How to Explore HEV Applications in Off-Road Vehicles?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Off-Road Evolution

The evolution of Hybrid Electric Vehicle (HEV) technology in off-road applications has been a gradual process, driven by the increasing demand for more efficient and environmentally friendly vehicles in various sectors. Initially, HEV technology was primarily focused on passenger vehicles and light-duty trucks, but its potential benefits for off-road applications have become increasingly apparent over time.

In the early 2000s, the first attempts to integrate HEV technology into off-road vehicles were made, primarily in the construction and agricultural sectors. These early prototypes demonstrated the potential for improved fuel efficiency and reduced emissions, but they were often limited by the available battery technology and the challenges of operating in harsh environments.

As battery technology advanced and became more robust, the feasibility of HEV off-road vehicles improved significantly. By the mid-2010s, several major manufacturers began introducing hybrid systems in their off-road equipment, particularly in excavators and wheel loaders. These machines utilized electric motors to assist the diesel engine during peak load periods, resulting in fuel savings and improved performance.

The mining industry has also been a key driver in the evolution of HEV off-road vehicles. Large mining trucks and excavators have been prime candidates for hybridization due to their high fuel consumption and the potential for energy recovery during braking and lowering of loads. Several major mining equipment manufacturers have developed and deployed hybrid systems in their vehicles, demonstrating significant reductions in fuel consumption and emissions.

In recent years, the focus has shifted towards more advanced hybrid systems and even fully electric off-road vehicles. The development of high-capacity lithium-ion batteries and more efficient electric motors has enabled the creation of off-road vehicles that can operate for extended periods on electric power alone. This has been particularly beneficial in applications where noise and emissions reduction are critical, such as in underground mining operations or in environmentally sensitive areas.

The evolution of HEV technology in off-road vehicles has also been influenced by advancements in power management systems and control algorithms. These sophisticated systems optimize the use of electric and combustion power sources, maximizing efficiency and performance across a wide range of operating conditions. Additionally, the integration of regenerative braking systems has further improved the energy efficiency of off-road HEVs, particularly in applications involving frequent stops and starts or downhill operations.

Looking forward, the trend towards electrification in off-road vehicles is expected to continue, with HEV technology serving as a crucial stepping stone towards fully electric solutions. As battery technology continues to improve and costs decrease, the adoption of HEV and electric off-road vehicles is likely to accelerate across various industries, driven by both environmental regulations and the economic benefits of reduced fuel consumption and maintenance costs.

In the early 2000s, the first attempts to integrate HEV technology into off-road vehicles were made, primarily in the construction and agricultural sectors. These early prototypes demonstrated the potential for improved fuel efficiency and reduced emissions, but they were often limited by the available battery technology and the challenges of operating in harsh environments.

As battery technology advanced and became more robust, the feasibility of HEV off-road vehicles improved significantly. By the mid-2010s, several major manufacturers began introducing hybrid systems in their off-road equipment, particularly in excavators and wheel loaders. These machines utilized electric motors to assist the diesel engine during peak load periods, resulting in fuel savings and improved performance.

The mining industry has also been a key driver in the evolution of HEV off-road vehicles. Large mining trucks and excavators have been prime candidates for hybridization due to their high fuel consumption and the potential for energy recovery during braking and lowering of loads. Several major mining equipment manufacturers have developed and deployed hybrid systems in their vehicles, demonstrating significant reductions in fuel consumption and emissions.

In recent years, the focus has shifted towards more advanced hybrid systems and even fully electric off-road vehicles. The development of high-capacity lithium-ion batteries and more efficient electric motors has enabled the creation of off-road vehicles that can operate for extended periods on electric power alone. This has been particularly beneficial in applications where noise and emissions reduction are critical, such as in underground mining operations or in environmentally sensitive areas.

The evolution of HEV technology in off-road vehicles has also been influenced by advancements in power management systems and control algorithms. These sophisticated systems optimize the use of electric and combustion power sources, maximizing efficiency and performance across a wide range of operating conditions. Additionally, the integration of regenerative braking systems has further improved the energy efficiency of off-road HEVs, particularly in applications involving frequent stops and starts or downhill operations.

