Uncovering CMOS Battery Potential in Strategic Industry Applications

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Evolution and Objectives

CMOS (Complementary Metal-Oxide-Semiconductor) battery technology has undergone significant evolution since its inception in the 1960s. Initially developed as a low-power solution for electronic devices, CMOS batteries have become an integral component in various strategic industry applications. The journey of CMOS battery technology reflects the broader trends in miniaturization, energy efficiency, and reliability in the electronics sector.

The primary objective of CMOS battery development has been to provide a stable, long-lasting power source for maintaining critical system information in electronic devices. This includes preserving BIOS settings, system time, and other vital data when the main power is disconnected. As industries increasingly rely on sophisticated electronic systems, the role of CMOS batteries has expanded beyond personal computers to encompass a wide range of strategic applications.

In the automotive industry, CMOS batteries play a crucial role in maintaining vehicle computer systems, ensuring that essential data such as engine management parameters and security codes are retained. The aerospace sector utilizes CMOS batteries in avionics systems, where maintaining system integrity during power cycles is paramount for safety and operational efficiency.

The evolution of CMOS battery technology has been driven by the need for increased capacity, reduced size, and enhanced reliability. Early CMOS batteries were relatively large and had limited lifespans. However, advancements in materials science and manufacturing techniques have led to the development of more compact, longer-lasting batteries with improved performance characteristics.

One of the key objectives in CMOS battery development has been to extend operational life while minimizing environmental impact. This has led to the exploration of alternative materials and designs that offer improved energy density and reduced reliance on potentially harmful substances. The push towards more sustainable and eco-friendly solutions aligns with broader industry trends and regulatory requirements.

Another significant goal in CMOS battery evolution has been to enhance integration capabilities. As electronic devices become more compact and feature-rich, there is a growing demand for CMOS batteries that can be seamlessly incorporated into increasingly complex system designs. This has spurred innovations in form factors and connection methods, allowing for greater flexibility in product design and manufacturing.

The future objectives for CMOS battery technology are focused on further improving energy density, reducing self-discharge rates, and exploring new applications in emerging industries. There is ongoing research into novel materials and architectures that could potentially revolutionize CMOS battery performance, opening up new possibilities for their use in strategic applications such as IoT devices, wearable technology, and advanced industrial control systems.

The primary objective of CMOS battery development has been to provide a stable, long-lasting power source for maintaining critical system information in electronic devices. This includes preserving BIOS settings, system time, and other vital data when the main power is disconnected. As industries increasingly rely on sophisticated electronic systems, the role of CMOS batteries has expanded beyond personal computers to encompass a wide range of strategic applications.

In the automotive industry, CMOS batteries play a crucial role in maintaining vehicle computer systems, ensuring that essential data such as engine management parameters and security codes are retained. The aerospace sector utilizes CMOS batteries in avionics systems, where maintaining system integrity during power cycles is paramount for safety and operational efficiency.

The evolution of CMOS battery technology has been driven by the need for increased capacity, reduced size, and enhanced reliability. Early CMOS batteries were relatively large and had limited lifespans. However, advancements in materials science and manufacturing techniques have led to the development of more compact, longer-lasting batteries with improved performance characteristics.

One of the key objectives in CMOS battery development has been to extend operational life while minimizing environmental impact. This has led to the exploration of alternative materials and designs that offer improved energy density and reduced reliance on potentially harmful substances. The push towards more sustainable and eco-friendly solutions aligns with broader industry trends and regulatory requirements.

Another significant goal in CMOS battery evolution has been to enhance integration capabilities. As electronic devices become more compact and feature-rich, there is a growing demand for CMOS batteries that can be seamlessly incorporated into increasingly complex system designs. This has spurred innovations in form factors and connection methods, allowing for greater flexibility in product design and manufacturing.

The future objectives for CMOS battery technology are focused on further improving energy density, reducing self-discharge rates, and exploring new applications in emerging industries. There is ongoing research into novel materials and architectures that could potentially revolutionize CMOS battery performance, opening up new possibilities for their use in strategic applications such as IoT devices, wearable technology, and advanced industrial control systems.

Market Demand Analysis for CMOS Batteries

The market demand for CMOS batteries has been steadily growing, driven by the increasing reliance on electronic devices and systems across various industries. These compact power sources play a crucial role in maintaining critical system settings and real-time clock functions in a wide range of applications, from personal computers to industrial equipment.

In the consumer electronics sector, the proliferation of laptops, desktops, and smart home devices has significantly contributed to the demand for CMOS batteries. As more households adopt multiple computing devices and smart appliances, the need for reliable power backup solutions has intensified. This trend is expected to continue as the Internet of Things (IoT) ecosystem expands, requiring more devices to maintain settings and connectivity even when unpowered.

The automotive industry represents another major market for CMOS batteries. Modern vehicles rely heavily on electronic control units (ECUs) and advanced driver assistance systems (ADAS), which require constant power to maintain settings and calibration data. As the automotive sector moves towards greater electrification and autonomous capabilities, the demand for CMOS batteries is projected to grow substantially.

In the industrial sector, CMOS batteries are essential components in programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other automation equipment. The ongoing trend of Industry 4.0 and smart manufacturing is driving the adoption of more sophisticated control systems, further boosting the demand for reliable backup power solutions.

The healthcare industry also presents a significant market opportunity for CMOS batteries. Medical devices, diagnostic equipment, and patient monitoring systems often require uninterrupted power to maintain critical settings and patient data. As healthcare facilities worldwide upgrade their equipment and adopt more advanced technologies, the demand for CMOS batteries in this sector is expected to rise.

The telecommunications industry, with its extensive network of base stations and data centers, represents another key market for CMOS batteries. These power sources are crucial for maintaining network configurations and ensuring rapid system recovery in the event of power failures. As 5G networks continue to expand globally, the demand for CMOS batteries in this sector is anticipated to grow significantly.

Market analysts project that the global CMOS battery market will experience steady growth in the coming years, driven by technological advancements and the increasing integration of electronic systems across various industries. However, the market also faces challenges, such as the need for longer-lasting and more environmentally friendly battery solutions, which may influence future demand patterns and technological developments in the field.

