How to Assess CMOS Battery Health in Devices?

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Overview

CMOS (Complementary Metal-Oxide-Semiconductor) batteries, also known as RTC (Real-Time Clock) batteries, play a crucial role in maintaining system settings and timekeeping functions in various electronic devices. These small, coin-shaped lithium batteries are typically found in computer motherboards, servers, and other electronic equipment that require persistent memory of system configurations and time-related data.

The primary function of a CMOS battery is to provide power to the CMOS chip when the main power source is disconnected. This ensures that critical information such as BIOS settings, system time, and date are retained even when the device is powered off or unplugged. The longevity and reliability of these batteries are essential for maintaining system integrity and preventing unexpected resets or loss of configuration data.

CMOS batteries are designed to last for several years, typically ranging from 3 to 10 years, depending on various factors such as usage patterns, environmental conditions, and the quality of the battery itself. However, as with all batteries, CMOS batteries gradually lose their capacity over time, which can lead to system instability, incorrect time and date settings, or frequent BIOS resets.

The technology behind CMOS batteries has evolved over the years, with improvements in energy density, longevity, and environmental impact. Modern CMOS batteries often use lithium-based chemistries, such as lithium manganese dioxide (LiMnO2) or lithium carbon monofluoride (LiCFx), which offer better performance and longer shelf life compared to earlier versions.

Understanding the health and status of CMOS batteries is crucial for maintaining the reliability of electronic devices, especially in critical systems where unexpected downtime can have significant consequences. As these batteries age, they may exhibit symptoms such as frequent system time resets, loss of BIOS settings, or difficulty in booting up the device. Proactive assessment and replacement of aging CMOS batteries can prevent these issues and ensure smooth operation of electronic equipment.

Given the importance of CMOS batteries in maintaining system functionality, developing effective methods for assessing their health is a key concern for device manufacturers, IT professionals, and end-users alike. This involves not only understanding the typical lifespan of these batteries but also developing techniques to accurately measure their remaining capacity and predict potential failures before they occur.

The primary function of a CMOS battery is to provide power to the CMOS chip when the main power source is disconnected. This ensures that critical information such as BIOS settings, system time, and date are retained even when the device is powered off or unplugged. The longevity and reliability of these batteries are essential for maintaining system integrity and preventing unexpected resets or loss of configuration data.

CMOS batteries are designed to last for several years, typically ranging from 3 to 10 years, depending on various factors such as usage patterns, environmental conditions, and the quality of the battery itself. However, as with all batteries, CMOS batteries gradually lose their capacity over time, which can lead to system instability, incorrect time and date settings, or frequent BIOS resets.

The technology behind CMOS batteries has evolved over the years, with improvements in energy density, longevity, and environmental impact. Modern CMOS batteries often use lithium-based chemistries, such as lithium manganese dioxide (LiMnO2) or lithium carbon monofluoride (LiCFx), which offer better performance and longer shelf life compared to earlier versions.

Understanding the health and status of CMOS batteries is crucial for maintaining the reliability of electronic devices, especially in critical systems where unexpected downtime can have significant consequences. As these batteries age, they may exhibit symptoms such as frequent system time resets, loss of BIOS settings, or difficulty in booting up the device. Proactive assessment and replacement of aging CMOS batteries can prevent these issues and ensure smooth operation of electronic equipment.

Given the importance of CMOS batteries in maintaining system functionality, developing effective methods for assessing their health is a key concern for device manufacturers, IT professionals, and end-users alike. This involves not only understanding the typical lifespan of these batteries but also developing techniques to accurately measure their remaining capacity and predict potential failures before they occur.

Market Need Analysis

The market need for assessing CMOS battery health in devices has grown significantly in recent years, driven by the increasing reliance on electronic devices across various sectors. CMOS batteries, also known as Real-Time Clock (RTC) batteries, play a crucial role in maintaining system settings and timekeeping functions in computers and other electronic devices. As these devices become more integral to business operations and personal use, the demand for reliable methods to assess CMOS battery health has intensified.

In the corporate sector, IT departments face the challenge of managing large fleets of computers and servers. The failure of a CMOS battery can lead to system instability, data loss, and unexpected downtime, resulting in significant productivity losses and potential financial impacts. This has created a strong market need for tools and techniques that can proactively assess CMOS battery health, allowing for timely replacements and minimizing disruptions to business operations.

