How Piezoelectric Motors Empower Micro-automation Solutions

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Motors: Evolution and Objectives

Piezoelectric motors have emerged as a revolutionary technology in the field of micro-automation, offering precise control and miniaturization capabilities that surpass traditional electromagnetic motors. The evolution of these motors can be traced back to the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880. This fundamental principle, where certain materials generate an electric charge in response to mechanical stress, laid the groundwork for the development of piezoelectric actuators and motors.

The journey from discovery to practical application spanned several decades. In the 1960s and 1970s, researchers began exploring the potential of piezoelectric materials for motion control. The first piezoelectric motors were developed in the 1980s, primarily for use in autofocus mechanisms in cameras. These early motors demonstrated the potential for precise, small-scale movement, but were limited in their power output and efficiency.

As material science and manufacturing techniques advanced, so did the capabilities of piezoelectric motors. The 1990s and 2000s saw significant improvements in piezoelectric ceramics and composite materials, leading to motors with higher power density, improved efficiency, and greater reliability. This period also marked the expansion of piezoelectric motor applications beyond optics into fields such as medical devices, aerospace, and robotics.

The objectives of piezoelectric motor development have evolved in tandem with technological advancements and market demands. Initially, the focus was on achieving basic functionality and proving the concept's viability. As the technology matured, objectives shifted towards enhancing performance metrics such as speed, torque, and precision. In recent years, the goals have expanded to include miniaturization, energy efficiency, and integration with smart systems.

Current objectives in piezoelectric motor research and development include further miniaturization to enable new applications in nanotechnology and microfluidics. There is also a push for increased power output and efficiency to compete more effectively with traditional motor technologies in a broader range of applications. Additionally, researchers are working on improving the control systems and feedback mechanisms to achieve even greater precision and responsiveness.

Another key objective is the development of more cost-effective manufacturing processes to make piezoelectric motors more accessible for mass-market applications. This includes exploring new materials and fabrication techniques that can reduce production costs while maintaining or improving performance characteristics. The integration of piezoelectric motors with advanced control systems and IoT technologies is also a priority, aiming to create more intelligent and adaptive micro-automation solutions.

As we look to the future, the evolution of piezoelectric motors is likely to continue along these trajectories, with a focus on pushing the boundaries of size, power, and precision. The ultimate goal is to establish piezoelectric motors as the go-to solution for a wide range of micro-automation challenges, empowering innovations across multiple industries and technological domains.

The journey from discovery to practical application spanned several decades. In the 1960s and 1970s, researchers began exploring the potential of piezoelectric materials for motion control. The first piezoelectric motors were developed in the 1980s, primarily for use in autofocus mechanisms in cameras. These early motors demonstrated the potential for precise, small-scale movement, but were limited in their power output and efficiency.

As material science and manufacturing techniques advanced, so did the capabilities of piezoelectric motors. The 1990s and 2000s saw significant improvements in piezoelectric ceramics and composite materials, leading to motors with higher power density, improved efficiency, and greater reliability. This period also marked the expansion of piezoelectric motor applications beyond optics into fields such as medical devices, aerospace, and robotics.

The objectives of piezoelectric motor development have evolved in tandem with technological advancements and market demands. Initially, the focus was on achieving basic functionality and proving the concept's viability. As the technology matured, objectives shifted towards enhancing performance metrics such as speed, torque, and precision. In recent years, the goals have expanded to include miniaturization, energy efficiency, and integration with smart systems.

Current objectives in piezoelectric motor research and development include further miniaturization to enable new applications in nanotechnology and microfluidics. There is also a push for increased power output and efficiency to compete more effectively with traditional motor technologies in a broader range of applications. Additionally, researchers are working on improving the control systems and feedback mechanisms to achieve even greater precision and responsiveness.

Another key objective is the development of more cost-effective manufacturing processes to make piezoelectric motors more accessible for mass-market applications. This includes exploring new materials and fabrication techniques that can reduce production costs while maintaining or improving performance characteristics. The integration of piezoelectric motors with advanced control systems and IoT technologies is also a priority, aiming to create more intelligent and adaptive micro-automation solutions.

