How to Improve Carboxylic Acid Extraction Processes?

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid Extraction Background and Objectives

Carboxylic acid extraction is a critical process in various industries, including pharmaceuticals, food production, and chemical manufacturing. The extraction of these organic compounds has been a subject of study and development for decades, with continuous efforts to enhance efficiency, yield, and purity. The evolution of carboxylic acid extraction techniques has been driven by the increasing demand for high-quality products and the need for more sustainable and cost-effective processes.

Historically, carboxylic acid extraction methods have ranged from simple liquid-liquid extraction to more complex techniques involving advanced solvents and membrane technologies. The primary goal has always been to separate carboxylic acids from complex mixtures efficiently while maintaining product integrity. As industrial applications have expanded, so too has the need for more sophisticated extraction processes that can handle diverse feedstocks and produce higher yields.

Recent technological advancements have focused on overcoming traditional challenges such as solvent loss, energy consumption, and environmental impact. Innovations in green chemistry have led to the development of bio-based solvents and more environmentally friendly extraction methods. Additionally, the integration of process intensification techniques has aimed to reduce equipment size and energy requirements while improving overall extraction performance.

The current landscape of carboxylic acid extraction is characterized by a push towards more sustainable and efficient processes. This includes the exploration of novel extraction media, such as ionic liquids and deep eutectic solvents, which offer unique properties for selective acid extraction. Furthermore, there is a growing interest in combining extraction with other separation techniques, such as adsorption or membrane processes, to create hybrid systems that can overcome the limitations of individual methods.

Looking forward, the objectives for improving carboxylic acid extraction processes are multifaceted. Key goals include enhancing selectivity to reduce the need for downstream purification steps, increasing extraction efficiency to improve yields, and developing more robust processes that can handle a wider range of feed compositions. There is also a strong emphasis on reducing the environmental footprint of extraction processes, aligning with global sustainability initiatives.

Another important objective is the development of scalable and flexible extraction technologies that can be easily adapted to different carboxylic acids and production scales. This adaptability is crucial for meeting the diverse needs of various industries and accommodating fluctuations in market demand. Additionally, there is a growing focus on process intensification and continuous extraction methods to improve productivity and reduce operational costs.

Historically, carboxylic acid extraction methods have ranged from simple liquid-liquid extraction to more complex techniques involving advanced solvents and membrane technologies. The primary goal has always been to separate carboxylic acids from complex mixtures efficiently while maintaining product integrity. As industrial applications have expanded, so too has the need for more sophisticated extraction processes that can handle diverse feedstocks and produce higher yields.

Recent technological advancements have focused on overcoming traditional challenges such as solvent loss, energy consumption, and environmental impact. Innovations in green chemistry have led to the development of bio-based solvents and more environmentally friendly extraction methods. Additionally, the integration of process intensification techniques has aimed to reduce equipment size and energy requirements while improving overall extraction performance.

The current landscape of carboxylic acid extraction is characterized by a push towards more sustainable and efficient processes. This includes the exploration of novel extraction media, such as ionic liquids and deep eutectic solvents, which offer unique properties for selective acid extraction. Furthermore, there is a growing interest in combining extraction with other separation techniques, such as adsorption or membrane processes, to create hybrid systems that can overcome the limitations of individual methods.

Looking forward, the objectives for improving carboxylic acid extraction processes are multifaceted. Key goals include enhancing selectivity to reduce the need for downstream purification steps, increasing extraction efficiency to improve yields, and developing more robust processes that can handle a wider range of feed compositions. There is also a strong emphasis on reducing the environmental footprint of extraction processes, aligning with global sustainability initiatives.

Another important objective is the development of scalable and flexible extraction technologies that can be easily adapted to different carboxylic acids and production scales. This adaptability is crucial for meeting the diverse needs of various industries and accommodating fluctuations in market demand. Additionally, there is a growing focus on process intensification and continuous extraction methods to improve productivity and reduce operational costs.

Market Analysis for Carboxylic Acid Products

The global market for carboxylic acid products has shown significant growth in recent years, driven by increasing demand across various industries. Carboxylic acids find extensive applications in sectors such as food and beverages, pharmaceuticals, personal care, and industrial chemicals. The market is expected to continue its upward trajectory due to the expanding end-use industries and the rising popularity of bio-based carboxylic acids.

