How to Handle Nichrome Elements in Industrial Processes?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Elements: Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in industrial processes for over a century. Its unique properties, including high electrical resistance and exceptional heat resistance, have made it indispensable in various applications across multiple industries. The evolution of nichrome elements in industrial processes has been driven by the increasing demands for efficiency, durability, and precision in manufacturing and production environments.

The primary objective of handling nichrome elements in industrial processes is to maximize their potential while addressing the challenges associated with their use. This involves optimizing their performance in high-temperature applications, enhancing their longevity, and ensuring their safe and efficient integration into various industrial systems. As industries continue to push the boundaries of what is possible in terms of heat generation and control, the role of nichrome elements becomes increasingly critical.

Historically, nichrome has undergone several iterations of development since its initial patenting in 1905. Early applications were primarily focused on electrical heating elements, but as industries evolved, so did the applications of nichrome. Today, it finds use in aerospace, automotive, chemical processing, and electronics manufacturing, among others. The technological trajectory of nichrome elements has been marked by continuous improvements in composition, manufacturing techniques, and application methodologies.

Current trends in nichrome element technology are focused on enhancing its already impressive properties. Research and development efforts are directed towards improving its resistance to oxidation at extreme temperatures, increasing its electrical efficiency, and developing new alloy compositions that can withstand even more demanding industrial environments. Additionally, there is a growing emphasis on developing nichrome elements that are more environmentally friendly and energy-efficient, aligning with global sustainability goals.

The challenges in handling nichrome elements primarily stem from their high operating temperatures and the potential for material degradation over time. Industrial processes must account for thermal expansion, potential chemical reactions at high temperatures, and the need for precise temperature control. Moreover, the integration of nichrome elements into complex industrial systems requires careful consideration of factors such as electrical insulation, heat distribution, and safety protocols.

As we look towards the future, the objectives for handling nichrome elements in industrial processes are multifaceted. They include developing more sophisticated control systems for precise temperature management, creating more durable nichrome alloys that can withstand even more extreme conditions, and innovating in the design of heating elements to improve energy efficiency and reduce environmental impact. The pursuit of these objectives will likely drive significant advancements in industrial heating technologies and processes across various sectors.

The primary objective of handling nichrome elements in industrial processes is to maximize their potential while addressing the challenges associated with their use. This involves optimizing their performance in high-temperature applications, enhancing their longevity, and ensuring their safe and efficient integration into various industrial systems. As industries continue to push the boundaries of what is possible in terms of heat generation and control, the role of nichrome elements becomes increasingly critical.

Historically, nichrome has undergone several iterations of development since its initial patenting in 1905. Early applications were primarily focused on electrical heating elements, but as industries evolved, so did the applications of nichrome. Today, it finds use in aerospace, automotive, chemical processing, and electronics manufacturing, among others. The technological trajectory of nichrome elements has been marked by continuous improvements in composition, manufacturing techniques, and application methodologies.

Current trends in nichrome element technology are focused on enhancing its already impressive properties. Research and development efforts are directed towards improving its resistance to oxidation at extreme temperatures, increasing its electrical efficiency, and developing new alloy compositions that can withstand even more demanding industrial environments. Additionally, there is a growing emphasis on developing nichrome elements that are more environmentally friendly and energy-efficient, aligning with global sustainability goals.

The challenges in handling nichrome elements primarily stem from their high operating temperatures and the potential for material degradation over time. Industrial processes must account for thermal expansion, potential chemical reactions at high temperatures, and the need for precise temperature control. Moreover, the integration of nichrome elements into complex industrial systems requires careful consideration of factors such as electrical insulation, heat distribution, and safety protocols.

As we look towards the future, the objectives for handling nichrome elements in industrial processes are multifaceted. They include developing more sophisticated control systems for precise temperature management, creating more durable nichrome alloys that can withstand even more extreme conditions, and innovating in the design of heating elements to improve energy efficiency and reduce environmental impact. The pursuit of these objectives will likely drive significant advancements in industrial heating technologies and processes across various sectors.

Industrial Demand Analysis

The industrial demand for nichrome elements has been steadily increasing due to their unique properties and versatile applications across various sectors. Nichrome, an alloy primarily composed of nickel and chromium, exhibits excellent resistance to high temperatures and corrosion, making it indispensable in numerous industrial processes.