Looking forward, the trend towards electrification in off-road vehicles is expected to continue, with HEV technology serving as a crucial stepping stone towards fully electric solutions. As battery technology continues to improve and costs decrease, the adoption of HEV and electric off-road vehicles is likely to accelerate across various industries, driven by both environmental regulations and the economic benefits of reduced fuel consumption and maintenance costs.

Market Demand Analysis

The market demand for Hybrid Electric Vehicle (HEV) applications in off-road vehicles is experiencing significant growth, driven by increasing environmental concerns and the need for improved fuel efficiency in various industries. Off-road vehicles, including construction equipment, agricultural machinery, and mining vehicles, are prime candidates for HEV technology adoption due to their high fuel consumption and emissions.

The construction industry, in particular, shows strong potential for HEV off-road vehicles. As urbanization continues to accelerate globally, the demand for construction equipment is rising. Simultaneously, there is growing pressure to reduce the environmental impact of construction activities. HEV technology offers a solution by reducing fuel consumption and emissions while maintaining the power and performance required for heavy-duty operations.

In the agricultural sector, farmers are increasingly looking for ways to reduce operating costs and improve sustainability. HEV tractors and other farm equipment can provide significant fuel savings, especially during low-load operations such as transportation or light fieldwork. The ability to use electric power for certain tasks also reduces noise pollution, which is beneficial in livestock farming and areas near residential zones.

The mining industry presents another substantial market for HEV off-road vehicles. Mining operations often occur in remote locations where fuel costs are high, making fuel efficiency a critical factor. HEV technology can offer extended operating times between refueling, reducing downtime and increasing productivity. Additionally, the reduced emissions from HEV vehicles contribute to improved air quality in underground mining operations, enhancing worker safety and potentially reducing ventilation costs.

Forestry and land management sectors also show potential for HEV off-road vehicle applications. These industries operate in environmentally sensitive areas where minimizing emissions and noise pollution is crucial. HEV technology can help meet these requirements while providing the necessary power for challenging terrain and heavy loads.

The market demand is further bolstered by increasingly stringent emissions regulations worldwide. Many countries are implementing stricter standards for off-road vehicle emissions, pushing manufacturers to adopt cleaner technologies. HEV systems offer a viable path to compliance without sacrificing performance, making them an attractive option for both manufacturers and end-users.

As battery technology continues to improve and costs decrease, the economic viability of HEV off-road vehicles is becoming more apparent. The initial higher purchase price of HEV equipment is increasingly offset by lower operating costs over the vehicle's lifetime, particularly in applications with high usage hours.

The construction industry, in particular, shows strong potential for HEV off-road vehicles. As urbanization continues to accelerate globally, the demand for construction equipment is rising. Simultaneously, there is growing pressure to reduce the environmental impact of construction activities. HEV technology offers a solution by reducing fuel consumption and emissions while maintaining the power and performance required for heavy-duty operations.

In the agricultural sector, farmers are increasingly looking for ways to reduce operating costs and improve sustainability. HEV tractors and other farm equipment can provide significant fuel savings, especially during low-load operations such as transportation or light fieldwork. The ability to use electric power for certain tasks also reduces noise pollution, which is beneficial in livestock farming and areas near residential zones.

The mining industry presents another substantial market for HEV off-road vehicles. Mining operations often occur in remote locations where fuel costs are high, making fuel efficiency a critical factor. HEV technology can offer extended operating times between refueling, reducing downtime and increasing productivity. Additionally, the reduced emissions from HEV vehicles contribute to improved air quality in underground mining operations, enhancing worker safety and potentially reducing ventilation costs.

Forestry and land management sectors also show potential for HEV off-road vehicle applications. These industries operate in environmentally sensitive areas where minimizing emissions and noise pollution is crucial. HEV technology can help meet these requirements while providing the necessary power for challenging terrain and heavy loads.