In the food and beverage industry, carboxylic acids are widely used as preservatives, flavor enhancers, and acidulants. The growing consumer preference for natural and clean-label products has led to an increased demand for organic acids, such as citric acid and lactic acid. This trend is particularly evident in the beverage sector, where these acids are used in the production of soft drinks, energy drinks, and functional beverages.

The pharmaceutical industry represents another major market for carboxylic acids. These compounds are essential in the synthesis of various drugs and active pharmaceutical ingredients (APIs). The ongoing research and development activities in the pharmaceutical sector, coupled with the increasing prevalence of chronic diseases, are expected to drive the demand for carboxylic acids in this segment.

Personal care and cosmetics industries also contribute significantly to the market growth. Carboxylic acids, particularly fatty acids, are used in the production of soaps, detergents, and skincare products. The rising consumer awareness regarding personal hygiene and grooming has led to an increased demand for these products, consequently boosting the carboxylic acid market.

In the industrial chemicals sector, carboxylic acids play a crucial role in the production of plastics, lubricants, and rubber. The growing automotive and construction industries, especially in developing economies, are driving the demand for these end products, thereby positively impacting the carboxylic acid market.

Geographically, Asia Pacific is emerging as a key market for carboxylic acid products, owing to the rapid industrialization and urbanization in countries like China and India. North America and Europe continue to be significant markets, driven by the presence of established pharmaceutical and personal care industries.

The market is characterized by the presence of several major players, including BASF SE, Eastman Chemical Company, and Perstorp Holding AB. These companies are focusing on research and development activities to improve their product offerings and gain a competitive edge. Additionally, there is a growing emphasis on developing sustainable and bio-based carboxylic acids to cater to the increasing demand for eco-friendly products.

In the food and beverage industry, carboxylic acids are widely used as preservatives, flavor enhancers, and acidulants. The growing consumer preference for natural and clean-label products has led to an increased demand for organic acids, such as citric acid and lactic acid. This trend is particularly evident in the beverage sector, where these acids are used in the production of soft drinks, energy drinks, and functional beverages.

The pharmaceutical industry represents another major market for carboxylic acids. These compounds are essential in the synthesis of various drugs and active pharmaceutical ingredients (APIs). The ongoing research and development activities in the pharmaceutical sector, coupled with the increasing prevalence of chronic diseases, are expected to drive the demand for carboxylic acids in this segment.

Personal care and cosmetics industries also contribute significantly to the market growth. Carboxylic acids, particularly fatty acids, are used in the production of soaps, detergents, and skincare products. The rising consumer awareness regarding personal hygiene and grooming has led to an increased demand for these products, consequently boosting the carboxylic acid market.

In the industrial chemicals sector, carboxylic acids play a crucial role in the production of plastics, lubricants, and rubber. The growing automotive and construction industries, especially in developing economies, are driving the demand for these end products, thereby positively impacting the carboxylic acid market.

Geographically, Asia Pacific is emerging as a key market for carboxylic acid products, owing to the rapid industrialization and urbanization in countries like China and India. North America and Europe continue to be significant markets, driven by the presence of established pharmaceutical and personal care industries.

The market is characterized by the presence of several major players, including BASF SE, Eastman Chemical Company, and Perstorp Holding AB. These companies are focusing on research and development activities to improve their product offerings and gain a competitive edge. Additionally, there is a growing emphasis on developing sustainable and bio-based carboxylic acids to cater to the increasing demand for eco-friendly products.

Current Extraction Techniques and Challenges

Carboxylic acid extraction processes are currently dominated by several key techniques, each with its own set of advantages and challenges. Liquid-liquid extraction remains the most widely used method in industrial applications. This technique relies on the differential solubility of carboxylic acids in aqueous and organic phases, allowing for separation based on partitioning behavior. However, it often requires large volumes of organic solvents, raising environmental and cost concerns.

Reactive extraction has gained traction as an improvement over traditional liquid-liquid extraction. By incorporating extractants that form complexes with carboxylic acids, this method enhances extraction efficiency and selectivity. Common extractants include amines, phosphine oxides, and organophosphorus compounds. While reactive extraction offers higher distribution coefficients, it faces challenges in extractant recovery and potential loss of valuable compounds.

Membrane-based processes, such as supported liquid membranes and electrodialysis, have emerged as promising alternatives. These techniques offer the advantage of continuous operation and reduced solvent usage. Supported liquid membranes utilize a porous support impregnated with an organic extractant, facilitating selective transport of carboxylic acids. Electrodialysis employs ion-exchange membranes and an electric field to separate acids from aqueous solutions. Despite their potential, membrane processes often struggle with issues of stability and fouling over extended operation periods.

