Aligning CMOS Battery Innovation with Market Needs

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Evolution

The evolution of CMOS battery technology has been closely intertwined with the development of electronic devices and the increasing demand for more efficient, longer-lasting power sources. Initially introduced in the 1980s, CMOS batteries were primarily used to maintain system settings and real-time clock functions in personal computers. These early batteries were typically small, non-rechargeable lithium cells with limited capacity and lifespan.

As electronic devices became more sophisticated and energy-demanding, the role of CMOS batteries expanded beyond simple memory retention. The 1990s saw the introduction of rechargeable CMOS batteries, which offered improved longevity and reduced the need for frequent replacements. This shift aligned with the growing emphasis on sustainability and reduced electronic waste.

The turn of the millennium brought about significant advancements in CMOS battery technology. Manufacturers began exploring new materials and designs to enhance energy density and reduce self-discharge rates. The integration of thin-film technology allowed for the development of smaller, more efficient CMOS batteries that could be seamlessly incorporated into increasingly compact devices.

In the 2000s, the rise of mobile computing and the Internet of Things (IoT) created new challenges and opportunities for CMOS battery innovation. The demand for batteries that could power a wide range of sensors and low-power devices led to the development of more versatile CMOS power solutions. This period saw the emergence of hybrid systems that combined traditional CMOS batteries with energy harvesting technologies, enabling devices to operate for extended periods without manual intervention.

Recent years have witnessed a focus on improving the environmental impact of CMOS batteries. Researchers have been exploring bio-based materials and eco-friendly manufacturing processes to create more sustainable power sources. Additionally, advancements in nanotechnology have opened up new possibilities for enhancing battery performance and longevity.

The current trajectory of CMOS battery evolution is aimed at addressing the needs of emerging technologies such as wearable devices, implantable medical sensors, and ultra-low-power IoT applications. Innovations in solid-state electrolytes and advanced electrode materials are paving the way for CMOS batteries with higher energy densities, faster charging capabilities, and improved safety profiles.

As we look to the future, the evolution of CMOS batteries is likely to continue in parallel with advancements in semiconductor technology and the increasing miniaturization of electronic devices. The integration of artificial intelligence and machine learning algorithms may lead to smart CMOS batteries capable of optimizing their performance based on usage patterns and environmental conditions.

As electronic devices became more sophisticated and energy-demanding, the role of CMOS batteries expanded beyond simple memory retention. The 1990s saw the introduction of rechargeable CMOS batteries, which offered improved longevity and reduced the need for frequent replacements. This shift aligned with the growing emphasis on sustainability and reduced electronic waste.

The turn of the millennium brought about significant advancements in CMOS battery technology. Manufacturers began exploring new materials and designs to enhance energy density and reduce self-discharge rates. The integration of thin-film technology allowed for the development of smaller, more efficient CMOS batteries that could be seamlessly incorporated into increasingly compact devices.

In the 2000s, the rise of mobile computing and the Internet of Things (IoT) created new challenges and opportunities for CMOS battery innovation. The demand for batteries that could power a wide range of sensors and low-power devices led to the development of more versatile CMOS power solutions. This period saw the emergence of hybrid systems that combined traditional CMOS batteries with energy harvesting technologies, enabling devices to operate for extended periods without manual intervention.

Recent years have witnessed a focus on improving the environmental impact of CMOS batteries. Researchers have been exploring bio-based materials and eco-friendly manufacturing processes to create more sustainable power sources. Additionally, advancements in nanotechnology have opened up new possibilities for enhancing battery performance and longevity.

The current trajectory of CMOS battery evolution is aimed at addressing the needs of emerging technologies such as wearable devices, implantable medical sensors, and ultra-low-power IoT applications. Innovations in solid-state electrolytes and advanced electrode materials are paving the way for CMOS batteries with higher energy densities, faster charging capabilities, and improved safety profiles.

As we look to the future, the evolution of CMOS batteries is likely to continue in parallel with advancements in semiconductor technology and the increasing miniaturization of electronic devices. The integration of artificial intelligence and machine learning algorithms may lead to smart CMOS batteries capable of optimizing their performance based on usage patterns and environmental conditions.

Market Demand Analysis

The market demand for CMOS battery innovation is driven by the rapid growth of portable electronic devices, wearables, and IoT applications. As these technologies continue to evolve, there is an increasing need for smaller, more efficient, and longer-lasting power sources. CMOS batteries, with their potential for integration directly into semiconductor chips, are well-positioned to meet these demands.

In the consumer electronics sector, smartphones, tablets, and laptops are key drivers of CMOS battery demand. These devices require compact power solutions that can support extended usage times without compromising on performance. The wearable technology market, including smartwatches, fitness trackers, and health monitoring devices, is another significant contributor to the growing demand for CMOS batteries. These devices often have limited space for power components, making integrated CMOS batteries an attractive option.

