Reducing CMOS Battery Usage Impact on Environment

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Evolution

The evolution of CMOS batteries has been closely tied to the development of computer systems and electronic devices. Initially introduced in the 1980s, CMOS batteries were designed to maintain system settings and real-time clock information when the main power was disconnected. These early batteries were typically lithium-based, with a lifespan of several years.

As technology progressed, the role of CMOS batteries expanded to support more complex system configurations and BIOS settings. The 1990s saw an increase in the capacity and reliability of these batteries, with manufacturers focusing on extending their operational life to match the longer lifespans of computer systems.

The turn of the millennium brought about a shift towards more energy-efficient designs in computing. This trend influenced CMOS battery technology, leading to the development of lower-power consumption circuits that could extend battery life even further. Manufacturers began to explore alternative materials and chemistries to improve performance and reduce environmental impact.

In the 2000s and 2010s, the miniaturization of electronic devices posed new challenges for CMOS battery design. Engineers worked on creating smaller, yet equally powerful batteries to fit into increasingly compact devices. This period also saw the introduction of rechargeable CMOS batteries in some systems, although non-rechargeable lithium cells remained the standard for most applications.

Recent years have witnessed a growing concern over the environmental impact of electronic waste, including CMOS batteries. This has spurred research into more eco-friendly alternatives and improved recycling methods. Some manufacturers have begun experimenting with bio-based materials and less toxic chemistries to reduce the environmental footprint of these essential components.

The latest developments in CMOS battery technology focus on sustainability and longevity. Researchers are exploring ways to integrate CMOS functionality with other power systems in devices, potentially eliminating the need for separate batteries. Additionally, advancements in low-power electronics and energy harvesting technologies are opening up possibilities for self-powered CMOS systems that could significantly reduce or eliminate battery usage.

As we look towards the future, the evolution of CMOS batteries is likely to continue in the direction of increased efficiency, reduced environmental impact, and integration with broader power management systems. The ongoing research into alternative energy storage technologies and materials promises to reshape the landscape of CMOS power solutions, potentially leading to more sustainable and long-lasting options for maintaining critical system information in electronic devices.

As technology progressed, the role of CMOS batteries expanded to support more complex system configurations and BIOS settings. The 1990s saw an increase in the capacity and reliability of these batteries, with manufacturers focusing on extending their operational life to match the longer lifespans of computer systems.

The turn of the millennium brought about a shift towards more energy-efficient designs in computing. This trend influenced CMOS battery technology, leading to the development of lower-power consumption circuits that could extend battery life even further. Manufacturers began to explore alternative materials and chemistries to improve performance and reduce environmental impact.

In the 2000s and 2010s, the miniaturization of electronic devices posed new challenges for CMOS battery design. Engineers worked on creating smaller, yet equally powerful batteries to fit into increasingly compact devices. This period also saw the introduction of rechargeable CMOS batteries in some systems, although non-rechargeable lithium cells remained the standard for most applications.

Recent years have witnessed a growing concern over the environmental impact of electronic waste, including CMOS batteries. This has spurred research into more eco-friendly alternatives and improved recycling methods. Some manufacturers have begun experimenting with bio-based materials and less toxic chemistries to reduce the environmental footprint of these essential components.

The latest developments in CMOS battery technology focus on sustainability and longevity. Researchers are exploring ways to integrate CMOS functionality with other power systems in devices, potentially eliminating the need for separate batteries. Additionally, advancements in low-power electronics and energy harvesting technologies are opening up possibilities for self-powered CMOS systems that could significantly reduce or eliminate battery usage.

As we look towards the future, the evolution of CMOS batteries is likely to continue in the direction of increased efficiency, reduced environmental impact, and integration with broader power management systems. The ongoing research into alternative energy storage technologies and materials promises to reshape the landscape of CMOS power solutions, potentially leading to more sustainable and long-lasting options for maintaining critical system information in electronic devices.

Green Tech Market Analysis

The green technology market has experienced significant growth in recent years, driven by increasing environmental concerns and the urgent need for sustainable solutions. The CMOS battery, a critical component in many electronic devices, has become a focal point for environmental impact reduction efforts. This market analysis explores the current landscape and future prospects of green technologies aimed at minimizing the environmental footprint of CMOS batteries.

The global market for eco-friendly electronic components, including green battery technologies, is projected to expand rapidly. This growth is fueled by stringent environmental regulations, consumer demand for sustainable products, and corporate sustainability initiatives. Major electronics manufacturers are investing heavily in research and development to create more environmentally friendly CMOS batteries and alternative power solutions.