The market demand is further bolstered by increasingly stringent emissions regulations worldwide. Many countries are implementing stricter standards for off-road vehicle emissions, pushing manufacturers to adopt cleaner technologies. HEV systems offer a viable path to compliance without sacrificing performance, making them an attractive option for both manufacturers and end-users.

As battery technology continues to improve and costs decrease, the economic viability of HEV off-road vehicles is becoming more apparent. The initial higher purchase price of HEV equipment is increasingly offset by lower operating costs over the vehicle's lifetime, particularly in applications with high usage hours.

Technical Challenges

The application of Hybrid Electric Vehicle (HEV) technology in off-road vehicles presents several significant technical challenges. One of the primary obstacles is the harsh operating environment these vehicles encounter. Off-road terrains often subject vehicles to extreme conditions, including severe vibrations, impacts, and exposure to dust, water, and mud. These factors necessitate robust and well-protected electrical systems, batteries, and power electronics that can withstand such demanding environments without compromising performance or safety.

Another major challenge lies in the power and torque requirements of off-road vehicles. These machines often need to deliver high torque at low speeds, maintain consistent power output over extended periods, and handle sudden load changes. Designing an HEV powertrain that can meet these demands while also providing fuel efficiency benefits requires careful optimization of the internal combustion engine, electric motor, and power management systems.

The integration of regenerative braking systems in off-road applications poses unique difficulties. While this technology is effective in on-road vehicles, the unpredictable and often low-traction surfaces encountered off-road can limit the effectiveness of energy recovery. Engineers must develop advanced control algorithms that can adapt to varying surface conditions to maximize energy recuperation without compromising vehicle stability or performance.

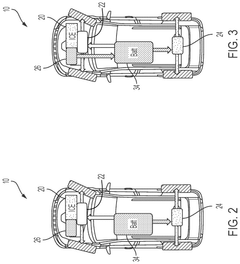

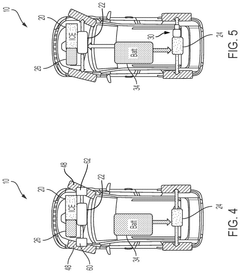

Weight distribution and packaging present additional challenges in off-road HEV design. The addition of electric components, particularly batteries, can significantly impact the vehicle's center of gravity and weight distribution. This affects not only the vehicle's off-road capabilities but also its stability and handling characteristics. Designers must find innovative ways to integrate these components without compromising the vehicle's essential off-road attributes.

Thermal management is another critical issue in off-road HEV applications. The combination of high-power demands, potentially dusty environments, and limited airflow can lead to overheating of electrical components and batteries. Developing efficient cooling systems that can operate effectively in these conditions is essential for maintaining performance and extending component life.

Lastly, the durability and longevity of HEV components in off-road applications require special consideration. The frequent exposure to shocks, vibrations, and environmental contaminants can accelerate wear and potentially lead to premature failure of sensitive electrical and electronic components. This necessitates the development of ruggedized versions of HEV technologies, including reinforced housings, enhanced sealing, and more robust electrical connections.

Another major challenge lies in the power and torque requirements of off-road vehicles. These machines often need to deliver high torque at low speeds, maintain consistent power output over extended periods, and handle sudden load changes. Designing an HEV powertrain that can meet these demands while also providing fuel efficiency benefits requires careful optimization of the internal combustion engine, electric motor, and power management systems.

The integration of regenerative braking systems in off-road applications poses unique difficulties. While this technology is effective in on-road vehicles, the unpredictable and often low-traction surfaces encountered off-road can limit the effectiveness of energy recovery. Engineers must develop advanced control algorithms that can adapt to varying surface conditions to maximize energy recuperation without compromising vehicle stability or performance.

Weight distribution and packaging present additional challenges in off-road HEV design. The addition of electric components, particularly batteries, can significantly impact the vehicle's center of gravity and weight distribution. This affects not only the vehicle's off-road capabilities but also its stability and handling characteristics. Designers must find innovative ways to integrate these components without compromising the vehicle's essential off-road attributes.

