How to Improve Productivity in HEV R&D Initiatives?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV R&D Landscape and Objectives

The landscape of Hybrid Electric Vehicle (HEV) research and development has evolved significantly over the past two decades, driven by the urgent need for more sustainable transportation solutions. The primary objective in this field is to enhance the overall efficiency and performance of HEVs while reducing costs and environmental impact. This goal encompasses improvements in powertrain design, energy management systems, and manufacturing processes.

As global concerns about climate change and energy security intensify, the HEV R&D sector has seen a surge in investment and innovation. Major automotive manufacturers, tech companies, and startups are all vying to develop cutting-edge HEV technologies. The focus has shifted from simply combining electric and combustion engines to creating sophisticated systems that optimize energy use, reduce emissions, and provide a seamless driving experience.

One of the key objectives in HEV R&D is to improve battery technology. This includes developing batteries with higher energy density, longer lifespan, and faster charging capabilities. Researchers are exploring new materials and chemistries, such as solid-state batteries, to overcome the limitations of current lithium-ion technology. Alongside battery development, there is a strong emphasis on enhancing power electronics and electric motor efficiency to maximize the overall system performance.

Another critical area of focus is the integration of advanced control systems and artificial intelligence. These technologies aim to optimize the interplay between the electric and combustion components of HEVs, adapting to driving conditions and user behavior in real-time. This not only improves fuel efficiency but also enhances the driving experience and vehicle longevity.

Manufacturing processes and supply chain optimization are also key objectives in HEV R&D. As demand for HEVs grows, there is a pressing need to develop more efficient and cost-effective production methods. This includes exploring new materials, such as lightweight composites, and implementing advanced manufacturing techniques like 3D printing for complex components.

The HEV R&D landscape is also shaped by regulatory frameworks and government incentives. Many countries have set ambitious targets for reducing vehicle emissions, driving research into more efficient and cleaner HEV technologies. This regulatory push has accelerated the pace of innovation and is steering the industry towards more radical solutions, such as fuel cell hybrid vehicles.

Collaboration has become a hallmark of HEV R&D initiatives. Automakers are partnering with tech companies, academic institutions, and even competitors to share costs and accelerate innovation. This collaborative approach is essential for addressing the complex challenges in HEV development and for bringing new technologies to market more quickly.

As global concerns about climate change and energy security intensify, the HEV R&D sector has seen a surge in investment and innovation. Major automotive manufacturers, tech companies, and startups are all vying to develop cutting-edge HEV technologies. The focus has shifted from simply combining electric and combustion engines to creating sophisticated systems that optimize energy use, reduce emissions, and provide a seamless driving experience.

One of the key objectives in HEV R&D is to improve battery technology. This includes developing batteries with higher energy density, longer lifespan, and faster charging capabilities. Researchers are exploring new materials and chemistries, such as solid-state batteries, to overcome the limitations of current lithium-ion technology. Alongside battery development, there is a strong emphasis on enhancing power electronics and electric motor efficiency to maximize the overall system performance.

Another critical area of focus is the integration of advanced control systems and artificial intelligence. These technologies aim to optimize the interplay between the electric and combustion components of HEVs, adapting to driving conditions and user behavior in real-time. This not only improves fuel efficiency but also enhances the driving experience and vehicle longevity.

Manufacturing processes and supply chain optimization are also key objectives in HEV R&D. As demand for HEVs grows, there is a pressing need to develop more efficient and cost-effective production methods. This includes exploring new materials, such as lightweight composites, and implementing advanced manufacturing techniques like 3D printing for complex components.

The HEV R&D landscape is also shaped by regulatory frameworks and government incentives. Many countries have set ambitious targets for reducing vehicle emissions, driving research into more efficient and cleaner HEV technologies. This regulatory push has accelerated the pace of innovation and is steering the industry towards more radical solutions, such as fuel cell hybrid vehicles.

Collaboration has become a hallmark of HEV R&D initiatives. Automakers are partnering with tech companies, academic institutions, and even competitors to share costs and accelerate innovation. This collaborative approach is essential for addressing the complex challenges in HEV development and for bringing new technologies to market more quickly.

Market Demand Analysis for HEVs

The market demand for Hybrid Electric Vehicles (HEVs) has been steadily growing over the past decade, driven by increasing environmental awareness, stricter emissions regulations, and rising fuel costs. This trend is expected to continue in the foreseeable future, with the global HEV market projected to expand significantly.

Consumer preferences are shifting towards more fuel-efficient and environmentally friendly vehicles, making HEVs an attractive option for many buyers. The combination of internal combustion engines and electric motors in HEVs offers improved fuel economy and reduced emissions compared to conventional vehicles, while addressing range anxiety concerns associated with fully electric vehicles.