As we look to the future, the evolution of piezoelectric motors is likely to continue along these trajectories, with a focus on pushing the boundaries of size, power, and precision. The ultimate goal is to establish piezoelectric motors as the go-to solution for a wide range of micro-automation challenges, empowering innovations across multiple industries and technological domains.

Market Demand for Micro-automation Solutions

The market demand for micro-automation solutions has been experiencing significant growth in recent years, driven by the increasing need for miniaturization and precision in various industries. Piezoelectric motors play a crucial role in this expanding market, offering unique advantages in micro-scale applications.

The healthcare sector represents a major driver of demand for micro-automation solutions. With the rise of minimally invasive surgical procedures and the development of advanced medical devices, there is a growing need for precise, compact actuators. Piezoelectric motors excel in this domain, providing high-resolution positioning and smooth motion control in applications such as surgical robots, drug delivery systems, and diagnostic equipment.

In the electronics manufacturing industry, the trend towards smaller and more complex devices has created a substantial market for micro-automation solutions. Piezoelectric motors are increasingly utilized in pick-and-place machines, micro-assembly systems, and testing equipment. Their ability to achieve nanometer-level precision makes them ideal for handling delicate components and ensuring accurate placement in miniature electronic assemblies.

The aerospace and defense sectors also contribute significantly to the market demand. Piezoelectric motors find applications in guidance systems, optical equipment, and unmanned aerial vehicles (UAVs). Their compact size, low power consumption, and high reliability make them suitable for space-constrained and mission-critical applications.

The automotive industry is another key market for micro-automation solutions. As vehicles become more sophisticated, there is an increasing need for precise actuation in various systems, such as adaptive headlights, mirror adjustments, and haptic feedback devices. Piezoelectric motors offer advantages in terms of size, speed, and energy efficiency compared to traditional electromagnetic motors.

In the field of optics and photonics, the demand for micro-automation solutions is driven by applications such as adaptive optics, laser beam steering, and microscopy. Piezoelectric motors provide the necessary precision and stability for fine adjustments in optical systems, contributing to advancements in imaging technologies and scientific instruments.

The semiconductor industry also presents significant opportunities for micro-automation solutions. As chip manufacturing processes become more complex and require higher precision, piezoelectric motors are increasingly used in wafer handling, lithography systems, and inspection equipment.

Market analysts project continued growth in the micro-automation solutions market, with piezoelectric motors playing a pivotal role. The global market for piezoelectric devices, including motors, is expected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is fueled by ongoing technological advancements, increasing adoption across diverse industries, and the continuous push for miniaturization and improved performance in automated systems.

The healthcare sector represents a major driver of demand for micro-automation solutions. With the rise of minimally invasive surgical procedures and the development of advanced medical devices, there is a growing need for precise, compact actuators. Piezoelectric motors excel in this domain, providing high-resolution positioning and smooth motion control in applications such as surgical robots, drug delivery systems, and diagnostic equipment.

In the electronics manufacturing industry, the trend towards smaller and more complex devices has created a substantial market for micro-automation solutions. Piezoelectric motors are increasingly utilized in pick-and-place machines, micro-assembly systems, and testing equipment. Their ability to achieve nanometer-level precision makes them ideal for handling delicate components and ensuring accurate placement in miniature electronic assemblies.

The aerospace and defense sectors also contribute significantly to the market demand. Piezoelectric motors find applications in guidance systems, optical equipment, and unmanned aerial vehicles (UAVs). Their compact size, low power consumption, and high reliability make them suitable for space-constrained and mission-critical applications.

The automotive industry is another key market for micro-automation solutions. As vehicles become more sophisticated, there is an increasing need for precise actuation in various systems, such as adaptive headlights, mirror adjustments, and haptic feedback devices. Piezoelectric motors offer advantages in terms of size, speed, and energy efficiency compared to traditional electromagnetic motors.

In the field of optics and photonics, the demand for micro-automation solutions is driven by applications such as adaptive optics, laser beam steering, and microscopy. Piezoelectric motors provide the necessary precision and stability for fine adjustments in optical systems, contributing to advancements in imaging technologies and scientific instruments.