The consumer electronics market has also contributed to the growing demand for CMOS battery health assessment. With the increasing lifespan of devices and the trend towards sustainability, consumers are seeking ways to extend the usability of their electronics. The ability to accurately assess CMOS battery health empowers users to make informed decisions about device maintenance and replacement, aligning with the broader trend of electronic waste reduction and sustainable consumption.

In the healthcare and industrial sectors, where equipment reliability is paramount, the need for CMOS battery health assessment is particularly acute. Medical devices, industrial control systems, and critical infrastructure rely on accurate timekeeping and consistent system settings. Failures in these areas can have severe consequences, ranging from compromised patient care to production line shutdowns. This has led to a growing market for specialized CMOS battery health monitoring solutions in these high-stakes environments.

The automotive industry, with its rapid shift towards electric and autonomous vehicles, has emerged as another significant market for CMOS battery health assessment. Modern vehicles rely on numerous electronic control units (ECUs) that often incorporate CMOS batteries. Ensuring the reliability of these components is crucial for vehicle safety and performance, driving demand for integrated battery health monitoring systems.

As the Internet of Things (IoT) continues to expand, the market need for CMOS battery health assessment extends to a vast array of connected devices. From smart home appliances to industrial sensors, the ability to remotely monitor and assess battery health becomes increasingly valuable. This trend is fueling innovation in low-power, long-life battery technologies and associated health monitoring solutions.

The market need is further amplified by regulatory requirements in certain industries that mandate regular equipment maintenance and reliability checks. This has created opportunities for software and hardware solutions that can provide documented evidence of CMOS battery health assessments, catering to compliance-driven markets.

In the corporate sector, IT departments face the challenge of managing large fleets of computers and servers. The failure of a CMOS battery can lead to system instability, data loss, and unexpected downtime, resulting in significant productivity losses and potential financial impacts. This has created a strong market need for tools and techniques that can proactively assess CMOS battery health, allowing for timely replacements and minimizing disruptions to business operations.

The consumer electronics market has also contributed to the growing demand for CMOS battery health assessment. With the increasing lifespan of devices and the trend towards sustainability, consumers are seeking ways to extend the usability of their electronics. The ability to accurately assess CMOS battery health empowers users to make informed decisions about device maintenance and replacement, aligning with the broader trend of electronic waste reduction and sustainable consumption.

In the healthcare and industrial sectors, where equipment reliability is paramount, the need for CMOS battery health assessment is particularly acute. Medical devices, industrial control systems, and critical infrastructure rely on accurate timekeeping and consistent system settings. Failures in these areas can have severe consequences, ranging from compromised patient care to production line shutdowns. This has led to a growing market for specialized CMOS battery health monitoring solutions in these high-stakes environments.

The automotive industry, with its rapid shift towards electric and autonomous vehicles, has emerged as another significant market for CMOS battery health assessment. Modern vehicles rely on numerous electronic control units (ECUs) that often incorporate CMOS batteries. Ensuring the reliability of these components is crucial for vehicle safety and performance, driving demand for integrated battery health monitoring systems.

As the Internet of Things (IoT) continues to expand, the market need for CMOS battery health assessment extends to a vast array of connected devices. From smart home appliances to industrial sensors, the ability to remotely monitor and assess battery health becomes increasingly valuable. This trend is fueling innovation in low-power, long-life battery technologies and associated health monitoring solutions.

The market need is further amplified by regulatory requirements in certain industries that mandate regular equipment maintenance and reliability checks. This has created opportunities for software and hardware solutions that can provide documented evidence of CMOS battery health assessments, catering to compliance-driven markets.

Technical Challenges

Assessing CMOS battery health in devices presents several technical challenges that researchers and engineers must address. One of the primary difficulties lies in accurately measuring the remaining capacity of the battery without disrupting the device's normal operation. Traditional methods often require removing the battery or powering down the system, which can be impractical for many devices.

The small size and low capacity of CMOS batteries further complicate the assessment process. These batteries typically have a capacity of only a few milliamp-hours, making precise measurements challenging with conventional testing equipment. Additionally, the slow discharge rate of CMOS batteries over extended periods makes it difficult to detect gradual degradation in real-time.

Another significant challenge is the lack of standardized testing protocols for CMOS battery health assessment. Unlike larger rechargeable batteries used in consumer electronics, CMOS batteries have not received the same level of attention in terms of health monitoring standards. This absence of uniformity makes it challenging to compare results across different devices and manufacturers.

