Ultra-broadband Piezoelectric Sensor Technologies

JUL 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception in the early 20th century. Initially discovered by the Curie brothers in 1880, piezoelectric materials' ability to generate an electric charge in response to mechanical stress has been harnessed for sensing applications across various industries. The development of these sensors has been driven by the increasing demand for precise measurement and monitoring in fields such as aerospace, automotive, medical, and industrial automation.

The evolution of piezoelectric sensor technology can be traced through several key milestones. Early applications were limited to simple pressure and acceleration measurements. However, as material science and manufacturing techniques advanced, the capabilities and performance of these sensors expanded dramatically. The introduction of synthetic piezoelectric materials, such as lead zirconate titanate (PZT) in the 1950s, marked a significant leap forward, offering improved sensitivity and stability compared to natural crystals.

In recent decades, the focus has shifted towards miniaturization and integration, with the development of micro-electromechanical systems (MEMS) based piezoelectric sensors. This has enabled the creation of highly compact and sensitive devices suitable for a wide range of applications, from consumer electronics to advanced scientific instrumentation.

The current technological landscape is characterized by a push towards ultra-broadband piezoelectric sensors. These sensors aim to overcome the traditional limitations of narrow frequency response, enabling the detection and measurement of signals across a much wider spectrum. This advancement is crucial for applications requiring high-fidelity sensing across diverse frequency ranges, such as structural health monitoring, acoustic emission detection, and advanced vibration analysis.

The primary objectives of research in ultra-broadband piezoelectric sensor technologies are multifaceted. Firstly, there is a drive to expand the operational frequency range of sensors, potentially covering from sub-Hz to MHz frequencies in a single device. This would enable more comprehensive data collection and analysis in complex systems.

Secondly, researchers aim to improve the sensitivity and signal-to-noise ratio across the entire frequency spectrum, ensuring accurate measurements even at the extremes of the sensor's range. This involves not only enhancing the piezoelectric materials themselves but also developing advanced signal processing and noise reduction techniques.

Another key objective is the integration of ultra-broadband capabilities with other desirable sensor characteristics, such as high temperature tolerance, miniaturization, and energy efficiency. This holistic approach to sensor design is essential for creating versatile devices that can operate in challenging environments and meet the diverse needs of modern applications.

Furthermore, there is a growing emphasis on developing sustainable and environmentally friendly piezoelectric materials. This includes research into lead-free alternatives to traditional PZT, addressing concerns about the environmental impact of lead-based electronics.

As the field progresses, the ultimate goal is to create intelligent, self-calibrating ultra-broadband piezoelectric sensors capable of adapting to various measurement scenarios autonomously. This vision aligns with the broader trends of Industry 4.0 and the Internet of Things, where sensors play a crucial role in creating smart, interconnected systems.

The evolution of piezoelectric sensor technology can be traced through several key milestones. Early applications were limited to simple pressure and acceleration measurements. However, as material science and manufacturing techniques advanced, the capabilities and performance of these sensors expanded dramatically. The introduction of synthetic piezoelectric materials, such as lead zirconate titanate (PZT) in the 1950s, marked a significant leap forward, offering improved sensitivity and stability compared to natural crystals.

In recent decades, the focus has shifted towards miniaturization and integration, with the development of micro-electromechanical systems (MEMS) based piezoelectric sensors. This has enabled the creation of highly compact and sensitive devices suitable for a wide range of applications, from consumer electronics to advanced scientific instrumentation.

The current technological landscape is characterized by a push towards ultra-broadband piezoelectric sensors. These sensors aim to overcome the traditional limitations of narrow frequency response, enabling the detection and measurement of signals across a much wider spectrum. This advancement is crucial for applications requiring high-fidelity sensing across diverse frequency ranges, such as structural health monitoring, acoustic emission detection, and advanced vibration analysis.

The primary objectives of research in ultra-broadband piezoelectric sensor technologies are multifaceted. Firstly, there is a drive to expand the operational frequency range of sensors, potentially covering from sub-Hz to MHz frequencies in a single device. This would enable more comprehensive data collection and analysis in complex systems.

Secondly, researchers aim to improve the sensitivity and signal-to-noise ratio across the entire frequency spectrum, ensuring accurate measurements even at the extremes of the sensor's range. This involves not only enhancing the piezoelectric materials themselves but also developing advanced signal processing and noise reduction techniques.