The Internet of Things (IoT) represents a vast and expanding market for CMOS battery technology. As the number of connected devices continues to grow exponentially, there is a pressing need for power solutions that can support long-term, low-maintenance operation. CMOS batteries, with their potential for extended lifespans and minimal power consumption, are well-suited to meet the requirements of IoT sensors and devices deployed in remote or hard-to-reach locations.

In the automotive industry, the shift towards electric and autonomous vehicles is creating new opportunities for CMOS battery innovation. These advanced vehicles require sophisticated power management systems and a multitude of sensors, many of which could benefit from integrated CMOS battery solutions. The ability to incorporate power sources directly into electronic components could lead to more efficient and compact automotive designs.

The healthcare sector is another area where CMOS battery technology shows significant promise. Implantable medical devices, such as pacemakers and insulin pumps, require reliable, long-lasting power sources that are safe for use within the human body. CMOS batteries, with their potential for biocompatibility and miniaturization, could revolutionize the design and functionality of these life-saving devices.

Industrial and manufacturing applications are also driving demand for CMOS battery innovations. Smart factories and Industry 4.0 initiatives rely on a wide array of sensors and connected devices to optimize production processes. CMOS batteries could provide the long-term, maintenance-free power needed to support these advanced manufacturing systems.

As environmental concerns continue to grow, there is an increasing demand for more sustainable and eco-friendly power solutions. CMOS batteries, with their potential for improved energy efficiency and reduced material usage, align well with these market trends. Companies and consumers alike are seeking products that minimize environmental impact, creating additional market pull for CMOS battery innovations.

In the consumer electronics sector, smartphones, tablets, and laptops are key drivers of CMOS battery demand. These devices require compact power solutions that can support extended usage times without compromising on performance. The wearable technology market, including smartwatches, fitness trackers, and health monitoring devices, is another significant contributor to the growing demand for CMOS batteries. These devices often have limited space for power components, making integrated CMOS batteries an attractive option.

The Internet of Things (IoT) represents a vast and expanding market for CMOS battery technology. As the number of connected devices continues to grow exponentially, there is a pressing need for power solutions that can support long-term, low-maintenance operation. CMOS batteries, with their potential for extended lifespans and minimal power consumption, are well-suited to meet the requirements of IoT sensors and devices deployed in remote or hard-to-reach locations.

In the automotive industry, the shift towards electric and autonomous vehicles is creating new opportunities for CMOS battery innovation. These advanced vehicles require sophisticated power management systems and a multitude of sensors, many of which could benefit from integrated CMOS battery solutions. The ability to incorporate power sources directly into electronic components could lead to more efficient and compact automotive designs.

The healthcare sector is another area where CMOS battery technology shows significant promise. Implantable medical devices, such as pacemakers and insulin pumps, require reliable, long-lasting power sources that are safe for use within the human body. CMOS batteries, with their potential for biocompatibility and miniaturization, could revolutionize the design and functionality of these life-saving devices.

Industrial and manufacturing applications are also driving demand for CMOS battery innovations. Smart factories and Industry 4.0 initiatives rely on a wide array of sensors and connected devices to optimize production processes. CMOS batteries could provide the long-term, maintenance-free power needed to support these advanced manufacturing systems.

As environmental concerns continue to grow, there is an increasing demand for more sustainable and eco-friendly power solutions. CMOS batteries, with their potential for improved energy efficiency and reduced material usage, align well with these market trends. Companies and consumers alike are seeking products that minimize environmental impact, creating additional market pull for CMOS battery innovations.

Technical Challenges

The CMOS battery industry faces several significant technical challenges as it strives to align innovation with market needs. One of the primary hurdles is the inherent trade-off between energy density and power density. As consumers demand longer-lasting devices with faster charging capabilities, manufacturers must balance these competing requirements within the constraints of current CMOS battery technology.

Another critical challenge lies in the scalability of production processes. While laboratory-scale innovations show promise, translating these advancements into large-scale manufacturing remains problematic. Issues such as maintaining consistent quality, reducing production costs, and ensuring safety at scale continue to impede the rapid commercialization of new CMOS battery technologies.

The quest for improved safety features presents an ongoing technical challenge. As energy densities increase, so does the risk of thermal runaway and other safety hazards. Developing robust safety mechanisms that do not compromise performance or add significant weight and bulk to the battery is a complex engineering problem that requires innovative solutions.

Environmental concerns and regulatory pressures add another layer of complexity to CMOS battery innovation. The industry must address issues related to the sourcing of raw materials, reducing the environmental impact of production processes, and improving the recyclability of batteries at end-of-life. These challenges necessitate the development of new materials and manufacturing techniques that are both eco-friendly and economically viable.

