How to Maximize CMOS Battery Output in Embedded Systems?

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Evolution

The evolution of CMOS batteries in embedded systems has been a critical factor in the advancement of portable and low-power electronic devices. Initially introduced in the 1980s, CMOS (Complementary Metal-Oxide-Semiconductor) batteries were primarily used to maintain system clock and BIOS settings in personal computers. Over time, their application expanded to various embedded systems, playing a crucial role in maintaining critical data and settings during power-off periods.

In the early stages, CMOS batteries were typically non-rechargeable lithium coin cells, such as the CR2032, which provided a stable voltage output but had limited capacity. As embedded systems became more complex and energy-demanding, the need for improved battery performance became apparent. This led to the development of rechargeable CMOS batteries, often based on lithium-ion or lithium-polymer technologies, which offered higher capacity and the ability to be recharged by the main system power.

The miniaturization trend in embedded systems has driven the evolution of CMOS batteries towards smaller form factors without compromising performance. This has resulted in the creation of thin-film batteries and solid-state batteries, which can be integrated directly into circuit boards, saving valuable space in compact devices. These advanced batteries offer improved energy density and longer lifespan compared to their predecessors.

Another significant development in CMOS battery technology has been the integration of power management circuits. These circuits optimize battery usage by implementing intelligent charging algorithms, voltage regulation, and power-saving modes. This integration has led to more efficient use of battery capacity and extended the operational life of embedded systems.

Recent advancements have focused on enhancing the environmental sustainability of CMOS batteries. Manufacturers are exploring alternative materials and designs that reduce the environmental impact of battery production and disposal. This includes the development of bio-degradable batteries and the use of less toxic materials in battery construction.

The evolution of CMOS batteries has also been influenced by the growing demand for Internet of Things (IoT) devices. These devices often require long-term, low-power operation, pushing battery technology towards ultra-low-power designs and energy harvesting capabilities. Some modern CMOS batteries now incorporate energy harvesting technologies, such as photovoltaic cells or thermoelectric generators, to supplement or even replace traditional battery power in certain applications.

As embedded systems continue to evolve, CMOS battery technology is expected to advance further, with a focus on increased energy density, faster charging capabilities, and improved integration with system-on-chip designs. The ongoing research in nanotechnology and advanced materials promises to bring about new breakthroughs in CMOS battery performance, potentially revolutionizing the power management landscape in embedded systems.

In the early stages, CMOS batteries were typically non-rechargeable lithium coin cells, such as the CR2032, which provided a stable voltage output but had limited capacity. As embedded systems became more complex and energy-demanding, the need for improved battery performance became apparent. This led to the development of rechargeable CMOS batteries, often based on lithium-ion or lithium-polymer technologies, which offered higher capacity and the ability to be recharged by the main system power.

The miniaturization trend in embedded systems has driven the evolution of CMOS batteries towards smaller form factors without compromising performance. This has resulted in the creation of thin-film batteries and solid-state batteries, which can be integrated directly into circuit boards, saving valuable space in compact devices. These advanced batteries offer improved energy density and longer lifespan compared to their predecessors.

Another significant development in CMOS battery technology has been the integration of power management circuits. These circuits optimize battery usage by implementing intelligent charging algorithms, voltage regulation, and power-saving modes. This integration has led to more efficient use of battery capacity and extended the operational life of embedded systems.

Recent advancements have focused on enhancing the environmental sustainability of CMOS batteries. Manufacturers are exploring alternative materials and designs that reduce the environmental impact of battery production and disposal. This includes the development of bio-degradable batteries and the use of less toxic materials in battery construction.

The evolution of CMOS batteries has also been influenced by the growing demand for Internet of Things (IoT) devices. These devices often require long-term, low-power operation, pushing battery technology towards ultra-low-power designs and energy harvesting capabilities. Some modern CMOS batteries now incorporate energy harvesting technologies, such as photovoltaic cells or thermoelectric generators, to supplement or even replace traditional battery power in certain applications.