Another key objective is the integration of ultra-broadband capabilities with other desirable sensor characteristics, such as high temperature tolerance, miniaturization, and energy efficiency. This holistic approach to sensor design is essential for creating versatile devices that can operate in challenging environments and meet the diverse needs of modern applications.

Furthermore, there is a growing emphasis on developing sustainable and environmentally friendly piezoelectric materials. This includes research into lead-free alternatives to traditional PZT, addressing concerns about the environmental impact of lead-based electronics.

As the field progresses, the ultimate goal is to create intelligent, self-calibrating ultra-broadband piezoelectric sensors capable of adapting to various measurement scenarios autonomously. This vision aligns with the broader trends of Industry 4.0 and the Internet of Things, where sensors play a crucial role in creating smart, interconnected systems.

Ultra-broadband Sensor Market Analysis

The ultra-broadband piezoelectric sensor market has experienced significant growth in recent years, driven by increasing demand across various industries. These sensors, capable of detecting a wide range of frequencies, have found applications in sectors such as aerospace, automotive, healthcare, and industrial monitoring. The market's expansion is primarily fueled by the growing need for advanced sensing technologies in structural health monitoring, vibration analysis, and acoustic emission detection.

In the aerospace industry, ultra-broadband piezoelectric sensors play a crucial role in aircraft structural health monitoring and engine diagnostics. The automotive sector utilizes these sensors for noise, vibration, and harshness (NVH) testing, as well as in advanced driver assistance systems (ADAS). The healthcare industry has adopted ultra-broadband sensors for medical imaging and diagnostic applications, particularly in ultrasound technology.

The industrial sector represents a significant portion of the market, with applications in predictive maintenance, process control, and quality assurance. The ability of ultra-broadband piezoelectric sensors to detect subtle changes in vibration patterns has made them invaluable in identifying potential equipment failures before they occur, thereby reducing downtime and maintenance costs.

Market analysts project continued growth for the ultra-broadband piezoelectric sensor market, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is attributed to ongoing technological advancements, increasing automation in manufacturing processes, and the rising adoption of Internet of Things (IoT) technologies across industries.

Geographically, North America and Europe currently dominate the market, owing to their advanced industrial infrastructure and high adoption rates of cutting-edge technologies. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, infrastructure development, and government initiatives promoting smart manufacturing.

Key market trends include the miniaturization of sensors, improved sensitivity and accuracy, and the integration of advanced signal processing capabilities. There is also a growing demand for wireless and energy-harvesting ultra-broadband piezoelectric sensors, particularly in remote monitoring applications and IoT devices.

Challenges facing the market include the high initial costs associated with advanced sensor technologies and the complexity of data interpretation from ultra-broadband sensors. However, ongoing research and development efforts are focused on addressing these issues, with promising advancements in materials science and signal processing algorithms.

As industries continue to prioritize efficiency, safety, and predictive maintenance, the demand for ultra-broadband piezoelectric sensors is expected to rise. The market's future growth will likely be shaped by innovations in sensor design, improvements in data analytics capabilities, and the expansion of applications across emerging industries and developing economies.

In the aerospace industry, ultra-broadband piezoelectric sensors play a crucial role in aircraft structural health monitoring and engine diagnostics. The automotive sector utilizes these sensors for noise, vibration, and harshness (NVH) testing, as well as in advanced driver assistance systems (ADAS). The healthcare industry has adopted ultra-broadband sensors for medical imaging and diagnostic applications, particularly in ultrasound technology.

The industrial sector represents a significant portion of the market, with applications in predictive maintenance, process control, and quality assurance. The ability of ultra-broadband piezoelectric sensors to detect subtle changes in vibration patterns has made them invaluable in identifying potential equipment failures before they occur, thereby reducing downtime and maintenance costs.

Market analysts project continued growth for the ultra-broadband piezoelectric sensor market, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is attributed to ongoing technological advancements, increasing automation in manufacturing processes, and the rising adoption of Internet of Things (IoT) technologies across industries.

Geographically, North America and Europe currently dominate the market, owing to their advanced industrial infrastructure and high adoption rates of cutting-edge technologies. However, the Asia-Pacific region is emerging as a rapidly growing market, driven by increasing industrialization, infrastructure development, and government initiatives promoting smart manufacturing.

