How to Strategize HEV Technology Upgrades Efficiently?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Tech Evolution

The evolution of Hybrid Electric Vehicle (HEV) technology has been marked by significant advancements over the past few decades. Initially introduced as a means to improve fuel efficiency and reduce emissions, HEV technology has undergone several iterations, each bringing substantial improvements in performance, efficiency, and cost-effectiveness.

In the early stages of HEV development, the focus was primarily on integrating electric motors with conventional internal combustion engines. This parallel hybrid system allowed for electric-only operation at low speeds and provided power assist during acceleration. As the technology matured, more sophisticated power management systems were developed, enabling seamless transitions between electric and gasoline power sources.

A major milestone in HEV evolution was the introduction of regenerative braking systems. This innovation significantly improved energy efficiency by capturing kinetic energy during deceleration and converting it into electrical energy to recharge the battery. This breakthrough not only extended the electric-only range but also reduced wear on traditional braking components.

Battery technology has been a critical factor in HEV advancement. Early HEVs utilized nickel-metal hydride (NiMH) batteries, which were later replaced by lithium-ion batteries. These newer batteries offer higher energy density, faster charging capabilities, and longer lifespans, contributing to improved vehicle performance and reduced costs.

The progression of power electronics and control systems has also played a crucial role in HEV technology evolution. More advanced inverters and converters have enabled better power management, resulting in smoother operation and increased overall system efficiency. Additionally, the integration of sophisticated software algorithms has optimized the interplay between electric and gasoline power sources, further enhancing fuel economy and reducing emissions.

Recent developments in HEV technology have focused on increasing the electric-only range and power output of hybrid systems. This has led to the emergence of plug-in hybrid electric vehicles (PHEVs), which offer extended electric-only driving capabilities and can be recharged from external power sources. PHEVs represent a significant step towards full electrification while still providing the flexibility of conventional fuel for longer journeys.

As HEV technology continues to evolve, there is an increasing emphasis on lightweight materials and aerodynamic designs to further improve efficiency. Advanced composites and high-strength steels are being employed to reduce vehicle weight without compromising safety. Moreover, the integration of artificial intelligence and machine learning algorithms is enabling predictive energy management, adapting to driving patterns and conditions to optimize power distribution and fuel consumption.

In the early stages of HEV development, the focus was primarily on integrating electric motors with conventional internal combustion engines. This parallel hybrid system allowed for electric-only operation at low speeds and provided power assist during acceleration. As the technology matured, more sophisticated power management systems were developed, enabling seamless transitions between electric and gasoline power sources.

A major milestone in HEV evolution was the introduction of regenerative braking systems. This innovation significantly improved energy efficiency by capturing kinetic energy during deceleration and converting it into electrical energy to recharge the battery. This breakthrough not only extended the electric-only range but also reduced wear on traditional braking components.

Battery technology has been a critical factor in HEV advancement. Early HEVs utilized nickel-metal hydride (NiMH) batteries, which were later replaced by lithium-ion batteries. These newer batteries offer higher energy density, faster charging capabilities, and longer lifespans, contributing to improved vehicle performance and reduced costs.

The progression of power electronics and control systems has also played a crucial role in HEV technology evolution. More advanced inverters and converters have enabled better power management, resulting in smoother operation and increased overall system efficiency. Additionally, the integration of sophisticated software algorithms has optimized the interplay between electric and gasoline power sources, further enhancing fuel economy and reducing emissions.

Recent developments in HEV technology have focused on increasing the electric-only range and power output of hybrid systems. This has led to the emergence of plug-in hybrid electric vehicles (PHEVs), which offer extended electric-only driving capabilities and can be recharged from external power sources. PHEVs represent a significant step towards full electrification while still providing the flexibility of conventional fuel for longer journeys.

