How to Implement Nichrome for Faster Thermal Response?

JUL 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Thermal Tech Evolution and Objectives

Nichrome, an alloy of nickel and chromium, has been a cornerstone in thermal technology since its invention in the early 20th century. Its evolution has been driven by the increasing demand for faster and more precise thermal control across various industries. The primary objective in implementing nichrome for faster thermal response is to enhance its heat generation and dissipation capabilities while maintaining its durability and cost-effectiveness.

The development of nichrome technology has seen significant advancements over the years. Initially used in simple heating elements, it has evolved to become a crucial component in sophisticated thermal management systems. The focus has shifted from mere heat generation to achieving rapid temperature changes and precise thermal control. This evolution has been propelled by the needs of industries such as aerospace, semiconductor manufacturing, and advanced materials processing, where quick thermal response is critical for operational efficiency and product quality.

Current technological goals in nichrome implementation center around optimizing its composition and structure to achieve faster heating and cooling rates. Researchers are exploring ways to modify the alloy's microstructure, potentially incorporating nanostructures or advanced coatings to enhance its thermal properties. Another objective is to improve the integration of nichrome elements with advanced control systems, enabling more responsive and precise temperature regulation.

The pursuit of faster thermal response in nichrome technology also involves addressing challenges related to power management and energy efficiency. As thermal systems become more dynamic, there's a growing need for nichrome implementations that can rapidly adjust to varying power inputs while maintaining optimal performance. This objective aligns with broader industry trends towards energy conservation and sustainability.

Furthermore, the development of nichrome technology is increasingly focused on expanding its application range. While traditionally used in resistive heating elements, researchers are exploring its potential in more complex thermal management solutions, such as in thermal batteries or advanced heat exchangers. The goal is to leverage nichrome's unique properties to create multifunctional thermal systems capable of rapid response across a wider temperature range and in more demanding environments.

In conclusion, the evolution of nichrome technology and its objectives for faster thermal response reflect a broader trend in thermal management: the need for more agile, precise, and efficient heating solutions. As industries continue to push the boundaries of thermal requirements, the development of nichrome technology remains at the forefront of innovation in thermal control systems.

The development of nichrome technology has seen significant advancements over the years. Initially used in simple heating elements, it has evolved to become a crucial component in sophisticated thermal management systems. The focus has shifted from mere heat generation to achieving rapid temperature changes and precise thermal control. This evolution has been propelled by the needs of industries such as aerospace, semiconductor manufacturing, and advanced materials processing, where quick thermal response is critical for operational efficiency and product quality.

Current technological goals in nichrome implementation center around optimizing its composition and structure to achieve faster heating and cooling rates. Researchers are exploring ways to modify the alloy's microstructure, potentially incorporating nanostructures or advanced coatings to enhance its thermal properties. Another objective is to improve the integration of nichrome elements with advanced control systems, enabling more responsive and precise temperature regulation.

The pursuit of faster thermal response in nichrome technology also involves addressing challenges related to power management and energy efficiency. As thermal systems become more dynamic, there's a growing need for nichrome implementations that can rapidly adjust to varying power inputs while maintaining optimal performance. This objective aligns with broader industry trends towards energy conservation and sustainability.

Furthermore, the development of nichrome technology is increasingly focused on expanding its application range. While traditionally used in resistive heating elements, researchers are exploring its potential in more complex thermal management solutions, such as in thermal batteries or advanced heat exchangers. The goal is to leverage nichrome's unique properties to create multifunctional thermal systems capable of rapid response across a wider temperature range and in more demanding environments.

In conclusion, the evolution of nichrome technology and its objectives for faster thermal response reflect a broader trend in thermal management: the need for more agile, precise, and efficient heating solutions. As industries continue to push the boundaries of thermal requirements, the development of nichrome technology remains at the forefront of innovation in thermal control systems.

Market Demand for Rapid Thermal Response Systems

The market demand for rapid thermal response systems has been steadily increasing across various industries, driven by the need for more efficient and precise temperature control in manufacturing processes, scientific research, and consumer applications. This growing demand is particularly evident in sectors such as semiconductor manufacturing, aerospace, automotive, and medical devices, where rapid and accurate temperature changes are critical for product quality and performance.