The environmental factors affecting CMOS battery performance add another layer of complexity to health assessment. Temperature fluctuations, humidity, and electromagnetic interference can all impact battery behavior, making it necessary to account for these variables when evaluating battery health. Developing accurate models that incorporate these environmental factors remains an ongoing challenge.

The integration of CMOS batteries within complex electronic systems also poses difficulties for health assessment. These batteries are often deeply embedded within devices, making direct access for testing purposes problematic. Non-invasive techniques for assessing battery health without disassembling the device are highly desirable but technologically challenging to implement.

Furthermore, the long lifespan of CMOS batteries, often measured in years, creates challenges for accelerated testing and prediction of long-term performance. Developing reliable methods to extrapolate short-term test results to predict years of battery life remains an area of active research and development.

Lastly, the increasing complexity of modern devices and their power management systems introduces additional variables that can affect CMOS battery health assessment. Advanced power-saving features and dynamic load conditions can mask battery degradation, making it difficult to isolate and evaluate the true state of the battery's health.

The small size and low capacity of CMOS batteries further complicate the assessment process. These batteries typically have a capacity of only a few milliamp-hours, making precise measurements challenging with conventional testing equipment. Additionally, the slow discharge rate of CMOS batteries over extended periods makes it difficult to detect gradual degradation in real-time.

Another significant challenge is the lack of standardized testing protocols for CMOS battery health assessment. Unlike larger rechargeable batteries used in consumer electronics, CMOS batteries have not received the same level of attention in terms of health monitoring standards. This absence of uniformity makes it challenging to compare results across different devices and manufacturers.

The environmental factors affecting CMOS battery performance add another layer of complexity to health assessment. Temperature fluctuations, humidity, and electromagnetic interference can all impact battery behavior, making it necessary to account for these variables when evaluating battery health. Developing accurate models that incorporate these environmental factors remains an ongoing challenge.

The integration of CMOS batteries within complex electronic systems also poses difficulties for health assessment. These batteries are often deeply embedded within devices, making direct access for testing purposes problematic. Non-invasive techniques for assessing battery health without disassembling the device are highly desirable but technologically challenging to implement.

Furthermore, the long lifespan of CMOS batteries, often measured in years, creates challenges for accelerated testing and prediction of long-term performance. Developing reliable methods to extrapolate short-term test results to predict years of battery life remains an area of active research and development.

Lastly, the increasing complexity of modern devices and their power management systems introduces additional variables that can affect CMOS battery health assessment. Advanced power-saving features and dynamic load conditions can mask battery degradation, making it difficult to isolate and evaluate the true state of the battery's health.

Current Assessment Methods

01 CMOS battery monitoring and health assessment

Systems and methods for monitoring CMOS battery health, including voltage level checks, capacity estimation, and predictive analysis to determine battery life expectancy and potential failure. This helps in proactive maintenance and prevents unexpected system failures due to CMOS battery issues.- CMOS battery monitoring and health assessment: Systems and methods for monitoring the health and performance of CMOS batteries in electronic devices. This includes techniques for measuring battery voltage, capacity, and overall condition to predict potential failures and ensure system reliability.

- Battery replacement notification and management: Implementations for detecting when a CMOS battery needs replacement and providing notifications to users or system administrators. This may involve setting thresholds for battery parameters and triggering alerts when these thresholds are reached.

- Power management and battery life extension: Techniques for optimizing power consumption and extending the life of CMOS batteries. This includes intelligent power management strategies, sleep modes, and methods to reduce the drain on the battery during periods of inactivity.

- CMOS battery testing and diagnostics: Advanced diagnostic tools and methods for testing CMOS batteries, including in-situ testing capabilities. These diagnostics can help identify potential issues before they lead to system failures and provide more accurate assessments of battery health.

- Integration with system management and reporting: Approaches for integrating CMOS battery health information into broader system management and reporting frameworks. This allows for centralized monitoring of battery status across multiple devices and facilitates proactive maintenance strategies.