As HEV technology continues to evolve, there is an increasing emphasis on lightweight materials and aerodynamic designs to further improve efficiency. Advanced composites and high-strength steels are being employed to reduce vehicle weight without compromising safety. Moreover, the integration of artificial intelligence and machine learning algorithms is enabling predictive energy management, adapting to driving patterns and conditions to optimize power distribution and fuel consumption.

Market Demand Analysis

The market demand for Hybrid Electric Vehicle (HEV) technology upgrades has been steadily increasing, driven by several key factors. Stringent environmental regulations, rising fuel costs, and growing consumer awareness of eco-friendly transportation options have all contributed to the expanding HEV market. According to recent industry reports, the global HEV market is projected to grow at a compound annual growth rate (CAGR) of over 8% in the next five years.

Consumer preferences are shifting towards vehicles that offer improved fuel efficiency and reduced emissions without compromising on performance. This trend is particularly evident in urban areas where air quality concerns are more pronounced. HEVs are seen as a practical intermediate step between conventional internal combustion engine vehicles and fully electric vehicles, appealing to consumers who are not yet ready to transition to all-electric options.

The automotive industry is responding to this demand by investing heavily in HEV technology upgrades. Major automakers are expanding their HEV product lines and allocating significant resources to research and development in this area. The focus is on enhancing battery technology, improving power management systems, and optimizing the integration of electric and combustion powertrains.

Government incentives and policies supporting the adoption of low-emission vehicles have also played a crucial role in stimulating market demand for HEVs. Many countries offer tax rebates, subsidies, and other financial incentives to consumers purchasing hybrid vehicles, further driving market growth.

The commercial vehicle sector is emerging as a significant market for HEV technology upgrades. Fleet operators are increasingly recognizing the long-term cost benefits and reduced environmental impact of hybrid vehicles. This has led to a growing demand for HEV solutions in light commercial vehicles, buses, and even in some heavy-duty applications.

Technological advancements in HEV systems are also shaping market demand. Consumers are showing interest in features such as improved regenerative braking systems, more efficient electric motors, and advanced battery management technologies. There is a growing expectation for HEVs to offer longer electric-only driving ranges and smoother transitions between electric and combustion power modes.

The aftermarket sector presents another dimension of market demand for HEV technology upgrades. As the existing fleet of HEVs ages, there is an increasing need for replacement parts, battery upgrades, and performance enhancements. This creates opportunities for both original equipment manufacturers and third-party suppliers to develop and market upgrade solutions for older HEV models.

Consumer preferences are shifting towards vehicles that offer improved fuel efficiency and reduced emissions without compromising on performance. This trend is particularly evident in urban areas where air quality concerns are more pronounced. HEVs are seen as a practical intermediate step between conventional internal combustion engine vehicles and fully electric vehicles, appealing to consumers who are not yet ready to transition to all-electric options.

The automotive industry is responding to this demand by investing heavily in HEV technology upgrades. Major automakers are expanding their HEV product lines and allocating significant resources to research and development in this area. The focus is on enhancing battery technology, improving power management systems, and optimizing the integration of electric and combustion powertrains.

Government incentives and policies supporting the adoption of low-emission vehicles have also played a crucial role in stimulating market demand for HEVs. Many countries offer tax rebates, subsidies, and other financial incentives to consumers purchasing hybrid vehicles, further driving market growth.

The commercial vehicle sector is emerging as a significant market for HEV technology upgrades. Fleet operators are increasingly recognizing the long-term cost benefits and reduced environmental impact of hybrid vehicles. This has led to a growing demand for HEV solutions in light commercial vehicles, buses, and even in some heavy-duty applications.

Technological advancements in HEV systems are also shaping market demand. Consumers are showing interest in features such as improved regenerative braking systems, more efficient electric motors, and advanced battery management technologies. There is a growing expectation for HEVs to offer longer electric-only driving ranges and smoother transitions between electric and combustion power modes.

The aftermarket sector presents another dimension of market demand for HEV technology upgrades. As the existing fleet of HEVs ages, there is an increasing need for replacement parts, battery upgrades, and performance enhancements. This creates opportunities for both original equipment manufacturers and third-party suppliers to develop and market upgrade solutions for older HEV models.