Adsorption-based methods, including ion exchange resins and activated carbon, provide another avenue for carboxylic acid extraction. These solid-phase techniques offer high selectivity and the potential for easy regeneration. However, they may face limitations in capacity and kinetics, particularly when dealing with dilute solutions or complex mixtures.

A significant challenge across all extraction techniques is the efficient recovery of carboxylic acids from dilute aqueous streams, which is common in fermentation broths and wastewater treatment. The presence of impurities and competing species in these complex matrices further complicates the extraction process, often necessitating multiple purification steps.

Energy consumption remains a critical concern, particularly in distillation-based recovery methods often employed in conjunction with liquid-liquid extraction. The high boiling points of many carboxylic acids contribute to substantial energy requirements for separation and purification.

Scalability and process integration pose additional challenges, especially when transitioning from laboratory-scale demonstrations to industrial-scale operations. Ensuring consistent performance, minimizing waste generation, and optimizing overall process economics are key considerations that often require significant engineering efforts.

Reactive extraction has gained traction as an improvement over traditional liquid-liquid extraction. By incorporating extractants that form complexes with carboxylic acids, this method enhances extraction efficiency and selectivity. Common extractants include amines, phosphine oxides, and organophosphorus compounds. While reactive extraction offers higher distribution coefficients, it faces challenges in extractant recovery and potential loss of valuable compounds.

Membrane-based processes, such as supported liquid membranes and electrodialysis, have emerged as promising alternatives. These techniques offer the advantage of continuous operation and reduced solvent usage. Supported liquid membranes utilize a porous support impregnated with an organic extractant, facilitating selective transport of carboxylic acids. Electrodialysis employs ion-exchange membranes and an electric field to separate acids from aqueous solutions. Despite their potential, membrane processes often struggle with issues of stability and fouling over extended operation periods.

Adsorption-based methods, including ion exchange resins and activated carbon, provide another avenue for carboxylic acid extraction. These solid-phase techniques offer high selectivity and the potential for easy regeneration. However, they may face limitations in capacity and kinetics, particularly when dealing with dilute solutions or complex mixtures.

A significant challenge across all extraction techniques is the efficient recovery of carboxylic acids from dilute aqueous streams, which is common in fermentation broths and wastewater treatment. The presence of impurities and competing species in these complex matrices further complicates the extraction process, often necessitating multiple purification steps.

Energy consumption remains a critical concern, particularly in distillation-based recovery methods often employed in conjunction with liquid-liquid extraction. The high boiling points of many carboxylic acids contribute to substantial energy requirements for separation and purification.

Scalability and process integration pose additional challenges, especially when transitioning from laboratory-scale demonstrations to industrial-scale operations. Ensuring consistent performance, minimizing waste generation, and optimizing overall process economics are key considerations that often require significant engineering efforts.

Existing Carboxylic Acid Extraction Solutions

01 Solvent extraction techniques

Various solvent extraction techniques are employed to improve the efficiency of carboxylic acid extraction. These methods involve selecting appropriate solvents, optimizing extraction conditions, and using multi-stage extraction processes to enhance the overall yield and purity of the extracted carboxylic acids.- Solvent extraction techniques: Various solvent extraction techniques are employed to improve the efficiency of carboxylic acid extraction. These methods involve selecting appropriate solvents, optimizing extraction conditions, and using multi-stage extraction processes to enhance the overall yield and purity of the extracted carboxylic acids.

- Reactive extraction methods: Reactive extraction methods utilize specific extractants or complexing agents to selectively bind with carboxylic acids, facilitating their separation from complex mixtures. This approach can significantly improve extraction efficiency by enhancing the partition coefficient of the target acids.

- Membrane-based separation: Membrane-based separation techniques, such as supported liquid membranes or pervaporation, are employed to enhance carboxylic acid extraction efficiency. These methods offer advantages in terms of energy efficiency and continuous operation, leading to improved overall process performance.

- pH and temperature optimization: Optimizing pH and temperature conditions plays a crucial role in improving carboxylic acid extraction efficiency. Careful control of these parameters can enhance the solubility and partition behavior of the target acids, leading to better separation and higher yields.