As embedded systems continue to evolve, CMOS battery technology is expected to advance further, with a focus on increased energy density, faster charging capabilities, and improved integration with system-on-chip designs. The ongoing research in nanotechnology and advanced materials promises to bring about new breakthroughs in CMOS battery performance, potentially revolutionizing the power management landscape in embedded systems.

Embedded Power Demands

Embedded systems are increasingly prevalent in various industries, from consumer electronics to industrial automation. As these systems become more complex and feature-rich, their power demands have grown significantly. The challenge of maximizing CMOS battery output in embedded systems is directly linked to the evolving power requirements of these devices.

Modern embedded systems often incorporate advanced processors, wireless connectivity, sensors, and other power-hungry components. These elements contribute to enhanced functionality but also place considerable strain on the power supply. The trend towards miniaturization further complicates this issue, as smaller form factors limit the physical size of batteries that can be used.

One of the primary drivers of increased power demand is the push for always-on functionality. Many embedded systems are expected to maintain constant connectivity or perform background tasks even when not actively in use. This requirement necessitates careful power management strategies to extend battery life while meeting performance expectations.

The Internet of Things (IoT) has also played a significant role in shaping embedded power demands. IoT devices often operate in remote or hard-to-reach locations, making frequent battery replacement impractical. As a result, there is a growing need for embedded systems that can operate for extended periods on a single battery charge or utilize energy harvesting techniques to supplement their power supply.

Another factor contributing to increased power demands is the integration of artificial intelligence and machine learning capabilities into embedded systems. These computationally intensive tasks require substantial processing power, which in turn leads to higher energy consumption. Balancing the desire for advanced AI features with the constraints of battery-powered operation presents a significant challenge for embedded system designers.

The automotive industry has also been a major driver of embedded power demands, particularly with the rise of electric and autonomous vehicles. These systems require a multitude of sensors, processors, and communication modules, all of which must operate reliably under varying conditions while drawing power from the vehicle's battery.

As embedded systems continue to evolve, addressing their power demands becomes increasingly critical. This necessitates a multi-faceted approach, combining advancements in battery technology, more efficient power management techniques, and innovative system design strategies. The goal is to create embedded systems that can deliver the required functionality and performance while maximizing battery life and minimizing power consumption.

Modern embedded systems often incorporate advanced processors, wireless connectivity, sensors, and other power-hungry components. These elements contribute to enhanced functionality but also place considerable strain on the power supply. The trend towards miniaturization further complicates this issue, as smaller form factors limit the physical size of batteries that can be used.

One of the primary drivers of increased power demand is the push for always-on functionality. Many embedded systems are expected to maintain constant connectivity or perform background tasks even when not actively in use. This requirement necessitates careful power management strategies to extend battery life while meeting performance expectations.

The Internet of Things (IoT) has also played a significant role in shaping embedded power demands. IoT devices often operate in remote or hard-to-reach locations, making frequent battery replacement impractical. As a result, there is a growing need for embedded systems that can operate for extended periods on a single battery charge or utilize energy harvesting techniques to supplement their power supply.

Another factor contributing to increased power demands is the integration of artificial intelligence and machine learning capabilities into embedded systems. These computationally intensive tasks require substantial processing power, which in turn leads to higher energy consumption. Balancing the desire for advanced AI features with the constraints of battery-powered operation presents a significant challenge for embedded system designers.

The automotive industry has also been a major driver of embedded power demands, particularly with the rise of electric and autonomous vehicles. These systems require a multitude of sensors, processors, and communication modules, all of which must operate reliably under varying conditions while drawing power from the vehicle's battery.

As embedded systems continue to evolve, addressing their power demands becomes increasingly critical. This necessitates a multi-faceted approach, combining advancements in battery technology, more efficient power management techniques, and innovative system design strategies. The goal is to create embedded systems that can deliver the required functionality and performance while maximizing battery life and minimizing power consumption.

CMOS Battery Limitations

CMOS batteries, while essential for maintaining system configurations and real-time clock functions in embedded systems, face several limitations that can impact their performance and longevity. One of the primary constraints is their limited capacity, typically ranging from 40 to 220 mAh. This relatively small capacity restricts the duration for which they can sustain critical system functions during main power loss, potentially leading to data loss or system instability in prolonged power outages.