In the semiconductor industry, the push for smaller and more powerful chips has intensified the need for precise thermal management during the manufacturing process. Rapid thermal processing (RTP) systems, which rely on fast-responding heating elements, are essential for tasks such as annealing, oxidation, and chemical vapor deposition. The global semiconductor market, valued at over $500 billion in 2021, is expected to grow at a CAGR of 9.2% through 2026, indicating a substantial potential market for advanced thermal response systems.

The aerospace and automotive industries also demonstrate significant demand for rapid thermal response technologies. In aerospace, these systems are crucial for testing materials and components under extreme temperature conditions, simulating the harsh environments encountered during flight. The automotive sector utilizes rapid thermal response systems in various applications, including engine testing, exhaust system development, and battery thermal management for electric vehicles. With the global electric vehicle market projected to reach 26.8 million units by 2030, the demand for efficient thermal management solutions is set to surge.

Medical device manufacturing represents another key market for rapid thermal response systems. Precise temperature control is vital in processes such as sterilization, materials testing, and the production of diagnostic equipment. The global medical devices market, valued at $495 billion in 2022, is expected to grow at a CAGR of 5.9% through 2030, further driving the demand for advanced thermal technologies.

Consumer electronics and appliances also contribute to the market demand for rapid thermal response systems. From smart ovens to advanced hair styling tools, consumers increasingly expect devices that can quickly reach and maintain specific temperatures. This trend is reflected in the growing smart home appliances market, which is projected to reach $133.4 billion by 2027, with a CAGR of 14.1% from 2022.

The energy sector, particularly in renewable energy applications, presents emerging opportunities for rapid thermal response technologies. Concentrated solar power systems and thermal energy storage solutions require precise and responsive temperature control to optimize efficiency and energy conversion.

As industries continue to prioritize energy efficiency, process optimization, and product quality, the demand for rapid thermal response systems is expected to grow. This trend is further reinforced by the increasing adoption of Industry 4.0 technologies, which emphasize real-time monitoring and control in manufacturing processes. The integration of rapid thermal response systems with IoT and AI technologies is likely to open new market opportunities and drive innovation in thermal management solutions across various sectors.

In the semiconductor industry, the push for smaller and more powerful chips has intensified the need for precise thermal management during the manufacturing process. Rapid thermal processing (RTP) systems, which rely on fast-responding heating elements, are essential for tasks such as annealing, oxidation, and chemical vapor deposition. The global semiconductor market, valued at over $500 billion in 2021, is expected to grow at a CAGR of 9.2% through 2026, indicating a substantial potential market for advanced thermal response systems.

The aerospace and automotive industries also demonstrate significant demand for rapid thermal response technologies. In aerospace, these systems are crucial for testing materials and components under extreme temperature conditions, simulating the harsh environments encountered during flight. The automotive sector utilizes rapid thermal response systems in various applications, including engine testing, exhaust system development, and battery thermal management for electric vehicles. With the global electric vehicle market projected to reach 26.8 million units by 2030, the demand for efficient thermal management solutions is set to surge.

Medical device manufacturing represents another key market for rapid thermal response systems. Precise temperature control is vital in processes such as sterilization, materials testing, and the production of diagnostic equipment. The global medical devices market, valued at $495 billion in 2022, is expected to grow at a CAGR of 5.9% through 2030, further driving the demand for advanced thermal technologies.

Consumer electronics and appliances also contribute to the market demand for rapid thermal response systems. From smart ovens to advanced hair styling tools, consumers increasingly expect devices that can quickly reach and maintain specific temperatures. This trend is reflected in the growing smart home appliances market, which is projected to reach $133.4 billion by 2027, with a CAGR of 14.1% from 2022.

The energy sector, particularly in renewable energy applications, presents emerging opportunities for rapid thermal response technologies. Concentrated solar power systems and thermal energy storage solutions require precise and responsive temperature control to optimize efficiency and energy conversion.

As industries continue to prioritize energy efficiency, process optimization, and product quality, the demand for rapid thermal response systems is expected to grow. This trend is further reinforced by the increasing adoption of Industry 4.0 technologies, which emphasize real-time monitoring and control in manufacturing processes. The integration of rapid thermal response systems with IoT and AI technologies is likely to open new market opportunities and drive innovation in thermal management solutions across various sectors.