The semiconductor industry also presents significant opportunities for micro-automation solutions. As chip manufacturing processes become more complex and require higher precision, piezoelectric motors are increasingly used in wafer handling, lithography systems, and inspection equipment.

Market analysts project continued growth in the micro-automation solutions market, with piezoelectric motors playing a pivotal role. The global market for piezoelectric devices, including motors, is expected to expand at a compound annual growth rate (CAGR) of over 4% in the coming years. This growth is fueled by ongoing technological advancements, increasing adoption across diverse industries, and the continuous push for miniaturization and improved performance in automated systems.

Current State and Challenges in Piezoelectric Technology

Piezoelectric motors have made significant strides in recent years, revolutionizing micro-automation solutions across various industries. The current state of piezoelectric technology is characterized by rapid advancements in materials science, precision engineering, and control systems. These motors leverage the piezoelectric effect to convert electrical energy into mechanical motion, offering unparalleled precision and efficiency at the microscale.

One of the primary challenges facing piezoelectric technology is the development of more efficient piezoelectric materials. While traditional materials like lead zirconate titanate (PZT) have been widely used, there is a growing demand for lead-free alternatives due to environmental concerns. Researchers are exploring new compositions and nanostructured materials to enhance piezoelectric properties and overcome these limitations.

Another significant challenge lies in the miniaturization of piezoelectric motors while maintaining or improving their performance. As micro-automation applications become increasingly sophisticated, there is a need for even smaller motors that can operate in confined spaces. This miniaturization process requires innovative design approaches and advanced manufacturing techniques to ensure optimal performance at reduced scales.

The integration of piezoelectric motors into complex micro-automation systems presents another hurdle. Engineers must overcome issues related to control precision, power management, and system compatibility. Developing robust control algorithms and driver electronics that can effectively harness the unique characteristics of piezoelectric actuators is crucial for expanding their application range.

Durability and reliability remain ongoing concerns in piezoelectric technology. The repetitive stress cycles experienced by these motors can lead to fatigue and degradation over time. Addressing these issues through improved material compositions, structural designs, and protective measures is essential for ensuring long-term performance in demanding industrial applications.

Cost-effectiveness is another challenge that impacts the widespread adoption of piezoelectric motors in micro-automation solutions. While these motors offer superior performance in many aspects, their production costs can be higher compared to conventional electromagnetic motors. Developing more cost-efficient manufacturing processes and scaling up production are key focus areas for making piezoelectric technology more accessible across various industries.

Lastly, the current state of piezoelectric technology is marked by a geographical concentration of expertise and production capabilities. Leading research institutions and manufacturers are primarily located in developed countries, creating potential barriers for global adoption and innovation. Efforts to disseminate knowledge and establish collaborative research networks are crucial for advancing the field and addressing regional disparities in technological capabilities.

One of the primary challenges facing piezoelectric technology is the development of more efficient piezoelectric materials. While traditional materials like lead zirconate titanate (PZT) have been widely used, there is a growing demand for lead-free alternatives due to environmental concerns. Researchers are exploring new compositions and nanostructured materials to enhance piezoelectric properties and overcome these limitations.

Another significant challenge lies in the miniaturization of piezoelectric motors while maintaining or improving their performance. As micro-automation applications become increasingly sophisticated, there is a need for even smaller motors that can operate in confined spaces. This miniaturization process requires innovative design approaches and advanced manufacturing techniques to ensure optimal performance at reduced scales.

The integration of piezoelectric motors into complex micro-automation systems presents another hurdle. Engineers must overcome issues related to control precision, power management, and system compatibility. Developing robust control algorithms and driver electronics that can effectively harness the unique characteristics of piezoelectric actuators is crucial for expanding their application range.

Durability and reliability remain ongoing concerns in piezoelectric technology. The repetitive stress cycles experienced by these motors can lead to fatigue and degradation over time. Addressing these issues through improved material compositions, structural designs, and protective measures is essential for ensuring long-term performance in demanding industrial applications.