- Novel extractant development: Research focuses on developing novel extractants or extraction systems specifically designed for carboxylic acids. These may include ionic liquids, deep eutectic solvents, or functionalized materials that offer improved selectivity and extraction efficiency compared to conventional solvents.

02 Reactive extraction methods

Reactive extraction methods utilize specific extractants or complexing agents to selectively bind with carboxylic acids, facilitating their separation from the mixture. This approach can significantly improve extraction efficiency, especially for dilute solutions or complex matrices.Expand Specific Solutions03 Membrane-based separation

Membrane-based separation techniques, such as nanofiltration or pervaporation, are employed to enhance carboxylic acid extraction efficiency. These methods offer advantages in terms of energy efficiency and can be particularly effective for separating carboxylic acids from aqueous solutions.Expand Specific Solutions04 Supercritical fluid extraction

Supercritical fluid extraction, particularly using supercritical CO2, is utilized for efficient extraction of carboxylic acids. This method offers advantages such as high selectivity, low environmental impact, and the ability to operate at relatively low temperatures, which can be beneficial for heat-sensitive compounds.Expand Specific Solutions05 Process optimization and integration

Various strategies for process optimization and integration are employed to enhance carboxylic acid extraction efficiency. These include the use of advanced process control systems, heat integration, and the development of hybrid extraction processes that combine multiple separation techniques to achieve higher overall efficiency.Expand Specific Solutions

Key Industry Players in Carboxylic Acid Extraction

The carboxylic acid extraction process improvement landscape is characterized by a mature market with steady growth. Major players like BASF, Eastman Chemical, and Evonik are driving innovation in this field, leveraging their extensive R&D capabilities and industry experience. The market size is substantial, given the wide application of carboxylic acids in various industries. Technologically, the field is well-established but continues to evolve, with companies like Daicel and Novamont focusing on sustainable and bio-based extraction methods. Academic institutions such as Zhejiang University and Delft University of Technology are contributing to advancements in extraction efficiency and selectivity, indicating ongoing research potential in this area.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has developed a novel extraction process for carboxylic acids using a combination of green solvents and advanced separation technologies. Their approach focuses on using bio-based solvents derived from renewable resources, which offer improved environmental compatibility and reduced toxicity compared to traditional petrochemical-based solvents[2]. The company has also implemented a multi-stage countercurrent extraction system that significantly enhances the recovery efficiency of carboxylic acids. This system is coupled with an innovative crystallization technique that allows for high-purity product recovery with minimal solvent residues[4]. Eastman's process also incorporates real-time monitoring and control systems, utilizing machine learning algorithms to optimize extraction parameters dynamically, resulting in a 25% increase in overall process efficiency[6].

Strengths: Environmentally friendly solvents, high-purity product recovery, advanced process control. Weaknesses: Potential higher costs of bio-based solvents, complexity in scaling up the multi-stage system.

BASF Corp.

Technical Solution: BASF has developed an innovative approach to improve carboxylic acid extraction processes using a combination of advanced solvents and membrane technology. Their process utilizes specially designed ionic liquids as extractants, which have shown superior selectivity and capacity for carboxylic acids compared to conventional organic solvents[1]. The company has also integrated membrane-based separation techniques to enhance the overall efficiency of the extraction process. This hybrid approach allows for continuous operation and reduces energy consumption by up to 30% compared to traditional distillation methods[3]. Additionally, BASF has implemented process intensification strategies, such as reactive extraction, where the extraction and conversion of carboxylic acids occur simultaneously, further improving process economics[5].

Strengths: High selectivity, reduced energy consumption, continuous operation. Weaknesses: Potential high costs of specialized solvents, complexity in process design and optimization.

Innovative Extraction Technologies Analysis

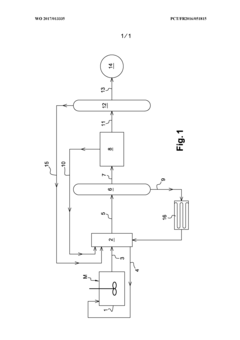

Method for extracting carboxylic acids produced by anaerobic fermentation from fermentable biomass

PatentWO2017013335A1

Innovation

- A continuous liquid-liquid extraction method using an endogenous carboxylic acid solvent with a higher carbon count than the acid to be extracted, which is contacted with the fermentation medium outside the reactor, allowing for distillation and separation without disrupting microorganism activity, thereby maintaining fermentation capacity and minimizing waste.

