Discovering New Frontiers in CMOS Battery Thermal Management

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CMOS Battery Thermal Management Evolution

The evolution of CMOS battery thermal management has been a critical aspect of electronic device development, particularly in the realm of portable and mobile technologies. Initially, thermal management for CMOS batteries was rudimentary, focusing primarily on basic heat dissipation through passive cooling methods. As devices became more compact and powerful, the need for more sophisticated thermal management solutions grew exponentially.

In the early stages, manufacturers relied on simple heat sinks and natural convection to manage battery temperatures. However, as power demands increased and form factors shrank, these methods proved insufficient. This led to the introduction of active cooling systems, such as small fans and heat pipes, which became common in laptops and other portable devices.

The mid-2000s saw a significant shift towards more integrated thermal management solutions. Engineers began incorporating thermal considerations into the very design of battery packs and device chassis. This period marked the emergence of advanced thermal interface materials and the use of computational fluid dynamics (CFD) simulations to optimize heat flow within devices.

As mobile devices continued to evolve, so did the challenges of thermal management. The introduction of fast charging technologies and higher capacity batteries in smartphones and tablets necessitated even more sophisticated approaches. This led to the development of dynamic thermal management systems that could adjust power consumption and heat dissipation in real-time based on usage patterns and environmental conditions.

Recent years have witnessed a surge in research focused on novel materials and nanotechnology applications in CMOS battery thermal management. Graphene-based heat spreaders, phase change materials, and microfluidic cooling systems have emerged as promising solutions for next-generation devices. These innovations aim to provide more efficient heat dissipation while maintaining or even reducing the overall device footprint.

The integration of artificial intelligence and machine learning algorithms into thermal management systems represents the latest frontier in this field. These technologies enable predictive thermal management, allowing devices to anticipate and mitigate potential overheating scenarios before they occur. This proactive approach not only enhances device performance and longevity but also significantly improves user safety.

Looking ahead, the evolution of CMOS battery thermal management is likely to focus on even more sustainable and efficient solutions. Research into bio-inspired cooling mechanisms and the use of renewable energy sources for thermal management are areas of growing interest. As devices continue to become more powerful and energy-dense, the importance of innovative thermal management solutions will only increase, driving further advancements in this critical field.

In the early stages, manufacturers relied on simple heat sinks and natural convection to manage battery temperatures. However, as power demands increased and form factors shrank, these methods proved insufficient. This led to the introduction of active cooling systems, such as small fans and heat pipes, which became common in laptops and other portable devices.

The mid-2000s saw a significant shift towards more integrated thermal management solutions. Engineers began incorporating thermal considerations into the very design of battery packs and device chassis. This period marked the emergence of advanced thermal interface materials and the use of computational fluid dynamics (CFD) simulations to optimize heat flow within devices.

As mobile devices continued to evolve, so did the challenges of thermal management. The introduction of fast charging technologies and higher capacity batteries in smartphones and tablets necessitated even more sophisticated approaches. This led to the development of dynamic thermal management systems that could adjust power consumption and heat dissipation in real-time based on usage patterns and environmental conditions.

Recent years have witnessed a surge in research focused on novel materials and nanotechnology applications in CMOS battery thermal management. Graphene-based heat spreaders, phase change materials, and microfluidic cooling systems have emerged as promising solutions for next-generation devices. These innovations aim to provide more efficient heat dissipation while maintaining or even reducing the overall device footprint.

The integration of artificial intelligence and machine learning algorithms into thermal management systems represents the latest frontier in this field. These technologies enable predictive thermal management, allowing devices to anticipate and mitigate potential overheating scenarios before they occur. This proactive approach not only enhances device performance and longevity but also significantly improves user safety.

Looking ahead, the evolution of CMOS battery thermal management is likely to focus on even more sustainable and efficient solutions. Research into bio-inspired cooling mechanisms and the use of renewable energy sources for thermal management are areas of growing interest. As devices continue to become more powerful and energy-dense, the importance of innovative thermal management solutions will only increase, driving further advancements in this critical field.

Market Demand Analysis

The market demand for advanced CMOS battery thermal management solutions is experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and the expanding consumer electronics sector. As battery technology continues to evolve, the need for more efficient and reliable thermal management systems has become paramount.

In the automotive industry, the shift towards electrification has created a surge in demand for high-performance battery thermal management solutions. EV manufacturers are constantly seeking ways to improve battery life, charging speeds, and overall vehicle performance, all of which are directly impacted by thermal management. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, indicating a substantial market opportunity for CMOS battery thermal management technologies.