Key market drivers include the rising awareness of electronic waste issues, the push for circular economy principles in the tech industry, and the increasing adoption of renewable energy sources. Governments worldwide are implementing policies to promote the development and adoption of green technologies, further stimulating market growth.

The CMOS battery market segment is witnessing a shift towards more sustainable materials and production processes. Manufacturers are exploring alternatives to traditional lithium-based batteries, such as bio-based electrolytes and recyclable components. This trend is expected to create new opportunities for innovative startups and established companies alike.

Market challenges include the higher initial costs associated with green technologies, the need for significant infrastructure changes, and the technical limitations of current sustainable materials. However, these challenges are driving innovation and creating a competitive landscape where companies strive to develop cost-effective and efficient green solutions.

Regional analysis shows that Asia-Pacific leads in the production of green electronic components, with China, Japan, and South Korea at the forefront. North America and Europe are major markets for eco-friendly technologies, driven by stringent environmental regulations and consumer preferences. Emerging economies are also showing increased interest in green tech, presenting growth opportunities for market players.

The competitive landscape is characterized by a mix of established electronics giants and innovative startups. Major players are investing in green R&D centers and forming strategic partnerships to gain a competitive edge. The market is also seeing a rise in collaborations between tech companies and environmental organizations to develop and promote sustainable solutions.

Looking ahead, the green tech market for CMOS batteries and related components is expected to continue its upward trajectory. Advancements in materials science, energy storage technologies, and recycling processes are likely to drive further innovation and market expansion. As sustainability becomes increasingly central to corporate strategies and consumer choices, the demand for environmentally friendly CMOS battery solutions is poised for substantial growth in the coming years.

The global market for eco-friendly electronic components, including green battery technologies, is projected to expand rapidly. This growth is fueled by stringent environmental regulations, consumer demand for sustainable products, and corporate sustainability initiatives. Major electronics manufacturers are investing heavily in research and development to create more environmentally friendly CMOS batteries and alternative power solutions.

Key market drivers include the rising awareness of electronic waste issues, the push for circular economy principles in the tech industry, and the increasing adoption of renewable energy sources. Governments worldwide are implementing policies to promote the development and adoption of green technologies, further stimulating market growth.

The CMOS battery market segment is witnessing a shift towards more sustainable materials and production processes. Manufacturers are exploring alternatives to traditional lithium-based batteries, such as bio-based electrolytes and recyclable components. This trend is expected to create new opportunities for innovative startups and established companies alike.

Market challenges include the higher initial costs associated with green technologies, the need for significant infrastructure changes, and the technical limitations of current sustainable materials. However, these challenges are driving innovation and creating a competitive landscape where companies strive to develop cost-effective and efficient green solutions.

Regional analysis shows that Asia-Pacific leads in the production of green electronic components, with China, Japan, and South Korea at the forefront. North America and Europe are major markets for eco-friendly technologies, driven by stringent environmental regulations and consumer preferences. Emerging economies are also showing increased interest in green tech, presenting growth opportunities for market players.

The competitive landscape is characterized by a mix of established electronics giants and innovative startups. Major players are investing in green R&D centers and forming strategic partnerships to gain a competitive edge. The market is also seeing a rise in collaborations between tech companies and environmental organizations to develop and promote sustainable solutions.

Looking ahead, the green tech market for CMOS batteries and related components is expected to continue its upward trajectory. Advancements in materials science, energy storage technologies, and recycling processes are likely to drive further innovation and market expansion. As sustainability becomes increasingly central to corporate strategies and consumer choices, the demand for environmentally friendly CMOS battery solutions is poised for substantial growth in the coming years.

Environmental Challenges

The environmental impact of CMOS batteries in electronic devices has become a growing concern in recent years. These small, coin-sized batteries, while essential for maintaining critical system functions, pose significant challenges to the environment throughout their lifecycle.

One of the primary environmental issues associated with CMOS batteries is the toxic materials they contain. Most CMOS batteries are lithium-based, often incorporating heavy metals such as mercury, lead, or cadmium. When improperly disposed of, these batteries can leach harmful substances into soil and water systems, potentially contaminating ecosystems and posing risks to human health.

The production process of CMOS batteries also contributes to environmental degradation. Mining and refining the raw materials required for battery manufacturing often leads to habitat destruction, soil erosion, and water pollution. Additionally, the energy-intensive manufacturing processes contribute to increased carbon emissions, exacerbating climate change concerns.

E-waste management presents another significant challenge. As electronic devices become obsolete at an increasingly rapid pace, the volume of discarded CMOS batteries grows. Many of these batteries end up in landfills, where they can release toxic chemicals over time. The small size of CMOS batteries makes them particularly difficult to separate from other electronic components during recycling processes, further complicating proper disposal efforts.