In the consumer electronics sector, the proliferation of laptops, desktops, and smart home devices has significantly contributed to the demand for CMOS batteries. As more households adopt multiple computing devices and smart appliances, the need for reliable power backup solutions has intensified. This trend is expected to continue as the Internet of Things (IoT) ecosystem expands, requiring more devices to maintain settings and connectivity even when unpowered.

The automotive industry represents another major market for CMOS batteries. Modern vehicles rely heavily on electronic control units (ECUs) and advanced driver assistance systems (ADAS), which require constant power to maintain settings and calibration data. As the automotive sector moves towards greater electrification and autonomous capabilities, the demand for CMOS batteries is projected to grow substantially.

In the industrial sector, CMOS batteries are essential components in programmable logic controllers (PLCs), human-machine interfaces (HMIs), and other automation equipment. The ongoing trend of Industry 4.0 and smart manufacturing is driving the adoption of more sophisticated control systems, further boosting the demand for reliable backup power solutions.

The healthcare industry also presents a significant market opportunity for CMOS batteries. Medical devices, diagnostic equipment, and patient monitoring systems often require uninterrupted power to maintain critical settings and patient data. As healthcare facilities worldwide upgrade their equipment and adopt more advanced technologies, the demand for CMOS batteries in this sector is expected to rise.

The telecommunications industry, with its extensive network of base stations and data centers, represents another key market for CMOS batteries. These power sources are crucial for maintaining network configurations and ensuring rapid system recovery in the event of power failures. As 5G networks continue to expand globally, the demand for CMOS batteries in this sector is anticipated to grow significantly.

Market analysts project that the global CMOS battery market will experience steady growth in the coming years, driven by technological advancements and the increasing integration of electronic systems across various industries. However, the market also faces challenges, such as the need for longer-lasting and more environmentally friendly battery solutions, which may influence future demand patterns and technological developments in the field.

CMOS Battery Technology Landscape

CMOS battery technology has evolved significantly since its inception, playing a crucial role in various electronic devices. Initially developed to maintain system settings and real-time clock information in personal computers, CMOS batteries have expanded their applications across multiple industries. The technology landscape has seen a shift from traditional lithium coin cells to more advanced and sustainable options.

In recent years, the focus has been on improving energy density, longevity, and environmental sustainability of CMOS batteries. Manufacturers have been exploring alternative materials and designs to enhance performance while reducing environmental impact. One notable trend is the development of rechargeable CMOS batteries, which aim to extend the lifespan of devices and reduce electronic waste.

The miniaturization of electronic components has driven the need for smaller, more efficient CMOS batteries. This has led to the emergence of thin-film battery technology, which offers improved integration capabilities and higher energy density in compact form factors. These advancements have opened up new possibilities for CMOS batteries in wearable devices, IoT sensors, and other space-constrained applications.

Another significant development in the CMOS battery landscape is the integration of smart features. Modern CMOS batteries often incorporate built-in monitoring and management systems, allowing for real-time status updates, predictive maintenance, and improved overall system reliability. This trend aligns with the growing demand for intelligent and connected devices across various industries.

The automotive sector has become a key driver of CMOS battery innovation, particularly with the rise of electric and autonomous vehicles. Advanced CMOS batteries are being developed to support the increasing number of electronic systems in modern vehicles, ensuring reliable operation of critical components even when the main power source is disconnected.

In the realm of industrial applications, CMOS batteries are finding new uses in smart manufacturing and Industry 4.0 initiatives. These batteries power sensors, data loggers, and control systems in industrial environments, where maintaining continuous operation and data integrity is crucial. The demand for rugged, long-lasting CMOS batteries capable of withstanding harsh conditions has spurred further technological advancements.

As environmental concerns gain prominence, there is a growing emphasis on developing eco-friendly CMOS battery solutions. Research is underway to create batteries with reduced toxic materials and improved recyclability. This shift towards sustainability is reshaping the CMOS battery landscape, with manufacturers exploring alternative chemistries and production methods to meet stringent environmental regulations.

In recent years, the focus has been on improving energy density, longevity, and environmental sustainability of CMOS batteries. Manufacturers have been exploring alternative materials and designs to enhance performance while reducing environmental impact. One notable trend is the development of rechargeable CMOS batteries, which aim to extend the lifespan of devices and reduce electronic waste.

The miniaturization of electronic components has driven the need for smaller, more efficient CMOS batteries. This has led to the emergence of thin-film battery technology, which offers improved integration capabilities and higher energy density in compact form factors. These advancements have opened up new possibilities for CMOS batteries in wearable devices, IoT sensors, and other space-constrained applications.

Another significant development in the CMOS battery landscape is the integration of smart features. Modern CMOS batteries often incorporate built-in monitoring and management systems, allowing for real-time status updates, predictive maintenance, and improved overall system reliability. This trend aligns with the growing demand for intelligent and connected devices across various industries.

The automotive sector has become a key driver of CMOS battery innovation, particularly with the rise of electric and autonomous vehicles. Advanced CMOS batteries are being developed to support the increasing number of electronic systems in modern vehicles, ensuring reliable operation of critical components even when the main power source is disconnected.

In the realm of industrial applications, CMOS batteries are finding new uses in smart manufacturing and Industry 4.0 initiatives. These batteries power sensors, data loggers, and control systems in industrial environments, where maintaining continuous operation and data integrity is crucial. The demand for rugged, long-lasting CMOS batteries capable of withstanding harsh conditions has spurred further technological advancements.

As environmental concerns gain prominence, there is a growing emphasis on developing eco-friendly CMOS battery solutions. Research is underway to create batteries with reduced toxic materials and improved recyclability. This shift towards sustainability is reshaping the CMOS battery landscape, with manufacturers exploring alternative chemistries and production methods to meet stringent environmental regulations.

Current CMOS Battery Solutions

01 CMOS battery power management

Systems and methods for managing power in CMOS batteries, including techniques for monitoring battery voltage, implementing power-saving modes, and extending battery life through efficient power distribution and consumption in electronic devices.- CMOS battery power management: Systems and methods for managing power in CMOS batteries, including techniques for monitoring battery voltage, implementing power-saving modes, and extending battery life through efficient power distribution and consumption in electronic devices.