The integration of CMOS batteries with advanced electronic systems poses additional technical hurdles. As devices become more sophisticated, batteries must be designed to interface seamlessly with power management systems, support rapid charge and discharge cycles, and maintain performance under varying environmental conditions. This requires a holistic approach to battery design that considers the entire ecosystem in which the battery will operate.

Lastly, the industry faces the challenge of extending battery lifespan and cycle life to meet consumer expectations and reduce electronic waste. Developing CMOS batteries that can withstand thousands of charge cycles without significant degradation in capacity or performance is a key area of focus. This involves addressing issues such as electrode degradation, electrolyte stability, and the formation of detrimental interface layers within the battery structure.

Overcoming these technical challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, manufacturing processes, and system integration. As the industry continues to innovate, addressing these challenges will be crucial in aligning CMOS battery technology with evolving market needs and ensuring its position as a key enabler of future electronic devices and systems.

Another critical challenge lies in the scalability of production processes. While laboratory-scale innovations show promise, translating these advancements into large-scale manufacturing remains problematic. Issues such as maintaining consistent quality, reducing production costs, and ensuring safety at scale continue to impede the rapid commercialization of new CMOS battery technologies.

The quest for improved safety features presents an ongoing technical challenge. As energy densities increase, so does the risk of thermal runaway and other safety hazards. Developing robust safety mechanisms that do not compromise performance or add significant weight and bulk to the battery is a complex engineering problem that requires innovative solutions.

Environmental concerns and regulatory pressures add another layer of complexity to CMOS battery innovation. The industry must address issues related to the sourcing of raw materials, reducing the environmental impact of production processes, and improving the recyclability of batteries at end-of-life. These challenges necessitate the development of new materials and manufacturing techniques that are both eco-friendly and economically viable.

The integration of CMOS batteries with advanced electronic systems poses additional technical hurdles. As devices become more sophisticated, batteries must be designed to interface seamlessly with power management systems, support rapid charge and discharge cycles, and maintain performance under varying environmental conditions. This requires a holistic approach to battery design that considers the entire ecosystem in which the battery will operate.

Lastly, the industry faces the challenge of extending battery lifespan and cycle life to meet consumer expectations and reduce electronic waste. Developing CMOS batteries that can withstand thousands of charge cycles without significant degradation in capacity or performance is a key area of focus. This involves addressing issues such as electrode degradation, electrolyte stability, and the formation of detrimental interface layers within the battery structure.

Overcoming these technical challenges requires a multidisciplinary approach, combining advancements in materials science, electrochemistry, manufacturing processes, and system integration. As the industry continues to innovate, addressing these challenges will be crucial in aligning CMOS battery technology with evolving market needs and ensuring its position as a key enabler of future electronic devices and systems.

Current Solutions

01 CMOS battery power management

Systems and methods for managing power in CMOS batteries, including techniques for monitoring battery voltage, implementing power-saving modes, and extending battery life through efficient power distribution and consumption in electronic devices.- CMOS battery power management: Systems and methods for managing power in CMOS batteries, including techniques for monitoring battery voltage, implementing power-saving modes, and extending battery life through efficient power distribution and consumption in electronic devices.

- CMOS battery replacement and backup systems: Innovations in CMOS battery replacement procedures and backup power systems, ensuring continuous operation of critical system functions during battery changes or failures, and improving overall system reliability.

- Integration of CMOS batteries in semiconductor devices: Advancements in integrating CMOS batteries within semiconductor devices, focusing on miniaturization, improved performance, and enhanced compatibility with various electronic components and systems.

- CMOS battery monitoring and diagnostics: Development of sophisticated monitoring and diagnostic systems for CMOS batteries, including real-time voltage tracking, predictive maintenance algorithms, and early warning systems for potential battery failures.

- Environmental and safety considerations for CMOS batteries: Innovations addressing environmental concerns and safety issues related to CMOS batteries, including eco-friendly materials, improved disposal methods, and enhanced protection against leakage or overheating.