The limited lifespan of CMOS batteries compounds these issues. Typically lasting between 2 to 10 years, these batteries require frequent replacement, leading to a continuous cycle of production, consumption, and disposal. This short lifecycle increases the overall environmental footprint of electronic devices and contributes to the growing e-waste problem.

Energy consumption during the use phase of CMOS batteries, while relatively low compared to other components, still contributes to the overall power demands of electronic devices. This ongoing energy requirement, multiplied across millions of devices worldwide, represents a significant cumulative environmental impact in terms of electricity generation and associated emissions.

Addressing these environmental challenges requires a multifaceted approach. Innovations in battery technology to reduce or eliminate toxic materials, improve energy efficiency, and extend battery lifespan are crucial. Enhancing recycling infrastructure and processes to better handle small batteries is equally important. Additionally, promoting consumer awareness about proper disposal methods and the importance of recycling can help mitigate the environmental impact of CMOS batteries.

One of the primary environmental issues associated with CMOS batteries is the toxic materials they contain. Most CMOS batteries are lithium-based, often incorporating heavy metals such as mercury, lead, or cadmium. When improperly disposed of, these batteries can leach harmful substances into soil and water systems, potentially contaminating ecosystems and posing risks to human health.

The production process of CMOS batteries also contributes to environmental degradation. Mining and refining the raw materials required for battery manufacturing often leads to habitat destruction, soil erosion, and water pollution. Additionally, the energy-intensive manufacturing processes contribute to increased carbon emissions, exacerbating climate change concerns.

E-waste management presents another significant challenge. As electronic devices become obsolete at an increasingly rapid pace, the volume of discarded CMOS batteries grows. Many of these batteries end up in landfills, where they can release toxic chemicals over time. The small size of CMOS batteries makes them particularly difficult to separate from other electronic components during recycling processes, further complicating proper disposal efforts.

The limited lifespan of CMOS batteries compounds these issues. Typically lasting between 2 to 10 years, these batteries require frequent replacement, leading to a continuous cycle of production, consumption, and disposal. This short lifecycle increases the overall environmental footprint of electronic devices and contributes to the growing e-waste problem.

Energy consumption during the use phase of CMOS batteries, while relatively low compared to other components, still contributes to the overall power demands of electronic devices. This ongoing energy requirement, multiplied across millions of devices worldwide, represents a significant cumulative environmental impact in terms of electricity generation and associated emissions.

Addressing these environmental challenges requires a multifaceted approach. Innovations in battery technology to reduce or eliminate toxic materials, improve energy efficiency, and extend battery lifespan are crucial. Enhancing recycling infrastructure and processes to better handle small batteries is equally important. Additionally, promoting consumer awareness about proper disposal methods and the importance of recycling can help mitigate the environmental impact of CMOS batteries.

Current Eco Solutions

01 Battery management systems for environmental impact reduction

Advanced battery management systems are being developed to optimize CMOS battery usage, extend their lifespan, and reduce waste. These systems monitor battery health, manage power consumption, and implement intelligent charging strategies to minimize environmental impact.- Battery management systems for environmental impact reduction: Advanced battery management systems are being developed to optimize CMOS battery usage, extend their lifespan, and reduce waste. These systems monitor battery health, predict failures, and implement power-saving strategies to minimize environmental impact.

- Eco-friendly CMOS battery materials and designs: Researchers are focusing on developing CMOS batteries using more environmentally friendly materials and designs. This includes exploring alternatives to traditional lithium-ion batteries, such as organic or biodegradable components, to reduce the ecological footprint of electronic devices.

- Recycling and disposal methods for CMOS batteries: Improved recycling and disposal methods are being implemented to mitigate the environmental impact of CMOS batteries. These include advanced recycling technologies to recover valuable materials and proper disposal techniques to prevent hazardous substances from entering the environment.

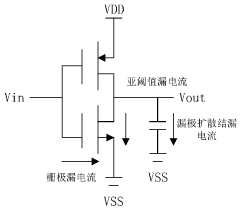

- Energy-efficient CMOS technologies: Development of energy-efficient CMOS technologies aims to reduce power consumption and extend battery life. This includes innovations in low-power circuit design, sleep modes, and dynamic voltage scaling, which collectively minimize the environmental impact by reducing the frequency of battery replacements.

- Life cycle assessment and environmental impact analysis: Comprehensive life cycle assessments and environmental impact analyses are being conducted for CMOS batteries. These studies evaluate the environmental effects from production to disposal, helping manufacturers and consumers make more informed decisions to reduce overall ecological impact.