- CMOS battery replacement and backup systems: Innovations in CMOS battery replacement procedures and backup power systems to maintain critical system information during battery changes or failures, ensuring continuous operation of timekeeping and configuration storage functions in computers and other electronic devices.

- CMOS battery integration in semiconductor devices: Advancements in integrating CMOS batteries directly into semiconductor devices and integrated circuits, improving overall system efficiency, reducing size, and enhancing performance of electronic components that require constant power for memory retention or real-time clock functions.

- CMOS battery charging and monitoring circuits: Development of specialized circuits for charging CMOS batteries and monitoring their status, including voltage regulation, charge level indication, and automatic switching between main and backup power sources to ensure uninterrupted operation of critical system functions.

- CMOS battery applications in imaging devices: Utilization of CMOS batteries in digital cameras, image sensors, and other imaging devices to maintain settings, calibration data, and provide power for low-power standby modes, enhancing overall device functionality and user experience.

02 CMOS battery replacement and backup systems

Innovations in CMOS battery replacement procedures and backup power systems to ensure continuous operation of critical components during battery changes or failures, including hot-swappable designs and temporary power storage solutions.Expand Specific Solutions03 Integration of CMOS batteries in semiconductor devices

Advancements in integrating CMOS batteries directly into semiconductor devices and integrated circuits, focusing on miniaturization, improved efficiency, and enhanced performance of electronic systems.Expand Specific Solutions04 CMOS battery monitoring and diagnostics

Development of sophisticated monitoring and diagnostic systems for CMOS batteries, including real-time voltage tracking, predictive maintenance algorithms, and early warning systems for potential battery failures in various electronic devices.Expand Specific Solutions05 Environmental and safety considerations for CMOS batteries

Innovations addressing environmental concerns and safety issues related to CMOS batteries, including eco-friendly materials, improved disposal methods, and enhanced safety features to prevent leakage or overheating in electronic devices.Expand Specific Solutions

Key CMOS Battery Manufacturers

The CMOS battery market is in a mature stage, with established players and steady demand across various industries. The global market size is estimated to be in the range of several hundred million dollars, driven by the widespread use of CMOS batteries in electronic devices, automotive applications, and industrial equipment. Technologically, CMOS batteries have reached a high level of maturity, with incremental improvements focusing on longevity, reliability, and environmental sustainability. Key players in this space include Samsung SDI, Panasonic, and LG Energy Solution, who are leveraging their expertise in battery technology to develop advanced CMOS solutions. Additionally, semiconductor giants like TSMC, Qualcomm, and NXP are exploring innovative applications of CMOS batteries in their chip designs, potentially opening new market opportunities.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed advanced CMOS battery technology for strategic industry applications. Their approach focuses on enhancing energy density and longevity through innovative materials and manufacturing processes. They have implemented a proprietary solid electrolyte interface (SEI) layer that significantly reduces capacity fade, extending battery life by up to 20% compared to conventional designs[1]. Additionally, Samsung has integrated their batteries with smart power management systems, allowing for real-time monitoring and optimization of battery performance in industrial settings[2]. This integration enables predictive maintenance and improved overall system efficiency. Samsung's CMOS batteries also feature enhanced thermal management, utilizing phase-change materials to maintain optimal operating temperatures even under high-stress conditions[3].

Strengths: High energy density, extended lifespan, smart integration capabilities. Weaknesses: Potentially higher initial cost, may require specialized charging infrastructure.

QUALCOMM, Inc.

Technical Solution: Qualcomm has leveraged its expertise in mobile technologies to develop CMOS battery solutions for strategic industry applications. Their approach focuses on ultra-low power consumption and seamless connectivity. Qualcomm's QCC5100 series of Bluetooth audio SoCs, for example, incorporates advanced power management techniques that extend CMOS battery life in wireless industrial headsets by up to 65% compared to previous generations[7]. They have also developed a proprietary quick charge technology that can be adapted for industrial CMOS batteries, enabling rapid charging without compromising battery longevity[8]. Additionally, Qualcomm's battery management systems integrate with their wireless communication technologies, allowing for efficient data transmission and remote diagnostics in industrial IoT environments[9].

Strengths: Ultra-low power consumption, rapid charging capabilities, strong wireless integration. Weaknesses: Primary focus on smaller form factor applications, may need adaptation for larger industrial systems.