Key market trends include the miniaturization of sensors, improved sensitivity and accuracy, and the integration of advanced signal processing capabilities. There is also a growing demand for wireless and energy-harvesting ultra-broadband piezoelectric sensors, particularly in remote monitoring applications and IoT devices.

Challenges facing the market include the high initial costs associated with advanced sensor technologies and the complexity of data interpretation from ultra-broadband sensors. However, ongoing research and development efforts are focused on addressing these issues, with promising advancements in materials science and signal processing algorithms.

As industries continue to prioritize efficiency, safety, and predictive maintenance, the demand for ultra-broadband piezoelectric sensors is expected to rise. The market's future growth will likely be shaped by innovations in sensor design, improvements in data analytics capabilities, and the expansion of applications across emerging industries and developing economies.

Current Challenges in Ultra-broadband Piezoelectric Sensing

Ultra-broadband piezoelectric sensing technology faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is the limited frequency range of current piezoelectric materials. While traditional piezoelectric sensors excel in specific frequency bands, they struggle to maintain sensitivity and accuracy across a broad spectrum, particularly at higher frequencies.

The trade-off between sensitivity and bandwidth presents another major challenge. As researchers attempt to expand the frequency range, they often encounter a decrease in sensitivity, which can compromise the sensor's ability to detect subtle vibrations or acoustic signals. This balance between broad frequency coverage and high sensitivity remains a critical area for improvement.

Miniaturization of ultra-broadband piezoelectric sensors poses additional difficulties. As devices become smaller, maintaining performance across a wide frequency range becomes increasingly challenging. This is particularly relevant in applications such as medical imaging, where compact sensors are essential for non-invasive diagnostics.

The development of advanced signal processing techniques is crucial for ultra-broadband piezoelectric sensing. Current methods often struggle to effectively interpret and analyze the complex data generated by these sensors, especially when dealing with multiple frequency components simultaneously. Improving signal processing algorithms is vital for extracting meaningful information from the sensor output.

Environmental factors, such as temperature fluctuations and electromagnetic interference, can significantly impact the performance of ultra-broadband piezoelectric sensors. Developing robust sensors that maintain accuracy and reliability under varying conditions remains a persistent challenge in the field.

The integration of ultra-broadband piezoelectric sensors into existing systems and technologies presents both technical and practical challenges. Compatibility issues with current hardware and software infrastructures can limit the adoption of these advanced sensors in various industries.

Lastly, the cost-effectiveness of ultra-broadband piezoelectric sensors is a significant hurdle. The materials and manufacturing processes required for these advanced sensors often result in higher production costs, which can limit their widespread implementation, particularly in cost-sensitive applications.

Addressing these challenges requires interdisciplinary collaboration among materials scientists, electrical engineers, and signal processing experts. Innovations in material science, such as the development of novel piezoelectric composites or nanostructured materials, may hold the key to overcoming some of these limitations. Additionally, advancements in artificial intelligence and machine learning could potentially revolutionize signal processing techniques, enabling more effective utilization of ultra-broadband piezoelectric sensor data.

The trade-off between sensitivity and bandwidth presents another major challenge. As researchers attempt to expand the frequency range, they often encounter a decrease in sensitivity, which can compromise the sensor's ability to detect subtle vibrations or acoustic signals. This balance between broad frequency coverage and high sensitivity remains a critical area for improvement.

Miniaturization of ultra-broadband piezoelectric sensors poses additional difficulties. As devices become smaller, maintaining performance across a wide frequency range becomes increasingly challenging. This is particularly relevant in applications such as medical imaging, where compact sensors are essential for non-invasive diagnostics.

The development of advanced signal processing techniques is crucial for ultra-broadband piezoelectric sensing. Current methods often struggle to effectively interpret and analyze the complex data generated by these sensors, especially when dealing with multiple frequency components simultaneously. Improving signal processing algorithms is vital for extracting meaningful information from the sensor output.

Environmental factors, such as temperature fluctuations and electromagnetic interference, can significantly impact the performance of ultra-broadband piezoelectric sensors. Developing robust sensors that maintain accuracy and reliability under varying conditions remains a persistent challenge in the field.