Cost-effectiveness is another challenge that impacts the widespread adoption of piezoelectric motors in micro-automation solutions. While these motors offer superior performance in many aspects, their production costs can be higher compared to conventional electromagnetic motors. Developing more cost-efficient manufacturing processes and scaling up production are key focus areas for making piezoelectric technology more accessible across various industries.

Lastly, the current state of piezoelectric technology is marked by a geographical concentration of expertise and production capabilities. Leading research institutions and manufacturers are primarily located in developed countries, creating potential barriers for global adoption and innovation. Efforts to disseminate knowledge and establish collaborative research networks are crucial for advancing the field and addressing regional disparities in technological capabilities.

Existing Micro-automation Solutions Using Piezoelectric Motors

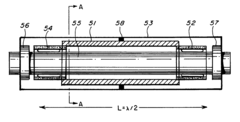

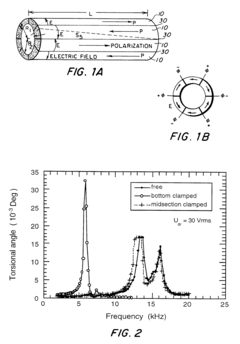

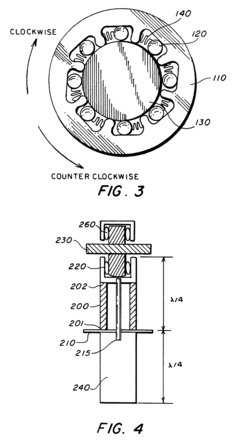

01 Piezoelectric motor design and structure

Piezoelectric motors utilize the piezoelectric effect to convert electrical energy into mechanical motion. These motors typically consist of a stator and a rotor, with piezoelectric elements arranged to create precise movements. The design often includes specific electrode patterns and vibration modes to optimize performance and efficiency.- Design and structure of piezoelectric motors: Piezoelectric motors utilize the piezoelectric effect to convert electrical energy into mechanical motion. These motors typically consist of a stator and a rotor, with piezoelectric elements arranged in specific configurations to generate precise movements. The design often includes multiple piezoelectric elements to create complex motion patterns or increase power output.

- Control systems for piezoelectric motors: Advanced control systems are crucial for optimizing the performance of piezoelectric motors. These systems often involve sophisticated algorithms and feedback mechanisms to precisely regulate the voltage and frequency applied to the piezoelectric elements. Such control systems can enhance motor efficiency, accuracy, and responsiveness in various applications.

- Applications of piezoelectric motors: Piezoelectric motors find applications in diverse fields due to their high precision and compact size. They are commonly used in optical and imaging systems, robotics, aerospace, and medical devices. These motors are particularly valuable in applications requiring nanometer-scale positioning or operation in extreme environments.

- Miniaturization and integration of piezoelectric motors: There is a growing trend towards miniaturization and integration of piezoelectric motors into microelectromechanical systems (MEMS). This involves developing novel fabrication techniques and materials to create ultra-small piezoelectric actuators that can be integrated into compact devices. Such advancements enable new applications in fields like microfluidics and portable electronics.

- Energy efficiency and power optimization: Improving the energy efficiency and power output of piezoelectric motors is an ongoing area of research. This involves developing new piezoelectric materials with enhanced properties, optimizing the motor geometry, and implementing advanced driving techniques. These efforts aim to increase the motor's power-to-size ratio and overall performance while reducing energy consumption.

02 Control systems for piezoelectric motors

Advanced control systems are crucial for the operation of piezoelectric motors. These systems often involve sophisticated algorithms, feedback mechanisms, and precise voltage control to manage the motor's movement, speed, and positioning accuracy. Some designs incorporate microcontrollers or dedicated integrated circuits for improved performance and responsiveness.Expand Specific Solutions03 Applications of piezoelectric motors

Piezoelectric motors find applications in various fields due to their high precision and compact size. They are used in optical systems, robotics, aerospace, medical devices, and precision manufacturing equipment. These motors are particularly suitable for applications requiring nanometer-scale positioning or operation in extreme environments.Expand Specific Solutions04 Miniaturization and integration techniques

