Piezoelectricity in Cutting-edge Timekeeping Devices

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Timekeeping Evolution and Objectives

Piezoelectric timekeeping has revolutionized the precision and reliability of timekeeping devices since its inception in the early 20th century. The journey of piezoelectric timekeeping began with the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880, which laid the foundation for its application in timekeeping mechanisms.

The evolution of piezoelectric timekeeping can be traced through several key milestones. In the 1920s, Walter Cady developed the first quartz crystal oscillator, marking a significant leap in timekeeping accuracy. This innovation paved the way for the development of quartz clocks in the 1930s, which offered unprecedented precision compared to mechanical timepieces.

The 1960s saw the commercialization of quartz watches, revolutionizing the consumer timepiece market. These watches utilized piezoelectric quartz crystals to maintain accurate timekeeping, offering superior performance to traditional mechanical watches. The subsequent decades witnessed continuous improvements in quartz technology, including the development of temperature-compensated crystal oscillators (TCXOs) and the integration of digital displays.

In recent years, the focus has shifted towards miniaturization and energy efficiency. Modern piezoelectric timekeeping devices incorporate advanced materials and manufacturing techniques to achieve higher frequencies and greater stability. The integration of microelectromechanical systems (MEMS) technology has further enhanced the performance and reduced the size of piezoelectric timekeepers.

The current technological landscape presents several objectives for the advancement of piezoelectric timekeeping. One primary goal is to improve frequency stability and reduce aging effects in quartz crystals, thereby enhancing long-term accuracy. Research is ongoing to develop new piezoelectric materials with superior properties, such as higher quality factors and temperature stability.

Another objective is to further miniaturize piezoelectric timekeeping components while maintaining or improving performance. This is crucial for applications in wearable technology and Internet of Things (IoT) devices, where space and power constraints are significant factors. Additionally, there is a push towards developing more energy-efficient piezoelectric oscillators to extend battery life in portable devices.

The integration of piezoelectric timekeeping with other emerging technologies, such as atomic clocks and quantum sensors, is also a key area of focus. This hybridization aims to combine the reliability and cost-effectiveness of piezoelectric systems with the ultra-high precision of more advanced timekeeping technologies.

Lastly, there is an increasing emphasis on developing environmentally friendly and sustainable piezoelectric materials and manufacturing processes. This aligns with the growing global focus on reducing the environmental impact of electronic devices and components.

The evolution of piezoelectric timekeeping can be traced through several key milestones. In the 1920s, Walter Cady developed the first quartz crystal oscillator, marking a significant leap in timekeeping accuracy. This innovation paved the way for the development of quartz clocks in the 1930s, which offered unprecedented precision compared to mechanical timepieces.

The 1960s saw the commercialization of quartz watches, revolutionizing the consumer timepiece market. These watches utilized piezoelectric quartz crystals to maintain accurate timekeeping, offering superior performance to traditional mechanical watches. The subsequent decades witnessed continuous improvements in quartz technology, including the development of temperature-compensated crystal oscillators (TCXOs) and the integration of digital displays.

In recent years, the focus has shifted towards miniaturization and energy efficiency. Modern piezoelectric timekeeping devices incorporate advanced materials and manufacturing techniques to achieve higher frequencies and greater stability. The integration of microelectromechanical systems (MEMS) technology has further enhanced the performance and reduced the size of piezoelectric timekeepers.

The current technological landscape presents several objectives for the advancement of piezoelectric timekeeping. One primary goal is to improve frequency stability and reduce aging effects in quartz crystals, thereby enhancing long-term accuracy. Research is ongoing to develop new piezoelectric materials with superior properties, such as higher quality factors and temperature stability.

Another objective is to further miniaturize piezoelectric timekeeping components while maintaining or improving performance. This is crucial for applications in wearable technology and Internet of Things (IoT) devices, where space and power constraints are significant factors. Additionally, there is a push towards developing more energy-efficient piezoelectric oscillators to extend battery life in portable devices.