02 CMOS battery replacement and backup systems

Innovations in CMOS battery replacement procedures and backup power systems to maintain critical data and settings during battery changes or failures, ensuring uninterrupted operation of electronic devices and preserving system configurations.Expand Specific Solutions03 CMOS battery integration in semiconductor devices

Advancements in integrating CMOS batteries within semiconductor devices, including novel packaging techniques, on-chip battery solutions, and improved connectivity between the battery and other components to enhance overall system performance and reliability.Expand Specific Solutions04 CMOS battery monitoring and diagnostics

Development of sophisticated monitoring and diagnostic systems for CMOS batteries, incorporating sensors and algorithms to accurately assess battery health, predict failures, and provide timely alerts for maintenance or replacement.Expand Specific Solutions05 CMOS battery applications in imaging devices

Specialized applications of CMOS batteries in imaging devices such as cameras and scanners, focusing on power management techniques to support image processing, sensor operation, and data retention in low-power states.Expand Specific Solutions

Industry Leaders

The CMOS battery innovation market is in a growth phase, driven by increasing demand for energy-efficient and high-performance electronic devices. The global market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with companies like Taiwan Semiconductor Manufacturing Co., Ltd., Samsung SDI Co., Ltd., and LG Energy Solution Ltd. leading the way in research and development. These firms are pushing the boundaries of CMOS battery technology, focusing on improving energy density, longevity, and miniaturization. Other players like Renesas Electronics Corp. and Qualcomm, Inc. are also making significant contributions, particularly in integrating CMOS batteries with advanced semiconductor technologies. The competitive landscape is intense, with both established tech giants and innovative startups vying for market share and technological breakthroughs.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has made significant strides in CMOS battery innovation, focusing on safety and longevity. Their approach involves the use of advanced cathode materials, such as nickel-rich NCM (Nickel Cobalt Manganese), which provides higher energy density while maintaining stability[1]. LG has also developed a proprietary separator technology that enhances the battery's safety by preventing internal short circuits[2]. Their CMOS batteries incorporate a smart battery management system (BMS) that optimizes charging and discharging cycles, extending the overall lifespan of the battery[3]. Additionally, LG has invested in sustainable manufacturing processes, reducing the carbon footprint of their CMOS battery production[4].

Strengths: Enhanced safety features, advanced BMS for longevity, and focus on sustainability. Weaknesses: Potentially higher costs due to advanced materials and manufacturing processes.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced CMOS battery technology that aligns with market needs for higher energy density and longer lifespan. Their innovative approach includes the use of silicon-based anodes, which can significantly increase the battery's capacity[1]. They have also implemented advanced electrolyte formulations that enhance the battery's stability and reduce degradation over time[2]. Samsung SDI's CMOS batteries feature a unique stacking architecture that optimizes space utilization and thermal management, resulting in improved performance in compact devices[3]. The company has also focused on developing fast-charging capabilities, with their latest CMOS batteries able to reach 80% charge in just 30 minutes[4].

Strengths: High energy density, fast charging capabilities, and improved thermal management. Weaknesses: Potentially higher production costs and the need for specialized manufacturing processes.