02 Eco-friendly CMOS battery materials and design

Researchers are focusing on developing CMOS batteries using more environmentally friendly materials and designs. This includes exploring alternatives to traditional lithium-ion batteries, such as organic or biodegradable components, to reduce the ecological footprint of electronic devices.Expand Specific Solutions03 Recycling and disposal strategies for CMOS batteries

Innovative recycling and disposal methods are being implemented to address the environmental concerns associated with CMOS batteries. These strategies aim to recover valuable materials, reduce e-waste, and minimize the release of harmful substances into the environment.Expand Specific Solutions04 Energy-efficient CMOS battery technologies

New energy-efficient CMOS battery technologies are being developed to reduce power consumption and extend battery life. These advancements aim to decrease the frequency of battery replacements, thereby reducing the overall environmental impact of electronic devices.Expand Specific Solutions05 Environmental impact assessment and mitigation strategies

Comprehensive environmental impact assessments are being conducted to evaluate the lifecycle of CMOS batteries. Based on these assessments, mitigation strategies are being developed to address potential environmental risks and improve the sustainability of CMOS battery production and use.Expand Specific Solutions

Key Industry Players

The research on reducing CMOS battery usage impact on the environment is at a critical juncture, with the market poised for significant growth as sustainability concerns drive innovation. The industry is in a transitional phase, moving from traditional battery technologies to more eco-friendly solutions. Major players like Samsung Electronics, SK hynix, and LG Energy Solution are investing heavily in R&D to develop low-impact CMOS batteries. The market size is expanding rapidly, driven by increasing demand for sustainable electronics. Technological maturity varies, with established companies like IBM and Applied Materials leveraging their expertise to advance solutions, while newer entrants like BattGenie are bringing fresh approaches to battery management systems.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed innovative CMOS battery technologies to reduce environmental impact. Their approach includes the use of eco-friendly materials and advanced power management systems. They have introduced low-power CMOS batteries that consume up to 30% less energy compared to traditional designs [1]. Samsung has also implemented a circular economy model for battery recycling, aiming to recover up to 95% of valuable metals from used batteries [2]. Additionally, they are exploring the use of organic electrolytes and bio-based materials to further reduce the environmental footprint of CMOS batteries [3].

Strengths: Strong R&D capabilities, global market presence, and integrated supply chain. Weaknesses: High production costs and potential for increased competition in the eco-friendly battery market.

SK hynix, Inc.

Technical Solution: SK hynix has focused on developing ultra-low power CMOS technologies to minimize battery usage and environmental impact. Their approach includes advanced process technologies and innovative circuit designs. They have introduced a new generation of CMOS image sensors that consume up to 40% less power than previous models [4]. SK hynix has also developed high-efficiency power management integrated circuits (PMICs) that optimize battery usage in various electronic devices [5]. Furthermore, they are investing in research on alternative materials and structures for CMOS batteries to reduce reliance on rare earth elements and improve recyclability [6].

Strengths: Cutting-edge semiconductor technology and strong focus on power efficiency. Weaknesses: Limited experience in battery manufacturing and potential challenges in scaling new technologies.