HEV Tech Challenges

Hybrid Electric Vehicles (HEVs) face several significant technological challenges that need to be addressed for efficient upgrades and widespread adoption. One of the primary hurdles is battery technology. Current HEV batteries struggle with limited energy density, which directly impacts the vehicle's electric-only range and overall efficiency. Improving battery chemistry and management systems is crucial for extending range and reducing costs.

Power management and control systems present another major challenge. Optimizing the interplay between the electric motor and internal combustion engine requires sophisticated algorithms and real-time decision-making capabilities. Enhancing these systems can lead to better fuel economy and reduced emissions, but it demands continuous refinement and testing.

Thermal management is a critical issue in HEVs. The combination of electric and combustion components generates significant heat, which can affect performance and longevity. Developing more efficient cooling systems and heat dissipation methods is essential for maintaining optimal operating conditions and extending component life.

Weight reduction remains a persistent challenge. The addition of electric components, particularly batteries, increases the overall weight of HEVs compared to conventional vehicles. This extra weight can negatively impact fuel efficiency and performance. Innovative materials and design strategies are needed to offset this weight gain without compromising safety or functionality.

Regenerative braking systems, while beneficial, still have room for improvement. Enhancing the efficiency of energy recovery during braking and deceleration can significantly boost overall vehicle efficiency. This requires advancements in both hardware and software components of the regenerative braking system.

The integration of power electronics poses another technical hurdle. Developing more compact, efficient, and reliable power converters and inverters is crucial for improving overall system performance and reducing costs. This includes addressing issues related to electromagnetic compatibility and thermal management within these components.

Lastly, the challenge of system durability and reliability cannot be overlooked. HEVs have more complex drivetrains compared to conventional vehicles, which can lead to increased maintenance requirements and potential points of failure. Improving the longevity and reliability of hybrid systems, particularly under varied driving conditions, is essential for consumer acceptance and long-term viability of HEV technology.

Power management and control systems present another major challenge. Optimizing the interplay between the electric motor and internal combustion engine requires sophisticated algorithms and real-time decision-making capabilities. Enhancing these systems can lead to better fuel economy and reduced emissions, but it demands continuous refinement and testing.

Thermal management is a critical issue in HEVs. The combination of electric and combustion components generates significant heat, which can affect performance and longevity. Developing more efficient cooling systems and heat dissipation methods is essential for maintaining optimal operating conditions and extending component life.

Weight reduction remains a persistent challenge. The addition of electric components, particularly batteries, increases the overall weight of HEVs compared to conventional vehicles. This extra weight can negatively impact fuel efficiency and performance. Innovative materials and design strategies are needed to offset this weight gain without compromising safety or functionality.

Regenerative braking systems, while beneficial, still have room for improvement. Enhancing the efficiency of energy recovery during braking and deceleration can significantly boost overall vehicle efficiency. This requires advancements in both hardware and software components of the regenerative braking system.

The integration of power electronics poses another technical hurdle. Developing more compact, efficient, and reliable power converters and inverters is crucial for improving overall system performance and reducing costs. This includes addressing issues related to electromagnetic compatibility and thermal management within these components.

Lastly, the challenge of system durability and reliability cannot be overlooked. HEVs have more complex drivetrains compared to conventional vehicles, which can lead to increased maintenance requirements and potential points of failure. Improving the longevity and reliability of hybrid systems, particularly under varied driving conditions, is essential for consumer acceptance and long-term viability of HEV technology.

Current HEV Solutions

01 HEV light protection in cosmetics

High Energy Visible (HEV) light protection technology is being incorporated into cosmetic formulations. This involves developing ingredients and compounds that can shield the skin from the potentially harmful effects of blue light emitted by electronic devices and sunlight. These formulations aim to prevent skin damage, premature aging, and hyperpigmentation caused by HEV light exposure.- HEV light protection in cosmetics: High Energy Visible (HEV) light protection technology is being incorporated into cosmetic formulations. This involves developing ingredients and compounds that can shield the skin from the potentially harmful effects of blue light emitted by electronic devices and sunlight. These formulations aim to prevent skin damage, premature aging, and hyperpigmentation caused by HEV light exposure.