Government policies and incentives play a crucial role in shaping the HEV market. Many countries have implemented tax breaks, subsidies, and other incentives to promote the adoption of hybrid vehicles. These measures have been particularly effective in markets such as Europe, Japan, and parts of North America, where stringent emissions standards are driving automakers to invest heavily in hybrid technology.

The commercial sector is also showing increased interest in HEVs, particularly for fleet operations. Companies are recognizing the potential for long-term cost savings through reduced fuel consumption and lower maintenance requirements of hybrid vehicles. This trend is especially prominent in industries such as logistics, taxi services, and public transportation.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for HEVs, with China and Japan leading the way. The European market is also showing strong growth potential, driven by strict emissions regulations and consumer demand for greener transportation options.

However, the HEV market faces competition from fully electric vehicles (EVs) and improving conventional internal combustion engine vehicles. As battery technology advances and EV charging infrastructure expands, some consumers may opt for fully electric options. This competition underscores the importance of continuous innovation in HEV technology to maintain its market position.

The demand for HEVs is closely tied to advancements in battery technology, power electronics, and drivetrain efficiency. As these technologies improve, the performance and cost-effectiveness of HEVs are expected to increase, potentially expanding their market appeal.

In conclusion, the market demand for HEVs remains strong, driven by environmental concerns, regulatory pressures, and economic factors. To capitalize on this demand and improve productivity in HEV R&D initiatives, manufacturers must focus on enhancing vehicle performance, reducing costs, and addressing evolving consumer preferences. This will require ongoing investment in research and development, as well as strategic partnerships across the automotive and technology sectors.

Consumer preferences are shifting towards more fuel-efficient and environmentally friendly vehicles, making HEVs an attractive option for many buyers. The combination of internal combustion engines and electric motors in HEVs offers improved fuel economy and reduced emissions compared to conventional vehicles, while addressing range anxiety concerns associated with fully electric vehicles.

Government policies and incentives play a crucial role in shaping the HEV market. Many countries have implemented tax breaks, subsidies, and other incentives to promote the adoption of hybrid vehicles. These measures have been particularly effective in markets such as Europe, Japan, and parts of North America, where stringent emissions standards are driving automakers to invest heavily in hybrid technology.

The commercial sector is also showing increased interest in HEVs, particularly for fleet operations. Companies are recognizing the potential for long-term cost savings through reduced fuel consumption and lower maintenance requirements of hybrid vehicles. This trend is especially prominent in industries such as logistics, taxi services, and public transportation.

Market analysis indicates that the Asia-Pacific region is expected to be the fastest-growing market for HEVs, with China and Japan leading the way. The European market is also showing strong growth potential, driven by strict emissions regulations and consumer demand for greener transportation options.

However, the HEV market faces competition from fully electric vehicles (EVs) and improving conventional internal combustion engine vehicles. As battery technology advances and EV charging infrastructure expands, some consumers may opt for fully electric options. This competition underscores the importance of continuous innovation in HEV technology to maintain its market position.

The demand for HEVs is closely tied to advancements in battery technology, power electronics, and drivetrain efficiency. As these technologies improve, the performance and cost-effectiveness of HEVs are expected to increase, potentially expanding their market appeal.

In conclusion, the market demand for HEVs remains strong, driven by environmental concerns, regulatory pressures, and economic factors. To capitalize on this demand and improve productivity in HEV R&D initiatives, manufacturers must focus on enhancing vehicle performance, reducing costs, and addressing evolving consumer preferences. This will require ongoing investment in research and development, as well as strategic partnerships across the automotive and technology sectors.

Current Challenges in HEV R&D

The development of Hybrid Electric Vehicles (HEVs) faces several significant challenges that impact productivity in research and development initiatives. One of the primary obstacles is the complexity of integrating multiple powertrain systems. HEVs require seamless coordination between internal combustion engines and electric motors, which demands extensive testing and optimization to achieve optimal performance and efficiency.

Battery technology remains a critical bottleneck in HEV development. Researchers struggle to balance energy density, longevity, safety, and cost-effectiveness. The pursuit of advanced battery chemistries and improved thermal management systems consumes substantial time and resources, often leading to delays in product development cycles.

Another challenge lies in the realm of power electronics and control systems. As HEVs become more sophisticated, the complexity of their electronic control units (ECUs) increases exponentially. Developing robust software algorithms for energy management, regenerative braking, and powertrain control requires extensive simulation and real-world testing, which can be time-consuming and resource-intensive.