The integration of ultra-broadband piezoelectric sensors into existing systems and technologies presents both technical and practical challenges. Compatibility issues with current hardware and software infrastructures can limit the adoption of these advanced sensors in various industries.

Lastly, the cost-effectiveness of ultra-broadband piezoelectric sensors is a significant hurdle. The materials and manufacturing processes required for these advanced sensors often result in higher production costs, which can limit their widespread implementation, particularly in cost-sensitive applications.

Addressing these challenges requires interdisciplinary collaboration among materials scientists, electrical engineers, and signal processing experts. Innovations in material science, such as the development of novel piezoelectric composites or nanostructured materials, may hold the key to overcoming some of these limitations. Additionally, advancements in artificial intelligence and machine learning could potentially revolutionize signal processing techniques, enabling more effective utilization of ultra-broadband piezoelectric sensor data.

State-of-the-Art Ultra-broadband Piezoelectric Solutions

01 Bandwidth enhancement techniques

Various methods are employed to enhance the bandwidth of piezoelectric sensors. These include optimizing the sensor design, using composite materials, and implementing advanced signal processing techniques. Improved bandwidth allows for better frequency response and more accurate measurements across a wider range of frequencies.- Bandwidth enhancement techniques: Various methods are employed to enhance the bandwidth of piezoelectric sensors. These include optimizing the sensor design, using composite materials, and implementing advanced signal processing techniques. Improved bandwidth allows for better frequency response and more accurate measurements across a wider range of frequencies.

- High-frequency piezoelectric sensors: Development of piezoelectric sensors capable of operating at high frequencies. These sensors utilize specialized materials and designs to achieve improved bandwidth in the high-frequency range, enabling applications in ultrasonic imaging, non-destructive testing, and high-speed data acquisition.

- Wideband piezoelectric transducers: Innovations in wideband piezoelectric transducers focus on expanding the operational frequency range. These transducers incorporate novel designs and materials to achieve a flat frequency response over a broad spectrum, making them suitable for applications requiring high sensitivity across multiple frequencies.

- Bandwidth control in piezoelectric systems: Methods for controlling and adjusting the bandwidth of piezoelectric sensor systems. This includes techniques for tuning the sensor's resonant frequency, implementing adaptive filtering, and using feedback mechanisms to optimize bandwidth based on specific application requirements.

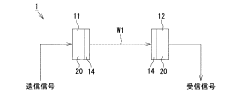

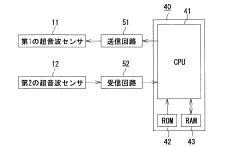

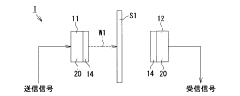

- Integration of piezoelectric sensors in communication systems: Incorporation of piezoelectric sensors with enhanced bandwidth into communication systems. These sensors are used for various purposes such as vibration detection, acoustic monitoring, and signal processing in wireless networks, benefiting from their improved frequency response characteristics.

02 High-frequency piezoelectric sensors

Development of piezoelectric sensors capable of operating at high frequencies. These sensors utilize specialized materials and designs to achieve improved bandwidth in the high-frequency range, enabling applications in ultrasonic imaging, non-destructive testing, and high-speed data acquisition.Expand Specific Solutions03 Wideband piezoelectric transducers

Innovations in wideband piezoelectric transducers focus on expanding the operational frequency range. These transducers incorporate novel structural designs and material combinations to achieve a flat frequency response over a broad spectrum, making them suitable for diverse sensing applications.Expand Specific Solutions04 Bandwidth control in piezoelectric systems

Methods for controlling and adjusting the bandwidth of piezoelectric sensor systems. This includes adaptive filtering techniques, tunable resonance circuits, and software-based bandwidth optimization algorithms to enhance sensor performance and adaptability to different measurement scenarios.Expand Specific Solutions05 Integration of piezoelectric sensors in communication systems

Incorporation of piezoelectric sensors with wide bandwidth capabilities into communication systems. These sensors are used for various purposes such as vibration detection, acoustic monitoring, and signal processing in wireless networks, contributing to improved data transmission and system performance.Expand Specific Solutions

Key Players in Piezoelectric Sensor Industry

The research on ultra-broadband piezoelectric sensor technologies is in a rapidly evolving phase, with significant market growth potential. The global market for these sensors is expanding due to increasing demand in various industries, including healthcare, automotive, and consumer electronics. The technology's maturity varies across applications, with some areas more advanced than others. Key players like BOE Technology Group, InvenSense, and DENSO Corp. are driving innovation in this field. Universities such as Chongqing University and North Carolina State University are contributing to fundamental research, while companies like Seiko Epson and FUJIFILM are focusing on practical applications. The competitive landscape is diverse, with both established electronics giants and specialized sensor manufacturers vying for market share in this promising technology sector.