- HEV-blocking materials in automotive applications: HEV technology is being applied in the automotive industry to develop materials that can block or filter high-energy visible light. This includes the creation of specialized windshields, windows, and other automotive components that can reduce glare and protect vehicle occupants from harmful light exposure while maintaining visibility and safety standards.

- HEV-related display technologies: Advancements in display technologies are focusing on managing HEV light emissions from screens. This involves developing display panels and protective films that can reduce blue light emission while maintaining color accuracy and visual quality. These technologies aim to minimize eye strain and potential health risks associated with prolonged exposure to HEV light from electronic devices.

- HEV light in biotechnology applications: HEV technology is being utilized in biotechnology for various applications, including the development of high-efficiency photobioreactors for algae cultivation, light-based therapies, and advanced imaging techniques. These applications leverage the specific wavelengths of HEV light to enhance biological processes or improve diagnostic and therapeutic outcomes.

- HEV-efficient lighting systems: Research is focused on developing lighting systems that optimize the use of HEV light for various applications. This includes creating energy-efficient LED lighting with controlled HEV output for indoor plant cultivation, aquaculture, and specialized industrial processes. These systems aim to balance the benefits of HEV light while minimizing potential negative effects on human health and the environment.

02 HEV-blocking materials in automotive applications

HEV technology is being applied in the automotive industry to develop materials that can block or filter high-energy visible light. This includes the creation of specialized windshields, windows, and coatings that can reduce glare and protect vehicle occupants from harmful light exposure while maintaining visibility and safety standards.Expand Specific Solutions03 HEV-related display technologies

Advancements in display technologies are focusing on managing HEV light emissions from screens. This involves developing new display materials, filters, and software solutions that can reduce blue light output from electronic devices such as smartphones, tablets, and computers, aiming to minimize eye strain and potential health impacts associated with prolonged screen use.Expand Specific Solutions04 HEV light in biotechnology applications

HEV technology is being utilized in biotechnology for various applications. This includes using high-energy visible light in cell culture systems, photobioreactors, and other bioprocessing applications. The technology is being explored for its potential to enhance growth rates, metabolic activities, or specific cellular processes in microorganisms and cell cultures.Expand Specific Solutions05 HEV-efficient lighting systems

Development of lighting systems that efficiently utilize or manage high-energy visible light. This includes creating LED lighting solutions that can provide optimal illumination while minimizing harmful effects of blue light exposure. The technology aims to balance energy efficiency, light quality, and health considerations in both indoor and outdoor lighting applications.Expand Specific Solutions

Key HEV Players

The HEV technology upgrade landscape is characterized by intense competition and rapid innovation. The market is in a growth phase, with increasing demand for more efficient and environmentally friendly vehicles driving substantial investments. The global HEV market size is projected to expand significantly in the coming years, reflecting growing consumer interest and stringent emissions regulations. Technologically, HEV systems are relatively mature, but continuous advancements are being made in areas such as battery efficiency, power management, and integration with other vehicle systems. Key players like Toyota, Ford, GM, and Geely are leading the charge, with significant contributions from academic institutions such as Beijing Institute of Technology and University of Michigan, indicating a strong industry-academia collaboration in driving HEV innovation.

Ford Global Technologies LLC

Technical Solution: Ford's strategy for HEV technology upgrades centers on their PowerSplit hybrid architecture, which allows for multiple hybrid modes to optimize efficiency. They are developing more advanced power electronics and motor designs to improve overall system efficiency. Ford is also investing in next-generation battery technology, including the exploration of solid-state batteries for future HEVs[4]. The company is focusing on integrating their hybrid systems with advanced driver assistance features and connectivity to enhance the overall driving experience. Additionally, Ford is working on improving regenerative braking systems to capture more energy during deceleration[5].