CMOS Battery Innovations

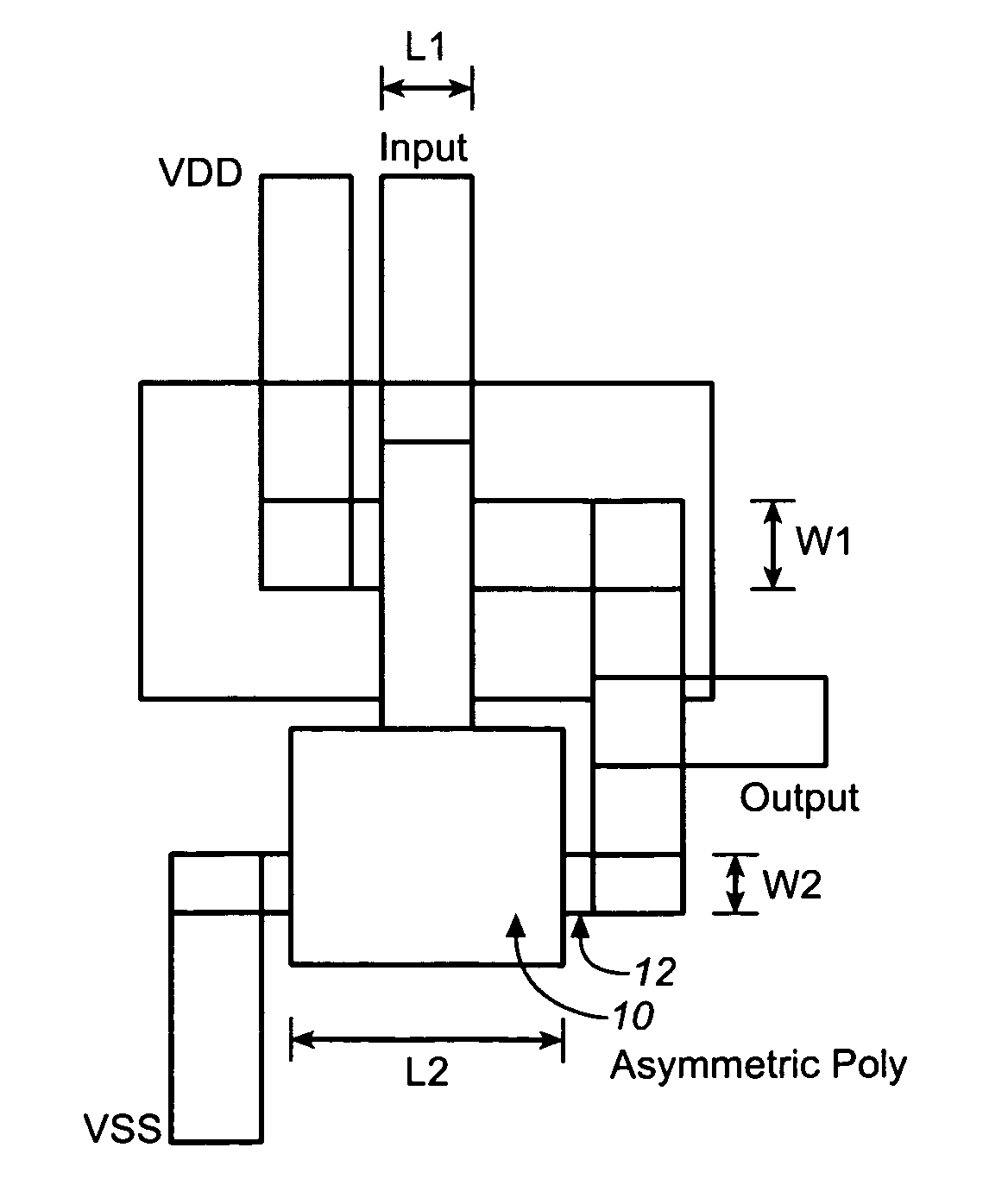

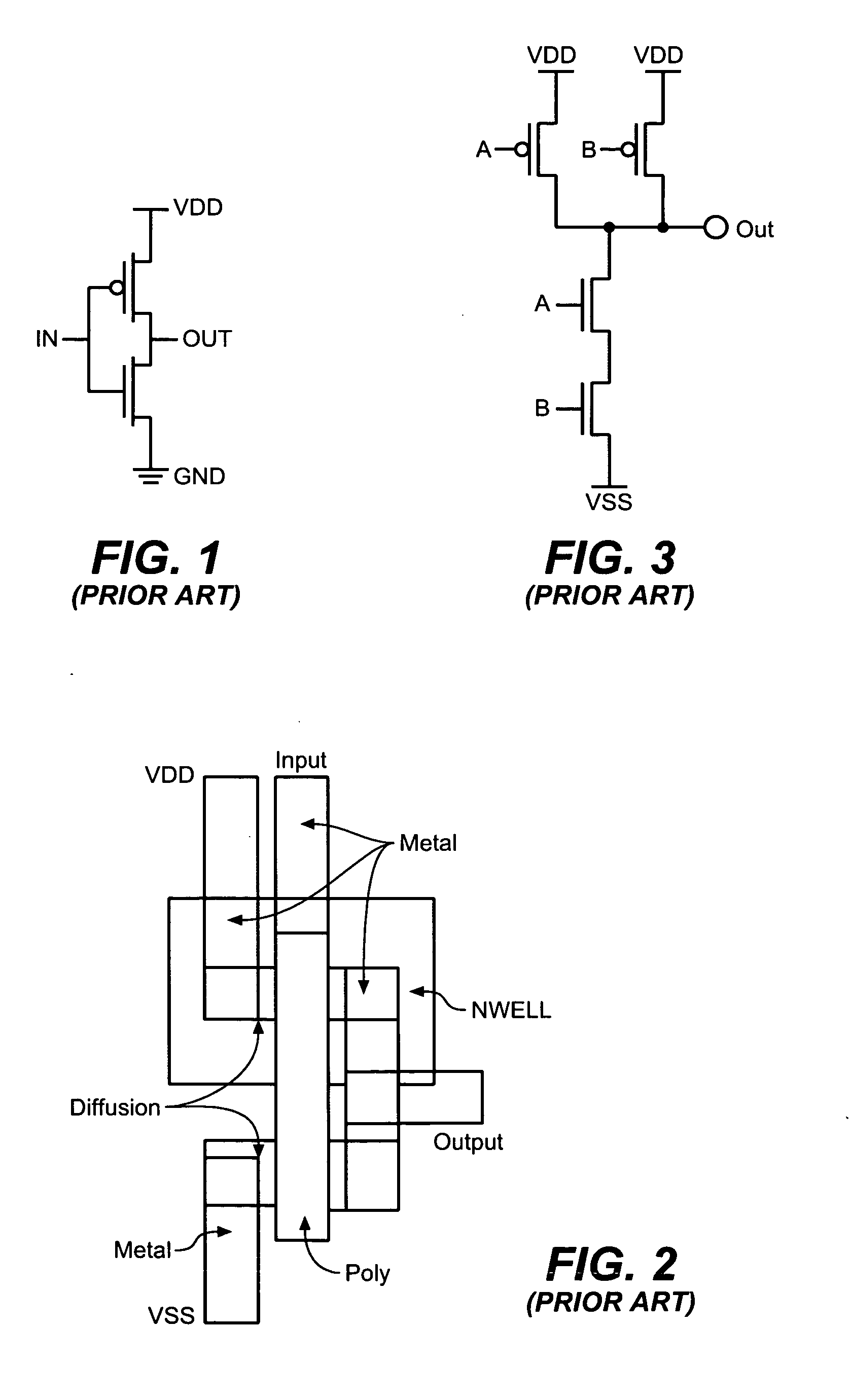

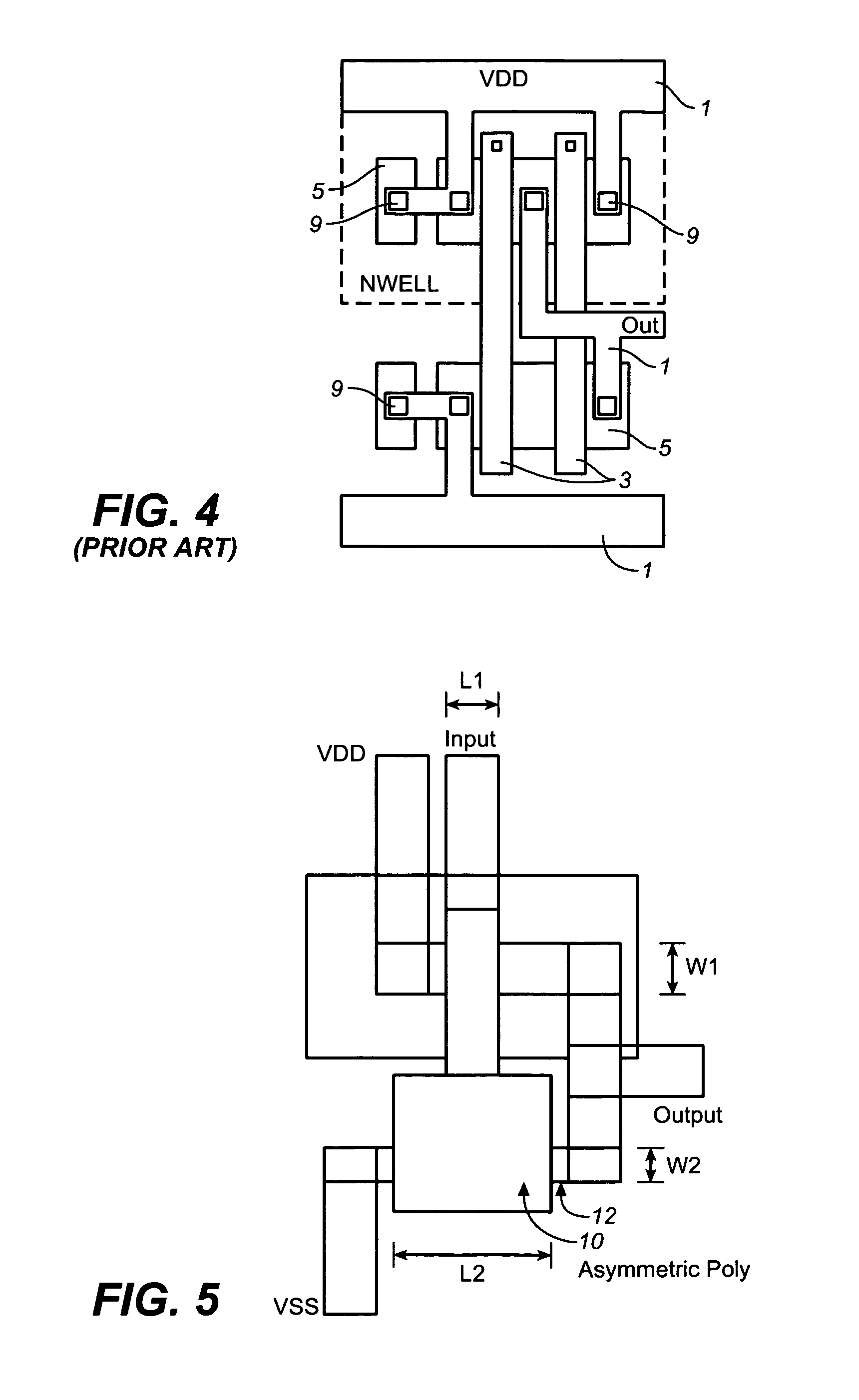

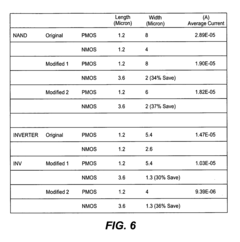

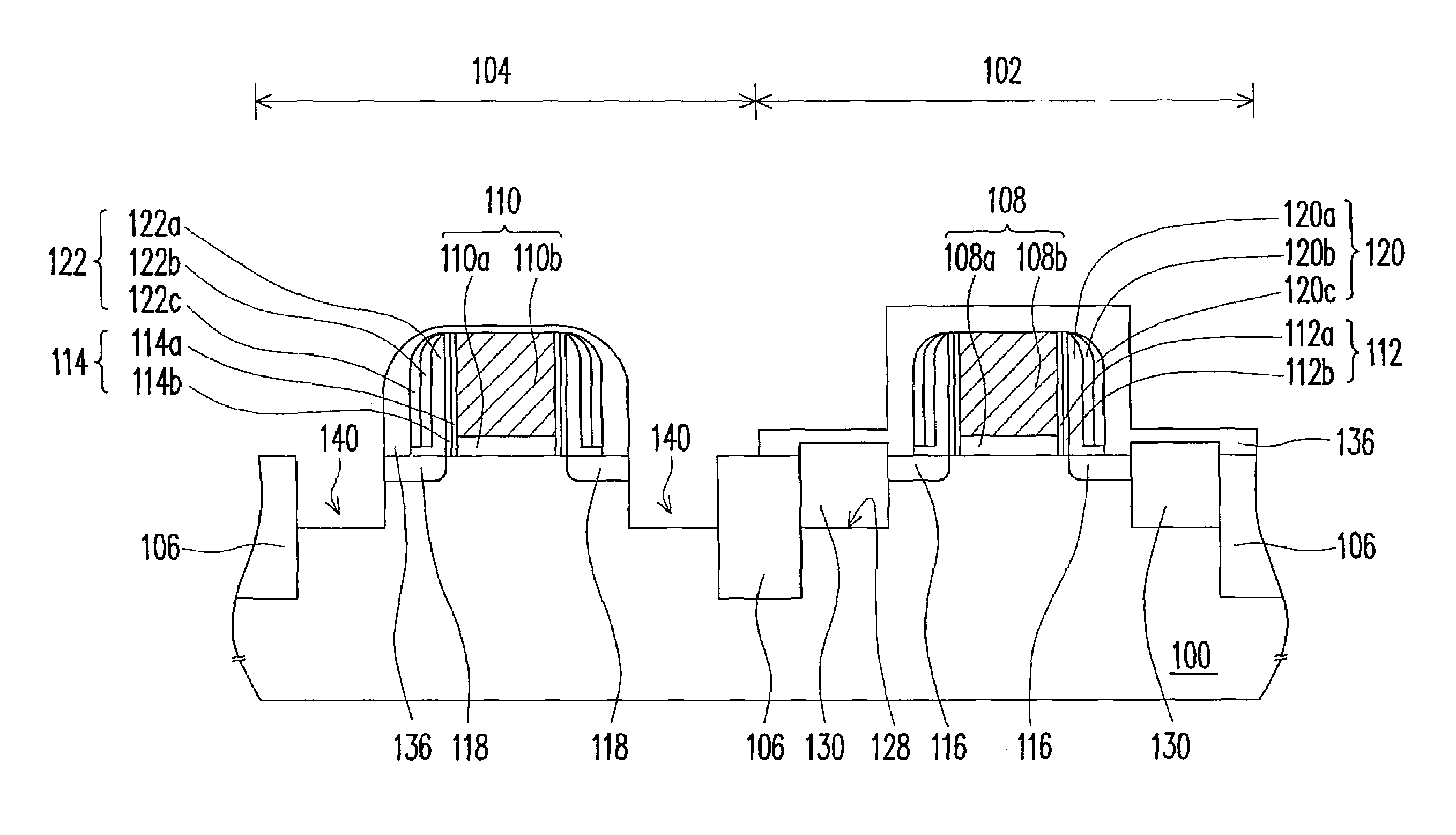