The self-discharge rate of CMOS batteries presents another significant limitation. Even when not in use, these batteries gradually lose their charge over time, with typical self-discharge rates of 1% to 3% per year. This natural degradation process can lead to unexpected system failures if not properly monitored and addressed, particularly in systems designed for long-term operation without frequent maintenance.

Temperature sensitivity is a crucial factor affecting CMOS battery performance. These batteries often struggle to maintain optimal output in extreme temperature conditions, common in many embedded system environments. High temperatures can accelerate chemical reactions within the battery, leading to faster self-discharge and reduced lifespan. Conversely, low temperatures can decrease the battery's ability to deliver sufficient current, potentially causing system instability or failure.

The limited recharge capability of most CMOS batteries also poses a challenge. Unlike rechargeable batteries used in other applications, CMOS batteries are typically non-rechargeable or have very limited recharge cycles. This characteristic necessitates periodic replacement, which can be problematic in embedded systems designed for long-term deployment or those in hard-to-reach locations.

Physical size constraints represent another limitation of CMOS batteries in embedded systems. As devices continue to shrink, the space allocated for CMOS batteries becomes increasingly limited. This size restriction can force designers to opt for smaller batteries with lower capacities, potentially compromising system reliability and longevity.

The environmental impact of CMOS batteries is an growing concern. Many of these batteries contain lithium and other materials that can be harmful to the environment if not properly disposed of. This aspect necessitates careful consideration in the design and end-of-life management of embedded systems, particularly in industries striving for greater sustainability.

Lastly, the cost factor associated with high-quality CMOS batteries can be a limitation, especially in mass-produced embedded systems where every component's price impacts the overall product cost. Balancing the need for reliable, long-lasting CMOS batteries with cost considerations often leads to compromises in battery selection, potentially affecting system performance and reliability.

The self-discharge rate of CMOS batteries presents another significant limitation. Even when not in use, these batteries gradually lose their charge over time, with typical self-discharge rates of 1% to 3% per year. This natural degradation process can lead to unexpected system failures if not properly monitored and addressed, particularly in systems designed for long-term operation without frequent maintenance.

Temperature sensitivity is a crucial factor affecting CMOS battery performance. These batteries often struggle to maintain optimal output in extreme temperature conditions, common in many embedded system environments. High temperatures can accelerate chemical reactions within the battery, leading to faster self-discharge and reduced lifespan. Conversely, low temperatures can decrease the battery's ability to deliver sufficient current, potentially causing system instability or failure.

The limited recharge capability of most CMOS batteries also poses a challenge. Unlike rechargeable batteries used in other applications, CMOS batteries are typically non-rechargeable or have very limited recharge cycles. This characteristic necessitates periodic replacement, which can be problematic in embedded systems designed for long-term deployment or those in hard-to-reach locations.

Physical size constraints represent another limitation of CMOS batteries in embedded systems. As devices continue to shrink, the space allocated for CMOS batteries becomes increasingly limited. This size restriction can force designers to opt for smaller batteries with lower capacities, potentially compromising system reliability and longevity.

The environmental impact of CMOS batteries is an growing concern. Many of these batteries contain lithium and other materials that can be harmful to the environment if not properly disposed of. This aspect necessitates careful consideration in the design and end-of-life management of embedded systems, particularly in industries striving for greater sustainability.

Lastly, the cost factor associated with high-quality CMOS batteries can be a limitation, especially in mass-produced embedded systems where every component's price impacts the overall product cost. Balancing the need for reliable, long-lasting CMOS batteries with cost considerations often leads to compromises in battery selection, potentially affecting system performance and reliability.

Current Optimization

01 CMOS battery voltage regulation

Voltage regulation circuits are used to maintain a stable output voltage from CMOS batteries. These circuits ensure that the battery provides a consistent power supply to the CMOS memory and real-time clock, even as the battery voltage decreases over time. This helps to prevent data loss and maintain accurate timekeeping in electronic devices.- CMOS battery voltage regulation: CMOS batteries require stable voltage output to maintain system settings and real-time clock functions. Voltage regulation circuits are implemented to ensure consistent power supply to CMOS components, preventing data loss and system instability due to voltage fluctuations.