Strengths: Strong focus on power electronics and motor design, integration of hybrid technology with other advanced features. Weaknesses: Relatively late entry into the HEV market compared to some competitors, potential challenges in scaling up production.

Zhejiang Geely Holding Group Co., Ltd.

Technical Solution: Geely's strategy for HEV technology upgrades focuses on their proprietary hybrid system called DHE (Dedicated Hybrid Engine). This system is designed to optimize fuel efficiency and reduce emissions in their hybrid vehicles. Geely is investing in the development of more efficient electric motors and power electronics to improve overall system performance. They are also working on integrating their hybrid technology with advanced connectivity features and over-the-air update capabilities[8]. Geely's approach includes the development of a modular hybrid architecture that can be easily adapted to different vehicle platforms, allowing for faster implementation across their product range[9].

Strengths: Proprietary hybrid system, focus on modular architecture for scalability. Weaknesses: Relatively new player in the global HEV market, potential challenges in competing with more established hybrid technologies.

Core HEV Innovations

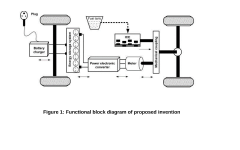

Hybrid electric vehicle with electric motor providing strategic power assist to load balance internal combustion engine

PatentPendingIN202441000035A

Innovation

- A Hybrid Electric Vehicle (HEV) system with an electric motor providing strategic power assist to the internal combustion engine, optimizing power distribution and energy management through advanced control algorithms.

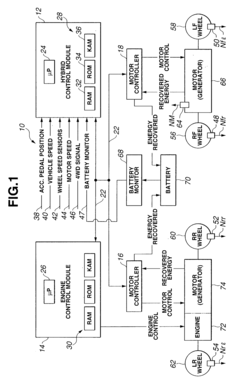

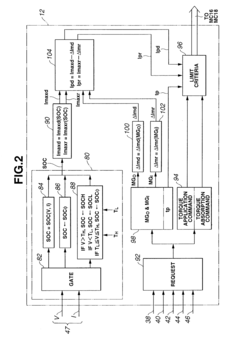

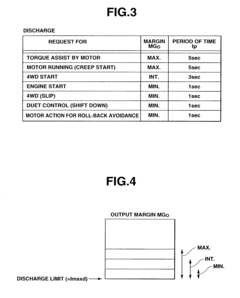

Hybrid electric vehicle with enhanced battery control

PatentInactiveUS7173396B2

Innovation

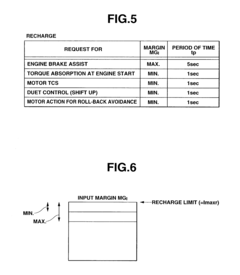

- A system that determines discharge and recharge allowances and time limits based on different operating conditions of the hybrid electric vehicle, using a hybrid control module and engine control module to regulate the battery's operation through microprocessors and sensors, allowing for dynamic adjustment of discharge and recharge currents.

HEV Regulatory Landscape

The regulatory landscape for Hybrid Electric Vehicles (HEVs) is a complex and dynamic environment that significantly influences the strategic planning for technology upgrades. Governments worldwide are implementing increasingly stringent emissions standards and fuel economy regulations, driving the automotive industry towards more efficient and environmentally friendly technologies.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) play a crucial role in shaping HEV development. These standards require automakers to achieve specific fleet-wide average fuel economy targets, which are progressively becoming more demanding. This regulatory pressure incentivizes manufacturers to invest in HEV technology upgrades to meet these requirements.

The European Union has implemented its own set of regulations, including the CO2 emissions standards for new passenger cars and light commercial vehicles. These standards are among the most stringent globally, pushing automakers to rapidly adopt and improve HEV technologies. The EU's commitment to reducing greenhouse gas emissions has led to the introduction of various incentives and penalties, further accelerating the transition towards electrified vehicles.