Thermal management is another critical issue in off-road HEV applications. The combination of high-power demands, potentially dusty environments, and limited airflow can lead to overheating of electrical components and batteries. Developing efficient cooling systems that can operate effectively in these conditions is essential for maintaining performance and extending component life.

Lastly, the durability and longevity of HEV components in off-road applications require special consideration. The frequent exposure to shocks, vibrations, and environmental contaminants can accelerate wear and potentially lead to premature failure of sensitive electrical and electronic components. This necessitates the development of ruggedized versions of HEV technologies, including reinforced housings, enhanced sealing, and more robust electrical connections.

Current HEV Solutions

01 Power management systems for HEVs

Advanced power management systems are crucial for optimizing the performance and efficiency of hybrid electric vehicles. These systems coordinate the operation of the internal combustion engine and electric motor, manage energy distribution, and control battery charging and discharging. They often incorporate intelligent algorithms to adapt to driving conditions and user preferences, maximizing fuel economy and reducing emissions.- Power management systems for HEVs: Advanced power management systems are crucial for optimizing the performance and efficiency of hybrid electric vehicles. These systems control the distribution of power between the electric motor and internal combustion engine, manage battery charging and discharging, and implement energy recovery strategies such as regenerative braking.

- Thermal management in HEVs: Effective thermal management is essential for maintaining optimal performance and longevity of HEV components. This includes cooling systems for batteries, power electronics, and electric motors, as well as heat recovery systems to improve overall vehicle efficiency.

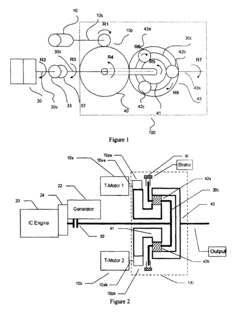

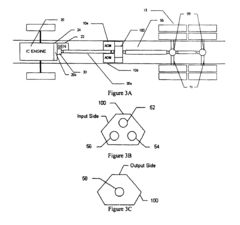

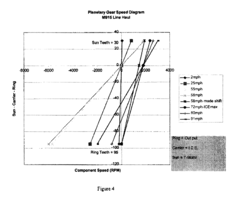

- HEV drivetrain and transmission technologies: Innovative drivetrain and transmission designs are developed to integrate electric motors with conventional powertrains efficiently. These may include power-split devices, multi-speed transmissions, or continuously variable transmissions optimized for hybrid applications.

- Battery technologies for HEVs: Advancements in battery technology are critical for improving HEV performance, range, and cost-effectiveness. This includes the development of high-energy-density batteries, fast-charging capabilities, and battery management systems to optimize performance and lifespan.

- HEV control and communication systems: Sophisticated control and communication systems are essential for coordinating the various components of an HEV. These systems manage power flow, implement driving modes, and integrate with vehicle diagnostics and infotainment systems to enhance overall vehicle performance and user experience.

02 Thermal management in HEVs

Effective thermal management is essential for maintaining optimal performance and longevity of HEV components. This includes cooling systems for batteries, power electronics, and electric motors, as well as heat recovery systems to improve overall efficiency. Advanced thermal management solutions may integrate phase-change materials, liquid cooling, or air cooling techniques to regulate temperatures across various vehicle systems.Expand Specific Solutions03 HEV battery technology advancements

Innovations in battery technology are driving improvements in HEV performance and range. This includes the development of high-energy-density batteries, fast-charging capabilities, and improved battery management systems. Advanced battery chemistries, such as lithium-ion variants and solid-state batteries, are being explored to enhance power output, energy storage, and overall vehicle efficiency.Expand Specific Solutions04 Electric drivetrain and motor innovations for HEVs

Advancements in electric drivetrains and motors are enhancing the performance and efficiency of hybrid vehicles. This includes the development of high-efficiency electric motors, improved power electronics, and integrated transmission systems. Innovations focus on reducing weight, increasing power density, and optimizing the interaction between electric and combustion power sources.Expand Specific Solutions05 HEV connectivity and intelligent systems