Weight reduction and packaging constraints present ongoing difficulties for HEV engineers. The need to accommodate both conventional and electric powertrain components within limited vehicle space while maintaining optimal weight distribution poses significant design challenges. This often necessitates multiple iterations and compromises, impacting overall development timelines.

Regulatory compliance and emissions standards add another layer of complexity to HEV R&D. As global emissions regulations become increasingly stringent, manufacturers must invest heavily in advanced emissions control technologies and conduct extensive testing to ensure compliance across various markets. This regulatory burden can divert resources from other areas of innovation and slow down the overall development process.

Supply chain management and component sourcing also present challenges in HEV development. The reliance on specialized components, such as rare earth magnets for electric motors and advanced battery materials, can lead to supply chain vulnerabilities and potential production bottlenecks. Securing stable, cost-effective supply chains for these critical components requires significant effort and strategic planning.

Lastly, the rapid pace of technological advancement in the automotive industry creates a moving target for HEV developers. Emerging technologies such as artificial intelligence, advanced driver assistance systems (ADAS), and vehicle-to-everything (V2X) communication must be integrated into HEV platforms, adding further complexity to the development process and requiring continuous upskilling of the R&D workforce.

Battery technology remains a critical bottleneck in HEV development. Researchers struggle to balance energy density, longevity, safety, and cost-effectiveness. The pursuit of advanced battery chemistries and improved thermal management systems consumes substantial time and resources, often leading to delays in product development cycles.

Another challenge lies in the realm of power electronics and control systems. As HEVs become more sophisticated, the complexity of their electronic control units (ECUs) increases exponentially. Developing robust software algorithms for energy management, regenerative braking, and powertrain control requires extensive simulation and real-world testing, which can be time-consuming and resource-intensive.

Weight reduction and packaging constraints present ongoing difficulties for HEV engineers. The need to accommodate both conventional and electric powertrain components within limited vehicle space while maintaining optimal weight distribution poses significant design challenges. This often necessitates multiple iterations and compromises, impacting overall development timelines.

Regulatory compliance and emissions standards add another layer of complexity to HEV R&D. As global emissions regulations become increasingly stringent, manufacturers must invest heavily in advanced emissions control technologies and conduct extensive testing to ensure compliance across various markets. This regulatory burden can divert resources from other areas of innovation and slow down the overall development process.

Supply chain management and component sourcing also present challenges in HEV development. The reliance on specialized components, such as rare earth magnets for electric motors and advanced battery materials, can lead to supply chain vulnerabilities and potential production bottlenecks. Securing stable, cost-effective supply chains for these critical components requires significant effort and strategic planning.

Lastly, the rapid pace of technological advancement in the automotive industry creates a moving target for HEV developers. Emerging technologies such as artificial intelligence, advanced driver assistance systems (ADAS), and vehicle-to-everything (V2X) communication must be integrated into HEV platforms, adding further complexity to the development process and requiring continuous upskilling of the R&D workforce.

Existing R&D Productivity Solutions

01 Improving R&D productivity through data analysis

Utilizing data analysis techniques to enhance research and development productivity in the HEV sector. This involves analyzing large datasets to identify trends, optimize processes, and make informed decisions, ultimately leading to more efficient and effective R&D efforts.- Improving R&D productivity through data analysis and management: Enhancing R&D productivity in HEV development by implementing advanced data analysis techniques and management systems. This approach involves utilizing big data analytics, machine learning algorithms, and integrated software platforms to streamline research processes, identify trends, and make data-driven decisions.

- Collaborative R&D strategies for HEV technology: Fostering collaboration between automotive manufacturers, suppliers, and research institutions to accelerate HEV R&D productivity. This strategy involves sharing resources, expertise, and research findings to overcome technical challenges and reduce development costs.

- Optimizing HEV powertrain design and integration: Focusing on the optimization of HEV powertrain design and integration to improve overall R&D productivity. This includes developing more efficient electric motors, advanced battery technologies, and intelligent power management systems to enhance vehicle performance and reduce development time.

- Simulation and virtual testing for HEV development: Utilizing advanced simulation tools and virtual testing environments to accelerate HEV R&D productivity. This approach allows for rapid prototyping, performance evaluation, and optimization of HEV components and systems without the need for extensive physical testing.

- Standardization and modular design in HEV R&D: Implementing standardization and modular design principles in HEV development to improve R&D productivity. This strategy involves creating common platforms, standardized components, and interchangeable modules that can be easily adapted for different HEV models, reducing development time and costs.