China, as the world's largest automotive market, has also established a comprehensive regulatory framework to promote new energy vehicles, including HEVs. The country's dual-credit policy, which includes both fuel consumption and new energy vehicle credits, has been a significant driver for HEV technology advancements. Manufacturers are required to meet specific targets for fuel efficiency and electric vehicle production, creating a strong impetus for continuous improvement in HEV systems.

Japan, a pioneer in HEV technology, maintains its leadership through a combination of regulatory measures and industry initiatives. The country's Top Runner Program sets efficiency standards based on the most efficient models in each vehicle class, encouraging ongoing innovation in HEV technology.

Global efforts to combat climate change, such as the Paris Agreement, have further influenced national and regional policies related to vehicle emissions. This has led to the introduction of various incentives, including tax breaks, subsidies, and preferential treatment for low-emission vehicles in many countries.

The regulatory landscape also extends to specific components of HEV technology. For instance, battery regulations concerning safety, recycling, and disposal are becoming increasingly important. As HEV technology evolves, regulators are working to keep pace with new developments, addressing issues such as electromagnetic compatibility, cybersecurity, and autonomous driving features that may be integrated into future HEV models.

Understanding this complex regulatory environment is crucial for efficiently strategizing HEV technology upgrades. Manufacturers must not only comply with current regulations but also anticipate future changes to ensure their investments in technology development align with long-term regulatory trends. This proactive approach allows companies to gain a competitive edge and avoid costly retrofitting or redesigns to meet unexpected regulatory requirements.

In the United States, the Corporate Average Fuel Economy (CAFE) standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) play a crucial role in shaping HEV development. These standards require automakers to achieve specific fleet-wide average fuel economy targets, which are progressively becoming more demanding. This regulatory pressure incentivizes manufacturers to invest in HEV technology upgrades to meet these requirements.

The European Union has implemented its own set of regulations, including the CO2 emissions standards for new passenger cars and light commercial vehicles. These standards are among the most stringent globally, pushing automakers to rapidly adopt and improve HEV technologies. The EU's commitment to reducing greenhouse gas emissions has led to the introduction of various incentives and penalties, further accelerating the transition towards electrified vehicles.

China, as the world's largest automotive market, has also established a comprehensive regulatory framework to promote new energy vehicles, including HEVs. The country's dual-credit policy, which includes both fuel consumption and new energy vehicle credits, has been a significant driver for HEV technology advancements. Manufacturers are required to meet specific targets for fuel efficiency and electric vehicle production, creating a strong impetus for continuous improvement in HEV systems.

Japan, a pioneer in HEV technology, maintains its leadership through a combination of regulatory measures and industry initiatives. The country's Top Runner Program sets efficiency standards based on the most efficient models in each vehicle class, encouraging ongoing innovation in HEV technology.

Global efforts to combat climate change, such as the Paris Agreement, have further influenced national and regional policies related to vehicle emissions. This has led to the introduction of various incentives, including tax breaks, subsidies, and preferential treatment for low-emission vehicles in many countries.

The regulatory landscape also extends to specific components of HEV technology. For instance, battery regulations concerning safety, recycling, and disposal are becoming increasingly important. As HEV technology evolves, regulators are working to keep pace with new developments, addressing issues such as electromagnetic compatibility, cybersecurity, and autonomous driving features that may be integrated into future HEV models.

Understanding this complex regulatory environment is crucial for efficiently strategizing HEV technology upgrades. Manufacturers must not only comply with current regulations but also anticipate future changes to ensure their investments in technology development align with long-term regulatory trends. This proactive approach allows companies to gain a competitive edge and avoid costly retrofitting or redesigns to meet unexpected regulatory requirements.

HEV Supply Chain

The HEV (Hybrid Electric Vehicle) supply chain plays a crucial role in the efficient upgrading of HEV technology. As the automotive industry continues to shift towards electrification, the supply chain must adapt to meet the evolving demands of HEV manufacturers and consumers.