Key Innovations

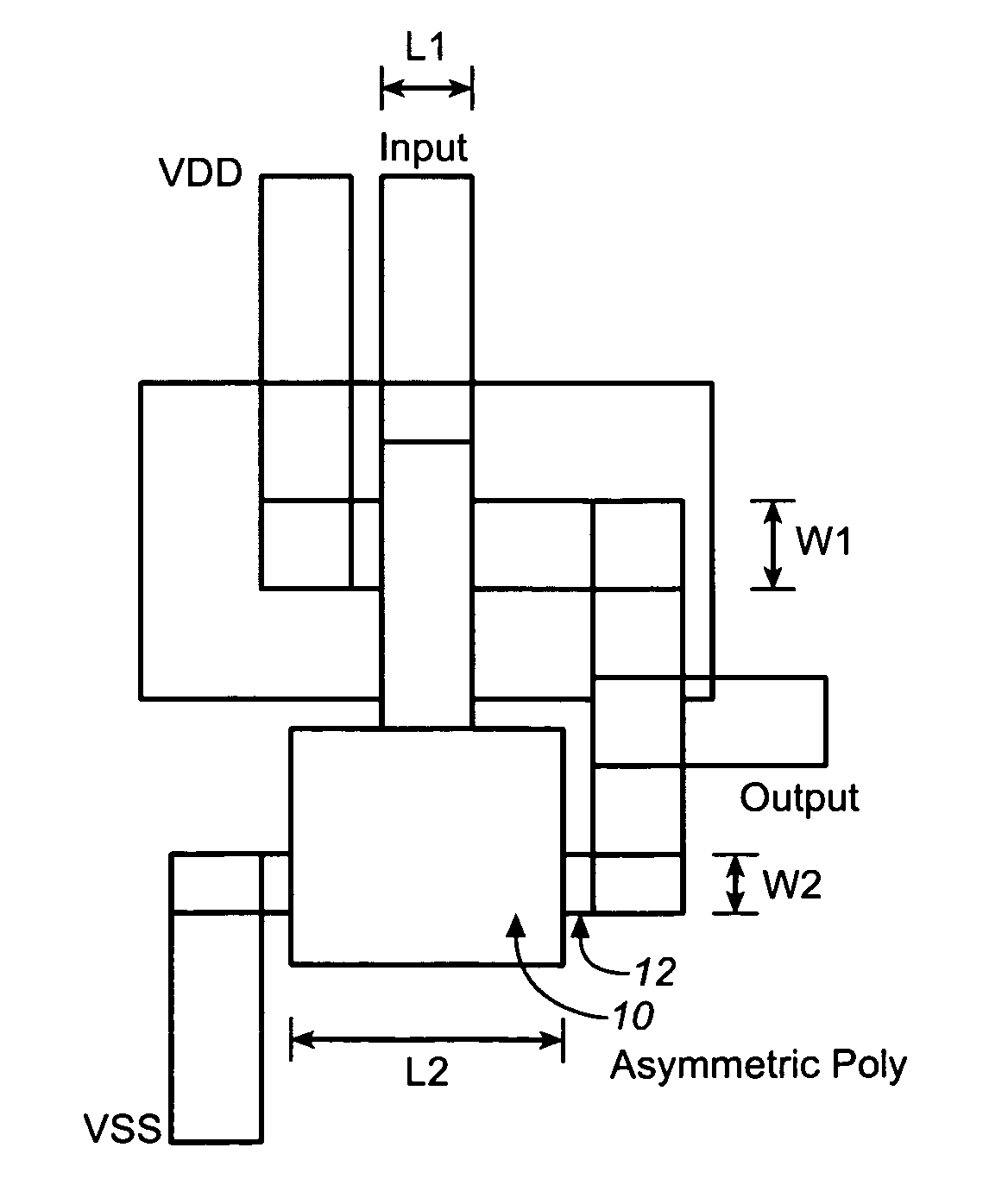

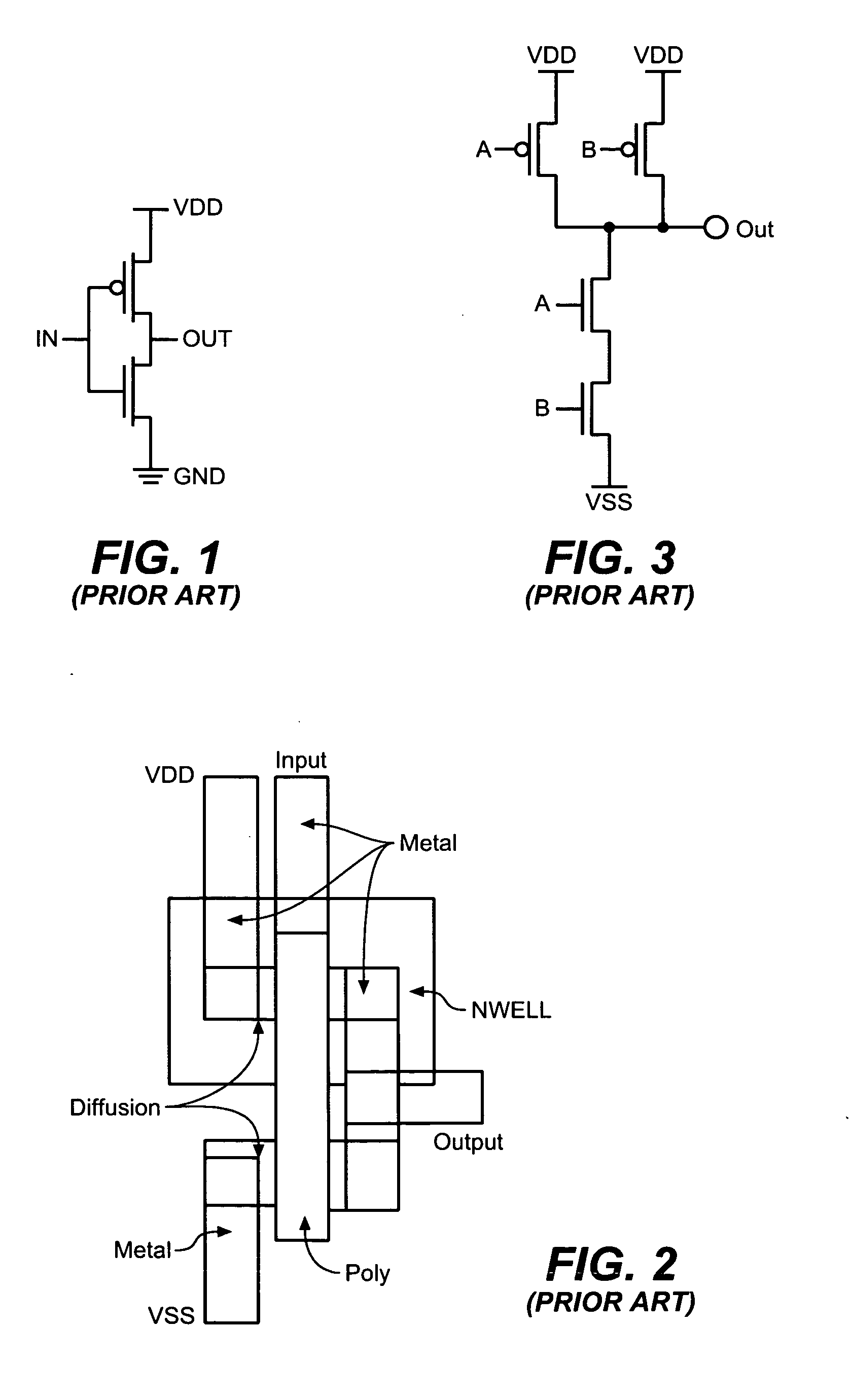

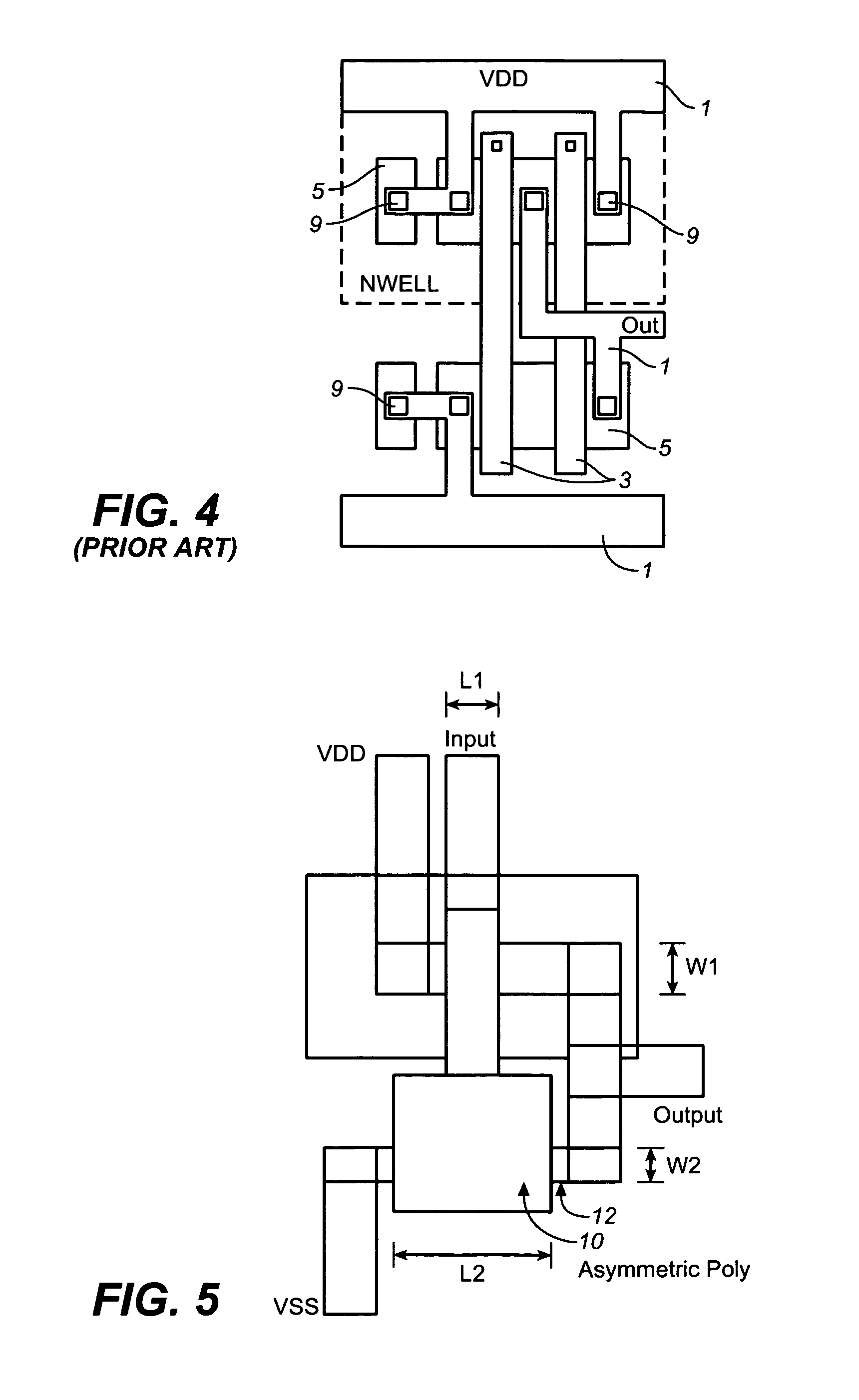

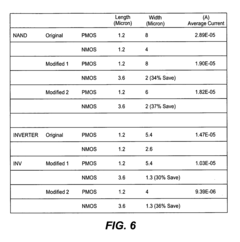

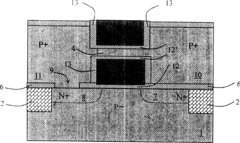

Asymmetrical layout for complementary metal-oxide-semiconductor integrated circuit to reduce power consumption