02 Collaborative R&D platforms for HEV technology

Implementing collaborative platforms that facilitate knowledge sharing and joint research efforts among various stakeholders in the HEV industry. These platforms can help streamline the R&D process, reduce duplication of efforts, and accelerate innovation in HEV technology.Expand Specific Solutions03 Advanced simulation and modeling for HEV development

Employing sophisticated simulation and modeling tools to optimize HEV design and performance before physical prototyping. This approach can significantly reduce development time and costs while improving the overall quality of HEV systems.Expand Specific Solutions04 Integration of AI and machine learning in HEV R&D

Incorporating artificial intelligence and machine learning algorithms into the HEV research and development process. These technologies can help identify patterns, predict outcomes, and optimize various aspects of HEV design and performance, leading to increased R&D productivity.Expand Specific Solutions05 Rapid prototyping and testing methodologies for HEV components

Implementing rapid prototyping and testing methodologies to accelerate the development cycle of HEV components. This approach allows for faster iteration and validation of designs, reducing time-to-market and improving overall R&D productivity in the HEV sector.Expand Specific Solutions

Key Players in HEV R&D

The competition landscape for improving productivity in HEV R&D initiatives is characterized by a mature market with significant growth potential. Major automotive manufacturers like Toyota, Ford, GM, and Hyundai are leading the charge, leveraging their extensive R&D capabilities and global resources. Chinese companies such as BYD, Chery, and Great Wall Motor are rapidly advancing, particularly in battery technology. The market is seeing increased collaboration between traditional automakers and tech companies, as well as investments in startups. With the global push towards electrification, the HEV sector is experiencing accelerated technological advancements, focusing on improving battery efficiency, reducing costs, and enhancing overall vehicle performance.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to improve HEV R&D productivity. They utilize advanced simulation tools and virtual testing environments to reduce physical prototype development time by up to 50%[1]. Their integrated development process combines powertrain, battery, and control system design, allowing for simultaneous optimization. Toyota's "Toyota New Global Architecture" (TNGA) platform standardizes HEV components across multiple models, reducing development costs by 20% and time-to-market by 30%[2]. They also employ AI and machine learning algorithms to analyze vast amounts of test data, identifying performance trends and potential issues early in the development cycle[3].

Strengths: Industry-leading HEV expertise, extensive R&D resources, and a proven track record of innovation. Weaknesses: High development costs and potential over-reliance on hybrid technology in a rapidly evolving EV market.

BYD Co., Ltd.

Technical Solution: BYD has implemented a vertically integrated R&D approach for HEV development, focusing on in-house production of key components. Their "Blade Battery" technology, which improves energy density and safety, has reduced battery development time by 40%[4]. BYD's "DM-i" super hybrid system integrates electric motors and internal combustion engines more efficiently, cutting fuel consumption by up to 75% compared to conventional vehicles[5]. They utilize advanced CAD/CAE tools and rapid prototyping techniques, reducing the design-to-production cycle by 35%. BYD also employs a modular design philosophy, allowing for quick adaptation of HEV powertrains across multiple vehicle platforms[6].

Strengths: Vertical integration allows for better control over the supply chain and faster innovation cycles. Weaknesses: Limited global presence compared to some competitors may restrict access to certain markets and technologies.

Innovative HEV R&D Methodologies

Hybrid electric vehicle with electric motor providing strategic power assist to load balance internal combustion engine