Integration of connectivity and intelligent systems in HEVs is enhancing vehicle performance, safety, and user experience. This includes advanced driver assistance systems, vehicle-to-grid (V2G) capabilities, and predictive energy management based on route information and traffic conditions. These technologies leverage data analytics, artificial intelligence, and cloud computing to optimize vehicle operation and energy utilization.Expand Specific Solutions

Key Off-Road HEV Players

The exploration of HEV applications in off-road vehicles is in a nascent stage, with the market showing significant growth potential. The technology is still evolving, with varying levels of maturity across different companies. Major players like Ford, GM, and Toyota are leveraging their extensive automotive experience to develop HEV solutions for off-road applications. Emerging companies such as BYD and Chery are also making strides in this field. The competitive landscape is diverse, with traditional automakers, new energy vehicle specialists, and technology firms all vying for market share. As the technology matures, we can expect increased competition and innovation in this sector.

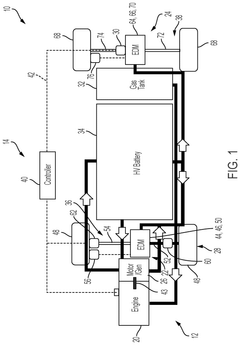

GM Global Technology Operations LLC

Technical Solution: GM's approach to HEV applications in off-road vehicles centers on their e-COPO (Electric Crate Motor) technology, adapted for rugged terrain use. The system integrates high-output electric motors with a scalable battery architecture, allowing for flexible power configurations suitable for various off-road vehicle sizes[4]. GM's HEV off-road solution incorporates advanced power electronics with intelligent thermal management, ensuring consistent performance in extreme conditions. The company has developed a unique regenerative braking system optimized for off-road use, capturing energy during descents and low-speed maneuvers[5]. Additionally, GM's HEV off-road vehicles feature an innovative torque vectoring system, enhancing traction and maneuverability on challenging terrains[6].

Strengths: Versatile e-COPO technology, advanced power electronics, and innovative off-road-specific features. Weaknesses: Relatively new to the off-road HEV market, potentially limited real-world testing compared to traditional off-road vehicles.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's approach to HEV applications in off-road vehicles leverages their HTRAC all-wheel drive technology, adapted for hybrid powertrains. Their system combines a turbocharged gasoline engine with electric motors, utilizing a sophisticated power distribution system that can send torque to individual wheels as needed[7]. Hyundai has developed a unique Active Air Flap system for their off-road HEVs, which dynamically manages aerodynamics and cooling based on driving conditions and terrain[8]. The company's HEV off-road vehicles also feature an advanced Battery Thermal Management System (BTMS) that ensures optimal battery performance in extreme temperatures and challenging terrains[9].

Strengths: Advanced HTRAC technology, innovative aerodynamic solutions, and robust battery thermal management. Weaknesses: Less established reputation in the off-road vehicle market compared to some competitors.

Core HEV Technologies

Electric vehicle powertrain

PatentPendingUS20250242683A1

Innovation

- A hybrid electric vehicle (HEV) powertrain with a front and rear electric drive module, an internal combustion engine, and a motor/generator system that provides four-wheel-drive capability, includes a front axle disconnect and an electronic locker for high efficiency and off-road modes, and a multi-speed gearbox for enhanced towing and maneuverability.

Power combining apparatus for hybrid electric vehicle

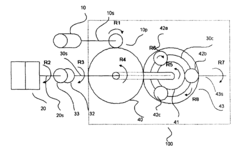

PatentInactiveUSRE41034E1

Innovation

- A vehicle transmission system utilizing a planetary gear set with a clutch and brake mechanism, enabling operation in three modes: mechanical, electrical, and combined, with a torque transmitting arrangement to synchronize power sources and optimize power transmission efficiency.