In the heating and electrical industry, nichrome elements are extensively used in the production of heating coils, resistors, and electric furnaces. The growing demand for energy-efficient heating systems in both residential and commercial sectors has significantly boosted the market for nichrome-based heating elements. Additionally, the automotive industry relies heavily on nichrome for manufacturing spark plugs, glow plugs, and exhaust gas temperature sensors, contributing to the overall market growth.

The aerospace and defense sectors have also shown a substantial increase in demand for nichrome elements. These industries require materials that can withstand extreme temperatures and harsh environments, making nichrome an ideal choice for components in jet engines, rocket nozzles, and other high-temperature applications.

In the chemical processing industry, nichrome's corrosion-resistant properties make it valuable for manufacturing reaction vessels, heat exchangers, and other equipment exposed to corrosive substances. As the chemical industry continues to expand, particularly in emerging economies, the demand for nichrome elements is expected to rise accordingly.

The food processing industry has also witnessed an uptick in nichrome usage, particularly in the production of industrial ovens, food packaging equipment, and sterilization systems. The increasing focus on food safety and hygiene standards has further propelled the demand for nichrome-based equipment in this sector.

Market analysis indicates that the global nichrome market is projected to grow at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is primarily driven by the expanding industrial base in developing countries, technological advancements in manufacturing processes, and the increasing adoption of nichrome in new applications.

However, the industry faces challenges in terms of raw material price volatility and environmental concerns associated with nickel mining. These factors may impact the overall demand and pricing of nichrome elements in the coming years. Despite these challenges, the unique properties of nichrome and its wide range of applications ensure a sustained industrial demand for the foreseeable future.

In the heating and electrical industry, nichrome elements are extensively used in the production of heating coils, resistors, and electric furnaces. The growing demand for energy-efficient heating systems in both residential and commercial sectors has significantly boosted the market for nichrome-based heating elements. Additionally, the automotive industry relies heavily on nichrome for manufacturing spark plugs, glow plugs, and exhaust gas temperature sensors, contributing to the overall market growth.

The aerospace and defense sectors have also shown a substantial increase in demand for nichrome elements. These industries require materials that can withstand extreme temperatures and harsh environments, making nichrome an ideal choice for components in jet engines, rocket nozzles, and other high-temperature applications.

In the chemical processing industry, nichrome's corrosion-resistant properties make it valuable for manufacturing reaction vessels, heat exchangers, and other equipment exposed to corrosive substances. As the chemical industry continues to expand, particularly in emerging economies, the demand for nichrome elements is expected to rise accordingly.

The food processing industry has also witnessed an uptick in nichrome usage, particularly in the production of industrial ovens, food packaging equipment, and sterilization systems. The increasing focus on food safety and hygiene standards has further propelled the demand for nichrome-based equipment in this sector.

Market analysis indicates that the global nichrome market is projected to grow at a compound annual growth rate (CAGR) of around 5% over the next five years. This growth is primarily driven by the expanding industrial base in developing countries, technological advancements in manufacturing processes, and the increasing adoption of nichrome in new applications.

However, the industry faces challenges in terms of raw material price volatility and environmental concerns associated with nickel mining. These factors may impact the overall demand and pricing of nichrome elements in the coming years. Despite these challenges, the unique properties of nichrome and its wide range of applications ensure a sustained industrial demand for the foreseeable future.

Nichrome Handling Challenges

Nichrome, an alloy primarily composed of nickel and chromium, presents significant challenges in industrial processes due to its unique properties. The high melting point and excellent resistance to oxidation and corrosion make nichrome a valuable material in various applications, but these same characteristics also create difficulties in handling and processing.

One of the primary challenges in handling nichrome elements is their high electrical resistance. This property, while beneficial in heating applications, can lead to unexpected voltage drops and heat generation in electrical systems. Engineers must carefully consider these factors when designing circuits or equipment that incorporate nichrome components to prevent overheating or electrical inefficiencies.

The material's high melting point, typically around 1400°C (2552°F), poses challenges in manufacturing and shaping processes. Traditional metalworking techniques may be insufficient, requiring specialized high-temperature equipment and processes. This can significantly increase production costs and complexity, particularly for small-scale or custom applications.

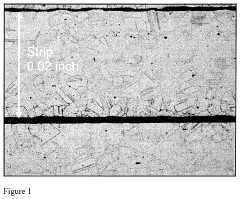

Nichrome's resistance to oxidation, while advantageous in many scenarios, can complicate joining processes such as welding or soldering. The protective oxide layer that forms on the surface can interfere with the formation of strong bonds, necessitating specialized techniques or surface treatments to ensure reliable connections.