PatentPendingIN202441000035A

Innovation

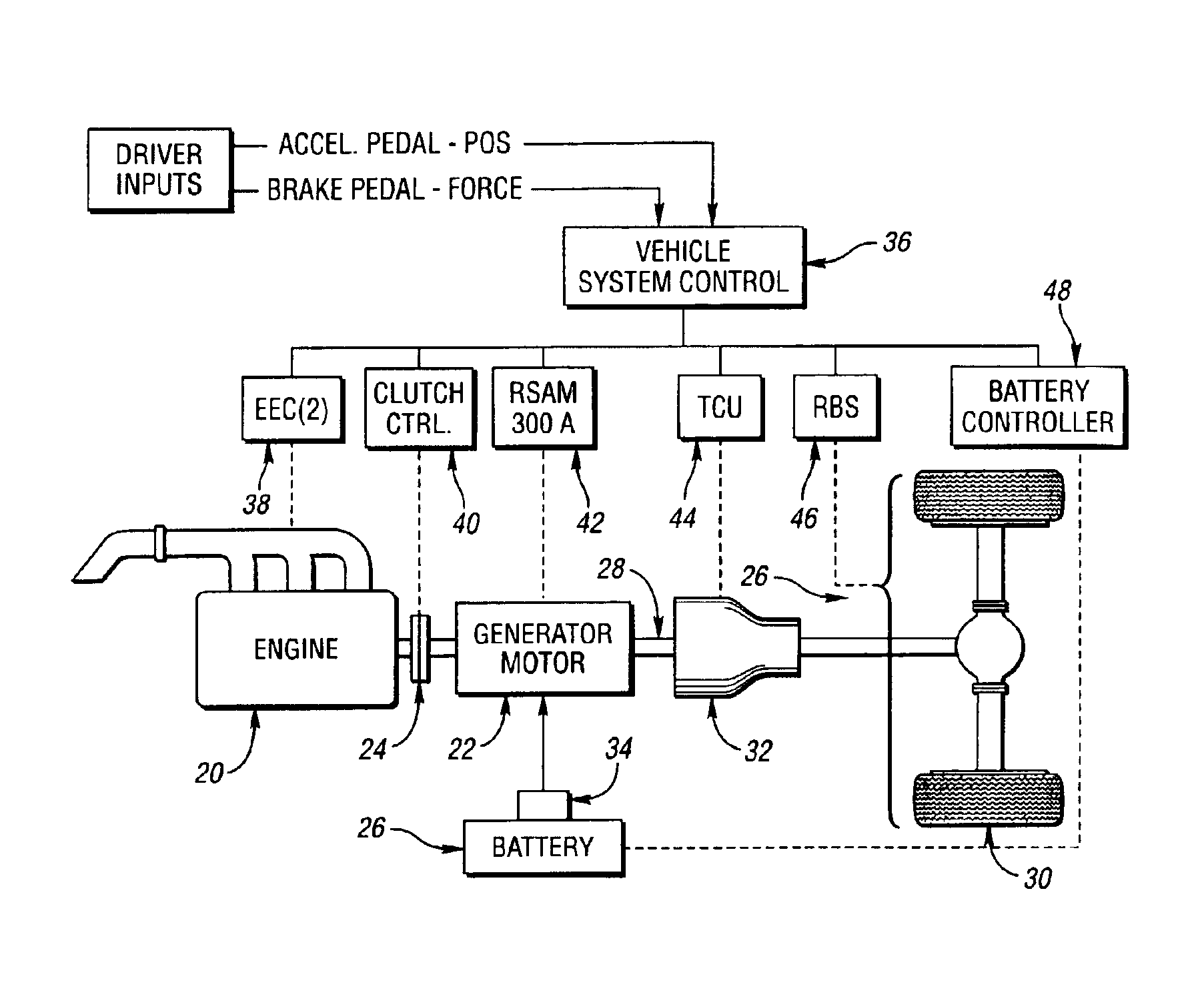

- A Hybrid Electric Vehicle (HEV) system with an electric motor providing strategic power assist to the internal combustion engine, optimizing power distribution and energy management through advanced control algorithms.

Control system for a hybrid electric vehicle to anticipate the need for a mode change