- Low-power CMOS battery management: Efficient power management techniques are employed to extend CMOS battery life. This includes implementing low-power modes, intelligent power switching, and optimized circuit designs to minimize current draw from the battery while maintaining essential functions.

- CMOS battery backup systems: Backup power systems are designed to ensure continuous operation of CMOS components during main power failure. These systems often include switching circuits to seamlessly transition between primary and backup power sources, maintaining data integrity and system functionality.

- CMOS battery monitoring and testing: Circuits and methods for monitoring CMOS battery health and performance are implemented to detect potential failures and ensure system reliability. This includes voltage level detection, capacity testing, and automated reporting mechanisms to alert users or systems of impending battery issues.

- CMOS battery charging and power management: Advanced charging and power management systems are developed to optimize CMOS battery performance and longevity. These systems may include intelligent charging algorithms, power source selection circuits, and energy harvesting techniques to supplement or recharge the CMOS battery.

02 Low-power CMOS battery backup systems

Low-power design techniques are implemented in CMOS battery backup systems to extend battery life. These systems often incorporate power management circuits that minimize current draw from the battery when the main power is off. This ensures that critical data and settings are preserved for longer periods without requiring frequent battery replacements.Expand Specific Solutions03 CMOS battery monitoring and switching

Circuits are designed to monitor CMOS battery voltage levels and automatically switch between the main power supply and the backup battery. These systems ensure uninterrupted power to critical components and can provide alerts when the battery voltage drops below a certain threshold, indicating the need for replacement.Expand Specific Solutions04 CMOS battery output protection

Protection circuits are implemented to prevent damage to CMOS components from battery output fluctuations or failures. These circuits may include voltage limiters, current limiters, and reverse polarity protection to ensure safe and reliable operation of the CMOS battery backup system.Expand Specific Solutions05 CMOS battery charging and management

Charging circuits and battery management systems are designed for rechargeable CMOS batteries. These systems optimize charging processes, monitor battery health, and manage power distribution to extend battery life and improve overall system reliability. They may also incorporate features like trickle charging and overcharge protection.Expand Specific Solutions

Key CMOS Manufacturers

The competition landscape for maximizing CMOS battery output in embedded systems is characterized by a mature market with established players and ongoing innovation. The market is substantial, driven by the increasing demand for energy-efficient embedded systems across various industries. Key players like Qualcomm, IBM, Intel, and Apple are investing heavily in research and development to enhance battery performance. Emerging companies such as Trispace Technologies are also contributing to technological advancements. The technology's maturity is evident, with major semiconductor manufacturers like TSMC, GlobalFoundries, and Renesas Electronics continuously improving CMOS processes. Universities like Zhejiang University and Southeast University are also actively involved in research, indicating a strong focus on future innovations in this field.

QUALCOMM, Inc.

Technical Solution: Qualcomm has developed advanced power management techniques for CMOS batteries in embedded systems. Their approach includes dynamic voltage and frequency scaling (DVFS) to optimize power consumption based on workload[1]. They've also implemented a proprietary low-power island design, allowing certain chip sections to remain powered while others are shut down[2]. Additionally, Qualcomm has introduced a novel charge recycling technique that can recover up to 30% of the energy typically lost during switching operations in CMOS circuits[3]. This technique involves temporarily storing charge in capacitors and reusing it in subsequent cycles, significantly extending battery life in mobile and IoT devices.

Strengths: Highly efficient power management, innovative charge recycling, and extensive experience in mobile chipsets. Weaknesses: Solutions may be proprietary and not easily adaptable to non-Qualcomm hardware.

International Business Machines Corp.