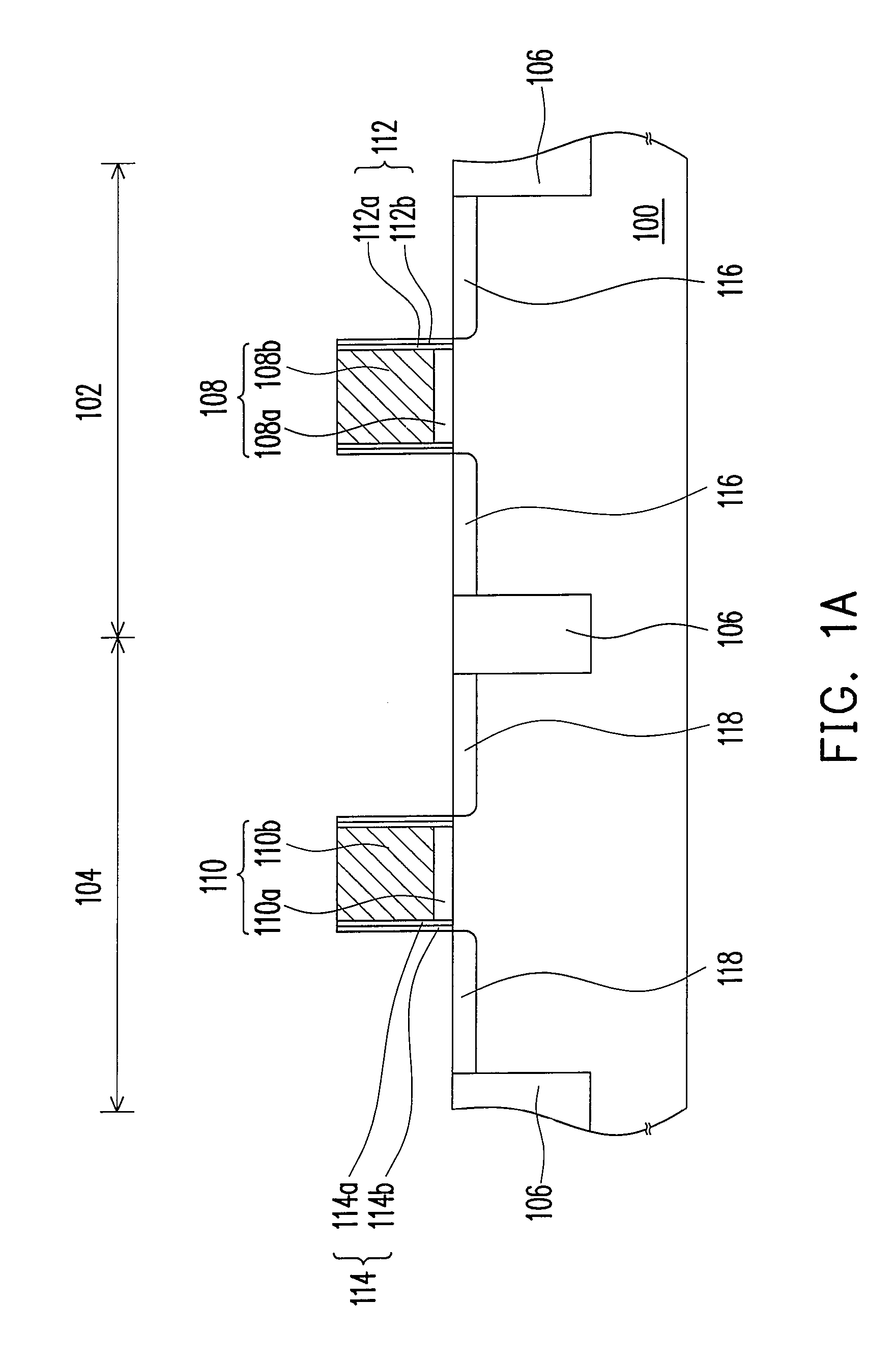

Asymmetrical layout for complementary metal-oxide-semiconductor integrated circuit to reduce power consumption

PatentInactiveUS20090072320A1

Innovation

- The implementation of an asymmetrical polysilicon gate and diffusion layout in CMOS integrated circuits, where the polysilicon gate and diffusion dimensions are asymmetrical, causing P-type and N-type transistors to switch at different times, thereby reducing short circuit current and power consumption.