InvenSense, Inc.

Technical Solution: InvenSense, Inc. has made significant strides in ultra-broadband piezoelectric sensor technologies, particularly in the field of motion sensing and acoustic applications. Their MEMS-based piezoelectric sensors utilize advanced materials and fabrication techniques to achieve high sensitivity and wide bandwidth. InvenSense's proprietary fabrication process allows for the integration of piezoelectric elements with CMOS circuitry on a single chip, enabling compact and power-efficient designs[3]. The company has developed sensors capable of detecting vibrations and acoustic signals across a broad frequency spectrum, typically ranging from sub-Hz to several kHz. These sensors incorporate innovative signal conditioning and processing techniques to maintain high signal-to-noise ratios across the entire bandwidth[4].

Strengths: Highly integrated solutions combining sensing elements with signal processing, excellent performance in motion and acoustic sensing applications. Weaknesses: May have limitations in extremely high-frequency applications beyond the audio range.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has been at the forefront of ultra-broadband piezoelectric sensor research, developing cutting-edge technologies for industrial and scientific applications. Their approach involves the use of novel piezoelectric materials and innovative sensor designs to achieve unprecedented bandwidth and sensitivity. Fraunhofer researchers have developed sensors using single-crystal piezoelectric materials that offer superior performance compared to traditional polycrystalline ceramics[7]. These sensors can operate effectively from near-DC frequencies up to several MHz, making them suitable for a wide range of applications. The institute has also pioneered the use of 3D-printed piezoelectric structures to create sensors with customized frequency responses and directional sensitivities[8]. Fraunhofer's ultra-broadband sensors incorporate advanced signal processing techniques, including adaptive filtering and machine learning algorithms, to extract meaningful data from complex vibration and acoustic environments.

Strengths: Cutting-edge research capabilities, expertise in a wide range of piezoelectric materials and fabrication techniques, and strong industry collaborations. Weaknesses: Some technologies may be at early stages of development and not yet commercially viable.

Breakthrough Innovations in Piezoelectric Materials

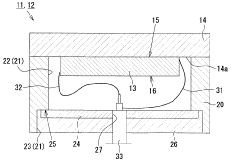

Ultrasonic sensor

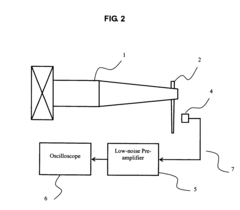

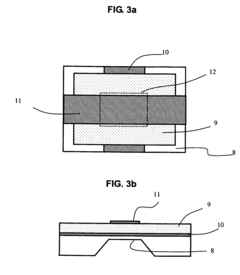

PatentActiveJP2020184714A

Innovation

- A disc-shaped piezoelectric element made of alkaline niobate ceramics with specific mechanical quality factor, frequency constant, and piezoelectric constant, combined with an acoustic matching layer having a defined thickness relative to the wavelength of ultrasonic waves, to enhance transmission/reception sensitivity and broaden the frequency band.

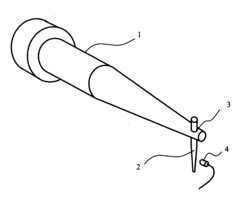

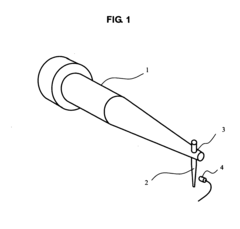

Method and apparatus for measuring oscillation amplitude of an ultrasonic device

PatentActiveUS20080006674A1

Innovation

- A piezoelectric sensor apparatus is positioned adjacent to the oscillating part of an ultrasonic vibration device, utilizing a silicon membrane and electrodes to generate electrical voltage signals proportional to the amplitude of vibrations, which are then amplified and processed using a low-noise pre-amplifier and oscilloscope for accurate measurement.