The alloy's low thermal expansion coefficient, compared to many other metals, can lead to stress and potential failure when nichrome elements are integrated with materials that have different thermal expansion rates. This mismatch must be carefully managed in designs that involve temperature fluctuations or thermal cycling.

Machining nichrome can be challenging due to its work-hardening properties. As the material is worked, it becomes increasingly harder and more brittle, potentially leading to tool wear and reduced surface quality. This necessitates careful selection of cutting tools, speeds, and coolants to achieve desired results.

The high cost of nickel, a primary component of nichrome, can make large-scale use economically prohibitive for some applications. This economic factor often requires engineers to balance the superior performance of nichrome against more cost-effective alternatives, particularly in price-sensitive industries.

Handling nichrome in powder form, such as in additive manufacturing or powder metallurgy processes, presents additional challenges. The fine particles can be reactive and potentially pose health and safety risks if not properly managed, requiring stringent safety protocols and specialized equipment.

In conclusion, while nichrome offers exceptional properties for many industrial applications, its handling and processing present a unique set of challenges. Addressing these issues requires a combination of specialized equipment, advanced techniques, and careful engineering considerations to fully leverage the material's benefits while mitigating its inherent difficulties.

One of the primary challenges in handling nichrome elements is their high electrical resistance. This property, while beneficial in heating applications, can lead to unexpected voltage drops and heat generation in electrical systems. Engineers must carefully consider these factors when designing circuits or equipment that incorporate nichrome components to prevent overheating or electrical inefficiencies.

The material's high melting point, typically around 1400°C (2552°F), poses challenges in manufacturing and shaping processes. Traditional metalworking techniques may be insufficient, requiring specialized high-temperature equipment and processes. This can significantly increase production costs and complexity, particularly for small-scale or custom applications.

Nichrome's resistance to oxidation, while advantageous in many scenarios, can complicate joining processes such as welding or soldering. The protective oxide layer that forms on the surface can interfere with the formation of strong bonds, necessitating specialized techniques or surface treatments to ensure reliable connections.

The alloy's low thermal expansion coefficient, compared to many other metals, can lead to stress and potential failure when nichrome elements are integrated with materials that have different thermal expansion rates. This mismatch must be carefully managed in designs that involve temperature fluctuations or thermal cycling.

Machining nichrome can be challenging due to its work-hardening properties. As the material is worked, it becomes increasingly harder and more brittle, potentially leading to tool wear and reduced surface quality. This necessitates careful selection of cutting tools, speeds, and coolants to achieve desired results.

The high cost of nickel, a primary component of nichrome, can make large-scale use economically prohibitive for some applications. This economic factor often requires engineers to balance the superior performance of nichrome against more cost-effective alternatives, particularly in price-sensitive industries.

Handling nichrome in powder form, such as in additive manufacturing or powder metallurgy processes, presents additional challenges. The fine particles can be reactive and potentially pose health and safety risks if not properly managed, requiring stringent safety protocols and specialized equipment.

In conclusion, while nichrome offers exceptional properties for many industrial applications, its handling and processing present a unique set of challenges. Addressing these issues requires a combination of specialized equipment, advanced techniques, and careful engineering considerations to fully leverage the material's benefits while mitigating its inherent difficulties.

Current Nichrome Handling Solutions

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, known for its high electrical resistance and heat resistance. It is widely used in heating elements due to its ability to withstand high temperatures without oxidizing or deforming. The specific composition can be adjusted to optimize properties for different applications.- Composition and properties of nichrome elements: Nichrome elements are typically composed of nickel and chromium alloys. They are known for their high electrical resistance and ability to withstand high temperatures, making them suitable for use in heating applications. The specific composition and properties of nichrome elements can be tailored to meet various requirements in different industries.

- Applications in heating devices: Nichrome elements are widely used in various heating devices due to their excellent heat-generating properties. They can be found in electric heaters, ovens, toasters, and other appliances that require reliable and efficient heating elements. The design and configuration of nichrome elements can be optimized for specific heating applications.

- Manufacturing processes for nichrome elements: The production of nichrome elements involves specific manufacturing processes to ensure their quality and performance. These processes may include alloy preparation, wire drawing, coiling, and heat treatment. Advanced manufacturing techniques can be employed to enhance the properties and durability of nichrome elements.