02 CMOS battery replacement notification

Techniques for alerting users or system administrators when CMOS battery replacement is necessary. This includes implementing warning systems, generating notifications, and providing guidance on the replacement process to ensure continuous system operation and data integrity.Expand Specific Solutions03 Power management and battery life extension

Strategies to optimize CMOS battery usage and extend its lifespan. This involves implementing power-saving modes, reducing unnecessary battery drain, and utilizing intelligent charging algorithms to maximize battery health and longevity in computer systems.Expand Specific Solutions04 CMOS battery backup and data preservation

Methods for ensuring data preservation and system integrity during CMOS battery failure or replacement. This includes implementing backup power sources, data redundancy techniques, and failsafe mechanisms to protect critical system information and settings.Expand Specific Solutions05 CMOS battery diagnostics and testing

Advanced diagnostic tools and testing procedures for assessing CMOS battery health. This encompasses automated testing routines, real-time monitoring systems, and comprehensive health reports to accurately determine battery condition and performance in various computing environments.Expand Specific Solutions

Key Industry Players

The assessment of CMOS battery health in devices is currently in a mature stage of industry development, with a stable market size and well-established technologies. Major players like Samsung Electronics, Huawei Technologies, and LG Energy Solution have significantly contributed to the advancement of battery health assessment techniques. The market is characterized by a mix of established electronics manufacturers and specialized battery technology companies, indicating a diverse competitive landscape. As the demand for longer-lasting and more reliable devices grows, companies are focusing on developing more sophisticated and accurate battery health assessment methods, integrating advanced sensors and AI-driven analytics to improve diagnostics and predictive maintenance capabilities.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed an advanced Battery Management System (BMS) that incorporates real-time monitoring of CMOS battery health. Their approach utilizes a combination of voltage measurement, internal resistance tracking, and temperature monitoring to accurately assess battery condition[1]. The system employs machine learning algorithms to analyze historical data and predict potential failures, allowing for proactive maintenance[3]. Additionally, Samsung has integrated this technology into their smart devices, enabling users to access battery health information through dedicated apps or system settings[5].

Strengths: Comprehensive approach combining multiple parameters for accurate assessment; predictive maintenance capabilities. Weaknesses: May require specialized hardware integration, potentially increasing device cost.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has implemented a multi-faceted CMOS battery health assessment system in their devices. Their approach involves continuous monitoring of battery voltage, current, and temperature, coupled with advanced algorithms to calculate State of Health (SoH)[2]. Huawei's system also incorporates adaptive charging techniques that adjust based on battery health to prolong lifespan[4]. The company has introduced AI-powered battery health prediction models that can estimate future degradation based on usage patterns and environmental factors[6]. This technology is integrated into Huawei's EMUI operating system, providing users with detailed battery health reports and optimization suggestions.

Strengths: AI-powered predictive modeling; integration with device OS for user accessibility. Weaknesses: Heavily reliant on proprietary algorithms, which may limit third-party verification or standardization.