Environmental Impact

The application of Hybrid Electric Vehicle (HEV) technology in off-road vehicles presents significant potential for reducing environmental impact across various sectors. Off-road vehicles, including construction equipment, agricultural machinery, and recreational vehicles, have traditionally been associated with high fuel consumption and emissions. By integrating HEV systems, these vehicles can substantially decrease their carbon footprint and overall environmental impact.

One of the primary environmental benefits of HEV technology in off-road applications is the reduction of greenhouse gas emissions. The combination of electric motors and internal combustion engines allows for more efficient power distribution, resulting in lower fuel consumption and, consequently, reduced CO2 emissions. This is particularly important in sectors such as construction and agriculture, where heavy machinery operates for extended periods and contributes significantly to overall emissions.

HEV systems also offer the advantage of regenerative braking, which is especially beneficial in off-road environments. This technology captures energy typically lost during braking and deceleration, converting it into electrical energy to recharge the battery. In off-road applications, where frequent stops and starts are common, this feature can lead to substantial energy savings and further reduce the vehicle's environmental impact.

The reduction of noise pollution is another crucial environmental benefit of HEV technology in off-road vehicles. Electric motors operate much more quietly than traditional internal combustion engines, which is particularly advantageous in sensitive environments such as forests, wildlife habitats, or urban construction sites. This reduction in noise can help minimize disturbance to local ecosystems and improve working conditions for operators.

Furthermore, HEV technology can contribute to the preservation of natural resources by reducing the overall fuel consumption of off-road vehicles. This not only conserves fossil fuels but also decreases the environmental impact associated with fuel extraction, transportation, and storage. Additionally, the improved efficiency of HEV systems can lead to extended service intervals, reducing the frequency of oil changes and other maintenance activities that generate waste materials.

The implementation of HEV technology in off-road vehicles also has the potential to improve air quality in localized areas. By reducing emissions of particulate matter, nitrogen oxides, and other pollutants associated with diesel engines, HEV off-road vehicles can contribute to healthier working environments and reduced impact on surrounding communities. This is particularly relevant in urban construction sites or agricultural areas near populated regions.

In conclusion, the exploration of HEV applications in off-road vehicles offers a promising path towards reducing the environmental impact of these traditionally high-polluting machines. By addressing emissions, energy efficiency, noise pollution, and resource conservation, HEV technology has the potential to transform the off-road vehicle sector into a more sustainable and environmentally responsible industry.

One of the primary environmental benefits of HEV technology in off-road applications is the reduction of greenhouse gas emissions. The combination of electric motors and internal combustion engines allows for more efficient power distribution, resulting in lower fuel consumption and, consequently, reduced CO2 emissions. This is particularly important in sectors such as construction and agriculture, where heavy machinery operates for extended periods and contributes significantly to overall emissions.

HEV systems also offer the advantage of regenerative braking, which is especially beneficial in off-road environments. This technology captures energy typically lost during braking and deceleration, converting it into electrical energy to recharge the battery. In off-road applications, where frequent stops and starts are common, this feature can lead to substantial energy savings and further reduce the vehicle's environmental impact.

The reduction of noise pollution is another crucial environmental benefit of HEV technology in off-road vehicles. Electric motors operate much more quietly than traditional internal combustion engines, which is particularly advantageous in sensitive environments such as forests, wildlife habitats, or urban construction sites. This reduction in noise can help minimize disturbance to local ecosystems and improve working conditions for operators.

Furthermore, HEV technology can contribute to the preservation of natural resources by reducing the overall fuel consumption of off-road vehicles. This not only conserves fossil fuels but also decreases the environmental impact associated with fuel extraction, transportation, and storage. Additionally, the improved efficiency of HEV systems can lead to extended service intervals, reducing the frequency of oil changes and other maintenance activities that generate waste materials.

The implementation of HEV technology in off-road vehicles also has the potential to improve air quality in localized areas. By reducing emissions of particulate matter, nitrogen oxides, and other pollutants associated with diesel engines, HEV off-road vehicles can contribute to healthier working environments and reduced impact on surrounding communities. This is particularly relevant in urban construction sites or agricultural areas near populated regions.