Technical Solution: IBM has developed a comprehensive approach to maximizing CMOS battery output in embedded systems. Their strategy involves a combination of hardware and software optimizations. On the hardware side, IBM has introduced a novel silicon-on-insulator (SOI) technology that reduces parasitic capacitance, leading to lower power consumption[4]. They've also implemented adaptive body biasing techniques that dynamically adjust transistor threshold voltages to minimize leakage current[5]. On the software front, IBM has developed sophisticated power-aware scheduling algorithms that intelligently distribute tasks to minimize overall system energy consumption. These algorithms can reduce power usage by up to 25% in certain embedded applications[6].

Strengths: Holistic approach combining hardware and software solutions, strong research capabilities. Weaknesses: Some solutions may be more suited to high-end embedded systems and may be costly for low-end applications.

Innovative Battery Tech

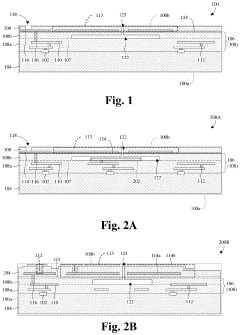

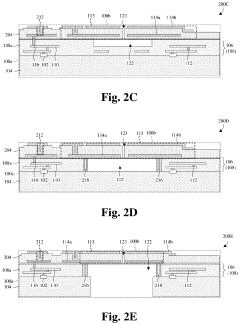

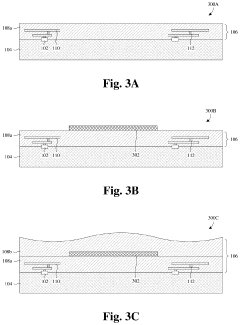

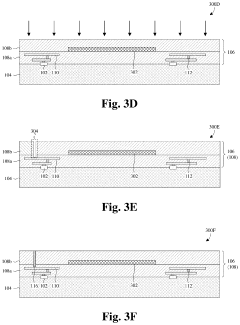

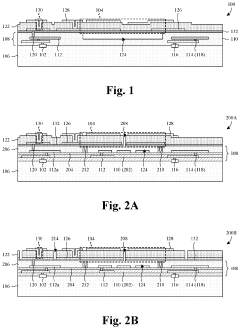

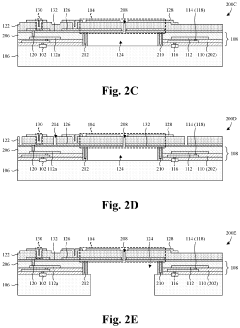

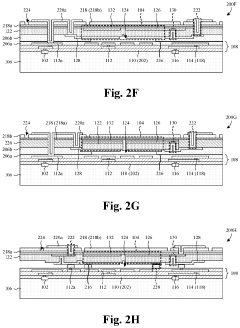

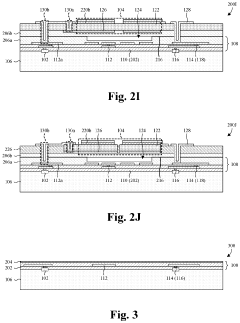

Method for integrating complementary metal-oxide-semiconductor (CMOS) devices with microelectromechanical systems (MEMS) devices using a flat surface above a sacrificial layer

PatentActiveUS20200346925A1

Innovation

- A method is developed to form MEMS structures on a planar surface using a sacrificial layer within the BEOL interconnect structure, allowing for cavity formation without wire bonding, which reduces parasitic capacitance and packaging complexity, and enables monolithic integration with low costs.

Integration scheme for microelectromechanical systems (MEMS) devices and complementary metal-oxide-semiconductor (CMOS) devices

PatentActiveUS11078074B2

Innovation

- A method involving the formation of a BEOL interconnect structure with a dielectric stack, a lateral etch to create a trench, and a piezoelectric layer over a semiconductor substrate, allowing for electrical coupling of MEMS devices to CMOS devices without wire bonding, performed at the wafer level to reduce packaging time and complexity.

Energy Harvesting

Energy harvesting techniques offer promising solutions for maximizing CMOS battery output in embedded systems. These methods capture ambient energy from the environment and convert it into usable electrical power, effectively extending battery life and enhancing system performance.