Nichrome Tech Status and Challenges

Nichrome, an alloy of nickel and chromium, has been widely used in heating elements due to its excellent thermal properties. However, the current state of nichrome technology faces several challenges in achieving faster thermal response times. The primary limitation lies in the material's inherent thermal mass, which affects its ability to rapidly heat up and cool down.

One of the main technical hurdles is optimizing the nichrome wire's diameter and configuration to balance resistance, current capacity, and heat dissipation. Thinner wires offer faster heating but are more prone to burnout, while thicker wires provide durability at the cost of slower thermal response. This trade-off necessitates careful engineering to achieve the desired performance characteristics.

Another significant challenge is the development of advanced manufacturing techniques to produce nichrome elements with consistent properties and uniform heating. Variations in alloy composition and wire thickness can lead to uneven heating and reduced overall efficiency. Precision control in the production process is crucial to overcome these issues and ensure reliable performance across different applications.

The integration of nichrome elements into complex systems presents additional challenges. Thermal management becomes critical, especially in confined spaces or when rapid cycling between high and low temperatures is required. Engineers must consider factors such as heat distribution, insulation, and thermal expansion to prevent mechanical stress and maintain system integrity.

Globally, research efforts are focused on enhancing nichrome's thermal response characteristics. In North America and Europe, emphasis is placed on developing advanced alloy compositions and surface treatments to improve heat transfer efficiency. Asian countries, particularly Japan and South Korea, are at the forefront of miniaturization techniques, exploring ways to incorporate nichrome into increasingly compact devices without compromising performance.

Recent advancements have shown promise in addressing some of these challenges. The development of nano-structured nichrome films has demonstrated potential for faster heating and cooling cycles. Additionally, the use of computer-aided design and simulation tools has enabled more precise control over heating element geometries, leading to optimized thermal profiles.

Despite these advancements, several constraints remain. The cost of high-purity nichrome and the complexity of manufacturing processes for advanced configurations can limit widespread adoption in cost-sensitive applications. Furthermore, environmental concerns related to the production and disposal of nichrome elements pose challenges for sustainability-focused industries.

As the demand for faster thermal response continues to grow across various sectors, including automotive, aerospace, and consumer electronics, overcoming these technical hurdles becomes increasingly crucial. The future of nichrome technology lies in interdisciplinary approaches, combining materials science, thermal engineering, and advanced manufacturing techniques to push the boundaries of thermal response capabilities.

One of the main technical hurdles is optimizing the nichrome wire's diameter and configuration to balance resistance, current capacity, and heat dissipation. Thinner wires offer faster heating but are more prone to burnout, while thicker wires provide durability at the cost of slower thermal response. This trade-off necessitates careful engineering to achieve the desired performance characteristics.

Another significant challenge is the development of advanced manufacturing techniques to produce nichrome elements with consistent properties and uniform heating. Variations in alloy composition and wire thickness can lead to uneven heating and reduced overall efficiency. Precision control in the production process is crucial to overcome these issues and ensure reliable performance across different applications.

The integration of nichrome elements into complex systems presents additional challenges. Thermal management becomes critical, especially in confined spaces or when rapid cycling between high and low temperatures is required. Engineers must consider factors such as heat distribution, insulation, and thermal expansion to prevent mechanical stress and maintain system integrity.

Globally, research efforts are focused on enhancing nichrome's thermal response characteristics. In North America and Europe, emphasis is placed on developing advanced alloy compositions and surface treatments to improve heat transfer efficiency. Asian countries, particularly Japan and South Korea, are at the forefront of miniaturization techniques, exploring ways to incorporate nichrome into increasingly compact devices without compromising performance.

Recent advancements have shown promise in addressing some of these challenges. The development of nano-structured nichrome films has demonstrated potential for faster heating and cooling cycles. Additionally, the use of computer-aided design and simulation tools has enabled more precise control over heating element geometries, leading to optimized thermal profiles.

Despite these advancements, several constraints remain. The cost of high-purity nichrome and the complexity of manufacturing processes for advanced configurations can limit widespread adoption in cost-sensitive applications. Furthermore, environmental concerns related to the production and disposal of nichrome elements pose challenges for sustainability-focused industries.