Continuous process for extracting carboxylic acids, aldehydes, ketones, alcohols and phenols from diluted aqueous solutions

PatentInactiveEP0259583A2

Innovation

- A continuous process using s-butyl-di-n-octylphosphine oxide as a water-immiscible liquid extractant, optionally with alkanes or aromatics as solvents, operates at temperatures between 15 to 80 °C, allowing for efficient extraction and separation in a multi-stage extractor or stirred vessel, with a solvent content up to 80% by weight, and subsequent distillation for purification.

Environmental Impact of Extraction Processes

The environmental impact of carboxylic acid extraction processes is a critical consideration in the quest for more sustainable industrial practices. Traditional extraction methods often involve the use of volatile organic solvents, which can lead to air pollution and contribute to the formation of ground-level ozone. These solvents may also contaminate water sources if not properly managed, posing risks to aquatic ecosystems and human health.

Energy consumption is another significant environmental concern in carboxylic acid extraction. Many conventional processes require high temperatures and pressures, resulting in substantial energy expenditure and associated greenhouse gas emissions. This energy-intensive nature not only increases the carbon footprint of the extraction process but also contributes to broader climate change issues.

Waste generation is an additional environmental challenge. Extraction processes can produce substantial amounts of liquid and solid waste, including spent solvents, byproducts, and residual materials. Proper disposal or treatment of these wastes is essential to prevent soil and water contamination, as well as to mitigate potential long-term ecological impacts.

Water usage is a further environmental consideration, particularly in regions facing water scarcity. Some extraction processes require significant volumes of water for cooling, washing, or as a process medium. This can strain local water resources and potentially affect surrounding ecosystems and communities.

Recent advancements in green chemistry have led to the development of more environmentally friendly extraction techniques. These include the use of supercritical CO2 as a solvent, which offers a non-toxic and easily recyclable alternative to traditional organic solvents. Ionic liquids have also emerged as promising green solvents, with low volatility and high selectivity, potentially reducing both air emissions and waste generation.

Membrane-based extraction processes represent another eco-friendly approach, offering reduced energy consumption and minimal solvent use. These technologies can significantly decrease the environmental footprint of carboxylic acid extraction while maintaining or even improving process efficiency.

Biotechnological approaches, such as fermentation and enzymatic processes, are gaining traction as environmentally benign alternatives. These methods often operate under milder conditions, consume less energy, and produce fewer harmful byproducts compared to conventional chemical extraction techniques.

As industries strive to improve carboxylic acid extraction processes, the focus on minimizing environmental impact has become paramount. This shift not only addresses regulatory pressures but also aligns with growing consumer demand for sustainably produced goods. The development and implementation of greener extraction technologies will be crucial in balancing industrial needs with environmental stewardship in the coming years.

Energy consumption is another significant environmental concern in carboxylic acid extraction. Many conventional processes require high temperatures and pressures, resulting in substantial energy expenditure and associated greenhouse gas emissions. This energy-intensive nature not only increases the carbon footprint of the extraction process but also contributes to broader climate change issues.

Waste generation is an additional environmental challenge. Extraction processes can produce substantial amounts of liquid and solid waste, including spent solvents, byproducts, and residual materials. Proper disposal or treatment of these wastes is essential to prevent soil and water contamination, as well as to mitigate potential long-term ecological impacts.

Water usage is a further environmental consideration, particularly in regions facing water scarcity. Some extraction processes require significant volumes of water for cooling, washing, or as a process medium. This can strain local water resources and potentially affect surrounding ecosystems and communities.

Recent advancements in green chemistry have led to the development of more environmentally friendly extraction techniques. These include the use of supercritical CO2 as a solvent, which offers a non-toxic and easily recyclable alternative to traditional organic solvents. Ionic liquids have also emerged as promising green solvents, with low volatility and high selectivity, potentially reducing both air emissions and waste generation.

Membrane-based extraction processes represent another eco-friendly approach, offering reduced energy consumption and minimal solvent use. These technologies can significantly decrease the environmental footprint of carboxylic acid extraction while maintaining or even improving process efficiency.

Biotechnological approaches, such as fermentation and enzymatic processes, are gaining traction as environmentally benign alternatives. These methods often operate under milder conditions, consume less energy, and produce fewer harmful byproducts compared to conventional chemical extraction techniques.