One of the key aspects of the HEV supply chain is the sourcing and production of critical components, such as batteries, electric motors, and power electronics. These components are essential for the performance and efficiency of HEVs, and their availability and quality directly impact the ability to upgrade HEV technology. Manufacturers must establish strong relationships with suppliers who can consistently deliver high-quality components and keep pace with technological advancements.

The supply chain for HEVs also involves the integration of traditional automotive components with advanced electric and hybrid systems. This requires close collaboration between suppliers of conventional vehicle parts and those specializing in electric vehicle technologies. Efficient coordination among these diverse suppliers is essential for streamlining the production process and ensuring seamless integration of new technologies into existing vehicle platforms.

Logistics and distribution networks are another critical element of the HEV supply chain. As HEV technology evolves, the supply chain must be flexible enough to accommodate changes in component specifications, production volumes, and market demands. This flexibility allows manufacturers to quickly implement technology upgrades and respond to shifts in consumer preferences or regulatory requirements.

The global nature of the HEV supply chain presents both opportunities and challenges for technology upgrades. While it provides access to a wide range of suppliers and technologies, it also introduces complexities in terms of trade regulations, transportation, and quality control. Manufacturers must carefully manage these global supply chain relationships to ensure consistent quality and timely delivery of components necessary for technology upgrades.

Sustainability considerations are becoming increasingly important in the HEV supply chain. As HEV technology advances, there is a growing focus on reducing the environmental impact of component production and vehicle manufacturing. This includes sourcing materials responsibly, implementing energy-efficient production processes, and developing recycling and reuse strategies for end-of-life components, particularly batteries.

To strategize HEV technology upgrades efficiently, manufacturers must closely monitor and anticipate changes in the supply chain. This involves staying informed about emerging technologies, supplier capabilities, and market trends. By maintaining a robust and adaptable supply chain, manufacturers can more readily implement technology upgrades, improve vehicle performance, and meet evolving consumer and regulatory demands.

One of the key aspects of the HEV supply chain is the sourcing and production of critical components, such as batteries, electric motors, and power electronics. These components are essential for the performance and efficiency of HEVs, and their availability and quality directly impact the ability to upgrade HEV technology. Manufacturers must establish strong relationships with suppliers who can consistently deliver high-quality components and keep pace with technological advancements.

The supply chain for HEVs also involves the integration of traditional automotive components with advanced electric and hybrid systems. This requires close collaboration between suppliers of conventional vehicle parts and those specializing in electric vehicle technologies. Efficient coordination among these diverse suppliers is essential for streamlining the production process and ensuring seamless integration of new technologies into existing vehicle platforms.

Logistics and distribution networks are another critical element of the HEV supply chain. As HEV technology evolves, the supply chain must be flexible enough to accommodate changes in component specifications, production volumes, and market demands. This flexibility allows manufacturers to quickly implement technology upgrades and respond to shifts in consumer preferences or regulatory requirements.

The global nature of the HEV supply chain presents both opportunities and challenges for technology upgrades. While it provides access to a wide range of suppliers and technologies, it also introduces complexities in terms of trade regulations, transportation, and quality control. Manufacturers must carefully manage these global supply chain relationships to ensure consistent quality and timely delivery of components necessary for technology upgrades.

Sustainability considerations are becoming increasingly important in the HEV supply chain. As HEV technology advances, there is a growing focus on reducing the environmental impact of component production and vehicle manufacturing. This includes sourcing materials responsibly, implementing energy-efficient production processes, and developing recycling and reuse strategies for end-of-life components, particularly batteries.

To strategize HEV technology upgrades efficiently, manufacturers must closely monitor and anticipate changes in the supply chain. This involves staying informed about emerging technologies, supplier capabilities, and market trends. By maintaining a robust and adaptable supply chain, manufacturers can more readily implement technology upgrades, improve vehicle performance, and meet evolving consumer and regulatory demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!