As the demand for faster thermal response continues to grow across various sectors, including automotive, aerospace, and consumer electronics, overcoming these technical hurdles becomes increasingly crucial. The future of nichrome technology lies in interdisciplinary approaches, combining materials science, thermal engineering, and advanced manufacturing techniques to push the boundaries of thermal response capabilities.

Current Nichrome Implementation Methods

01 Thermal response characteristics of nichrome in sensors

Nichrome's thermal response properties make it suitable for use in various sensing applications. Its rapid temperature change in response to electrical current allows for precise temperature control and measurement in devices such as thermal sensors, flow meters, and gas detectors.- Thermal response characteristics of nichrome in sensors: Nichrome's thermal response properties make it suitable for use in various sensors. Its rapid and predictable temperature changes in response to electrical current allow for accurate measurements in applications such as flow sensors, temperature sensors, and thermal anemometers. The material's stability and reliability contribute to its effectiveness in sensing devices.

- Nichrome in heating elements and thermal management: Nichrome is widely used in heating elements due to its excellent thermal response. Its high resistivity and ability to withstand high temperatures make it ideal for applications in electric heaters, ovens, and thermal management systems. The material's quick heating and cooling properties allow for precise temperature control in various industrial and consumer products.

- Nichrome alloy composition and thermal properties: The specific composition of nichrome alloys can be tailored to optimize thermal response for different applications. Variations in the nickel-chromium ratio and the addition of other elements can affect properties such as resistivity, temperature coefficient of resistance, and maximum operating temperature. These compositional adjustments allow for fine-tuning of the alloy's thermal behavior.

- Nichrome in thin film and microelectronic applications: Nichrome's thermal properties are utilized in thin film and microelectronic applications. Its stability and consistent thermal response make it suitable for use in resistive elements, microheaters, and thermal sensors in miniaturized devices. The material's compatibility with microfabrication processes contributes to its adoption in MEMS (Micro-Electro-Mechanical Systems) and other advanced electronic applications.

- Nichrome in thermal imaging and infrared applications: The thermal response characteristics of nichrome are exploited in thermal imaging and infrared technologies. Its ability to rapidly change temperature in response to electrical stimuli makes it useful in uncooled infrared detectors, bolometers, and other devices that rely on precise thermal management for imaging and sensing applications.

02 Nichrome heating elements in electronic devices

Nichrome is widely used as a heating element in electronic devices due to its high resistivity and thermal stability. It is employed in applications such as electric heaters, 3D printers, and vaporizers, where precise temperature control is crucial for optimal performance.Expand Specific Solutions03 Nichrome in thin film resistors and microelectronics

Nichrome's properties make it an excellent material for thin film resistors and microelectronic applications. Its stability and resistance to oxidation allow for the creation of precise, reliable components in integrated circuits and other miniaturized electronic devices.Expand Specific Solutions04 Nichrome alloy composition and thermal properties

The specific composition of nichrome alloys can be tailored to achieve desired thermal and electrical properties. Variations in the nickel-chromium ratio and the addition of other elements can affect the alloy's resistivity, temperature coefficient of resistance, and overall thermal response.Expand Specific Solutions05 Nichrome in thermal management systems

Nichrome's thermal properties make it valuable in thermal management systems for various industries. It is used in temperature control units, heat dissipation devices, and thermal regulation systems in aerospace, automotive, and industrial applications.Expand Specific Solutions