PatentInactiveUS7021409B2

Innovation

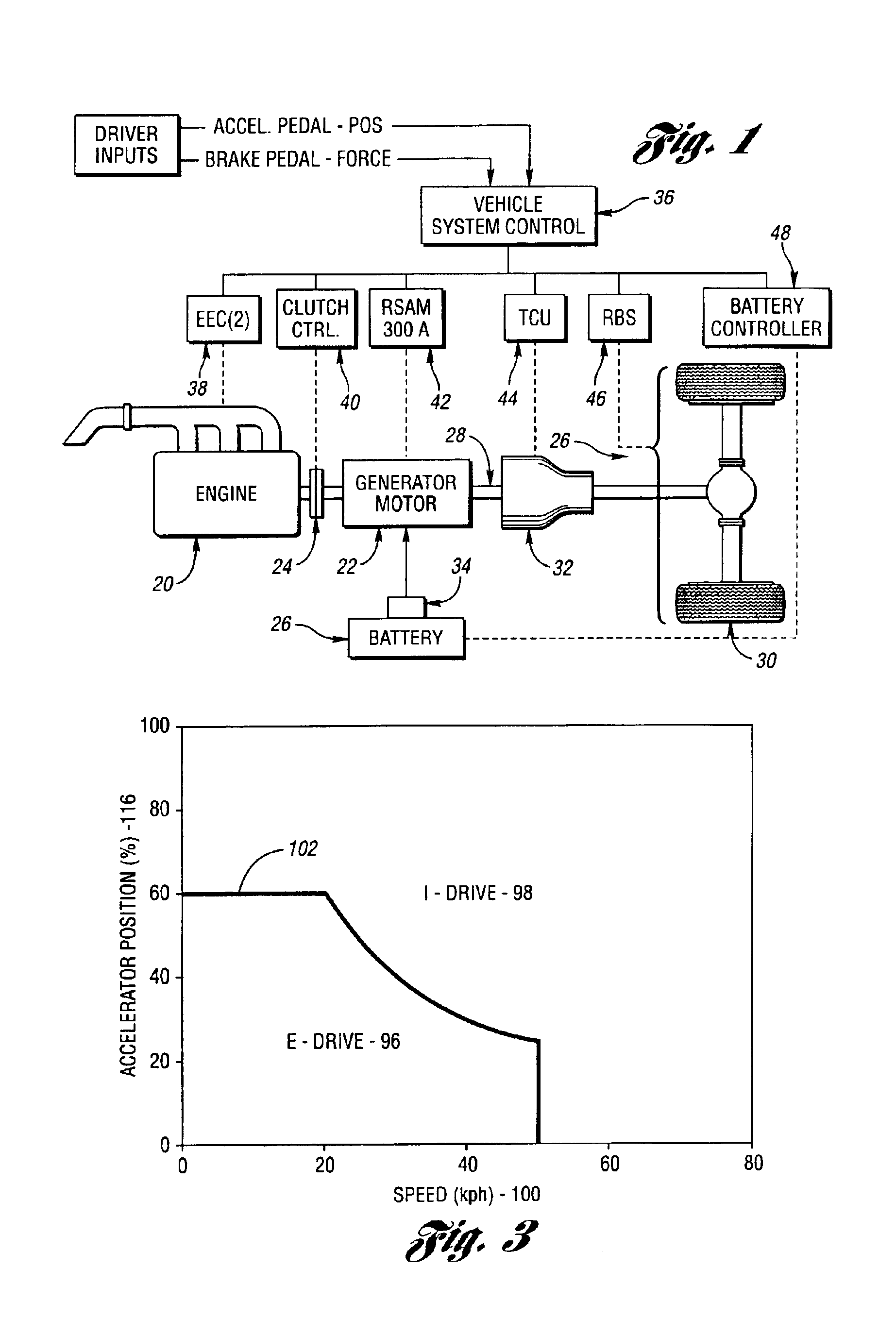

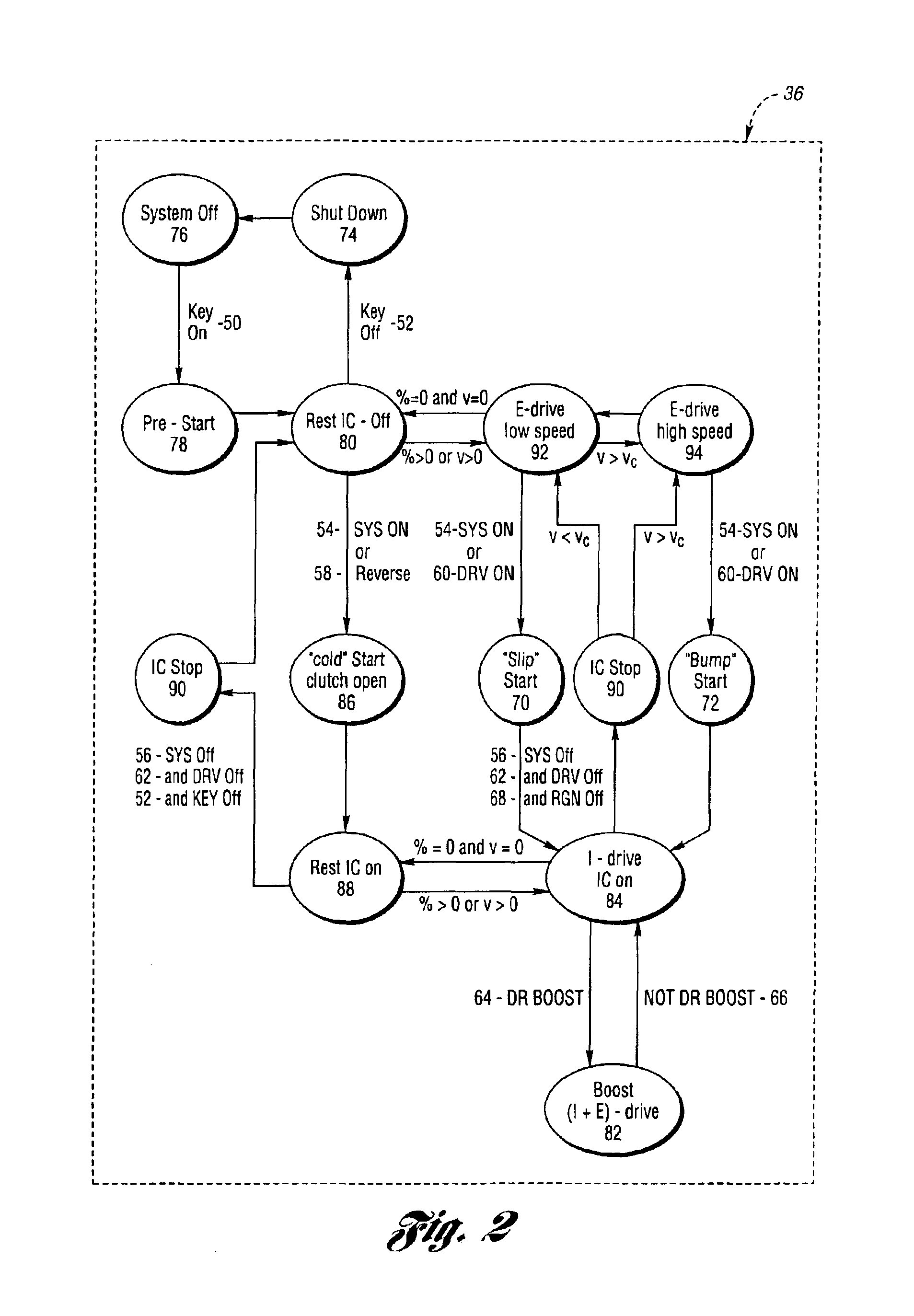

- A control strategy that monitors vehicle speed, driver demand, and their rates of change to anticipate and optimize engine state transitions, preventing undesired engine starts and performance lags by calculating the time remaining to meet driver demand and executing transitions smoothly, using a mathematical function of system variables like master cylinder brake pressure, throttle position, vehicle speed, and road grade.

Regulatory Framework for HEV Development

The regulatory framework for Hybrid Electric Vehicle (HEV) development plays a crucial role in shaping the research and development initiatives in this sector. Governments worldwide have implemented various policies and regulations to promote the adoption of HEVs and reduce greenhouse gas emissions from the transportation sector.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a significant driver for HEV development. These standards require automakers to improve the fuel efficiency of their vehicle fleets progressively. The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly administer these regulations, which have led to increased investment in HEV technologies.

The European Union has also established stringent CO2 emission targets for new vehicles. The EU's regulation (EU) 2019/631 sets CO2 emission performance standards for new passenger cars and light commercial vehicles. These standards have created a strong incentive for automotive manufacturers to invest in HEV technologies to meet the increasingly stringent emission targets.

In China, the world's largest automotive market, the government has implemented a dual-credit policy that combines Corporate Average Fuel Consumption (CAFC) credits and New Energy Vehicle (NEV) credits. This policy encourages automakers to produce more fuel-efficient vehicles, including HEVs, to meet their credit requirements.

Tax incentives and subsidies have been widely used to promote HEV adoption. Many countries offer tax credits, rebates, or reduced registration fees for HEV purchases. These financial incentives have helped to offset the higher initial costs of HEVs and stimulate consumer demand, which in turn drives R&D efforts.