As industries strive to improve carboxylic acid extraction processes, the focus on minimizing environmental impact has become paramount. This shift not only addresses regulatory pressures but also aligns with growing consumer demand for sustainably produced goods. The development and implementation of greener extraction technologies will be crucial in balancing industrial needs with environmental stewardship in the coming years.

Economic Feasibility of Improved Extraction Methods

The economic feasibility of improved carboxylic acid extraction methods is a critical consideration for industrial applications. Traditional extraction processes often involve high energy consumption, significant solvent usage, and substantial operational costs. Improved extraction techniques aim to address these challenges while enhancing efficiency and yield.

One of the most promising approaches is the development of novel solvents with higher selectivity and capacity for carboxylic acids. These advanced solvents can potentially reduce the number of extraction stages required, thereby lowering energy consumption and operational expenses. For instance, ionic liquids have shown remarkable potential in this regard, offering enhanced extraction efficiency and the ability to be recycled multiple times, which could significantly reduce solvent replacement costs.

Membrane-based extraction technologies represent another economically viable improvement. These systems can operate continuously and require less energy compared to conventional liquid-liquid extraction methods. The initial investment in membrane technology may be higher, but the long-term operational costs are often lower due to reduced energy and solvent consumption. Additionally, membrane processes can be more easily scaled up or down, providing flexibility in production capacity.

Supercritical fluid extraction, particularly using CO2, is gaining attention for its potential economic benefits. While the initial setup costs are considerable, the process offers several advantages that can offset these expenses over time. Supercritical CO2 extraction typically results in higher purity products, reducing downstream processing costs. Moreover, CO2 is inexpensive, non-toxic, and can be easily recycled, leading to lower ongoing operational expenses.

The integration of process intensification techniques, such as reactive extraction or extractive distillation, can also improve the economic viability of carboxylic acid extraction. These methods combine reaction and separation steps, potentially reducing equipment costs and energy consumption. By optimizing process parameters and utilizing advanced control systems, these integrated processes can achieve higher yields and purities with lower resource inputs.

From an economic standpoint, the implementation of improved extraction methods must be evaluated in terms of capital expenditure (CAPEX) versus operational expenditure (OPEX) trade-offs. While some advanced technologies may require significant upfront investment, their long-term benefits in terms of reduced energy consumption, increased yield, and improved product quality can lead to substantial cost savings over the lifecycle of the operation. Additionally, as environmental regulations become more stringent, improved extraction methods that reduce waste and emissions may become economically advantageous due to reduced compliance costs and potential tax incentives.

One of the most promising approaches is the development of novel solvents with higher selectivity and capacity for carboxylic acids. These advanced solvents can potentially reduce the number of extraction stages required, thereby lowering energy consumption and operational expenses. For instance, ionic liquids have shown remarkable potential in this regard, offering enhanced extraction efficiency and the ability to be recycled multiple times, which could significantly reduce solvent replacement costs.

Membrane-based extraction technologies represent another economically viable improvement. These systems can operate continuously and require less energy compared to conventional liquid-liquid extraction methods. The initial investment in membrane technology may be higher, but the long-term operational costs are often lower due to reduced energy and solvent consumption. Additionally, membrane processes can be more easily scaled up or down, providing flexibility in production capacity.

Supercritical fluid extraction, particularly using CO2, is gaining attention for its potential economic benefits. While the initial setup costs are considerable, the process offers several advantages that can offset these expenses over time. Supercritical CO2 extraction typically results in higher purity products, reducing downstream processing costs. Moreover, CO2 is inexpensive, non-toxic, and can be easily recycled, leading to lower ongoing operational expenses.

The integration of process intensification techniques, such as reactive extraction or extractive distillation, can also improve the economic viability of carboxylic acid extraction. These methods combine reaction and separation steps, potentially reducing equipment costs and energy consumption. By optimizing process parameters and utilizing advanced control systems, these integrated processes can achieve higher yields and purities with lower resource inputs.

From an economic standpoint, the implementation of improved extraction methods must be evaluated in terms of capital expenditure (CAPEX) versus operational expenditure (OPEX) trade-offs. While some advanced technologies may require significant upfront investment, their long-term benefits in terms of reduced energy consumption, increased yield, and improved product quality can lead to substantial cost savings over the lifecycle of the operation. Additionally, as environmental regulations become more stringent, improved extraction methods that reduce waste and emissions may become economically advantageous due to reduced compliance costs and potential tax incentives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!