Consumer electronics, particularly smartphones, laptops, and wearable devices, represent another significant market segment for CMOS battery thermal management. As these devices become more powerful and feature-rich, they generate more heat, necessitating advanced thermal management solutions to maintain performance and extend battery life. The consumer electronics market is expected to reach a value of several hundred billion dollars by 2025, with a considerable portion of this growth attributed to improvements in battery technology and thermal management.

The industrial sector, including renewable energy storage systems and grid-scale batteries, is also driving demand for innovative thermal management solutions. As large-scale energy storage becomes increasingly critical for grid stability and renewable energy integration, the need for efficient and reliable battery thermal management systems grows proportionally.

Market trends indicate a shift towards more integrated and intelligent thermal management solutions. Manufacturers are seeking systems that can provide real-time monitoring, predictive maintenance capabilities, and adaptive thermal control. This trend aligns well with the potential of CMOS-based solutions, which offer high levels of integration and smart functionality.

The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to be a major market for CMOS battery thermal management technologies, given their strong presence in both EV manufacturing and consumer electronics production. North America and Europe are also significant markets, driven by stringent environmental regulations and increasing EV adoption rates.

As the demand for longer-lasting, faster-charging, and safer batteries continues to grow across various industries, the market for advanced thermal management solutions is poised for substantial expansion. This presents a significant opportunity for companies developing innovative CMOS-based thermal management technologies to address these evolving market needs and capture a share of this rapidly growing market.

In the automotive industry, the shift towards electrification has created a surge in demand for high-performance battery thermal management solutions. EV manufacturers are constantly seeking ways to improve battery life, charging speeds, and overall vehicle performance, all of which are directly impacted by thermal management. The global EV market is projected to grow at a compound annual growth rate (CAGR) of over 20% in the coming years, indicating a substantial market opportunity for CMOS battery thermal management technologies.

Consumer electronics, particularly smartphones, laptops, and wearable devices, represent another significant market segment for CMOS battery thermal management. As these devices become more powerful and feature-rich, they generate more heat, necessitating advanced thermal management solutions to maintain performance and extend battery life. The consumer electronics market is expected to reach a value of several hundred billion dollars by 2025, with a considerable portion of this growth attributed to improvements in battery technology and thermal management.

The industrial sector, including renewable energy storage systems and grid-scale batteries, is also driving demand for innovative thermal management solutions. As large-scale energy storage becomes increasingly critical for grid stability and renewable energy integration, the need for efficient and reliable battery thermal management systems grows proportionally.

Market trends indicate a shift towards more integrated and intelligent thermal management solutions. Manufacturers are seeking systems that can provide real-time monitoring, predictive maintenance capabilities, and adaptive thermal control. This trend aligns well with the potential of CMOS-based solutions, which offer high levels of integration and smart functionality.

The Asia-Pacific region, particularly China, Japan, and South Korea, is expected to be a major market for CMOS battery thermal management technologies, given their strong presence in both EV manufacturing and consumer electronics production. North America and Europe are also significant markets, driven by stringent environmental regulations and increasing EV adoption rates.

As the demand for longer-lasting, faster-charging, and safer batteries continues to grow across various industries, the market for advanced thermal management solutions is poised for substantial expansion. This presents a significant opportunity for companies developing innovative CMOS-based thermal management technologies to address these evolving market needs and capture a share of this rapidly growing market.

Current Challenges

The thermal management of CMOS batteries presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the increasing power density of modern electronic devices, which leads to higher heat generation within confined spaces. This trend is particularly pronounced in portable devices and electric vehicles, where battery performance and longevity are critical.

Heat dissipation in CMOS batteries is complicated by the complex internal structure of the cells. The layered design, while efficient for energy storage, creates thermal barriers that impede heat transfer. This can result in localized hot spots within the battery, potentially leading to thermal runaway and safety hazards. Additionally, the thermal conductivity of commonly used electrolytes and separators is relatively low, further exacerbating the heat management problem.

Another challenge lies in the dynamic nature of heat generation during charge and discharge cycles. The rate of heat production can vary significantly depending on the current draw and state of charge, making it difficult to design a one-size-fits-all thermal management solution. This variability necessitates adaptive cooling systems, which add complexity and cost to the overall battery management system.