One of the most common energy harvesting techniques for embedded systems is photovoltaic harvesting. This approach utilizes small solar cells to convert light energy into electrical power. In indoor environments, specialized low-light solar cells can efficiently capture energy from artificial lighting sources. Outdoor applications benefit from higher-efficiency solar panels that can generate significant power even in low-light conditions.

Thermoelectric energy harvesting is another viable option for embedded systems. This method leverages temperature differences between two surfaces to generate electricity through the Seebeck effect. In wearable devices or industrial sensors, body heat or machinery-generated heat can be converted into usable power, supplementing the CMOS battery.

Piezoelectric energy harvesting capitalizes on mechanical stress or vibrations to generate electrical energy. This technique is particularly useful in environments with consistent vibrations, such as industrial machinery or transportation systems. Piezoelectric materials can be integrated into embedded system designs to capture and convert these mechanical energies into electrical power.

Radio frequency (RF) energy harvesting is gaining traction in embedded systems, especially in IoT applications. This method captures ambient RF signals from sources like Wi-Fi routers, cellular towers, or dedicated RF transmitters and converts them into DC power. While the power output is typically low, it can be sufficient for low-power sensors and communication modules.

Electromagnetic energy harvesting utilizes changing magnetic fields to induce electrical currents. This technique can be applied in embedded systems near power lines, motors, or other sources of electromagnetic fields. By incorporating small coils or inductors, these systems can capture and convert electromagnetic energy to supplement their power supply.

To maximize the effectiveness of energy harvesting in embedded systems, designers often employ power management integrated circuits (PMICs). These specialized chips efficiently manage the harvested energy, optimizing power conversion and storage. PMICs can intelligently switch between energy sources, regulate voltage levels, and implement advanced power-saving techniques to ensure optimal utilization of both harvested energy and CMOS battery power.

By integrating these energy harvesting techniques with efficient power management strategies, embedded system designers can significantly extend CMOS battery life, reduce maintenance requirements, and enable deployment in challenging environments where frequent battery replacement is impractical or impossible.

One of the most common energy harvesting techniques for embedded systems is photovoltaic harvesting. This approach utilizes small solar cells to convert light energy into electrical power. In indoor environments, specialized low-light solar cells can efficiently capture energy from artificial lighting sources. Outdoor applications benefit from higher-efficiency solar panels that can generate significant power even in low-light conditions.

Thermoelectric energy harvesting is another viable option for embedded systems. This method leverages temperature differences between two surfaces to generate electricity through the Seebeck effect. In wearable devices or industrial sensors, body heat or machinery-generated heat can be converted into usable power, supplementing the CMOS battery.

Piezoelectric energy harvesting capitalizes on mechanical stress or vibrations to generate electrical energy. This technique is particularly useful in environments with consistent vibrations, such as industrial machinery or transportation systems. Piezoelectric materials can be integrated into embedded system designs to capture and convert these mechanical energies into electrical power.

Radio frequency (RF) energy harvesting is gaining traction in embedded systems, especially in IoT applications. This method captures ambient RF signals from sources like Wi-Fi routers, cellular towers, or dedicated RF transmitters and converts them into DC power. While the power output is typically low, it can be sufficient for low-power sensors and communication modules.

Electromagnetic energy harvesting utilizes changing magnetic fields to induce electrical currents. This technique can be applied in embedded systems near power lines, motors, or other sources of electromagnetic fields. By incorporating small coils or inductors, these systems can capture and convert electromagnetic energy to supplement their power supply.

To maximize the effectiveness of energy harvesting in embedded systems, designers often employ power management integrated circuits (PMICs). These specialized chips efficiently manage the harvested energy, optimizing power conversion and storage. PMICs can intelligently switch between energy sources, regulate voltage levels, and implement advanced power-saving techniques to ensure optimal utilization of both harvested energy and CMOS battery power.

By integrating these energy harvesting techniques with efficient power management strategies, embedded system designers can significantly extend CMOS battery life, reduce maintenance requirements, and enable deployment in challenging environments where frequent battery replacement is impractical or impossible.