- Nichrome elements in electronic components: Nichrome elements find applications in various electronic components, particularly in resistors and sensors. Their stable electrical properties and temperature resistance make them suitable for use in precision electronic devices. The integration of nichrome elements in electronic circuits can contribute to improved performance and reliability.

- Innovations in nichrome element design: Ongoing research and development efforts focus on improving the design and performance of nichrome elements. This includes exploring new alloy compositions, optimizing element geometries, and developing novel manufacturing techniques. These innovations aim to enhance the efficiency, longevity, and versatility of nichrome elements in various applications.

02 Manufacturing processes for nichrome elements

Various manufacturing techniques are employed to produce nichrome elements, including wire drawing, ribbon forming, and powder metallurgy. These processes aim to create uniform, high-quality elements with consistent electrical and mechanical properties. Heat treatment and surface finishing may be applied to enhance performance and durability.Expand Specific Solutions03 Applications of nichrome elements in heating devices

Nichrome elements are extensively used in electric heating appliances such as toasters, hair dryers, and industrial furnaces. Their high resistance and ability to generate heat efficiently make them ideal for these applications. Design considerations include element shape, winding pattern, and insulation to optimize heat distribution and energy efficiency.Expand Specific Solutions04 Nichrome elements in sensor and measurement technologies

Nichrome is utilized in various sensing and measurement devices due to its stable electrical properties and temperature coefficient of resistance. Applications include temperature sensors, strain gauges, and flow meters. The elements are often incorporated into precision instruments for accurate and reliable measurements in diverse industrial and scientific fields.Expand Specific Solutions05 Innovations in nichrome element design and coatings

Recent advancements focus on improving the performance and longevity of nichrome elements through innovative designs and protective coatings. These developments aim to enhance oxidation resistance, reduce power consumption, and extend the operational life of the elements. New manufacturing techniques and material combinations are being explored to create more efficient and durable nichrome-based components.Expand Specific Solutions

Key Industry Players

The handling of nichrome elements in industrial processes is a mature technology, yet the market continues to evolve. The industry is in a growth phase, driven by increasing demand in various sectors such as electronics, aerospace, and energy. The global market size for nichrome-related products is expanding, with key players like BASF Corp., Henkel AG & Co. KGaA, and Tata Steel Ltd. leading innovation. These companies are investing in research and development to improve nichrome handling techniques, focusing on efficiency and sustainability. Emerging players such as GEM Co., Ltd. and Guangdong Bangpu Recycling Technology Co., Ltd. are introducing novel recycling methods, indicating a shift towards circular economy practices in the industry.

BASF Corp.

Technical Solution: BASF has developed advanced catalytic processes for handling nichrome elements in industrial applications. Their approach involves using proprietary catalysts to facilitate the controlled oxidation and reduction of nichrome alloys. This process allows for precise manipulation of the material's properties, enabling tailored solutions for various industrial needs. BASF's method includes a multi-stage treatment process that can adjust the nichrome's composition and microstructure, resulting in improved corrosion resistance and mechanical properties[1]. The company has also implemented sophisticated monitoring systems to ensure optimal process control and product quality throughout the handling of nichrome elements[3].

Strengths: Highly customizable process, improved material properties, and precise control. Weaknesses: Potentially high implementation costs and specialized equipment requirements.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute has pioneered a novel approach to handling nichrome elements using advanced electrochemical techniques. Their method involves a combination of selective leaching and electrowinning processes to efficiently extract and purify nichrome components from industrial waste streams. This innovative process achieves high recovery rates of up to 98% for nickel and chromium[2]. The institute has also developed a unique membrane separation technology that allows for the selective removal of impurities during the handling process, resulting in ultra-high purity nichrome products[5]. Additionally, they have implemented machine learning algorithms to optimize process parameters in real-time, significantly improving efficiency and reducing energy consumption[7].

Strengths: High recovery rates, production of ultra-high purity materials, and energy-efficient processes. Weaknesses: Potential scalability issues for large-scale industrial applications.

Innovative Nichrome Processing Techniques

Nickel-chromium alloy and method of making the same

PatentPendingUS20210402524A1

Innovation

- A process involving roll compaction of nickel and chromium powders, followed by sintering and cold rolling, to produce a Ni-Cr alloy strip with a chromium content of 33 to 50 wt.% and a nickel content of at least 47 wt.%, eliminating the need for melting and thus avoiding brittle phases, and allowing for sufficient ductility and formability for use as a welding electrode sheath.

