectric sensor array fabric is developed, embedding sensors, a communications array, and a display into a fabric with laminar layers, allowing for the measurement and visualization of object properties, featuring a high density of sensors and integrated data analysis and display capabilities.

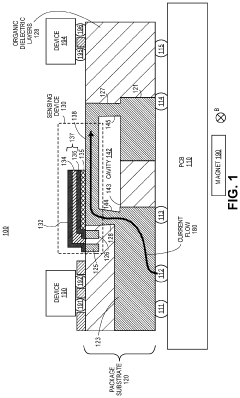

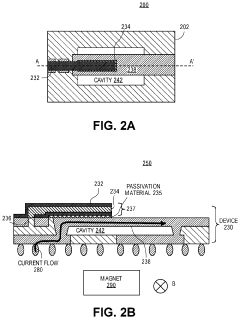

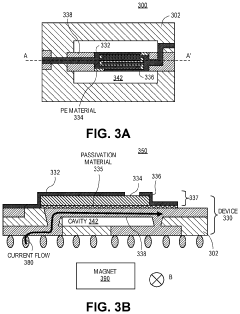

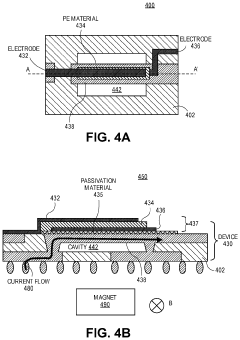

Piezoelectric package-integrated current sensing devices

PatentActiveUS10921349B2

Innovation

- The development of package-integrated piezoelectric current sensing devices that utilize a hybrid piezoelectric-electromagnetic principle, where released conductive traces within the package substrate are mechanically coupled to piezoelectric stacks, generating a voltage proportional to the current flowing through them in the presence of a magnetic field, allowing for non-contact, localized current sensing without altering the electrical characteristics or design of the system.

Wearable Tech Standards

The development of smart fabrics with integrated piezoelectric sensing capabilities has necessitated the establishment of comprehensive standards to ensure consistency, reliability, and interoperability across the wearable technology industry. These standards address various aspects of smart fabric design, manufacturing, and performance evaluation.

One key area of focus is the standardization of piezoelectric materials used in smart fabrics. This includes specifications for the types of piezoelectric materials suitable for textile integration, their physical and electrical properties, and methods for assessing their durability and performance under different environmental conditions. Standards also define testing protocols for measuring the piezoelectric response of these materials when incorporated into fabrics, ensuring consistent and comparable results across different manufacturers and research institutions.

Another critical aspect of wearable tech standards for smart fabrics with piezoelectric sensing is the integration process itself. Guidelines have been developed to standardize the methods for incorporating piezoelectric elements into textiles, including techniques for attaching sensors, creating conductive pathways, and ensuring the overall structural integrity of the fabric. These standards aim to balance the need for effective sensing capabilities with the comfort and flexibility requirements of wearable textiles.

Data collection and processing standards are also crucial in this field. These standards define protocols for signal acquisition from piezoelectric sensors in smart fabrics, including sampling rates, signal filtering, and noise reduction techniques. Additionally, they establish guidelines for data formatting and transmission, ensuring compatibility with various devices and platforms that may interface with smart fabric systems.

Safety and biocompatibility standards play a vital role in the development of smart fabrics with piezoelectric sensing. These standards outline requirements for materials used in direct contact with the skin, addressing potential allergenic or toxic properties. They also set guidelines for electrical safety, considering the unique challenges posed by integrating electronic components into textiles worn close to the body.

Lastly, performance evaluation standards have been developed to assess the functionality and reliability of smart fabrics with piezoelectric sensing. These standards define metrics for measuring sensing accuracy, response time, and consistency under various wear conditions. They also establish benchmarks for durability, including resistance to washing, stretching, and other typical stresses encountered in everyday use.

One key area of focus is the standardization of piezoelectric materials used in smart fabrics. This includes specifications for the types of piezoelectric materials suitable for textile integration, their physical and electrical properties, and methods for assessing their durability and performance under different environmental conditions. Standards also define testing protocols for measuring the piezoelectric response of these materials when incorporated into fabrics, ensuring consistent and comparable results across different manufacturers and research institutions.

Another critical aspect of wearable tech standards for smart fabrics with piezoelectric sensing is the integration process itself. Guidelines have been developed to standardize the methods for incorporating piezoelectric elements into textiles, including techniques for attaching sensors, creating conductive pathways, and ensuring the overall structural integrity of the fabric. These standards aim to balance the need for effective sensing capabilities with the comfort and flexibility requirements of wearable textiles.

Data collection and processing standards are also crucial in this field. These standards define protocols for signal acquisition from piezoelectric sensors in smart fabrics, including sampling rates, signal filtering, and noise reduction techniques. Additionally, they establish guidelines for data formatting and transmission, ensuring compatibility with various devices and platforms that may interface with smart fabric systems.

Safety and biocompatibility standards play a vital role in the development of smart fabrics with piezoelectric sensing. These standards outline requirements for materials used in direct contact with the skin, addressing potential allergenic or toxic properties. They also set guidelines for electrical safety, considering the unique challenges posed by integrating electronic components into textiles worn close to the body.