Innovative Technologies

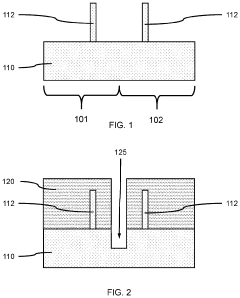

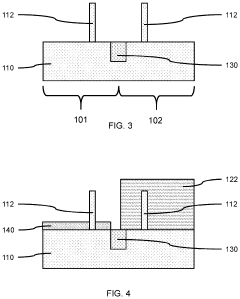

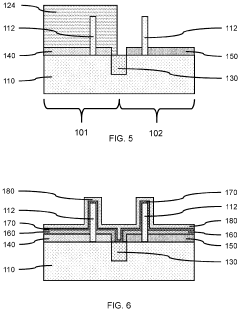

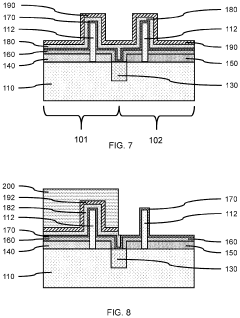

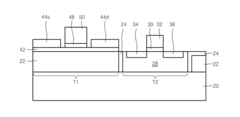

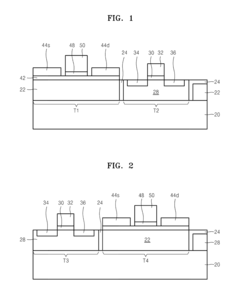

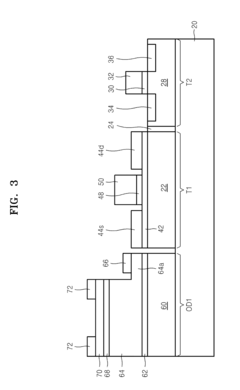

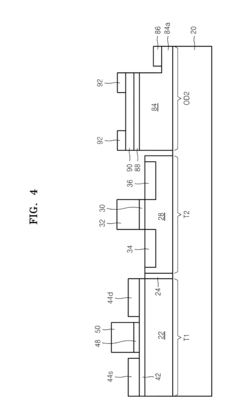

FinFET complementary metal-oxide-semiconductor (CMOS) devices

PatentActiveUS11652006B2

Innovation

- A method is developed to form a modified work function material layer on n-type fin FETs through heat treatment, while maintaining unmodified work function materials on p-type fin FETs, allowing for adjacent n-type and p-type FETs with different work functions on the same substrate, enabling effective coupling in CMOS devices.

Complementary metal oxide semiconductor device, optical apparatus including the same, and method of manufacturing the same

PatentActiveUS20150303114A1

Innovation

- Simultaneously forming Group III-V and germanium base materials on a silicon substrate, with specific transistor configurations and manufacturing methods that include forming substrates, electrodes, and gate structures, and using insulating layers to minimize defects and optimize performance.

Regulatory Compliance

Regulatory compliance is a critical aspect of assessing CMOS battery health in devices, as it ensures that manufacturers and users adhere to established standards and guidelines. The primary regulatory bodies governing CMOS battery usage and disposal include the Environmental Protection Agency (EPA) and the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive.

In the United States, the EPA regulates the disposal of batteries, including CMOS batteries, under the Resource Conservation and Recovery Act (RCRA). This act mandates proper handling and disposal of potentially hazardous materials, which includes lithium-based CMOS batteries. Manufacturers and service providers must comply with these regulations when assessing and replacing CMOS batteries in devices.

The European Union's WEEE Directive aims to reduce electronic waste and promote recycling. It requires manufacturers to provide information on the proper disposal and recycling of electronic components, including CMOS batteries. This directive influences the design and assessment processes for CMOS batteries, encouraging manufacturers to develop easily removable and recyclable battery solutions.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide guidelines for battery safety and performance. These standards often include specifications for assessing battery health and determining when replacement is necessary. Compliance with these standards is crucial for ensuring device reliability and user safety.

Many countries have implemented regulations requiring manufacturers to provide battery health information to consumers. For instance, some jurisdictions mandate that device manufacturers include tools or indicators for users to assess CMOS battery health. This requirement has led to the development of various software-based battery health monitoring systems integrated into device firmware.

Regulatory compliance also extends to the transportation of devices containing CMOS batteries. The International Air Transport Association (IATA) has specific guidelines for the air transport of lithium batteries, which include CMOS batteries. These regulations impact how devices with CMOS batteries are shipped and handled during distribution and service.

As environmental concerns grow, regulations are evolving to promote more sustainable practices in electronic device manufacturing and maintenance. This trend is influencing the development of new CMOS battery technologies and assessment methods that prioritize longevity, energy efficiency, and recyclability.

Manufacturers and service providers must stay informed about changing regulations and standards related to CMOS battery health assessment. Compliance with these regulations not only ensures legal operation but also contributes to improved device performance, user safety, and environmental protection. As technology advances, regulatory frameworks are likely to adapt, potentially leading to more sophisticated and standardized methods for assessing CMOS battery health in devices.

In the United States, the EPA regulates the disposal of batteries, including CMOS batteries, under the Resource Conservation and Recovery Act (RCRA). This act mandates proper handling and disposal of potentially hazardous materials, which includes lithium-based CMOS batteries. Manufacturers and service providers must comply with these regulations when assessing and replacing CMOS batteries in devices.

The European Union's WEEE Directive aims to reduce electronic waste and promote recycling. It requires manufacturers to provide information on the proper disposal and recycling of electronic components, including CMOS batteries. This directive influences the design and assessment processes for CMOS batteries, encouraging manufacturers to develop easily removable and recyclable battery solutions.

International standards, such as those set by the International Electrotechnical Commission (IEC), provide guidelines for battery safety and performance. These standards often include specifications for assessing battery health and determining when replacement is necessary. Compliance with these standards is crucial for ensuring device reliability and user safety.

Many countries have implemented regulations requiring manufacturers to provide battery health information to consumers. For instance, some jurisdictions mandate that device manufacturers include tools or indicators for users to assess CMOS battery health. This requirement has led to the development of various software-based battery health monitoring systems integrated into device firmware.