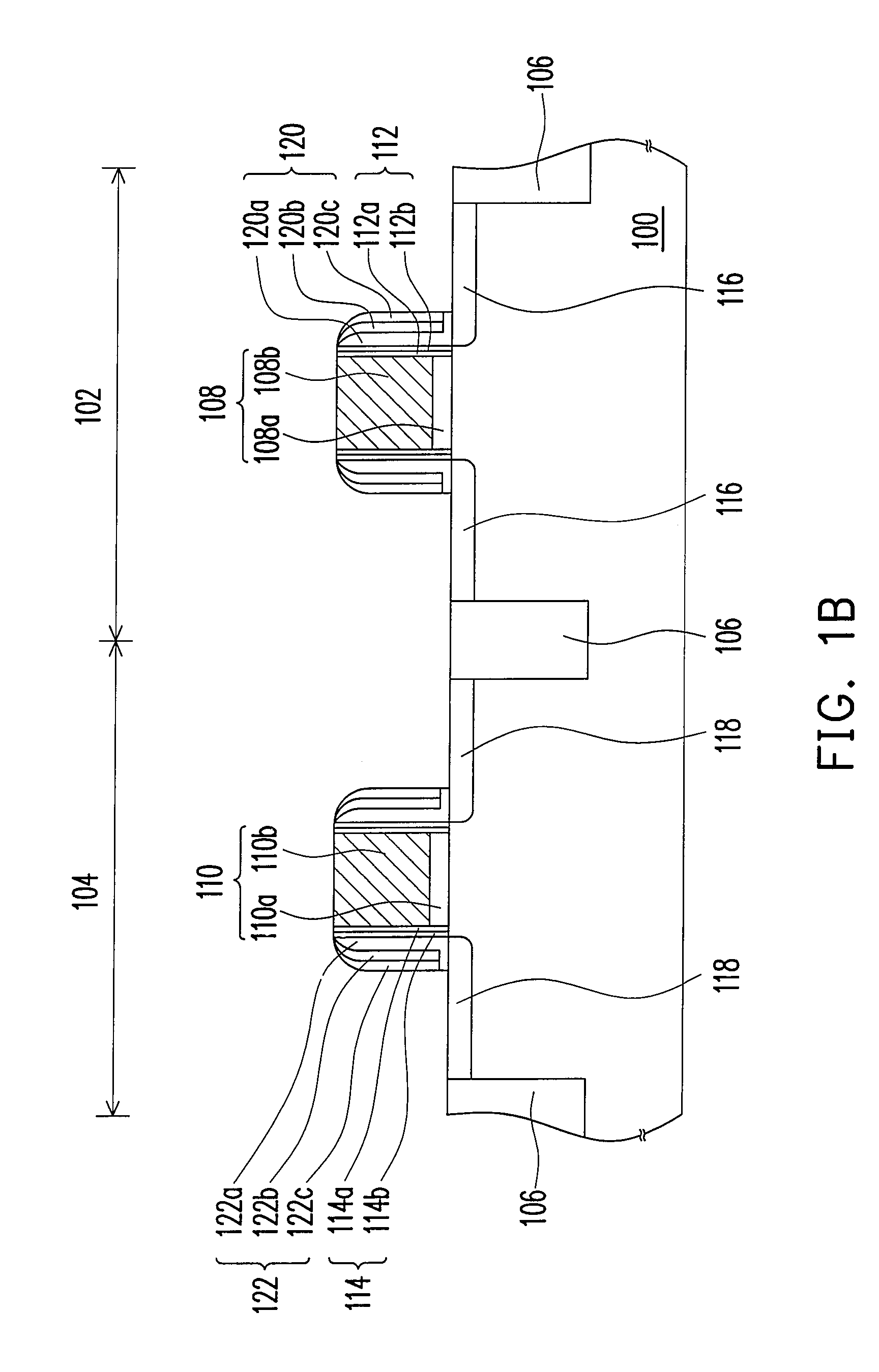

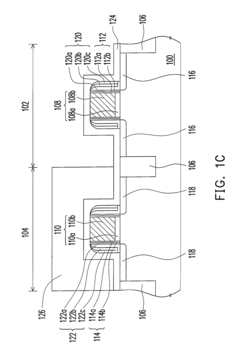

Complementary metal-oxide-semiconductor device and fabricating method thereof

PatentActiveUS7402496B2

Innovation

- A method involving the use of a carbon-containing oxynitride passivation layer with a low etching rate, formed through low-pressure chemical-vapor deposition, is employed to prevent the improper removal of the passivation layer during device manufacturing, and a thermal process is applied to densify the passivation layer, reducing the etching rate and avoiding the formation of poly bumps.

CMOS Battery Industry Standards

CMOS battery industry standards play a crucial role in ensuring the reliability, safety, and interoperability of these essential components across various strategic applications. These standards encompass a wide range of specifications, including physical dimensions, electrical characteristics, performance requirements, and testing procedures.

One of the primary standards governing CMOS batteries is the IEC 60086 series, which provides comprehensive guidelines for primary batteries. Specifically, IEC 60086-3 focuses on watch batteries, which are often used in CMOS applications. This standard defines the physical and electrical specifications for various types of button cells, including those commonly used in CMOS circuits.

The ANSI C18 series of standards, particularly ANSI C18.3M, also provides important guidelines for lithium primary batteries, which are frequently used in CMOS applications. These standards cover aspects such as safety requirements, performance testing, and labeling specifications.

In terms of safety, the UL 1642 standard for lithium batteries is widely recognized and adopted in the industry. This standard addresses safety issues related to lithium batteries used in various applications, including CMOS batteries. It outlines requirements for construction, performance, and marking of lithium batteries to ensure their safe operation.