Innovative Materials

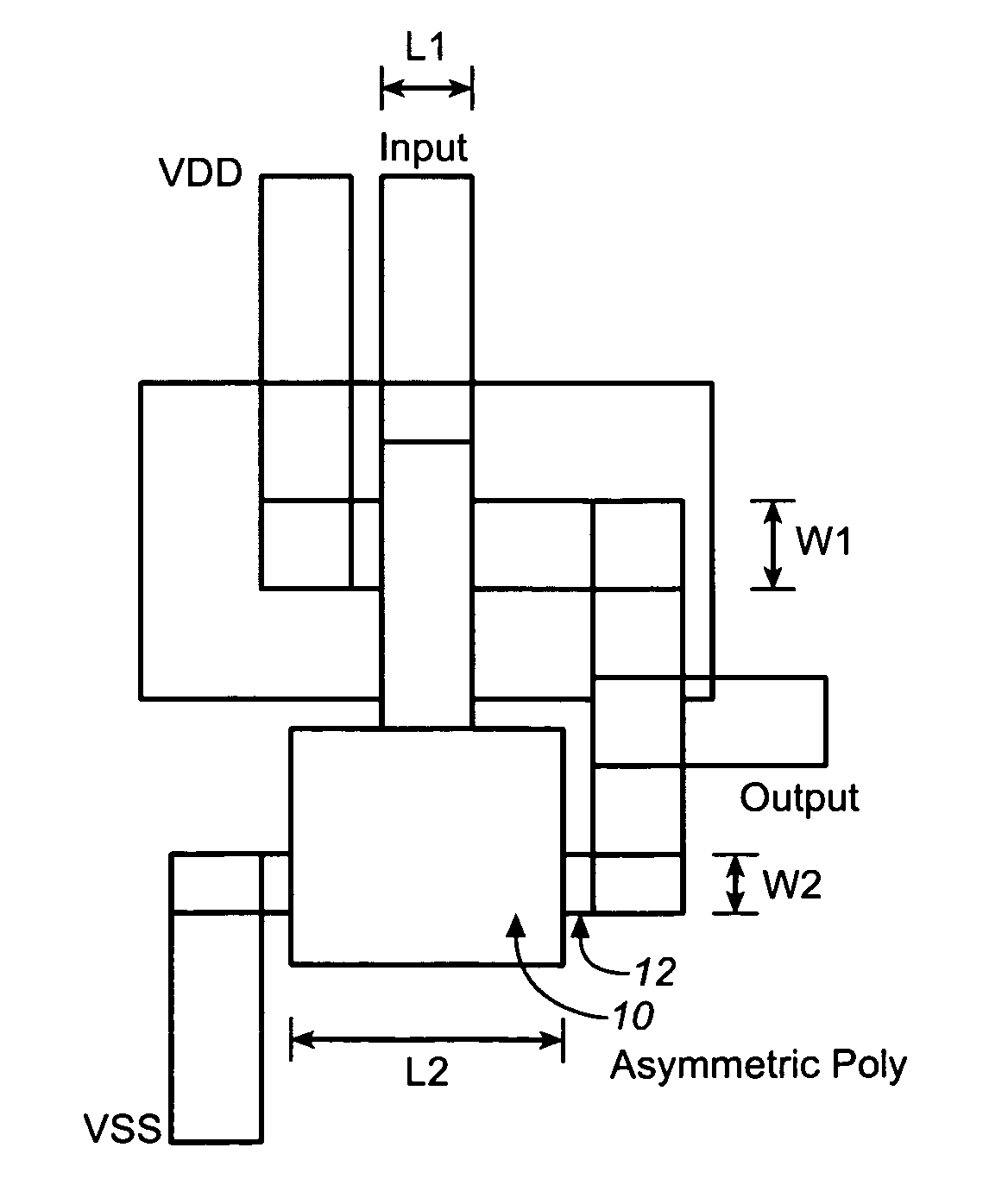

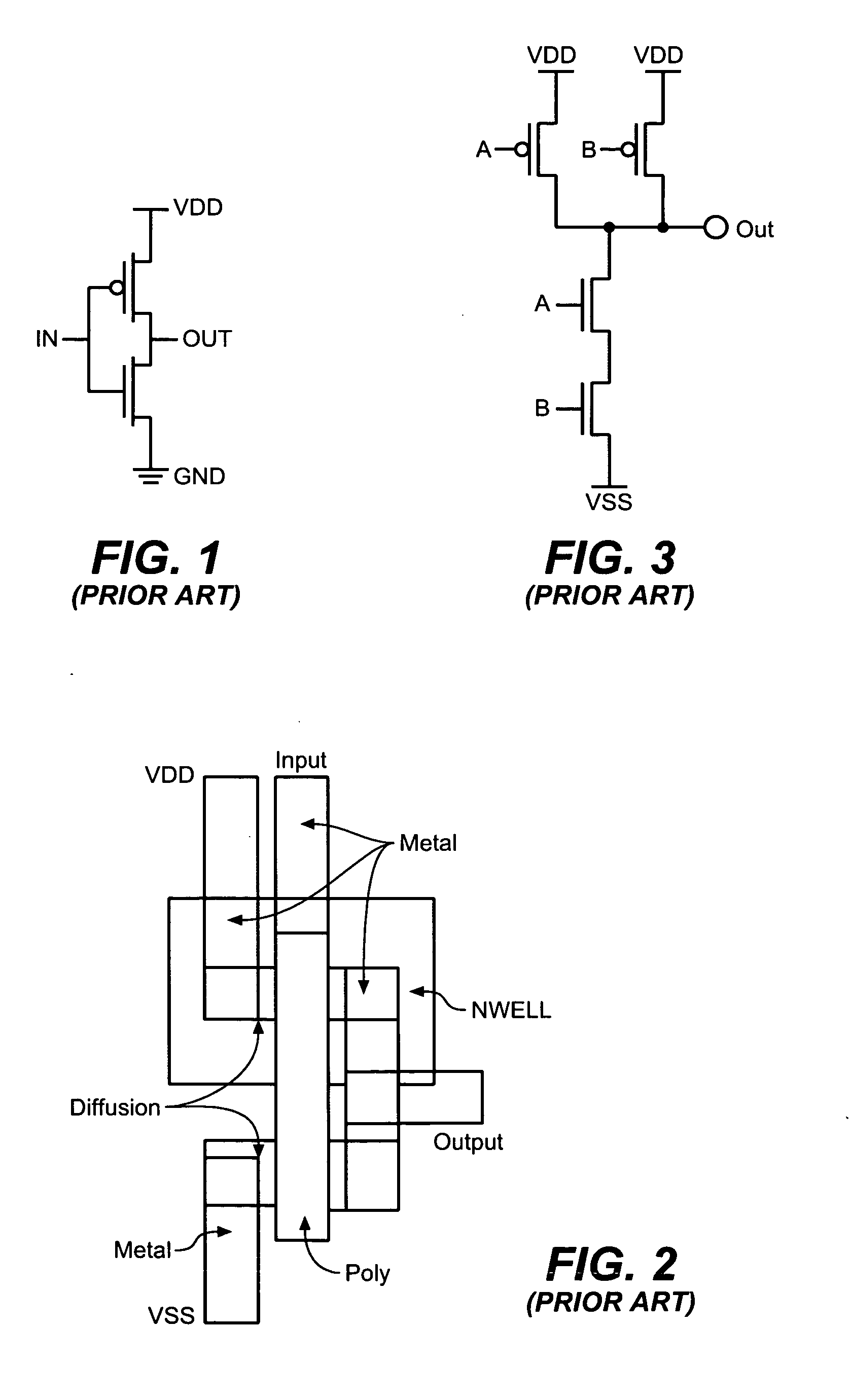

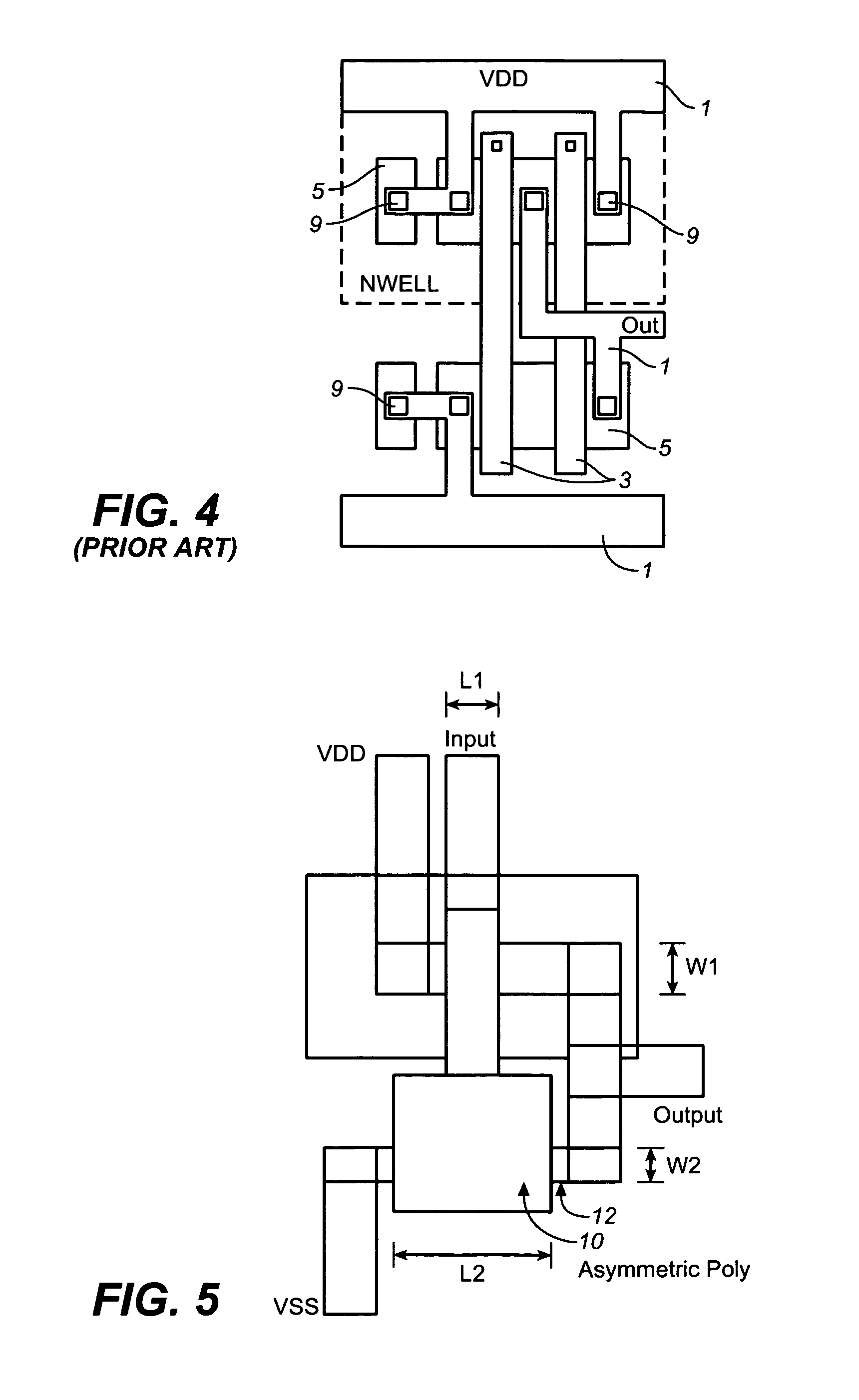

Asymmetrical layout for complementary metal-oxide-semiconductor integrated circuit to reduce power consumption

PatentInactiveUS20090072320A1

Innovation

- The implementation of an asymmetrical polysilicon gate and diffusion layout in CMOS integrated circuits, where the polysilicon gate and diffusion dimensions are asymmetrical, causing P-type and N-type transistors to switch at different times, thereby reducing short circuit current and power consumption.

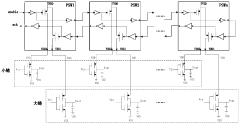

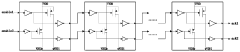

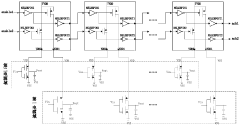

Power domain switch control circuit and method and chip

PatentActiveCN110011654A

Innovation

- A power domain switch control circuit using N PSWs, in which each PSW is controlled by two enable signals separated by a preset time delay, respectively controlling the on and off of the first switch unit and the second switch unit to avoid simultaneous conduction and excessive Large current instantaneous pulses.

Regulatory Framework

The regulatory framework surrounding CMOS battery usage and its environmental impact is becoming increasingly stringent worldwide. Governments and international organizations are implementing stricter regulations to address the environmental concerns associated with battery production, use, and disposal. The European Union's Battery Directive, for instance, sets targets for the collection and recycling of batteries, including those used in CMOS systems. This directive aims to minimize the negative impact of batteries on the environment by promoting their proper disposal and recycling.