The integration of piezoelectric timekeeping with other emerging technologies, such as atomic clocks and quantum sensors, is also a key area of focus. This hybridization aims to combine the reliability and cost-effectiveness of piezoelectric systems with the ultra-high precision of more advanced timekeeping technologies.

Lastly, there is an increasing emphasis on developing environmentally friendly and sustainable piezoelectric materials and manufacturing processes. This aligns with the growing global focus on reducing the environmental impact of electronic devices and components.

Market Analysis for Precision Timekeeping Devices

The precision timekeeping devices market has experienced significant growth in recent years, driven by advancements in piezoelectric technology and increasing demand for accurate time measurement across various industries. The global market for high-precision timekeeping devices is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing many other segments in the electronics industry.

The demand for precision timekeeping devices is primarily fueled by sectors such as telecommunications, aerospace, scientific research, and financial services. In telecommunications, the need for precise synchronization in network operations has led to increased adoption of atomic clocks and other high-accuracy timekeeping solutions. The aerospace industry relies heavily on ultra-precise timing for satellite navigation systems and space missions, further driving market growth.

Scientific research institutions and metrology laboratories represent another significant market segment, requiring cutting-edge timekeeping devices for experiments and measurements at the quantum level. Financial services, particularly high-frequency trading operations, demand nanosecond-level precision to maintain competitive advantages in algorithmic trading.

Consumer applications are also contributing to market expansion, albeit to a lesser extent. Luxury watch manufacturers are incorporating piezoelectric elements in high-end timepieces, appealing to collectors and enthusiasts seeking the pinnacle of accuracy in mechanical watches.

Geographically, North America and Europe currently dominate the market for precision timekeeping devices, owing to their advanced technological infrastructure and concentration of industries requiring high-precision timing. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing investments in research and development, and the expansion of telecommunications networks.

The market is characterized by a mix of established players and innovative startups. Traditional timekeeping device manufacturers are facing competition from technology companies entering the space with novel approaches to precision timing. This competitive landscape is fostering innovation and driving down costs, making high-precision timekeeping more accessible to a broader range of applications.

Challenges in the market include the high cost of ultra-precise timekeeping devices, which can limit adoption in price-sensitive sectors. Additionally, the complexity of integrating these devices into existing systems poses technical hurdles for some potential users. However, ongoing research in miniaturization and improved manufacturing processes is expected to address these challenges over time.

The demand for precision timekeeping devices is primarily fueled by sectors such as telecommunications, aerospace, scientific research, and financial services. In telecommunications, the need for precise synchronization in network operations has led to increased adoption of atomic clocks and other high-accuracy timekeeping solutions. The aerospace industry relies heavily on ultra-precise timing for satellite navigation systems and space missions, further driving market growth.

Scientific research institutions and metrology laboratories represent another significant market segment, requiring cutting-edge timekeeping devices for experiments and measurements at the quantum level. Financial services, particularly high-frequency trading operations, demand nanosecond-level precision to maintain competitive advantages in algorithmic trading.

Consumer applications are also contributing to market expansion, albeit to a lesser extent. Luxury watch manufacturers are incorporating piezoelectric elements in high-end timepieces, appealing to collectors and enthusiasts seeking the pinnacle of accuracy in mechanical watches.

Geographically, North America and Europe currently dominate the market for precision timekeeping devices, owing to their advanced technological infrastructure and concentration of industries requiring high-precision timing. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing investments in research and development, and the expansion of telecommunications networks.

The market is characterized by a mix of established players and innovative startups. Traditional timekeeping device manufacturers are facing competition from technology companies entering the space with novel approaches to precision timing. This competitive landscape is fostering innovation and driving down costs, making high-precision timekeeping more accessible to a broader range of applications.

Challenges in the market include the high cost of ultra-precise timekeeping devices, which can limit adoption in price-sensitive sectors. Additionally, the complexity of integrating these devices into existing systems poses technical hurdles for some potential users. However, ongoing research in miniaturization and improved manufacturing processes is expected to address these challenges over time.