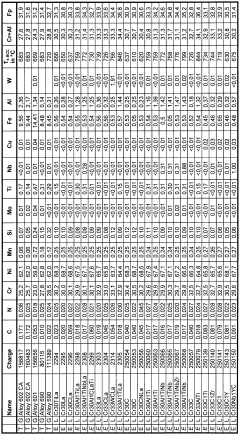

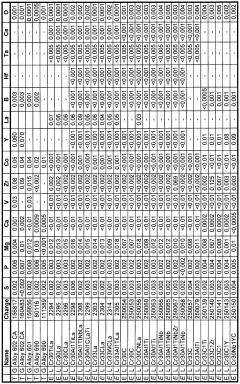

Key Players in Nichrome and Thermal Tech

The implementation of Nichrome for faster thermal response is in a mature stage of development, with a competitive landscape shaped by established players and emerging technologies. The market size for thermal management solutions is expanding, driven by increasing demand in electronics, automotive, and industrial sectors. Companies like Arkema France SA, Battelle Memorial Institute, and Konfoong Materials International Co., Ltd. are at the forefront of research and development in this field. The technology's maturity is evident in its widespread application, but ongoing innovations by companies such as Yancheng Xinyang Electric Heating Material Co., Ltd. and Jiangsu National Nickel New Material Technology Co., Ltd. are pushing the boundaries of thermal response capabilities, indicating a dynamic and evolving market.

Arkema France SA

Technical Solution: Arkema has developed advanced nichrome alloys with optimized composition for faster thermal response. Their approach involves fine-tuning the nickel-chromium ratio and adding trace elements to enhance electrical resistivity and heat generation. The company utilizes precision controlled vapor deposition techniques to create ultra-thin nichrome films, allowing for rapid heating and cooling cycles. Arkema's nichrome implementations feature nano-structured surfaces that increase the effective heat transfer area, improving thermal efficiency[1]. They have also integrated smart control systems that use predictive algorithms to anticipate temperature changes, further reducing response times[3].

Strengths: High-precision manufacturing capabilities, advanced material science expertise. Weaknesses: Potentially higher production costs, may require specialized equipment for implementation.

Battelle Memorial Institute

Technical Solution: Battelle has pioneered a novel approach to nichrome implementation focusing on microstructure optimization. Their method involves creating a hierarchical porous structure within the nichrome material, significantly increasing the surface area for heat transfer. This is achieved through a proprietary sintering process that controls pore size distribution[2]. Additionally, Battelle has developed a unique coating technology that applies a thin, thermally conductive layer over the nichrome elements, enhancing heat dissipation. The institute has also integrated advanced sensors and control systems that allow for real-time temperature monitoring and adjustment, further improving response times[4].

Strengths: Innovative microstructure design, comprehensive system integration approach. Weaknesses: Complex manufacturing process, may have scalability challenges for mass production.

Core Innovations in Nichrome Thermal Response

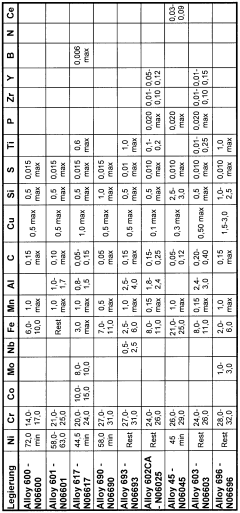

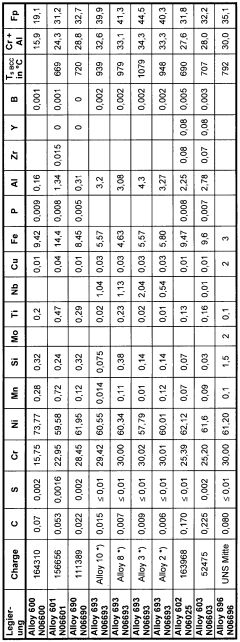

Nickel-chromium alloy having good processability, creep resistance and corrosion resistance

PatentWO2013182178A1

Innovation

- A nickel-chromium alloy with a chromium content of 29-37%, 0.001-1.8% aluminum, and specific ranges of other elements, optimized to ensure Cr + Al > 30 and satisfying certain relationships among element concentrations to enhance metal dusting resistance, phase stability, and workability, while maintaining high heat resistance and creep resistance.

Use of nickel-chromium alloy in heat treatment

PatentWO2014177611A1

Innovation

- The use of a nickel-chromium alloy with a Cr content of more than 19% by weight, specifically in the form of a knitted, woven, or fiber web fabric, which provides excellent heat resistance and retains strength and physical properties at temperatures above 700°C for extended periods, reducing the need for frequent replacements.

Thermal Management System Integration

Integrating nichrome into thermal management systems requires careful consideration of various factors to optimize performance and ensure seamless operation. The implementation process begins with a thorough analysis of the existing thermal management infrastructure, identifying key areas where nichrome can be incorporated to enhance thermal response times. This involves evaluating heat dissipation requirements, power consumption constraints, and spatial limitations within the system.