In conclusion, the exploration of HEV applications in off-road vehicles offers a promising path towards reducing the environmental impact of these traditionally high-polluting machines. By addressing emissions, energy efficiency, noise pollution, and resource conservation, HEV technology has the potential to transform the off-road vehicle sector into a more sustainable and environmentally responsible industry.

Regulatory Landscape

The regulatory landscape for hybrid electric vehicles (HEVs) in off-road applications is complex and evolving, with varying requirements across different regions and vehicle categories. In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) play crucial roles in setting emissions standards for off-road vehicles. These agencies have been progressively tightening regulations to reduce greenhouse gas emissions and improve fuel efficiency in the off-road sector.

The European Union has also been at the forefront of implementing stringent emissions regulations for off-road vehicles through its Non-Road Mobile Machinery (NRMM) Regulation. This framework sets limits on emissions of carbon monoxide, hydrocarbons, nitrogen oxides, and particulate matter for a wide range of off-road equipment, including construction machinery, agricultural tractors, and forestry equipment.

In Asia, countries like China and Japan have been implementing their own emissions standards for off-road vehicles, often modeled after European or American regulations but adapted to local conditions. China, in particular, has been pushing for the adoption of new energy vehicles in various sectors, including off-road applications, through a combination of regulations and incentives.

One of the key challenges in the regulatory landscape is the diversity of off-road vehicle types and their operating environments. Regulators must balance the need for emissions reductions with the practical requirements of different industries, such as agriculture, construction, and mining. This has led to the development of tiered systems and phase-in periods for new regulations, allowing manufacturers and end-users time to adapt to more stringent standards.

The trend towards electrification in on-road vehicles is gradually influencing the off-road sector, with regulators beginning to consider how to incorporate hybrid and fully electric powertrains into existing frameworks. This includes developing new test cycles and measurement methods that accurately reflect the unique duty cycles of off-road vehicles.

As the technology for HEVs in off-road applications continues to advance, regulators are likely to introduce more specific guidelines and standards. This may include requirements for energy storage systems, power electronics, and overall system efficiency. Additionally, there is growing interest in lifecycle assessments of off-road vehicles, which could lead to regulations that consider not only tailpipe emissions but also the environmental impact of vehicle production and end-of-life disposal.

The European Union has also been at the forefront of implementing stringent emissions regulations for off-road vehicles through its Non-Road Mobile Machinery (NRMM) Regulation. This framework sets limits on emissions of carbon monoxide, hydrocarbons, nitrogen oxides, and particulate matter for a wide range of off-road equipment, including construction machinery, agricultural tractors, and forestry equipment.

In Asia, countries like China and Japan have been implementing their own emissions standards for off-road vehicles, often modeled after European or American regulations but adapted to local conditions. China, in particular, has been pushing for the adoption of new energy vehicles in various sectors, including off-road applications, through a combination of regulations and incentives.

One of the key challenges in the regulatory landscape is the diversity of off-road vehicle types and their operating environments. Regulators must balance the need for emissions reductions with the practical requirements of different industries, such as agriculture, construction, and mining. This has led to the development of tiered systems and phase-in periods for new regulations, allowing manufacturers and end-users time to adapt to more stringent standards.

The trend towards electrification in on-road vehicles is gradually influencing the off-road sector, with regulators beginning to consider how to incorporate hybrid and fully electric powertrains into existing frameworks. This includes developing new test cycles and measurement methods that accurately reflect the unique duty cycles of off-road vehicles.

As the technology for HEVs in off-road applications continues to advance, regulators are likely to introduce more specific guidelines and standards. This may include requirements for energy storage systems, power electronics, and overall system efficiency. Additionally, there is growing interest in lifecycle assessments of off-road vehicles, which could lead to regulations that consider not only tailpipe emissions but also the environmental impact of vehicle production and end-of-life disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!