Current Piezoelectric Technology in Timekeeping

Piezoelectric technology has become a cornerstone in modern timekeeping devices, offering unparalleled precision and reliability. The current state of piezoelectric technology in timekeeping is characterized by its widespread adoption in quartz watches and clocks, which dominate the market due to their accuracy and affordability.

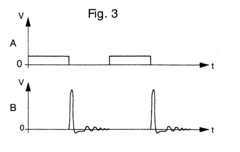

At the heart of these devices is the quartz crystal oscillator, which utilizes the piezoelectric effect to maintain a stable frequency. When an electric field is applied to a quartz crystal, it deforms slightly, and when the field is removed, it generates a small electric charge. This property allows the crystal to vibrate at a precise frequency, typically 32,768 Hz, which is then divided down to provide accurate timekeeping.

The manufacturing process for piezoelectric timekeeping components has been refined over decades, resulting in highly standardized and cost-effective production. Modern techniques allow for the creation of extremely thin quartz wafers, often less than 0.1 mm thick, which are then cut into specific shapes and sizes to achieve the desired frequency response.

Recent advancements in piezoelectric timekeeping technology have focused on improving temperature compensation and reducing power consumption. Temperature-compensated crystal oscillators (TCXOs) use additional circuitry to adjust for frequency variations caused by temperature changes, achieving accuracies of up to ±2 parts per million per year.

Microelectromechanical systems (MEMS) technology has also been applied to piezoelectric timekeeping, resulting in even smaller and more efficient oscillators. These MEMS-based devices offer the potential for further miniaturization and integration with other electronic components, making them particularly suitable for wearable technology and Internet of Things (IoT) devices.

Energy harvesting is another area of innovation in piezoelectric timekeeping. Some experimental designs use the motion of the wearer to generate small amounts of electricity, potentially extending battery life or even eliminating the need for battery replacement in certain applications.

Despite the dominance of quartz technology, research continues into alternative piezoelectric materials that could offer improved performance or new functionalities. Materials such as lithium niobate and langasite are being explored for their potential to operate at higher frequencies or in more extreme environments than traditional quartz crystals.

The integration of piezoelectric timekeeping with other technologies is also advancing. For instance, some high-end watches now combine traditional mechanical movements with piezoelectric regulators, offering the aesthetic appeal of mechanical watches with the accuracy of quartz technology.

At the heart of these devices is the quartz crystal oscillator, which utilizes the piezoelectric effect to maintain a stable frequency. When an electric field is applied to a quartz crystal, it deforms slightly, and when the field is removed, it generates a small electric charge. This property allows the crystal to vibrate at a precise frequency, typically 32,768 Hz, which is then divided down to provide accurate timekeeping.

The manufacturing process for piezoelectric timekeeping components has been refined over decades, resulting in highly standardized and cost-effective production. Modern techniques allow for the creation of extremely thin quartz wafers, often less than 0.1 mm thick, which are then cut into specific shapes and sizes to achieve the desired frequency response.

Recent advancements in piezoelectric timekeeping technology have focused on improving temperature compensation and reducing power consumption. Temperature-compensated crystal oscillators (TCXOs) use additional circuitry to adjust for frequency variations caused by temperature changes, achieving accuracies of up to ±2 parts per million per year.

Microelectromechanical systems (MEMS) technology has also been applied to piezoelectric timekeeping, resulting in even smaller and more efficient oscillators. These MEMS-based devices offer the potential for further miniaturization and integration with other electronic components, making them particularly suitable for wearable technology and Internet of Things (IoT) devices.

Energy harvesting is another area of innovation in piezoelectric timekeeping. Some experimental designs use the motion of the wearer to generate small amounts of electricity, potentially extending battery life or even eliminating the need for battery replacement in certain applications.

Despite the dominance of quartz technology, research continues into alternative piezoelectric materials that could offer improved performance or new functionalities. Materials such as lithium niobate and langasite are being explored for their potential to operate at higher frequencies or in more extreme environments than traditional quartz crystals.