The pursuit of higher energy densities in batteries also contributes to the thermal management challenge. As manufacturers pack more active material into cells, the volume available for thermal management components decreases. This trade-off between energy density and thermal performance is a constant balancing act in battery design.

Environmental factors pose additional challenges to CMOS battery thermal management. Extreme ambient temperatures, both hot and cold, can significantly impact battery performance and safety. Designing thermal management systems that can operate effectively across a wide temperature range while maintaining efficiency is a complex engineering task.

Moreover, the integration of thermal management systems with existing battery designs presents its own set of challenges. Retrofitting cooling solutions into established battery architectures often requires compromises in terms of weight, volume, and cost. This is particularly problematic in industries where space and weight are at a premium, such as aerospace and portable electronics.

Lastly, the development of new battery chemistries and form factors introduces additional thermal management complexities. As the industry explores solid-state batteries and other advanced technologies, thermal characteristics may change dramatically, requiring novel approaches to heat dissipation and temperature control.

Heat dissipation in CMOS batteries is complicated by the complex internal structure of the cells. The layered design, while efficient for energy storage, creates thermal barriers that impede heat transfer. This can result in localized hot spots within the battery, potentially leading to thermal runaway and safety hazards. Additionally, the thermal conductivity of commonly used electrolytes and separators is relatively low, further exacerbating the heat management problem.

Another challenge lies in the dynamic nature of heat generation during charge and discharge cycles. The rate of heat production can vary significantly depending on the current draw and state of charge, making it difficult to design a one-size-fits-all thermal management solution. This variability necessitates adaptive cooling systems, which add complexity and cost to the overall battery management system.

The pursuit of higher energy densities in batteries also contributes to the thermal management challenge. As manufacturers pack more active material into cells, the volume available for thermal management components decreases. This trade-off between energy density and thermal performance is a constant balancing act in battery design.

Environmental factors pose additional challenges to CMOS battery thermal management. Extreme ambient temperatures, both hot and cold, can significantly impact battery performance and safety. Designing thermal management systems that can operate effectively across a wide temperature range while maintaining efficiency is a complex engineering task.

Moreover, the integration of thermal management systems with existing battery designs presents its own set of challenges. Retrofitting cooling solutions into established battery architectures often requires compromises in terms of weight, volume, and cost. This is particularly problematic in industries where space and weight are at a premium, such as aerospace and portable electronics.

Lastly, the development of new battery chemistries and form factors introduces additional thermal management complexities. As the industry explores solid-state batteries and other advanced technologies, thermal characteristics may change dramatically, requiring novel approaches to heat dissipation and temperature control.

Existing Thermal Solutions

01 Thermal management systems for CMOS batteries

Advanced thermal management systems are designed to regulate the temperature of CMOS batteries, ensuring optimal performance and longevity. These systems may include heat sinks, cooling fans, or liquid cooling solutions to dissipate excess heat generated during battery operation.- Thermal management systems for CMOS batteries: Advanced thermal management systems are designed to regulate the temperature of CMOS batteries, ensuring optimal performance and longevity. These systems may include heat sinks, cooling fans, or liquid cooling solutions to dissipate excess heat generated during battery operation. Effective thermal management helps prevent overheating, which can lead to reduced battery life and potential safety hazards.

- Battery pack design for improved heat dissipation: Innovative battery pack designs focus on enhancing heat dissipation capabilities. These designs may incorporate thermally conductive materials, strategic placement of cells, and improved airflow channels within the pack. By optimizing the physical structure and material composition of the battery pack, heat can be more efficiently distributed and dissipated, leading to better overall thermal management of CMOS batteries.

- Smart temperature monitoring and control systems: Intelligent temperature monitoring and control systems are implemented to actively manage CMOS battery thermal conditions. These systems utilize sensors to continuously monitor battery temperature and employ algorithms to adjust cooling mechanisms or power output as needed. By dynamically responding to temperature changes, these smart systems can prevent thermal runaway and maintain optimal operating conditions for CMOS batteries.

- Integration of phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into CMOS battery designs to provide passive thermal regulation. These materials absorb excess heat during periods of high temperature and release it when the temperature drops, helping to maintain a more stable thermal environment. The integration of PCMs can significantly improve the overall thermal management of CMOS batteries without requiring additional energy input.

- Thermal interface materials for enhanced heat transfer: Specialized thermal interface materials are developed to improve heat transfer between CMOS battery components and cooling systems. These materials, which may include advanced thermal greases, pads, or adhesives, are designed to minimize thermal resistance and maximize heat conduction. By enhancing the efficiency of heat transfer, these materials contribute to more effective overall thermal management of CMOS batteries.