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the management of used batteries under the Resource Conservation and Recovery Act (RCRA). These regulations classify certain types of batteries as hazardous waste and mandate specific handling and disposal procedures. Additionally, many states have enacted their own battery recycling laws, further emphasizing the importance of responsible battery management.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal plays a crucial role in regulating the international trade of used batteries. This convention aims to prevent the transfer of hazardous waste, including certain types of batteries, from developed to developing countries, ensuring that battery disposal is managed responsibly on a global scale.

In response to these regulatory pressures, manufacturers are increasingly focusing on developing more environmentally friendly CMOS battery technologies. This includes research into alternative materials that have less environmental impact, as well as designs that facilitate easier recycling and disposal. Some countries have introduced extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including end-of-life management.

The regulatory landscape is also evolving to address the growing concern over the carbon footprint associated with battery production and use. Several jurisdictions are implementing carbon pricing mechanisms and emissions trading schemes that indirectly affect battery manufacturers by incentivizing the development of more energy-efficient and environmentally friendly technologies.

As awareness of the environmental impact of CMOS batteries grows, it is likely that regulatory frameworks will continue to evolve. Future regulations may focus on promoting the use of renewable energy in battery production, setting stricter standards for battery longevity, and encouraging the development of more sustainable battery chemistries. The ongoing global shift towards circular economy principles is expected to further influence regulatory approaches, emphasizing the importance of designing batteries for reuse, refurbishment, and recycling from the outset.

In the United States, the Environmental Protection Agency (EPA) has established guidelines for the management of used batteries under the Resource Conservation and Recovery Act (RCRA). These regulations classify certain types of batteries as hazardous waste and mandate specific handling and disposal procedures. Additionally, many states have enacted their own battery recycling laws, further emphasizing the importance of responsible battery management.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal plays a crucial role in regulating the international trade of used batteries. This convention aims to prevent the transfer of hazardous waste, including certain types of batteries, from developed to developing countries, ensuring that battery disposal is managed responsibly on a global scale.

In response to these regulatory pressures, manufacturers are increasingly focusing on developing more environmentally friendly CMOS battery technologies. This includes research into alternative materials that have less environmental impact, as well as designs that facilitate easier recycling and disposal. Some countries have introduced extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including end-of-life management.