PatentInactiveUS20090072320A1

Innovation

- The implementation of an asymmetrical polysilicon gate and diffusion layout in CMOS integrated circuits, where the polysilicon gate and diffusion dimensions are asymmetrical, causing P-type and N-type transistors to switch at different times, thereby reducing short circuit current and power consumption.

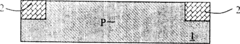

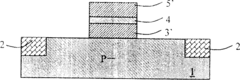

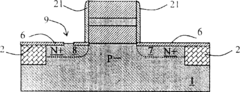

A CMOS integrated circuit and method for making same

PatentInactiveCN1299364C

Innovation

- A stacked CMOS structure is adopted, in which the pMOS device is located on top of the nMOS device and shares the same gate electrode. The pMOS device has a self-aligned double gate or gate-all-around structure, with thick source and drain regions and thin channel regions. It is formed through specific preparation methods such as The three-layer film of silicon dioxide, silicon and silicon dioxide, sidewall protection and polysilicon doping and other steps achieve self-alignment and area sharing of the device.

Supply Chain Analysis

The supply chain for CMOS battery innovation is a complex network involving multiple stakeholders and processes. Raw material suppliers play a crucial role, providing essential components such as lithium, cobalt, and nickel. These materials are often sourced from various global locations, creating potential vulnerabilities in the supply chain due to geopolitical factors and market fluctuations.

Manufacturing processes for CMOS batteries require specialized equipment and expertise. Key players in this segment include established electronics manufacturers and emerging battery technology companies. The production chain typically involves multiple stages, from electrode fabrication to cell assembly and final integration into devices. Quality control and consistency are critical factors throughout the manufacturing process.

Distribution channels for CMOS batteries vary depending on the end-use application. For consumer electronics, batteries are often integrated into devices before reaching retailers. In contrast, industrial and automotive applications may involve direct supply relationships between battery manufacturers and end-users. The increasing demand for electric vehicles has led to the development of dedicated battery supply chains, with some automakers investing in their own battery production facilities.

Recycling and end-of-life management are becoming increasingly important aspects of the CMOS battery supply chain. As environmental concerns grow, there is a push for more efficient recycling processes to recover valuable materials and reduce waste. This has led to the emergence of specialized recycling companies and the development of new technologies for battery material recovery.

The global nature of the CMOS battery supply chain presents both opportunities and challenges. While it allows for cost optimization and access to diverse resources, it also exposes the industry to risks such as trade disputes, transportation disruptions, and regional regulatory changes. To mitigate these risks, many companies are exploring strategies such as supply chain diversification, vertical integration, and the development of local production capabilities.

Innovation in CMOS battery technology is closely tied to supply chain developments. Advances in materials science and manufacturing processes often require corresponding changes in the supply chain, from sourcing new materials to adapting production techniques. This dynamic relationship between innovation and supply chain management is crucial for aligning CMOS battery development with market needs and ensuring the successful commercialization of new technologies.

Manufacturing processes for CMOS batteries require specialized equipment and expertise. Key players in this segment include established electronics manufacturers and emerging battery technology companies. The production chain typically involves multiple stages, from electrode fabrication to cell assembly and final integration into devices. Quality control and consistency are critical factors throughout the manufacturing process.

Distribution channels for CMOS batteries vary depending on the end-use application. For consumer electronics, batteries are often integrated into devices before reaching retailers. In contrast, industrial and automotive applications may involve direct supply relationships between battery manufacturers and end-users. The increasing demand for electric vehicles has led to the development of dedicated battery supply chains, with some automakers investing in their own battery production facilities.

Recycling and end-of-life management are becoming increasingly important aspects of the CMOS battery supply chain. As environmental concerns grow, there is a push for more efficient recycling processes to recover valuable materials and reduce waste. This has led to the emergence of specialized recycling companies and the development of new technologies for battery material recovery.

The global nature of the CMOS battery supply chain presents both opportunities and challenges. While it allows for cost optimization and access to diverse resources, it also exposes the industry to risks such as trade disputes, transportation disruptions, and regional regulatory changes. To mitigate these risks, many companies are exploring strategies such as supply chain diversification, vertical integration, and the development of local production capabilities.