Efforts to miniaturize piezoelectric motors have led to the development of novel fabrication techniques and integration methods. These include the use of MEMS technology, thin-film deposition processes, and advanced packaging solutions. Miniaturization enables the incorporation of piezoelectric motors into compact devices and microsystems.Expand Specific Solutions05 Energy efficiency and power management

Improving the energy efficiency of piezoelectric motors is a key area of research and development. This involves optimizing the motor's design, materials, and driving circuits to minimize power consumption while maintaining performance. Some approaches include resonant driving techniques, energy recovery systems, and the use of low-power control electronics.Expand Specific Solutions

Key Players in Piezoelectric Motor Industry

The piezoelectric motor market is in a growth phase, driven by increasing demand for micro-automation solutions across various industries. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, piezoelectric motors are reaching maturity, with ongoing innovations enhancing their performance and applications. Key players like Physik Instrumente (PI) GmbH & Co. KG and PI Ceramic GmbH are leading in research and development, while companies such as Siemens Corp. and Samsung Electronics Co., Ltd. are integrating these motors into diverse applications. Universities like Peking University and Tianjin University are contributing to advancements in piezoelectric technology, fostering industry-academia collaborations and driving further innovation in this field.

Physik Instrumente (PI) GmbH & Co. KG

Technical Solution: PI is a leading manufacturer of piezoelectric motors and micro-positioning systems. Their PICMA® multilayer piezo actuators offer sub-nanometer precision and high reliability[1]. PI's ultrasonic piezo motors, such as the PILine® series, provide high-speed motion in a compact form factor. These motors utilize the inverse piezoelectric effect to generate linear or rotary motion through high-frequency oscillations[2]. PI has also developed novel stick-slip piezo drives like the PiezoWalk® technology, which combines high force, long travel, and nanometer precision[3].

Strengths: Exceptional precision, high reliability, and compact design. Weaknesses: Higher cost compared to conventional motors, limited force output for some applications.

PI Ceramic GmbH

Technical Solution: PI Ceramic, a subsidiary of Physik Instrumente, specializes in piezoelectric materials and components. They have developed advanced piezoelectric ceramics with improved performance characteristics, such as higher Curie temperatures and enhanced electromechanical coupling factors[4]. Their multilayer actuators feature proprietary cofiring technology, resulting in monolithic structures with superior reliability and lifetime. PI Ceramic's custom-engineered piezo elements are used in various micro-automation applications, including precision valves, micropumps, and ultrasonic transducers[5].

Strengths: Expertise in piezoelectric materials, customization capabilities, and high-performance components. Weaknesses: Focused primarily on components rather than complete motor systems.

Core Innovations in Piezoelectric Motor Technology

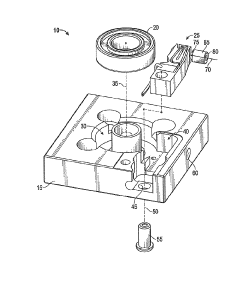

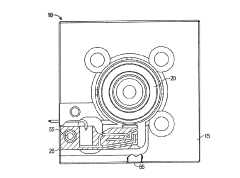

Small general-purpose stick-slip piezoelectric motor

PatentPendingJP2016533159A

Innovation

- A novel configuration of the stick-slip motor with a base, stage, and motor assembly that includes a mounting base, friction pad, connecting portion, and piezoelectric element, allowing for adjustable preload force through externally accessible screws, and a compact design with efficient use of space using tapered springs and flexible elements.

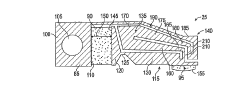

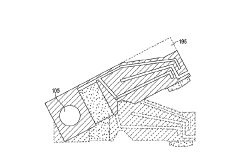

Piezoelectric torsional vibration driven motor

PatentInactiveUS6417601B1

Innovation

- A compact, lightweight piezoelectric motor utilizing a torsional actuator with alternately poled electroactive segments and a one-way clutch to convert an alternating electric field into torsional vibration and directly into rotary motion, featuring a full cycle operation that maximizes angular displacement and torque transmission.