Environmental considerations are also addressed in industry standards. The European Union's Batteries Directive (2006/66/EC) and its subsequent amendments set requirements for battery composition, collection, and recycling, which impact CMOS battery manufacturing and disposal practices.

For specific industrial applications, additional standards may apply. For instance, in the automotive industry, the SAE J537 standard provides guidelines for storage batteries, including those used in vehicle electronic systems. Similarly, in the aerospace sector, standards such as RTCA DO-311 outline performance criteria for rechargeable lithium batteries in airborne applications.

Compliance with these standards is essential for manufacturers to ensure their CMOS batteries meet industry requirements and can be safely integrated into various electronic systems. As technology evolves, these standards are periodically reviewed and updated to address new developments and emerging safety concerns in the field of CMOS batteries.

One of the primary standards governing CMOS batteries is the IEC 60086 series, which provides comprehensive guidelines for primary batteries. Specifically, IEC 60086-3 focuses on watch batteries, which are often used in CMOS applications. This standard defines the physical and electrical specifications for various types of button cells, including those commonly used in CMOS circuits.

The ANSI C18 series of standards, particularly ANSI C18.3M, also provides important guidelines for lithium primary batteries, which are frequently used in CMOS applications. These standards cover aspects such as safety requirements, performance testing, and labeling specifications.

In terms of safety, the UL 1642 standard for lithium batteries is widely recognized and adopted in the industry. This standard addresses safety issues related to lithium batteries used in various applications, including CMOS batteries. It outlines requirements for construction, performance, and marking of lithium batteries to ensure their safe operation.

Environmental considerations are also addressed in industry standards. The European Union's Batteries Directive (2006/66/EC) and its subsequent amendments set requirements for battery composition, collection, and recycling, which impact CMOS battery manufacturing and disposal practices.

For specific industrial applications, additional standards may apply. For instance, in the automotive industry, the SAE J537 standard provides guidelines for storage batteries, including those used in vehicle electronic systems. Similarly, in the aerospace sector, standards such as RTCA DO-311 outline performance criteria for rechargeable lithium batteries in airborne applications.

Compliance with these standards is essential for manufacturers to ensure their CMOS batteries meet industry requirements and can be safely integrated into various electronic systems. As technology evolves, these standards are periodically reviewed and updated to address new developments and emerging safety concerns in the field of CMOS batteries.

Environmental Impact of CMOS Batteries

The environmental impact of CMOS batteries is a critical consideration in their strategic industry applications. These small but essential components play a significant role in maintaining system configurations and real-time clocks in various electronic devices. However, their production, use, and disposal have notable environmental implications that must be addressed.

The manufacturing process of CMOS batteries involves the extraction and processing of raw materials, including lithium, manganese, and other metals. This process can lead to habitat disruption, soil erosion, and water pollution in mining areas. Additionally, the energy-intensive production methods contribute to greenhouse gas emissions, further exacerbating climate change concerns.

During their operational lifetime, CMOS batteries have a relatively low environmental impact compared to larger power sources. Their long lifespan, typically ranging from 3 to 10 years, reduces the frequency of replacement and associated waste generation. However, the cumulative effect of millions of devices containing these batteries should not be underestimated.

The end-of-life phase presents significant environmental challenges. Improper disposal of CMOS batteries can lead to soil and water contamination due to the leaching of toxic materials. Many electronic waste recycling facilities are not adequately equipped to handle these small components, resulting in their incineration or landfill disposal, both of which pose environmental risks.

To mitigate these impacts, several strategies are being explored and implemented. Manufacturers are investing in more sustainable production methods, including the use of recycled materials and cleaner energy sources. Some companies are developing CMOS batteries with reduced toxic content, making them safer for disposal.

Efforts to improve recycling infrastructure for electronic waste, including specialized processes for small battery components, are underway. Extended producer responsibility programs are being implemented in various regions, encouraging manufacturers to take responsibility for the entire lifecycle of their products, including CMOS batteries.

The development of alternative technologies, such as supercapacitors or energy harvesting systems, is also being pursued to potentially replace CMOS batteries in certain applications. These alternatives may offer reduced environmental impact while maintaining or improving functionality.

As industries continue to rely on CMOS batteries for critical applications, balancing technological needs with environmental responsibility remains a key challenge. Ongoing research and development efforts are focused on creating more sustainable solutions that minimize the ecological footprint of these essential components throughout their lifecycle.

The manufacturing process of CMOS batteries involves the extraction and processing of raw materials, including lithium, manganese, and other metals. This process can lead to habitat disruption, soil erosion, and water pollution in mining areas. Additionally, the energy-intensive production methods contribute to greenhouse gas emissions, further exacerbating climate change concerns.

During their operational lifetime, CMOS batteries have a relatively low environmental impact compared to larger power sources. Their long lifespan, typically ranging from 3 to 10 years, reduces the frequency of replacement and associated waste generation. However, the cumulative effect of millions of devices containing these batteries should not be underestimated.

The end-of-life phase presents significant environmental challenges. Improper disposal of CMOS batteries can lead to soil and water contamination due to the leaching of toxic materials. Many electronic waste recycling facilities are not adequately equipped to handle these small components, resulting in their incineration or landfill disposal, both of which pose environmental risks.

To mitigate these impacts, several strategies are being explored and implemented. Manufacturers are investing in more sustainable production methods, including the use of recycled materials and cleaner energy sources. Some companies are developing CMOS batteries with reduced toxic content, making them safer for disposal.

Efforts to improve recycling infrastructure for electronic waste, including specialized processes for small battery components, are underway. Extended producer responsibility programs are being implemented in various regions, encouraging manufacturers to take responsibility for the entire lifecycle of their products, including CMOS batteries.

The development of alternative technologies, such as supercapacitors or energy harvesting systems, is also being pursued to potentially replace CMOS batteries in certain applications. These alternatives may offer reduced environmental impact while maintaining or improving functionality.

As industries continue to rely on CMOS batteries for critical applications, balancing technological needs with environmental responsibility remains a key challenge. Ongoing research and development efforts are focused on creating more sustainable solutions that minimize the ecological footprint of these essential components throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!