Innovation in CMOS battery technology is closely tied to supply chain developments. Advances in materials science and manufacturing processes often require corresponding changes in the supply chain, from sourcing new materials to adapting production techniques. This dynamic relationship between innovation and supply chain management is crucial for aligning CMOS battery development with market needs and ensuring the successful commercialization of new technologies.

Environmental Impact

The environmental impact of CMOS battery innovation is a critical consideration in aligning technological advancements with market needs. As the demand for more efficient and sustainable energy storage solutions grows, the CMOS battery industry faces increasing pressure to minimize its ecological footprint throughout the product lifecycle.

One of the primary environmental concerns associated with CMOS batteries is the use of potentially hazardous materials in their production. Traditional lithium-ion batteries often contain toxic elements such as cobalt and nickel, which can pose significant environmental risks if not properly managed. However, recent innovations in CMOS battery technology have focused on developing more environmentally friendly alternatives, such as lithium iron phosphate (LiFePO4) batteries, which utilize less toxic materials and offer improved safety profiles.

The manufacturing process of CMOS batteries also contributes to their environmental impact. Energy-intensive production methods and the use of non-renewable resources can lead to increased carbon emissions and resource depletion. To address these issues, manufacturers are exploring more sustainable production techniques, including the use of renewable energy sources in manufacturing facilities and the implementation of closed-loop recycling systems to recover and reuse valuable materials.

Battery lifespan and disposal are additional environmental concerns. Longer-lasting CMOS batteries can reduce the frequency of replacements, thereby minimizing electronic waste. Innovations in battery management systems and improved charge-discharge cycles are extending the operational life of CMOS batteries, aligning with market demands for more durable and sustainable products. Furthermore, advancements in recycling technologies are enabling more efficient recovery of materials from spent batteries, reducing the environmental burden associated with disposal.

The potential for CMOS batteries to enable broader adoption of renewable energy systems also contributes to their positive environmental impact. By providing efficient and reliable energy storage solutions, CMOS batteries can support the integration of intermittent renewable energy sources into the power grid, potentially reducing reliance on fossil fuels and lowering overall carbon emissions.

As environmental regulations become more stringent globally, CMOS battery manufacturers are increasingly focusing on eco-design principles. This approach considers the entire lifecycle of the battery, from raw material extraction to end-of-life disposal, aiming to minimize environmental impact at every stage. Innovations in this area include the development of biodegradable battery components and the use of recycled materials in battery production.

In conclusion, aligning CMOS battery innovation with market needs necessitates a strong focus on environmental sustainability. As consumers and regulators demand more eco-friendly products, the industry's ability to develop environmentally responsible solutions will be crucial for long-term success and market acceptance.

One of the primary environmental concerns associated with CMOS batteries is the use of potentially hazardous materials in their production. Traditional lithium-ion batteries often contain toxic elements such as cobalt and nickel, which can pose significant environmental risks if not properly managed. However, recent innovations in CMOS battery technology have focused on developing more environmentally friendly alternatives, such as lithium iron phosphate (LiFePO4) batteries, which utilize less toxic materials and offer improved safety profiles.

The manufacturing process of CMOS batteries also contributes to their environmental impact. Energy-intensive production methods and the use of non-renewable resources can lead to increased carbon emissions and resource depletion. To address these issues, manufacturers are exploring more sustainable production techniques, including the use of renewable energy sources in manufacturing facilities and the implementation of closed-loop recycling systems to recover and reuse valuable materials.

Battery lifespan and disposal are additional environmental concerns. Longer-lasting CMOS batteries can reduce the frequency of replacements, thereby minimizing electronic waste. Innovations in battery management systems and improved charge-discharge cycles are extending the operational life of CMOS batteries, aligning with market demands for more durable and sustainable products. Furthermore, advancements in recycling technologies are enabling more efficient recovery of materials from spent batteries, reducing the environmental burden associated with disposal.

The potential for CMOS batteries to enable broader adoption of renewable energy systems also contributes to their positive environmental impact. By providing efficient and reliable energy storage solutions, CMOS batteries can support the integration of intermittent renewable energy sources into the power grid, potentially reducing reliance on fossil fuels and lowering overall carbon emissions.

As environmental regulations become more stringent globally, CMOS battery manufacturers are increasingly focusing on eco-design principles. This approach considers the entire lifecycle of the battery, from raw material extraction to end-of-life disposal, aiming to minimize environmental impact at every stage. Innovations in this area include the development of biodegradable battery components and the use of recycled materials in battery production.

In conclusion, aligning CMOS battery innovation with market needs necessitates a strong focus on environmental sustainability. As consumers and regulators demand more eco-friendly products, the industry's ability to develop environmentally responsible solutions will be crucial for long-term success and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!