Environmental Impact of Piezoelectric Sensor Production

The production of ultra-broadband piezoelectric sensors involves various processes that can have significant environmental impacts. These impacts primarily stem from the materials used, manufacturing techniques, and waste management practices associated with sensor production.

One of the main environmental concerns is the use of lead-based materials in many piezoelectric sensors. Lead zirconate titanate (PZT) is a commonly used piezoelectric material due to its excellent performance characteristics. However, lead is a toxic heavy metal that can cause severe environmental pollution and health hazards if not properly managed. The mining, processing, and disposal of lead-containing materials can lead to soil and water contamination, affecting ecosystems and human health.

To address this issue, there is a growing trend towards developing lead-free piezoelectric materials. Alternatives such as bismuth sodium titanate (BNT) and potassium sodium niobate (KNN) are being researched and implemented. While these materials offer reduced environmental impact, their production processes may still involve energy-intensive steps and the use of other potentially harmful chemicals.

The manufacturing of piezoelectric sensors also requires the use of various chemicals and solvents, some of which may be hazardous or contribute to air and water pollution if not properly handled. Etching processes, for instance, often involve acids that need careful management and disposal. Additionally, the production of thin films and nanostructures used in advanced sensors may require specialized equipment and processes that consume significant amounts of energy.

Energy consumption is another critical environmental factor in sensor production. The high-temperature sintering processes often used in piezoelectric material synthesis can be energy-intensive, contributing to greenhouse gas emissions. Furthermore, the clean room environments required for the fabrication of high-precision sensors demand substantial energy for maintaining controlled conditions.

Waste management is a crucial aspect of mitigating the environmental impact of piezoelectric sensor production. Proper recycling and disposal of materials, especially those containing heavy metals or toxic substances, are essential to prevent environmental contamination. Some manufacturers are implementing closed-loop systems to recycle materials and reduce waste, but these practices are not yet universal in the industry.

Water usage is also a consideration, particularly in cleaning processes and chemical treatments. The semiconductor industry, which shares some similarities with piezoelectric sensor production, has made strides in reducing water consumption and improving water recycling techniques. Similar approaches could be beneficial in piezoelectric sensor manufacturing.

As the demand for ultra-broadband piezoelectric sensors grows, particularly in emerging applications such as 5G networks and Internet of Things (IoT) devices, the cumulative environmental impact of their production is likely to increase. This underscores the importance of developing more sustainable manufacturing processes and materials to mitigate long-term environmental consequences.

One of the main environmental concerns is the use of lead-based materials in many piezoelectric sensors. Lead zirconate titanate (PZT) is a commonly used piezoelectric material due to its excellent performance characteristics. However, lead is a toxic heavy metal that can cause severe environmental pollution and health hazards if not properly managed. The mining, processing, and disposal of lead-containing materials can lead to soil and water contamination, affecting ecosystems and human health.

To address this issue, there is a growing trend towards developing lead-free piezoelectric materials. Alternatives such as bismuth sodium titanate (BNT) and potassium sodium niobate (KNN) are being researched and implemented. While these materials offer reduced environmental impact, their production processes may still involve energy-intensive steps and the use of other potentially harmful chemicals.

The manufacturing of piezoelectric sensors also requires the use of various chemicals and solvents, some of which may be hazardous or contribute to air and water pollution if not properly handled. Etching processes, for instance, often involve acids that need careful management and disposal. Additionally, the production of thin films and nanostructures used in advanced sensors may require specialized equipment and processes that consume significant amounts of energy.

Energy consumption is another critical environmental factor in sensor production. The high-temperature sintering processes often used in piezoelectric material synthesis can be energy-intensive, contributing to greenhouse gas emissions. Furthermore, the clean room environments required for the fabrication of high-precision sensors demand substantial energy for maintaining controlled conditions.

Waste management is a crucial aspect of mitigating the environmental impact of piezoelectric sensor production. Proper recycling and disposal of materials, especially those containing heavy metals or toxic substances, are essential to prevent environmental contamination. Some manufacturers are implementing closed-loop systems to recycle materials and reduce waste, but these practices are not yet universal in the industry.

Water usage is also a consideration, particularly in cleaning processes and chemical treatments. The semiconductor industry, which shares some similarities with piezoelectric sensor production, has made strides in reducing water consumption and improving water recycling techniques. Similar approaches could be beneficial in piezoelectric sensor manufacturing.