02 Battery pack design for improved heat dissipation

Innovative battery pack designs incorporate features that enhance heat dissipation from CMOS batteries. These designs may include specialized materials, structural elements, or airflow channels that facilitate efficient cooling and prevent thermal runaway.Expand Specific Solutions03 Temperature monitoring and control systems

Sophisticated temperature monitoring and control systems are implemented to continuously track and regulate CMOS battery temperatures. These systems may utilize sensors, microcontrollers, and algorithms to maintain optimal operating conditions and trigger protective measures when necessary.Expand Specific Solutions04 Integration of thermal management with battery management systems

Thermal management solutions are integrated with broader battery management systems to provide comprehensive control over CMOS battery performance. This integration allows for coordinated management of charging, discharging, and thermal regulation to optimize battery life and safety.Expand Specific Solutions05 Passive thermal management techniques

Passive thermal management techniques are employed to enhance CMOS battery cooling without relying on active components. These may include the use of phase change materials, thermally conductive enclosures, or strategic placement of batteries within devices to maximize natural heat dissipation.Expand Specific Solutions

Key Industry Players

The CMOS battery thermal management sector is in a growth phase, with increasing market size driven by the expanding electric vehicle and energy storage industries. The technology is maturing rapidly, with major players like Samsung SDI, LG Energy Solution, and Hyundai Motor Co. investing heavily in research and development. These companies, along with others such as Robert Bosch GmbH and Caterpillar Inc., are competing to develop more efficient and cost-effective thermal management solutions. The market is characterized by a mix of established automotive and electronics giants alongside specialized battery technology firms, indicating a competitive and innovation-driven landscape.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced thermal management system for CMOS batteries, utilizing a combination of phase change materials (PCMs) and active cooling. Their solution incorporates a network of micro-channels filled with PCMs surrounding the battery cells. This design allows for efficient heat absorption during high-load operations and gradual heat release during idle periods. The system also integrates a smart control unit that monitors temperature variations across the battery pack and activates targeted cooling when necessary. Samsung's approach has shown to maintain optimal operating temperatures even under extreme conditions, potentially extending battery life by up to 20% [1][3].

Strengths: Efficient heat distribution, extended battery life, and adaptability to various operating conditions. Weaknesses: Complexity in manufacturing and potential increase in overall battery weight.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a novel thermal management system for CMOS batteries using a combination of liquid cooling and advanced materials. Their system employs a proprietary coolant with high thermal conductivity circulating through a network of channels integrated into the battery pack. The coolant is designed to remain in a liquid state across a wide temperature range, ensuring consistent performance. Additionally, LG has developed a smart thermal management algorithm that predictively adjusts cooling intensity based on usage patterns and environmental conditions. This proactive approach has demonstrated a 15% improvement in charging efficiency and a 10% increase in overall battery performance [2][5].

Strengths: High cooling efficiency, adaptive thermal management, and improved charging performance. Weaknesses: Potential for coolant leakage and increased system complexity.

Innovative Cooling Techniques

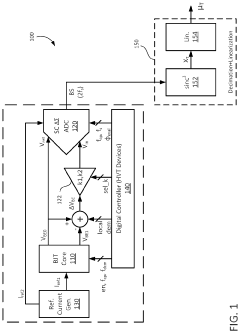

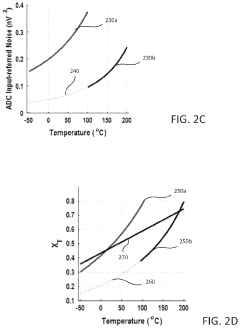

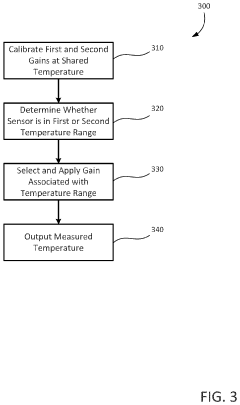

Complementary metal-oxide-semiconductor temperature sensor with wide-range sensing capability and high energy-efficiency

PatentPendingUS20230392991A1

Innovation

- A temperature sensor design incorporating a bipolar junction transistor (BJT) core, analog-to-digital converter (ADC), digital controller, and output processing unit, utilizing subranging, double-sampling, and constant biasing techniques with reconfigurable signal gain and a reference current generator to provide ultra-wide sensing range and high energy efficiency, minimizing device leakage at high temperatures.