One crucial aspect of integration is the design of nichrome heating elements. These elements must be tailored to the specific thermal needs of the system, taking into account factors such as surface area, resistance, and power density. Engineers must carefully calculate the optimal nichrome wire gauge, length, and configuration to achieve the desired heating characteristics while maintaining efficiency and reliability.

The placement of nichrome elements within the thermal management system is another critical consideration. Strategic positioning ensures uniform heat distribution and rapid thermal response. This may involve embedding nichrome wires in heat spreaders, integrating them into heat sinks, or incorporating them into specialized thermal interface materials. The goal is to create a synergistic relationship between the nichrome elements and existing thermal management components, maximizing overall system performance.

Control systems play a vital role in the effective integration of nichrome for faster thermal response. Advanced temperature sensing and feedback mechanisms must be implemented to monitor and regulate the nichrome heating elements in real-time. This may involve the use of thermocouples, RTDs, or infrared sensors coupled with sophisticated control algorithms. The control system should be capable of rapid adjustments to maintain precise temperature levels and respond quickly to changing thermal loads.

Power delivery and management are essential aspects of nichrome integration. The thermal management system must be equipped with appropriate power supplies and distribution networks to support the nichrome heating elements. This includes considerations for voltage regulation, current limiting, and safety features to prevent overheating or electrical hazards. In some cases, the integration of nichrome may necessitate upgrades to the overall power infrastructure of the system.

Thermal insulation and isolation strategies must be carefully implemented to maximize the efficiency of nichrome heating elements and prevent unintended heat transfer to sensitive components. This may involve the use of advanced insulating materials, heat shields, or thermal barriers to direct heat flow and minimize thermal losses. Proper insulation also helps to reduce power consumption and improve the overall energy efficiency of the thermal management system.

Finally, the integration process must address long-term reliability and maintenance considerations. This includes implementing protective measures against oxidation and degradation of nichrome elements, designing for easy access and replacement of components, and establishing monitoring systems to track performance over time. Regular calibration and maintenance procedures should be developed to ensure consistent thermal response and system longevity.

One crucial aspect of integration is the design of nichrome heating elements. These elements must be tailored to the specific thermal needs of the system, taking into account factors such as surface area, resistance, and power density. Engineers must carefully calculate the optimal nichrome wire gauge, length, and configuration to achieve the desired heating characteristics while maintaining efficiency and reliability.

The placement of nichrome elements within the thermal management system is another critical consideration. Strategic positioning ensures uniform heat distribution and rapid thermal response. This may involve embedding nichrome wires in heat spreaders, integrating them into heat sinks, or incorporating them into specialized thermal interface materials. The goal is to create a synergistic relationship between the nichrome elements and existing thermal management components, maximizing overall system performance.

Control systems play a vital role in the effective integration of nichrome for faster thermal response. Advanced temperature sensing and feedback mechanisms must be implemented to monitor and regulate the nichrome heating elements in real-time. This may involve the use of thermocouples, RTDs, or infrared sensors coupled with sophisticated control algorithms. The control system should be capable of rapid adjustments to maintain precise temperature levels and respond quickly to changing thermal loads.

Power delivery and management are essential aspects of nichrome integration. The thermal management system must be equipped with appropriate power supplies and distribution networks to support the nichrome heating elements. This includes considerations for voltage regulation, current limiting, and safety features to prevent overheating or electrical hazards. In some cases, the integration of nichrome may necessitate upgrades to the overall power infrastructure of the system.

Thermal insulation and isolation strategies must be carefully implemented to maximize the efficiency of nichrome heating elements and prevent unintended heat transfer to sensitive components. This may involve the use of advanced insulating materials, heat shields, or thermal barriers to direct heat flow and minimize thermal losses. Proper insulation also helps to reduce power consumption and improve the overall energy efficiency of the thermal management system.

Finally, the integration process must address long-term reliability and maintenance considerations. This includes implementing protective measures against oxidation and degradation of nichrome elements, designing for easy access and replacement of components, and establishing monitoring systems to track performance over time. Regular calibration and maintenance procedures should be developed to ensure consistent thermal response and system longevity.