The integration of piezoelectric timekeeping with other technologies is also advancing. For instance, some high-end watches now combine traditional mechanical movements with piezoelectric regulators, offering the aesthetic appeal of mechanical watches with the accuracy of quartz technology.

Existing Piezoelectric Oscillator Solutions

01 Piezoelectric oscillators for timekeeping

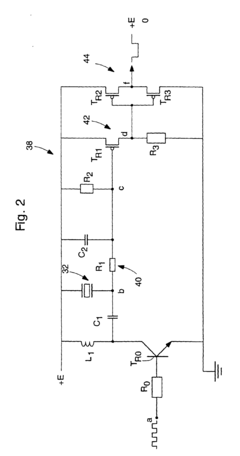

Piezoelectric oscillators are used in timekeeping devices to generate precise frequencies for accurate timekeeping. These oscillators utilize the piezoelectric effect to convert electrical energy into mechanical vibrations and vice versa, providing a stable and reliable time base for various applications.- Piezoelectric oscillator for timekeeping: Piezoelectric oscillators are used in timekeeping devices to generate precise frequencies for accurate timekeeping. These oscillators utilize the piezoelectric effect to convert electrical energy into mechanical vibrations and vice versa, providing a stable and reliable time base for various applications.

- Temperature compensation in piezoelectric timekeeping: Temperature variations can affect the accuracy of piezoelectric timekeeping devices. To address this issue, temperature compensation techniques are employed to maintain accuracy across a range of temperatures. These methods may involve using temperature-sensitive components or digital correction algorithms to adjust the oscillator frequency.

- Digital frequency correction for improved accuracy: Digital frequency correction techniques are used to enhance the accuracy of piezoelectric timekeeping devices. These methods involve measuring and analyzing the oscillator's output frequency and applying digital corrections to compensate for any deviations, resulting in improved overall timekeeping accuracy.

- Power management in piezoelectric timekeeping devices: Efficient power management is crucial for maintaining accuracy in battery-powered piezoelectric timekeeping devices. Various techniques are employed to minimize power consumption while ensuring consistent performance, including low-power oscillator designs and intelligent power-saving modes.

- Calibration and synchronization methods: To maintain high accuracy in piezoelectric timekeeping devices, calibration and synchronization methods are implemented. These techniques involve comparing the device's time against a reference source and making necessary adjustments to ensure long-term accuracy and reliability.

02 Temperature compensation techniques

Temperature compensation techniques are employed to maintain timekeeping accuracy across different environmental conditions. These methods involve adjusting the oscillator frequency or implementing temperature-sensitive components to counteract the effects of temperature variations on the piezoelectric element.Expand Specific Solutions03 Digital frequency control and calibration

Digital frequency control and calibration methods are used to fine-tune the piezoelectric oscillator's output frequency. These techniques involve digital processing, feedback loops, and adaptive algorithms to maintain high accuracy and compensate for aging and other factors affecting timekeeping precision.Expand Specific Solutions04 Power management for piezoelectric timekeeping

Power management strategies are implemented to optimize energy consumption in piezoelectric timekeeping devices. These approaches include low-power modes, energy harvesting techniques, and efficient circuit designs to extend battery life while maintaining accurate timekeeping.Expand Specific Solutions05 Miniaturization and integration of piezoelectric timekeeping components

Advancements in miniaturization and integration techniques allow for the development of compact and efficient piezoelectric timekeeping devices. These innovations include MEMS-based designs, integrated circuits, and novel packaging methods to reduce size and improve performance.Expand Specific Solutions

Key Players in Piezoelectric Timekeeping Industry

The piezoelectric timekeeping device market is in a mature growth stage, with established players and ongoing innovation. The global market size for piezoelectric devices is projected to reach several billion dollars by 2025, driven by increasing demand in consumer electronics and automotive sectors. Technologically, the field is well-developed but continues to evolve, with companies like Seiko Epson, Murata Manufacturing, and NGK Insulators leading in precision and miniaturization. Research institutions such as The Johns Hopkins University and Xidian University contribute to advancing the technology. Major electronics corporations like IBM and Canon are also active in this space, indicating the technology's broad applicability and potential for further integration into diverse products.