Energy Efficiency and Sustainability Aspects

Piezoelectric motors, known for their high precision and compact size, offer significant advantages in terms of energy efficiency and sustainability compared to traditional electromagnetic motors. These motors operate on the principle of converting electrical energy directly into mechanical motion through the piezoelectric effect, resulting in minimal energy loss and heat generation.

The energy efficiency of piezoelectric motors is particularly noteworthy in micro-automation applications. Unlike conventional motors that require gears or other mechanical transmission components, piezoelectric motors can directly drive loads, reducing energy losses associated with friction and mechanical wear. This direct drive capability also contributes to their longevity, as there are fewer moving parts subject to wear and tear.

In terms of power consumption, piezoelectric motors excel in low-power applications. They can maintain their position without continuous power input, a feature known as self-locking. This characteristic is especially valuable in micro-automation systems where precise positioning is critical, as it eliminates the need for constant power supply to maintain a specific position, thereby reducing overall energy consumption.

The materials used in piezoelectric motors also contribute to their sustainability profile. Many piezoelectric materials, such as lead zirconate titanate (PZT), are highly durable and have a long operational lifespan. This durability translates to reduced need for replacement and maintenance, minimizing waste and resource consumption over time.

Furthermore, the compact size of piezoelectric motors allows for the design of smaller, more efficient automation systems. This miniaturization can lead to reduced material usage in the overall system design, contributing to resource conservation and sustainability in manufacturing processes.

From an environmental perspective, piezoelectric motors offer advantages in terms of noise reduction and elimination of electromagnetic interference. Their silent operation makes them suitable for noise-sensitive environments, while their lack of electromagnetic emissions reduces the need for shielding materials, further enhancing their eco-friendly profile.

As the demand for energy-efficient and sustainable technologies grows, piezoelectric motors are likely to play an increasingly important role in micro-automation solutions. Their inherent energy efficiency, coupled with their long lifespan and minimal environmental impact, positions them as a key technology for future sustainable automation systems. Ongoing research in piezoelectric materials and motor designs continues to improve their performance and expand their applications, further enhancing their potential as an environmentally friendly alternative in precision motion control.

The energy efficiency of piezoelectric motors is particularly noteworthy in micro-automation applications. Unlike conventional motors that require gears or other mechanical transmission components, piezoelectric motors can directly drive loads, reducing energy losses associated with friction and mechanical wear. This direct drive capability also contributes to their longevity, as there are fewer moving parts subject to wear and tear.

In terms of power consumption, piezoelectric motors excel in low-power applications. They can maintain their position without continuous power input, a feature known as self-locking. This characteristic is especially valuable in micro-automation systems where precise positioning is critical, as it eliminates the need for constant power supply to maintain a specific position, thereby reducing overall energy consumption.

The materials used in piezoelectric motors also contribute to their sustainability profile. Many piezoelectric materials, such as lead zirconate titanate (PZT), are highly durable and have a long operational lifespan. This durability translates to reduced need for replacement and maintenance, minimizing waste and resource consumption over time.

Furthermore, the compact size of piezoelectric motors allows for the design of smaller, more efficient automation systems. This miniaturization can lead to reduced material usage in the overall system design, contributing to resource conservation and sustainability in manufacturing processes.

From an environmental perspective, piezoelectric motors offer advantages in terms of noise reduction and elimination of electromagnetic interference. Their silent operation makes them suitable for noise-sensitive environments, while their lack of electromagnetic emissions reduces the need for shielding materials, further enhancing their eco-friendly profile.

As the demand for energy-efficient and sustainable technologies grows, piezoelectric motors are likely to play an increasingly important role in micro-automation solutions. Their inherent energy efficiency, coupled with their long lifespan and minimal environmental impact, positions them as a key technology for future sustainable automation systems. Ongoing research in piezoelectric materials and motor designs continues to improve their performance and expand their applications, further enhancing their potential as an environmentally friendly alternative in precision motion control.