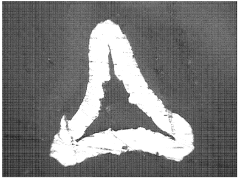

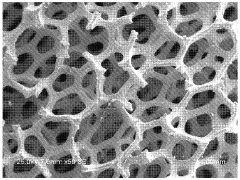

Foam nichrome and preparation method therefor

PatentWO2024036691A1

Innovation

- Under vacuum conditions, the nickel foam is mixed with alloy materials for alloying treatment. The oxide film on the surface of the chromium powder is removed by the reducing agent. The activator promotes the alloying of chromium and nickel, avoiding the powder removal problem introduced by ammonium chloride. Thermal diffusion achieves uniform penetration of chromium to form a dense nickel-chromium alloy layer.

Safety Regulations in Nichrome Handling

Safety regulations in nichrome handling are crucial for ensuring the well-being of workers and maintaining operational integrity in industrial processes. The Occupational Safety and Health Administration (OSHA) has established specific guidelines for handling nichrome elements, which are widely used in heating applications due to their high resistance and durability.

One of the primary safety concerns when working with nichrome is the potential for electrical hazards. As nichrome is an excellent conductor of electricity, proper insulation and grounding procedures must be implemented to prevent electric shocks. Workers should be equipped with appropriate personal protective equipment (PPE), including insulated gloves and safety footwear. Regular inspection and maintenance of electrical systems connected to nichrome elements are essential to identify and address any potential risks.

Thermal safety is another critical aspect of nichrome handling. Given that nichrome elements can reach extremely high temperatures during operation, proper heat management systems must be in place. This includes adequate ventilation, heat-resistant barriers, and cooling mechanisms to prevent accidental burns or fire hazards. Workers should be trained in proper handling techniques and the use of heat-resistant tools when interacting with heated nichrome components.

Chemical safety regulations are also pertinent when dealing with nichrome, particularly in environments where it may come into contact with corrosive substances. Nichrome's resistance to oxidation at high temperatures makes it suitable for various industrial applications, but precautions must be taken to prevent chemical reactions that could compromise its integrity or release harmful byproducts.

Proper storage and disposal procedures for nichrome elements are outlined in safety regulations to minimize environmental impact and prevent contamination. This includes guidelines for recycling used nichrome components and managing any waste products generated during industrial processes involving nichrome.

Workplace safety training programs specific to nichrome handling should be implemented and regularly updated. These programs should cover proper equipment usage, emergency response procedures, and the recognition of potential hazards associated with nichrome elements. Regular safety audits and risk assessments are recommended to ensure ongoing compliance with established regulations and to identify areas for improvement in safety protocols.

In addition to general safety regulations, industry-specific guidelines may apply depending on the particular application of nichrome elements. For instance, the food processing industry may have additional requirements to prevent contamination, while aerospace applications might necessitate more stringent quality control measures.

By adhering to these comprehensive safety regulations, industries can effectively mitigate risks associated with nichrome handling, ensuring a safer work environment and more reliable industrial processes. Continuous monitoring and adaptation of safety practices are essential as technology and industrial applications of nichrome continue to evolve.

One of the primary safety concerns when working with nichrome is the potential for electrical hazards. As nichrome is an excellent conductor of electricity, proper insulation and grounding procedures must be implemented to prevent electric shocks. Workers should be equipped with appropriate personal protective equipment (PPE), including insulated gloves and safety footwear. Regular inspection and maintenance of electrical systems connected to nichrome elements are essential to identify and address any potential risks.

Thermal safety is another critical aspect of nichrome handling. Given that nichrome elements can reach extremely high temperatures during operation, proper heat management systems must be in place. This includes adequate ventilation, heat-resistant barriers, and cooling mechanisms to prevent accidental burns or fire hazards. Workers should be trained in proper handling techniques and the use of heat-resistant tools when interacting with heated nichrome components.

Chemical safety regulations are also pertinent when dealing with nichrome, particularly in environments where it may come into contact with corrosive substances. Nichrome's resistance to oxidation at high temperatures makes it suitable for various industrial applications, but precautions must be taken to prevent chemical reactions that could compromise its integrity or release harmful byproducts.

Proper storage and disposal procedures for nichrome elements are outlined in safety regulations to minimize environmental impact and prevent contamination. This includes guidelines for recycling used nichrome components and managing any waste products generated during industrial processes involving nichrome.