Regulatory bodies have also established specific safety standards for HEVs. For instance, the United Nations Economic Commission for Europe (UNECE) has developed regulations such as UN Regulation No. 100, which addresses the safety requirements for electric power train of road vehicles. These safety regulations ensure that HEV technologies are developed with a focus on passenger and pedestrian safety.

The regulatory landscape for HEV development is dynamic and continues to evolve. Many countries are now shifting their focus towards full electric vehicles, which may impact future regulations for HEVs. However, HEVs are likely to remain an important transitional technology in the medium term, and regulations will continue to play a crucial role in driving innovation and productivity in HEV R&D initiatives.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a significant driver for HEV development. These standards require automakers to improve the fuel efficiency of their vehicle fleets progressively. The Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly administer these regulations, which have led to increased investment in HEV technologies.

The European Union has also established stringent CO2 emission targets for new vehicles. The EU's regulation (EU) 2019/631 sets CO2 emission performance standards for new passenger cars and light commercial vehicles. These standards have created a strong incentive for automotive manufacturers to invest in HEV technologies to meet the increasingly stringent emission targets.

In China, the world's largest automotive market, the government has implemented a dual-credit policy that combines Corporate Average Fuel Consumption (CAFC) credits and New Energy Vehicle (NEV) credits. This policy encourages automakers to produce more fuel-efficient vehicles, including HEVs, to meet their credit requirements.

Tax incentives and subsidies have been widely used to promote HEV adoption. Many countries offer tax credits, rebates, or reduced registration fees for HEV purchases. These financial incentives have helped to offset the higher initial costs of HEVs and stimulate consumer demand, which in turn drives R&D efforts.

Regulatory bodies have also established specific safety standards for HEVs. For instance, the United Nations Economic Commission for Europe (UNECE) has developed regulations such as UN Regulation No. 100, which addresses the safety requirements for electric power train of road vehicles. These safety regulations ensure that HEV technologies are developed with a focus on passenger and pedestrian safety.