Miniaturization Trends and Limitations

The trend towards miniaturization in automation has been a driving force in the development of piezoelectric motors and their applications in micro-automation solutions. This push for smaller, more precise, and energy-efficient systems has led to significant advancements in piezoelectric motor technology, but it has also revealed certain limitations that must be addressed.

One of the primary trends in miniaturization is the reduction of component size while maintaining or improving performance. Piezoelectric motors have excelled in this area, as they can be manufactured at extremely small scales, often less than a millimeter in size. This miniaturization has enabled the integration of these motors into increasingly compact devices, such as medical instruments, optical systems, and precision positioning equipment.

Another key trend is the demand for higher precision and resolution in motion control. As devices become smaller, the need for nanometer-scale positioning accuracy has grown. Piezoelectric motors have proven particularly adept at meeting this challenge, offering sub-nanometer resolution in some applications. This level of precision is crucial for fields like semiconductor manufacturing, microscopy, and nanotechnology.

However, the pursuit of miniaturization has also exposed certain limitations. One significant challenge is the trade-off between size and power output. As piezoelectric motors are scaled down, their force and torque capabilities can diminish, potentially limiting their applicability in certain micro-automation scenarios that require higher power outputs.

Heat dissipation presents another limitation in miniaturized systems. As components are packed more densely, managing thermal issues becomes increasingly complex. While piezoelectric motors generally produce less heat than electromagnetic alternatives, thermal management remains a concern in ultra-compact designs.

The miniaturization of control electronics and power supplies for piezoelectric motors has also proven challenging. While the motors themselves can be made extremely small, the supporting circuitry often cannot be reduced at the same rate, potentially limiting the overall miniaturization of the system.

Material limitations have also become apparent as sizes decrease. The piezoelectric materials used in these motors may exhibit reduced performance or reliability when manufactured at extremely small scales, necessitating ongoing research into novel materials and fabrication techniques.

Despite these challenges, the trend towards miniaturization continues to drive innovation in piezoelectric motor technology. Researchers and engineers are actively working to overcome these limitations through advancements in materials science, nanofabrication techniques, and innovative motor designs. As these efforts progress, the capabilities of piezoelectric motors in micro-automation solutions are expected to expand, enabling even more compact and precise systems in the future.

One of the primary trends in miniaturization is the reduction of component size while maintaining or improving performance. Piezoelectric motors have excelled in this area, as they can be manufactured at extremely small scales, often less than a millimeter in size. This miniaturization has enabled the integration of these motors into increasingly compact devices, such as medical instruments, optical systems, and precision positioning equipment.

Another key trend is the demand for higher precision and resolution in motion control. As devices become smaller, the need for nanometer-scale positioning accuracy has grown. Piezoelectric motors have proven particularly adept at meeting this challenge, offering sub-nanometer resolution in some applications. This level of precision is crucial for fields like semiconductor manufacturing, microscopy, and nanotechnology.

However, the pursuit of miniaturization has also exposed certain limitations. One significant challenge is the trade-off between size and power output. As piezoelectric motors are scaled down, their force and torque capabilities can diminish, potentially limiting their applicability in certain micro-automation scenarios that require higher power outputs.

Heat dissipation presents another limitation in miniaturized systems. As components are packed more densely, managing thermal issues becomes increasingly complex. While piezoelectric motors generally produce less heat than electromagnetic alternatives, thermal management remains a concern in ultra-compact designs.

The miniaturization of control electronics and power supplies for piezoelectric motors has also proven challenging. While the motors themselves can be made extremely small, the supporting circuitry often cannot be reduced at the same rate, potentially limiting the overall miniaturization of the system.

Material limitations have also become apparent as sizes decrease. The piezoelectric materials used in these motors may exhibit reduced performance or reliability when manufactured at extremely small scales, necessitating ongoing research into novel materials and fabrication techniques.

Despite these challenges, the trend towards miniaturization continues to drive innovation in piezoelectric motor technology. Researchers and engineers are actively working to overcome these limitations through advancements in materials science, nanofabrication techniques, and innovative motor designs. As these efforts progress, the capabilities of piezoelectric motors in micro-automation solutions are expected to expand, enabling even more compact and precise systems in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!