Lastly, performance evaluation standards have been developed to assess the functionality and reliability of smart fabrics with piezoelectric sensing. These standards define metrics for measuring sensing accuracy, response time, and consistency under various wear conditions. They also establish benchmarks for durability, including resistance to washing, stretching, and other typical stresses encountered in everyday use.

Sustainability in E-Textiles

The integration of smart fabrics with piezoelectric sensing capabilities has raised important questions about sustainability in the rapidly evolving field of e-textiles. As these technologies advance, it becomes crucial to address environmental concerns and promote sustainable practices throughout the lifecycle of smart fabric products.

One of the primary sustainability challenges in e-textiles is the use of materials. Many piezoelectric sensors incorporate synthetic polymers or rare earth elements, which can have significant environmental impacts during extraction and processing. To mitigate these issues, researchers are exploring bio-based alternatives and renewable materials that can provide similar sensing capabilities while reducing the ecological footprint.

Energy consumption is another critical aspect of sustainability in smart fabrics. While piezoelectric sensors can generate small amounts of electricity from mechanical stress, the overall power requirements for data processing and transmission in e-textiles can be substantial. Innovations in low-power electronics and energy harvesting techniques are essential for improving the energy efficiency of these systems and reducing their reliance on traditional power sources.

The durability and longevity of smart fabrics also play a crucial role in their sustainability profile. Piezoelectric sensors integrated into textiles must withstand repeated washing, stretching, and wear without degradation. Enhancing the robustness of these components not only improves product lifespan but also reduces electronic waste generation. Researchers are developing encapsulation methods and flexible, washable electronics to address these challenges.

End-of-life considerations are becoming increasingly important in the e-textiles industry. The complex integration of electronic components with traditional textiles poses significant recycling challenges. Developing modular designs that allow for easy separation of electronic elements from fabric substrates can facilitate more effective recycling processes. Additionally, exploring biodegradable electronics and conductive materials could provide more environmentally friendly disposal options for smart fabrics at the end of their useful life.

The manufacturing processes for smart fabrics with piezoelectric sensing capabilities also present opportunities for improving sustainability. Adopting cleaner production methods, such as water-based conductive inks and solvent-free adhesives, can reduce the environmental impact of e-textile manufacturing. Furthermore, optimizing production techniques to minimize material waste and energy consumption is crucial for enhancing the overall sustainability of these innovative textiles.

As the e-textiles market continues to grow, establishing comprehensive lifecycle assessments and sustainability standards for smart fabrics becomes increasingly important. These frameworks can guide manufacturers in making environmentally conscious decisions throughout the design, production, and disposal stages of piezoelectric-enabled textiles. By addressing sustainability challenges proactively, the e-textiles industry can ensure that the benefits of smart fabrics are realized without compromising environmental stewardship.

One of the primary sustainability challenges in e-textiles is the use of materials. Many piezoelectric sensors incorporate synthetic polymers or rare earth elements, which can have significant environmental impacts during extraction and processing. To mitigate these issues, researchers are exploring bio-based alternatives and renewable materials that can provide similar sensing capabilities while reducing the ecological footprint.

Energy consumption is another critical aspect of sustainability in smart fabrics. While piezoelectric sensors can generate small amounts of electricity from mechanical stress, the overall power requirements for data processing and transmission in e-textiles can be substantial. Innovations in low-power electronics and energy harvesting techniques are essential for improving the energy efficiency of these systems and reducing their reliance on traditional power sources.

The durability and longevity of smart fabrics also play a crucial role in their sustainability profile. Piezoelectric sensors integrated into textiles must withstand repeated washing, stretching, and wear without degradation. Enhancing the robustness of these components not only improves product lifespan but also reduces electronic waste generation. Researchers are developing encapsulation methods and flexible, washable electronics to address these challenges.

End-of-life considerations are becoming increasingly important in the e-textiles industry. The complex integration of electronic components with traditional textiles poses significant recycling challenges. Developing modular designs that allow for easy separation of electronic elements from fabric substrates can facilitate more effective recycling processes. Additionally, exploring biodegradable electronics and conductive materials could provide more environmentally friendly disposal options for smart fabrics at the end of their useful life.

The manufacturing processes for smart fabrics with piezoelectric sensing capabilities also present opportunities for improving sustainability. Adopting cleaner production methods, such as water-based conductive inks and solvent-free adhesives, can reduce the environmental impact of e-textile manufacturing. Furthermore, optimizing production techniques to minimize material waste and energy consumption is crucial for enhancing the overall sustainability of these innovative textiles.

As the e-textiles market continues to grow, establishing comprehensive lifecycle assessments and sustainability standards for smart fabrics becomes increasingly important. These frameworks can guide manufacturers in making environmentally conscious decisions throughout the design, production, and disposal stages of piezoelectric-enabled textiles. By addressing sustainability challenges proactively, the e-textiles industry can ensure that the benefits of smart fabrics are realized without compromising environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!