The regulatory landscape for HEV development is dynamic and continues to evolve. Many countries are now shifting their focus towards full electric vehicles, which may impact future regulations for HEVs. However, HEVs are likely to remain an important transitional technology in the medium term, and regulations will continue to play a crucial role in driving innovation and productivity in HEV R&D initiatives.

Collaborative R&D Ecosystems

Collaborative R&D ecosystems have emerged as a powerful approach to accelerate innovation and improve productivity in Hybrid Electric Vehicle (HEV) research and development initiatives. These ecosystems bring together diverse stakeholders, including automotive manufacturers, suppliers, research institutions, and technology partners, to collectively address the complex challenges associated with HEV development.

One of the key advantages of collaborative R&D ecosystems is the pooling of resources and expertise. By leveraging the strengths of multiple organizations, HEV developers can access a wider range of specialized knowledge, advanced technologies, and cutting-edge research facilities. This collaborative approach enables faster problem-solving and reduces redundancy in research efforts, ultimately leading to improved productivity and accelerated time-to-market for new HEV technologies.

Furthermore, collaborative ecosystems foster open innovation and knowledge sharing. Through regular meetings, workshops, and joint research projects, participants can exchange ideas, share best practices, and collectively overcome technical hurdles. This cross-pollination of ideas often leads to breakthrough innovations that may not have been possible within the confines of a single organization.

The establishment of standardized platforms and protocols within collaborative ecosystems can significantly streamline HEV R&D processes. By developing common interfaces, testing methodologies, and data-sharing frameworks, ecosystem partners can reduce integration challenges and accelerate the validation of new technologies. This standardization also promotes interoperability between different components and systems, facilitating more efficient development cycles.

Collaborative R&D ecosystems also provide opportunities for risk-sharing and cost reduction. By distributing the financial burden of research and development across multiple partners, individual organizations can pursue more ambitious projects and explore higher-risk, higher-reward innovations. This shared approach to R&D investment can lead to more rapid advancements in HEV technology while mitigating the financial risks associated with cutting-edge research.

Moreover, these ecosystems often attract government support and funding, as they align with broader policy objectives related to sustainable transportation and energy efficiency. Public-private partnerships within collaborative R&D ecosystems can unlock additional resources and create a more favorable regulatory environment for HEV innovation.

In conclusion, collaborative R&D ecosystems offer a powerful framework for improving productivity in HEV research and development initiatives. By fostering collaboration, knowledge sharing, and resource optimization, these ecosystems can accelerate innovation, reduce costs, and ultimately drive the advancement of HEV technology to meet the growing demand for sustainable transportation solutions.

One of the key advantages of collaborative R&D ecosystems is the pooling of resources and expertise. By leveraging the strengths of multiple organizations, HEV developers can access a wider range of specialized knowledge, advanced technologies, and cutting-edge research facilities. This collaborative approach enables faster problem-solving and reduces redundancy in research efforts, ultimately leading to improved productivity and accelerated time-to-market for new HEV technologies.

Furthermore, collaborative ecosystems foster open innovation and knowledge sharing. Through regular meetings, workshops, and joint research projects, participants can exchange ideas, share best practices, and collectively overcome technical hurdles. This cross-pollination of ideas often leads to breakthrough innovations that may not have been possible within the confines of a single organization.

The establishment of standardized platforms and protocols within collaborative ecosystems can significantly streamline HEV R&D processes. By developing common interfaces, testing methodologies, and data-sharing frameworks, ecosystem partners can reduce integration challenges and accelerate the validation of new technologies. This standardization also promotes interoperability between different components and systems, facilitating more efficient development cycles.

Collaborative R&D ecosystems also provide opportunities for risk-sharing and cost reduction. By distributing the financial burden of research and development across multiple partners, individual organizations can pursue more ambitious projects and explore higher-risk, higher-reward innovations. This shared approach to R&D investment can lead to more rapid advancements in HEV technology while mitigating the financial risks associated with cutting-edge research.

Moreover, these ecosystems often attract government support and funding, as they align with broader policy objectives related to sustainable transportation and energy efficiency. Public-private partnerships within collaborative R&D ecosystems can unlock additional resources and create a more favorable regulatory environment for HEV innovation.

In conclusion, collaborative R&D ecosystems offer a powerful framework for improving productivity in HEV research and development initiatives. By fostering collaboration, knowledge sharing, and resource optimization, these ecosystems can accelerate innovation, reduce costs, and ultimately drive the advancement of HEV technology to meet the growing demand for sustainable transportation solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!