The regulatory landscape is also evolving to address the growing concern over the carbon footprint associated with battery production and use. Several jurisdictions are implementing carbon pricing mechanisms and emissions trading schemes that indirectly affect battery manufacturers by incentivizing the development of more energy-efficient and environmentally friendly technologies.

As awareness of the environmental impact of CMOS batteries grows, it is likely that regulatory frameworks will continue to evolve. Future regulations may focus on promoting the use of renewable energy in battery production, setting stricter standards for battery longevity, and encouraging the development of more sustainable battery chemistries. The ongoing global shift towards circular economy principles is expected to further influence regulatory approaches, emphasizing the importance of designing batteries for reuse, refurbishment, and recycling from the outset.

Lifecycle Assessment

Lifecycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of CMOS batteries throughout their entire lifecycle, from raw material extraction to disposal. In the context of reducing CMOS battery usage impact on the environment, LCA provides valuable insights into the areas where improvements can be made to minimize ecological footprints.

The LCA process for CMOS batteries typically begins with the extraction and processing of raw materials, such as lithium, cobalt, and other metals. This stage often accounts for a significant portion of the battery's overall environmental impact due to energy-intensive mining operations and potential habitat disruption.

Manufacturing is the next phase in the lifecycle, involving the production of battery components and their assembly. This stage contributes to environmental concerns through energy consumption, chemical processes, and potential emissions. Advancements in manufacturing techniques and the use of cleaner energy sources can help mitigate these impacts.

The use phase of CMOS batteries is generally considered to have a lower environmental impact compared to other stages. However, the longevity and efficiency of the battery during this phase can significantly influence its overall environmental footprint. Extending battery life and improving energy efficiency are key areas for reducing environmental impact during use.

End-of-life management is a critical stage in the CMOS battery lifecycle. Proper recycling and disposal methods are essential to recover valuable materials and prevent hazardous substances from entering the environment. Developing more efficient recycling technologies and implementing effective collection systems can greatly reduce the environmental burden of spent batteries.

Transportation throughout the lifecycle, from raw material sourcing to distribution and eventual disposal, also contributes to the overall environmental impact. Optimizing logistics and utilizing cleaner transportation methods can help minimize these effects.

By conducting comprehensive lifecycle assessments, researchers and manufacturers can identify hotspots of environmental impact and prioritize areas for improvement. This may lead to the development of more sustainable materials, cleaner production processes, and improved recycling technologies. Additionally, LCA results can inform policy decisions and guide consumer choices towards more environmentally friendly CMOS battery options.

Continuous refinement of LCA methodologies specific to CMOS batteries is essential to ensure accurate and relevant environmental impact assessments. This includes developing standardized metrics, improving data collection methods, and incorporating emerging environmental concerns into the analysis framework.

The LCA process for CMOS batteries typically begins with the extraction and processing of raw materials, such as lithium, cobalt, and other metals. This stage often accounts for a significant portion of the battery's overall environmental impact due to energy-intensive mining operations and potential habitat disruption.

Manufacturing is the next phase in the lifecycle, involving the production of battery components and their assembly. This stage contributes to environmental concerns through energy consumption, chemical processes, and potential emissions. Advancements in manufacturing techniques and the use of cleaner energy sources can help mitigate these impacts.

The use phase of CMOS batteries is generally considered to have a lower environmental impact compared to other stages. However, the longevity and efficiency of the battery during this phase can significantly influence its overall environmental footprint. Extending battery life and improving energy efficiency are key areas for reducing environmental impact during use.

End-of-life management is a critical stage in the CMOS battery lifecycle. Proper recycling and disposal methods are essential to recover valuable materials and prevent hazardous substances from entering the environment. Developing more efficient recycling technologies and implementing effective collection systems can greatly reduce the environmental burden of spent batteries.

Transportation throughout the lifecycle, from raw material sourcing to distribution and eventual disposal, also contributes to the overall environmental impact. Optimizing logistics and utilizing cleaner transportation methods can help minimize these effects.

By conducting comprehensive lifecycle assessments, researchers and manufacturers can identify hotspots of environmental impact and prioritize areas for improvement. This may lead to the development of more sustainable materials, cleaner production processes, and improved recycling technologies. Additionally, LCA results can inform policy decisions and guide consumer choices towards more environmentally friendly CMOS battery options.

Continuous refinement of LCA methodologies specific to CMOS batteries is essential to ensure accurate and relevant environmental impact assessments. This includes developing standardized metrics, improving data collection methods, and incorporating emerging environmental concerns into the analysis framework.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!