As the demand for ultra-broadband piezoelectric sensors grows, particularly in emerging applications such as 5G networks and Internet of Things (IoT) devices, the cumulative environmental impact of their production is likely to increase. This underscores the importance of developing more sustainable manufacturing processes and materials to mitigate long-term environmental consequences.

Standardization Efforts for Ultra-broadband Sensors

Standardization efforts for ultra-broadband piezoelectric sensors have become increasingly important as these technologies advance and find applications across various industries. The development of common standards ensures interoperability, reliability, and consistent performance across different manufacturers and applications.

Several international organizations are actively involved in the standardization process for ultra-broadband sensors. The Institute of Electrical and Electronics Engineers (IEEE) has established working groups focused on developing standards for piezoelectric and ultrasonic transducers. These efforts aim to define common terminology, measurement methods, and performance criteria for ultra-broadband sensors.

The International Electrotechnical Commission (IEC) has also contributed significantly to the standardization of piezoelectric devices. Their standards cover various aspects of piezoelectric materials and sensors, including terminology, measurement techniques, and characterization methods. These standards provide a foundation for the development of ultra-broadband sensor technologies.

In addition to these broader standardization efforts, industry-specific organizations are working on standards tailored to their particular needs. For example, the American Society for Testing and Materials (ASTM) has developed standards for ultrasonic testing and non-destructive evaluation, which incorporate aspects of ultra-broadband sensor technology.

One of the key challenges in standardizing ultra-broadband piezoelectric sensors is the wide range of frequencies and applications they cover. Efforts are underway to develop standards that address the unique requirements of different frequency ranges, from low-frequency vibration sensing to high-frequency ultrasonic applications.

Standardization efforts also focus on establishing uniform methods for characterizing sensor performance. This includes defining parameters such as bandwidth, sensitivity, and signal-to-noise ratio, as well as specifying test procedures to ensure consistent measurements across different laboratories and manufacturers.

Another important aspect of standardization is the development of guidelines for sensor integration and signal processing. As ultra-broadband sensors become more complex and incorporate advanced signal processing techniques, standards are needed to ensure compatibility and optimal performance in various systems and applications.

Collaboration between academia, industry, and standardization bodies is crucial for the development of comprehensive and effective standards. Many research institutions and companies are actively participating in standardization committees, contributing their expertise and insights to shape the future of ultra-broadband sensor technologies.

Several international organizations are actively involved in the standardization process for ultra-broadband sensors. The Institute of Electrical and Electronics Engineers (IEEE) has established working groups focused on developing standards for piezoelectric and ultrasonic transducers. These efforts aim to define common terminology, measurement methods, and performance criteria for ultra-broadband sensors.

The International Electrotechnical Commission (IEC) has also contributed significantly to the standardization of piezoelectric devices. Their standards cover various aspects of piezoelectric materials and sensors, including terminology, measurement techniques, and characterization methods. These standards provide a foundation for the development of ultra-broadband sensor technologies.

In addition to these broader standardization efforts, industry-specific organizations are working on standards tailored to their particular needs. For example, the American Society for Testing and Materials (ASTM) has developed standards for ultrasonic testing and non-destructive evaluation, which incorporate aspects of ultra-broadband sensor technology.

One of the key challenges in standardizing ultra-broadband piezoelectric sensors is the wide range of frequencies and applications they cover. Efforts are underway to develop standards that address the unique requirements of different frequency ranges, from low-frequency vibration sensing to high-frequency ultrasonic applications.

Standardization efforts also focus on establishing uniform methods for characterizing sensor performance. This includes defining parameters such as bandwidth, sensitivity, and signal-to-noise ratio, as well as specifying test procedures to ensure consistent measurements across different laboratories and manufacturers.

Another important aspect of standardization is the development of guidelines for sensor integration and signal processing. As ultra-broadband sensors become more complex and incorporate advanced signal processing techniques, standards are needed to ensure compatibility and optimal performance in various systems and applications.

Collaboration between academia, industry, and standardization bodies is crucial for the development of comprehensive and effective standards. Many research institutions and companies are actively participating in standardization committees, contributing their expertise and insights to shape the future of ultra-broadband sensor technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!