Seiko Epson Corp.

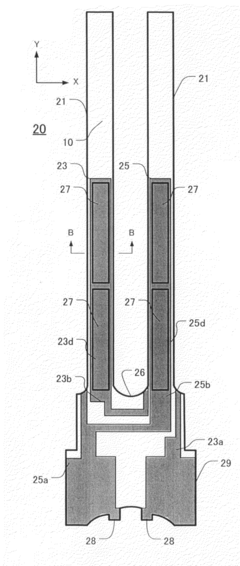

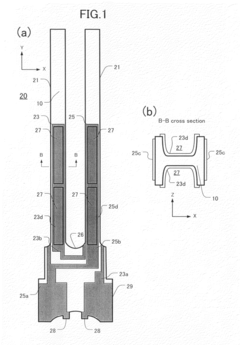

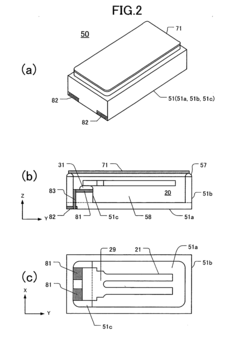

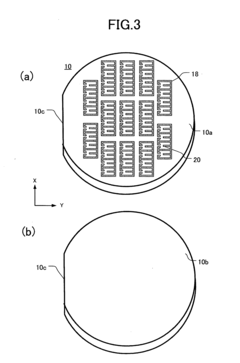

Technical Solution: Seiko Epson has pioneered the use of piezoelectric technology in timekeeping devices, particularly in their quartz watches. Their approach combines traditional quartz crystals with advanced piezoelectric actuators to achieve high precision. Epson's Spring Drive technology, while not purely piezoelectric, incorporates piezoelectric elements for energy regulation, resulting in exceptionally smooth and accurate timekeeping[1]. In recent developments, Epson has focused on integrating piezoelectric MEMS oscillators into their timing devices, offering improved temperature stability and shock resistance compared to traditional quartz oscillators[2]. These MEMS-based solutions also allow for significant size reduction, enabling the creation of more compact and energy-efficient timepieces[3].

Strengths: Long history of innovation in timekeeping, integration of piezoelectric technology with traditional watchmaking. Weaknesses: Higher production costs, complexity in manufacturing process.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has made significant advancements in piezoelectric timekeeping technology, particularly for automotive and industrial applications. Their approach combines piezoelectric sensors with microelectromechanical systems (MEMS) to create highly accurate and robust timing devices. Bosch has developed proprietary piezoelectric materials that offer improved temperature stability and reduced aging effects, crucial for maintaining long-term accuracy in harsh environments[1]. Their timing solutions often integrate multiple sensing modalities, combining piezoelectric elements with accelerometers and gyroscopes to provide comprehensive motion and timing data[2]. Recent innovations include the development of piezoelectric resonators with built-in temperature compensation, eliminating the need for external correction circuits and reducing overall system complexity[3]. Bosch's focus on miniaturization has also led to the creation of ultra-compact timing modules suitable for space-constrained applications in modern vehicles and industrial equipment.

Strengths: Extensive experience in automotive and industrial applications, robust and reliable designs for harsh environments. Weaknesses: Less focus on consumer-grade timekeeping devices, potentially higher costs due to specialized nature of products.

Core Innovations in Piezoelectric Timekeeping

Piezoelectric vibrators, piezoelectric devices comprising same, and methods for producing same

PatentInactiveUS20080209703A1

Innovation

- A method involving a flat plate of single-crystal piezoelectric material with a corrosion-resistant film on both surfaces, where a pattern is exposed and etched from one surface only, eliminating misalignment concerns and ensuring precise registration, followed by additional etching steps to form recesses and optimize arm dimensions for reduced crystal impedance and stable vibrations.