Energy Efficiency Considerations

Energy efficiency is a critical consideration when implementing Nichrome for faster thermal response. The use of Nichrome wire in heating elements offers several advantages in terms of energy efficiency, but also presents challenges that need to be addressed for optimal performance.

Nichrome's high electrical resistance and ability to withstand high temperatures make it an excellent choice for rapid heating applications. However, to maximize energy efficiency, careful attention must be paid to the design and control of the heating system. One key factor is the precise control of power input to the Nichrome element. By implementing advanced control algorithms and feedback mechanisms, it is possible to minimize energy waste and ensure that only the necessary amount of heat is generated.

The thermal mass of the system plays a crucial role in energy efficiency. Reducing the thermal mass of the heating element and its surrounding components can lead to faster response times and lower energy consumption. This can be achieved through careful material selection and innovative design approaches, such as using thinner Nichrome wire or incorporating it into lightweight, thermally responsive structures.

Heat distribution and insulation are also vital aspects of energy-efficient Nichrome implementations. Proper insulation helps to minimize heat loss to the environment, while efficient heat distribution ensures that the thermal energy is directed where it is needed most. Advanced materials and design techniques, such as reflective coatings or strategic placement of heat-directing elements, can significantly improve overall system efficiency.

The integration of smart control systems and IoT technologies can further enhance the energy efficiency of Nichrome-based heating solutions. These systems can optimize heating cycles based on usage patterns, environmental conditions, and user preferences, leading to substantial energy savings over time. Additionally, the incorporation of energy recovery systems, such as heat exchangers, can capture and reuse waste heat, further improving overall efficiency.

When considering energy efficiency, it is also important to evaluate the entire lifecycle of the Nichrome heating system. This includes the energy required for manufacturing, installation, maintenance, and eventual disposal or recycling. Choosing durable materials and designing for longevity can reduce the overall environmental impact and improve long-term energy efficiency.

In conclusion, while Nichrome offers excellent properties for fast thermal response, achieving optimal energy efficiency requires a holistic approach. By addressing factors such as precise control, thermal mass reduction, heat distribution, smart technologies, and lifecycle considerations, it is possible to create Nichrome-based heating solutions that are both responsive and energy-efficient.

Nichrome's high electrical resistance and ability to withstand high temperatures make it an excellent choice for rapid heating applications. However, to maximize energy efficiency, careful attention must be paid to the design and control of the heating system. One key factor is the precise control of power input to the Nichrome element. By implementing advanced control algorithms and feedback mechanisms, it is possible to minimize energy waste and ensure that only the necessary amount of heat is generated.

The thermal mass of the system plays a crucial role in energy efficiency. Reducing the thermal mass of the heating element and its surrounding components can lead to faster response times and lower energy consumption. This can be achieved through careful material selection and innovative design approaches, such as using thinner Nichrome wire or incorporating it into lightweight, thermally responsive structures.

Heat distribution and insulation are also vital aspects of energy-efficient Nichrome implementations. Proper insulation helps to minimize heat loss to the environment, while efficient heat distribution ensures that the thermal energy is directed where it is needed most. Advanced materials and design techniques, such as reflective coatings or strategic placement of heat-directing elements, can significantly improve overall system efficiency.

The integration of smart control systems and IoT technologies can further enhance the energy efficiency of Nichrome-based heating solutions. These systems can optimize heating cycles based on usage patterns, environmental conditions, and user preferences, leading to substantial energy savings over time. Additionally, the incorporation of energy recovery systems, such as heat exchangers, can capture and reuse waste heat, further improving overall efficiency.

When considering energy efficiency, it is also important to evaluate the entire lifecycle of the Nichrome heating system. This includes the energy required for manufacturing, installation, maintenance, and eventual disposal or recycling. Choosing durable materials and designing for longevity can reduce the overall environmental impact and improve long-term energy efficiency.

In conclusion, while Nichrome offers excellent properties for fast thermal response, achieving optimal energy efficiency requires a holistic approach. By addressing factors such as precise control, thermal mass reduction, heat distribution, smart technologies, and lifecycle considerations, it is possible to create Nichrome-based heating solutions that are both responsive and energy-efficient.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!