Thermal Management

Thermal management plays a crucial role in maximizing CMOS battery output in embedded systems. As electronic components become more compact and powerful, the heat generated during operation can significantly impact battery performance and longevity. Effective thermal management strategies are essential to maintain optimal operating temperatures and ensure efficient power utilization.

One key aspect of thermal management in embedded systems is the implementation of intelligent power management techniques. By dynamically adjusting clock speeds and voltage levels based on system load and temperature, power consumption can be reduced without compromising performance. This approach helps minimize heat generation and extends battery life.

Heat dissipation is another critical factor in thermal management. Proper design of heat sinks, thermal vias, and copper planes can effectively distribute and dissipate heat away from sensitive components. In some cases, active cooling solutions such as small fans or thermoelectric coolers may be necessary for high-performance embedded systems.

Temperature monitoring and control systems are integral to effective thermal management. Implementing temperature sensors throughout the system allows for real-time monitoring of critical components. This data can be used to trigger thermal throttling or activate cooling mechanisms when temperatures approach predefined thresholds, preventing thermal runaway and protecting the CMOS battery.

Optimizing component placement and PCB layout is essential for efficient thermal management. Careful consideration of heat-generating components and their proximity to temperature-sensitive elements can significantly impact overall system thermal performance. Utilizing thermal simulation tools during the design phase can help identify potential hotspots and optimize component placement for better heat distribution.

In battery-powered embedded systems, thermal management extends to the battery itself. Implementing battery temperature monitoring and protection circuits can prevent overheating and ensure safe operation. Additionally, considering the thermal characteristics of different battery chemistries can inform design decisions and help maximize battery output and lifespan.

Advanced packaging techniques, such as 3D IC stacking and system-in-package (SiP) solutions, present both challenges and opportunities for thermal management in embedded systems. While these approaches allow for increased functionality in smaller form factors, they also require innovative cooling solutions to manage the increased heat density.

As embedded systems continue to evolve, emerging technologies like phase-change materials and microfluidic cooling systems show promise for future thermal management solutions. These advanced techniques may offer more efficient and compact ways to manage heat in next-generation embedded systems, further optimizing CMOS battery output and overall system performance.

One key aspect of thermal management in embedded systems is the implementation of intelligent power management techniques. By dynamically adjusting clock speeds and voltage levels based on system load and temperature, power consumption can be reduced without compromising performance. This approach helps minimize heat generation and extends battery life.

Heat dissipation is another critical factor in thermal management. Proper design of heat sinks, thermal vias, and copper planes can effectively distribute and dissipate heat away from sensitive components. In some cases, active cooling solutions such as small fans or thermoelectric coolers may be necessary for high-performance embedded systems.

Temperature monitoring and control systems are integral to effective thermal management. Implementing temperature sensors throughout the system allows for real-time monitoring of critical components. This data can be used to trigger thermal throttling or activate cooling mechanisms when temperatures approach predefined thresholds, preventing thermal runaway and protecting the CMOS battery.

Optimizing component placement and PCB layout is essential for efficient thermal management. Careful consideration of heat-generating components and their proximity to temperature-sensitive elements can significantly impact overall system thermal performance. Utilizing thermal simulation tools during the design phase can help identify potential hotspots and optimize component placement for better heat distribution.

In battery-powered embedded systems, thermal management extends to the battery itself. Implementing battery temperature monitoring and protection circuits can prevent overheating and ensure safe operation. Additionally, considering the thermal characteristics of different battery chemistries can inform design decisions and help maximize battery output and lifespan.

Advanced packaging techniques, such as 3D IC stacking and system-in-package (SiP) solutions, present both challenges and opportunities for thermal management in embedded systems. While these approaches allow for increased functionality in smaller form factors, they also require innovative cooling solutions to manage the increased heat density.

As embedded systems continue to evolve, emerging technologies like phase-change materials and microfluidic cooling systems show promise for future thermal management solutions. These advanced techniques may offer more efficient and compact ways to manage heat in next-generation embedded systems, further optimizing CMOS battery output and overall system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!