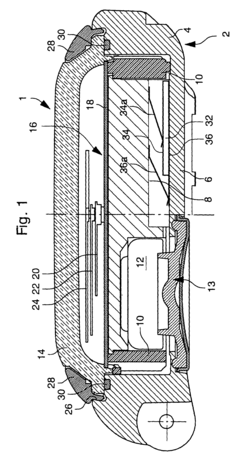

Portable object, in particular time piece, incorporating a piezo-electric transducer for manually introducing data

PatentInactiveEP1128239A1

Innovation

- A piezoelectric transducer is rigidly connected to the watch case, allowing data entry through mechanical pressure on the crystal, eliminating the risk of damage from excessive pressure and ensuring reliable sealing by fixing the crystal in place, thus reducing manufacturing costs and enhancing water resistance.

Environmental Impact of Piezoelectric Materials

The environmental impact of piezoelectric materials used in cutting-edge timekeeping devices is a growing concern as these technologies become more prevalent. Piezoelectric materials, which convert mechanical stress into electrical energy and vice versa, are essential components in many modern timekeeping devices due to their precision and efficiency. However, their production, use, and disposal can have significant environmental implications.

The manufacturing process of piezoelectric materials often involves the use of toxic substances and rare earth elements. Lead zirconate titanate (PZT), a commonly used piezoelectric material, contains lead, which is known to be harmful to both human health and the environment. The extraction and processing of these materials can lead to soil and water pollution, as well as contribute to greenhouse gas emissions.

During the operational life of piezoelectric timekeeping devices, the environmental impact is generally minimal. These devices are typically energy-efficient, consuming very little power and often utilizing the piezoelectric effect to generate their own electricity. This self-powering capability can reduce the need for battery replacements, potentially decreasing electronic waste.

However, the end-of-life stage presents significant environmental challenges. Many piezoelectric materials are not easily recyclable due to their complex composition. Improper disposal can lead to the leaching of toxic substances into soil and groundwater. The presence of lead and other heavy metals in these materials poses a particular risk to ecosystems and human health if not managed correctly.

Efforts are being made to develop more environmentally friendly alternatives to traditional piezoelectric materials. Research is focused on lead-free piezoelectric materials, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). These materials aim to maintain the high performance of PZT while reducing environmental impact. However, challenges remain in matching the efficiency and reliability of lead-based piezoelectrics.

The electronics industry is also exploring ways to improve the recyclability and biodegradability of piezoelectric devices. This includes developing modular designs that allow for easier separation of components and the use of more environmentally benign substrates and packaging materials.

As the demand for precise timekeeping devices continues to grow, particularly in sectors like telecommunications, aerospace, and scientific research, addressing the environmental impact of piezoelectric materials becomes increasingly important. Balancing technological advancement with environmental sustainability will be crucial for the future development of cutting-edge timekeeping devices.

The manufacturing process of piezoelectric materials often involves the use of toxic substances and rare earth elements. Lead zirconate titanate (PZT), a commonly used piezoelectric material, contains lead, which is known to be harmful to both human health and the environment. The extraction and processing of these materials can lead to soil and water pollution, as well as contribute to greenhouse gas emissions.

During the operational life of piezoelectric timekeeping devices, the environmental impact is generally minimal. These devices are typically energy-efficient, consuming very little power and often utilizing the piezoelectric effect to generate their own electricity. This self-powering capability can reduce the need for battery replacements, potentially decreasing electronic waste.

However, the end-of-life stage presents significant environmental challenges. Many piezoelectric materials are not easily recyclable due to their complex composition. Improper disposal can lead to the leaching of toxic substances into soil and groundwater. The presence of lead and other heavy metals in these materials poses a particular risk to ecosystems and human health if not managed correctly.

Efforts are being made to develop more environmentally friendly alternatives to traditional piezoelectric materials. Research is focused on lead-free piezoelectric materials, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT). These materials aim to maintain the high performance of PZT while reducing environmental impact. However, challenges remain in matching the efficiency and reliability of lead-based piezoelectrics.

The electronics industry is also exploring ways to improve the recyclability and biodegradability of piezoelectric devices. This includes developing modular designs that allow for easier separation of components and the use of more environmentally benign substrates and packaging materials.