Workplace safety training programs specific to nichrome handling should be implemented and regularly updated. These programs should cover proper equipment usage, emergency response procedures, and the recognition of potential hazards associated with nichrome elements. Regular safety audits and risk assessments are recommended to ensure ongoing compliance with established regulations and to identify areas for improvement in safety protocols.

In addition to general safety regulations, industry-specific guidelines may apply depending on the particular application of nichrome elements. For instance, the food processing industry may have additional requirements to prevent contamination, while aerospace applications might necessitate more stringent quality control measures.

By adhering to these comprehensive safety regulations, industries can effectively mitigate risks associated with nichrome handling, ensuring a safer work environment and more reliable industrial processes. Continuous monitoring and adaptation of safety practices are essential as technology and industrial applications of nichrome continue to evolve.

Environmental Impact Assessment

The environmental impact of handling nichrome elements in industrial processes is a critical consideration that requires thorough assessment. Nichrome, an alloy primarily composed of nickel and chromium, is widely used in various industrial applications due to its high resistance to heat and corrosion. However, its production, use, and disposal can have significant environmental implications.

The manufacturing process of nichrome elements often involves energy-intensive methods, contributing to greenhouse gas emissions and climate change. The extraction and refining of nickel and chromium, the primary components of nichrome, can lead to habitat destruction, soil erosion, and water pollution in mining areas. These activities may also result in the release of toxic substances into the environment, potentially affecting local ecosystems and biodiversity.

During industrial processes, the use of nichrome elements can generate particulate matter and potentially harmful fumes. When heated to high temperatures, nichrome may release chromium and nickel compounds into the air, which can be hazardous to both human health and the environment. Proper ventilation and filtration systems are essential to mitigate these risks and minimize air pollution.

The disposal of nichrome-containing products and waste materials presents another environmental challenge. Improper disposal can lead to soil and groundwater contamination, as heavy metals from nichrome can leach into the environment. Recycling and proper waste management practices are crucial to reduce the environmental footprint of nichrome usage.

Water resources can also be impacted by nichrome-related industrial processes. Cooling systems and cleaning operations may introduce nichrome particles or dissolved metals into wastewater streams. Without adequate treatment, these contaminants can harm aquatic ecosystems and potentially enter the food chain.

To address these environmental concerns, industries must implement comprehensive environmental management systems. This includes adopting cleaner production technologies, optimizing energy efficiency, and implementing robust waste reduction and recycling programs. Regular environmental monitoring and compliance with regulatory standards are essential to minimize the ecological impact of nichrome handling.

Furthermore, life cycle assessments should be conducted to evaluate the environmental impact of nichrome elements throughout their entire lifespan, from raw material extraction to end-of-life disposal. This holistic approach can help identify opportunities for improvement and guide the development of more sustainable practices in industrial processes involving nichrome.

The manufacturing process of nichrome elements often involves energy-intensive methods, contributing to greenhouse gas emissions and climate change. The extraction and refining of nickel and chromium, the primary components of nichrome, can lead to habitat destruction, soil erosion, and water pollution in mining areas. These activities may also result in the release of toxic substances into the environment, potentially affecting local ecosystems and biodiversity.

During industrial processes, the use of nichrome elements can generate particulate matter and potentially harmful fumes. When heated to high temperatures, nichrome may release chromium and nickel compounds into the air, which can be hazardous to both human health and the environment. Proper ventilation and filtration systems are essential to mitigate these risks and minimize air pollution.

The disposal of nichrome-containing products and waste materials presents another environmental challenge. Improper disposal can lead to soil and groundwater contamination, as heavy metals from nichrome can leach into the environment. Recycling and proper waste management practices are crucial to reduce the environmental footprint of nichrome usage.

Water resources can also be impacted by nichrome-related industrial processes. Cooling systems and cleaning operations may introduce nichrome particles or dissolved metals into wastewater streams. Without adequate treatment, these contaminants can harm aquatic ecosystems and potentially enter the food chain.

To address these environmental concerns, industries must implement comprehensive environmental management systems. This includes adopting cleaner production technologies, optimizing energy efficiency, and implementing robust waste reduction and recycling programs. Regular environmental monitoring and compliance with regulatory standards are essential to minimize the ecological impact of nichrome handling.

Furthermore, life cycle assessments should be conducted to evaluate the environmental impact of nichrome elements throughout their entire lifespan, from raw material extraction to end-of-life disposal. This holistic approach can help identify opportunities for improvement and guide the development of more sustainable practices in industrial processes involving nichrome.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!