Regulatory compliance also extends to the transportation of devices containing CMOS batteries. The International Air Transport Association (IATA) has specific guidelines for the air transport of lithium batteries, which include CMOS batteries. These regulations impact how devices with CMOS batteries are shipped and handled during distribution and service.

As environmental concerns grow, regulations are evolving to promote more sustainable practices in electronic device manufacturing and maintenance. This trend is influencing the development of new CMOS battery technologies and assessment methods that prioritize longevity, energy efficiency, and recyclability.

Manufacturers and service providers must stay informed about changing regulations and standards related to CMOS battery health assessment. Compliance with these regulations not only ensures legal operation but also contributes to improved device performance, user safety, and environmental protection. As technology advances, regulatory frameworks are likely to adapt, potentially leading to more sophisticated and standardized methods for assessing CMOS battery health in devices.

Environmental Impact

The environmental impact of CMOS battery assessment and management in devices is a critical consideration in the broader context of electronic waste and sustainability. CMOS batteries, typically lithium-based, pose potential environmental risks if not properly handled throughout their lifecycle. The assessment process itself, when conducted regularly, can contribute to extending the lifespan of devices, thereby reducing electronic waste generation.

Proper assessment techniques can lead to more accurate predictions of battery failure, allowing for timely replacements and preventing sudden device malfunctions. This proactive approach not only enhances device reliability but also minimizes the premature disposal of otherwise functional electronics. By extending device lifespans, the demand for new device production is reduced, consequently lowering the environmental footprint associated with manufacturing processes.

However, the assessment process may require specialized equipment or tools, which themselves have environmental implications in terms of production and eventual disposal. It is crucial to balance the environmental costs of assessment against the benefits of prolonged device use. Additionally, the energy consumption during assessment procedures, while typically minimal, should be considered in the overall environmental impact calculation.

The disposal of CMOS batteries identified as failing or at the end of their life cycle presents another environmental challenge. These batteries contain hazardous materials that can harm ecosystems if improperly discarded. Implementing effective recycling programs for CMOS batteries is essential to mitigate these risks and recover valuable materials. Such programs can significantly reduce the environmental burden associated with battery production and disposal.

Furthermore, the development of more environmentally friendly CMOS battery technologies is an important area of focus. Research into alternative materials and designs that reduce toxicity and improve recyclability can lead to substantial environmental benefits. Innovations in this field could potentially decrease the frequency of required assessments and replacements, further minimizing the overall environmental impact of CMOS battery use in devices.

Educating consumers and technicians about the importance of proper CMOS battery assessment and disposal is crucial for maximizing environmental benefits. Raising awareness about the role of regular maintenance in extending device lifespans and the proper channels for battery recycling can lead to more sustainable practices across the industry and among end-users.

Proper assessment techniques can lead to more accurate predictions of battery failure, allowing for timely replacements and preventing sudden device malfunctions. This proactive approach not only enhances device reliability but also minimizes the premature disposal of otherwise functional electronics. By extending device lifespans, the demand for new device production is reduced, consequently lowering the environmental footprint associated with manufacturing processes.

However, the assessment process may require specialized equipment or tools, which themselves have environmental implications in terms of production and eventual disposal. It is crucial to balance the environmental costs of assessment against the benefits of prolonged device use. Additionally, the energy consumption during assessment procedures, while typically minimal, should be considered in the overall environmental impact calculation.

The disposal of CMOS batteries identified as failing or at the end of their life cycle presents another environmental challenge. These batteries contain hazardous materials that can harm ecosystems if improperly discarded. Implementing effective recycling programs for CMOS batteries is essential to mitigate these risks and recover valuable materials. Such programs can significantly reduce the environmental burden associated with battery production and disposal.

Furthermore, the development of more environmentally friendly CMOS battery technologies is an important area of focus. Research into alternative materials and designs that reduce toxicity and improve recyclability can lead to substantial environmental benefits. Innovations in this field could potentially decrease the frequency of required assessments and replacements, further minimizing the overall environmental impact of CMOS battery use in devices.

Educating consumers and technicians about the importance of proper CMOS battery assessment and disposal is crucial for maximizing environmental benefits. Raising awareness about the role of regular maintenance in extending device lifespans and the proper channels for battery recycling can lead to more sustainable practices across the industry and among end-users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!