As the demand for precise timekeeping devices continues to grow, particularly in sectors like telecommunications, aerospace, and scientific research, addressing the environmental impact of piezoelectric materials becomes increasingly important. Balancing technological advancement with environmental sustainability will be crucial for the future development of cutting-edge timekeeping devices.

Standardization of Piezoelectric Timekeeping

The standardization of piezoelectric timekeeping is a critical aspect in the development and widespread adoption of cutting-edge timekeeping devices. As the technology continues to evolve, establishing uniform standards becomes increasingly important to ensure consistency, reliability, and interoperability across different manufacturers and applications.

One of the primary areas of standardization focuses on the piezoelectric materials used in timekeeping devices. This includes defining specific material compositions, crystal structures, and manufacturing processes that yield optimal performance for timekeeping applications. By standardizing these aspects, manufacturers can ensure consistent quality and performance across their product lines, while also facilitating easier sourcing of materials from multiple suppliers.

Another key area of standardization involves the electrical characteristics of piezoelectric timekeeping components. This encompasses parameters such as resonant frequency, quality factor, and temperature coefficient of frequency. Establishing standard measurement methods and acceptable ranges for these parameters enables better comparison between different products and ensures compatibility with associated electronic circuits.

Mechanical design standards for piezoelectric timekeeping devices are also crucial. These standards define aspects such as package dimensions, mounting configurations, and environmental protection requirements. By adhering to these standards, manufacturers can create products that are easily integrated into a wide range of applications, from wristwatches to industrial timing systems.

Calibration and testing procedures form another important aspect of standardization. Developing standardized methods for measuring and verifying the accuracy and stability of piezoelectric timekeeping devices ensures that all products meet specified performance criteria. This includes defining test conditions, measurement equipment, and acceptable tolerances for various performance parameters.

Lastly, standardization efforts extend to the communication protocols and interfaces used in piezoelectric timekeeping systems. This is particularly important for devices that need to synchronize with external time sources or integrate into larger systems. Establishing standard communication protocols ensures seamless integration and interoperability across different devices and platforms.

By implementing comprehensive standards for piezoelectric timekeeping, the industry can drive innovation, improve product quality, and expand the application of this technology across various sectors. These standards not only benefit manufacturers but also provide consumers with greater confidence in the reliability and performance of piezoelectric timekeeping devices.

One of the primary areas of standardization focuses on the piezoelectric materials used in timekeeping devices. This includes defining specific material compositions, crystal structures, and manufacturing processes that yield optimal performance for timekeeping applications. By standardizing these aspects, manufacturers can ensure consistent quality and performance across their product lines, while also facilitating easier sourcing of materials from multiple suppliers.

Another key area of standardization involves the electrical characteristics of piezoelectric timekeeping components. This encompasses parameters such as resonant frequency, quality factor, and temperature coefficient of frequency. Establishing standard measurement methods and acceptable ranges for these parameters enables better comparison between different products and ensures compatibility with associated electronic circuits.

Mechanical design standards for piezoelectric timekeeping devices are also crucial. These standards define aspects such as package dimensions, mounting configurations, and environmental protection requirements. By adhering to these standards, manufacturers can create products that are easily integrated into a wide range of applications, from wristwatches to industrial timing systems.

Calibration and testing procedures form another important aspect of standardization. Developing standardized methods for measuring and verifying the accuracy and stability of piezoelectric timekeeping devices ensures that all products meet specified performance criteria. This includes defining test conditions, measurement equipment, and acceptable tolerances for various performance parameters.

Lastly, standardization efforts extend to the communication protocols and interfaces used in piezoelectric timekeeping systems. This is particularly important for devices that need to synchronize with external time sources or integrate into larger systems. Establishing standard communication protocols ensures seamless integration and interoperability across different devices and platforms.

By implementing comprehensive standards for piezoelectric timekeeping, the industry can drive innovation, improve product quality, and expand the application of this technology across various sectors. These standards not only benefit manufacturers but also provide consumers with greater confidence in the reliability and performance of piezoelectric timekeeping devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!