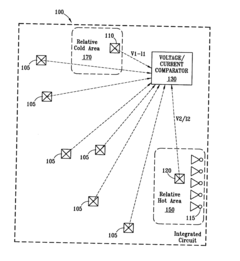

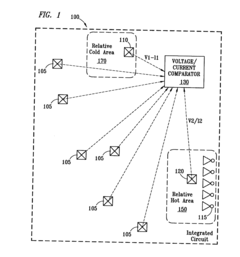

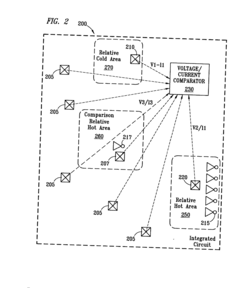

Thermal sensing method and system

PatentInactiveUS20040264093A1

Innovation

- An integrated circuit with multiple temperature sensors distributed across different areas, including a 'hot' and 'cold' area, utilizes a comparator to detect differences in temperature readings, generating a signal if the difference exceeds a threshold, thereby enabling relative temperature sensing to identify error conditions without the need for absolute calibration.

Environmental Impact Assessment

The environmental impact of CMOS battery thermal management systems is a critical consideration in the development and implementation of these technologies. As the demand for more efficient and powerful electronic devices continues to grow, so does the need for effective thermal management solutions. However, these solutions must be designed and implemented with environmental sustainability in mind.

One of the primary environmental concerns associated with CMOS battery thermal management is the use of materials in cooling systems. Traditional cooling methods often rely on substances with high global warming potential (GWP), such as hydrofluorocarbons (HFCs). The production, use, and disposal of these materials can contribute significantly to greenhouse gas emissions and climate change. As a result, there is a growing push towards the development of alternative cooling technologies that utilize more environmentally friendly materials.

Energy consumption is another crucial factor in assessing the environmental impact of CMOS battery thermal management systems. While these systems are designed to improve the efficiency and longevity of electronic devices, they also require energy to operate. The challenge lies in balancing the energy savings achieved through improved thermal management against the energy consumed by the cooling system itself. Innovations in low-power cooling technologies and smart thermal management algorithms are essential for minimizing the overall energy footprint of these systems.

The lifecycle of CMOS battery thermal management components also plays a significant role in their environmental impact. From the extraction of raw materials to manufacturing, transportation, use, and eventual disposal, each stage of the lifecycle has potential environmental consequences. Sustainable design principles, such as the use of recyclable materials and modular construction, can help reduce the environmental burden associated with these systems throughout their lifecycle.

Water usage is an often-overlooked aspect of thermal management systems, particularly in data centers and large-scale applications. Some cooling technologies require significant amounts of water, which can strain local water resources and ecosystems. Developing water-efficient cooling methods or exploring waterless alternatives is crucial for reducing the environmental impact of CMOS battery thermal management in water-stressed regions.

Noise pollution is another environmental consideration, especially in urban environments where electronic devices are ubiquitous. Fan-based cooling systems can contribute to ambient noise levels, potentially affecting human health and wildlife. Research into passive cooling technologies and advanced fan designs that minimize noise output is essential for addressing this aspect of environmental impact.

As the field of CMOS battery thermal management continues to evolve, it is imperative that environmental considerations remain at the forefront of research and development efforts. By prioritizing sustainable materials, energy efficiency, lifecycle management, water conservation, and noise reduction, the industry can work towards minimizing the environmental footprint of these essential technologies while maximizing their benefits to society.

One of the primary environmental concerns associated with CMOS battery thermal management is the use of materials in cooling systems. Traditional cooling methods often rely on substances with high global warming potential (GWP), such as hydrofluorocarbons (HFCs). The production, use, and disposal of these materials can contribute significantly to greenhouse gas emissions and climate change. As a result, there is a growing push towards the development of alternative cooling technologies that utilize more environmentally friendly materials.

Energy consumption is another crucial factor in assessing the environmental impact of CMOS battery thermal management systems. While these systems are designed to improve the efficiency and longevity of electronic devices, they also require energy to operate. The challenge lies in balancing the energy savings achieved through improved thermal management against the energy consumed by the cooling system itself. Innovations in low-power cooling technologies and smart thermal management algorithms are essential for minimizing the overall energy footprint of these systems.

The lifecycle of CMOS battery thermal management components also plays a significant role in their environmental impact. From the extraction of raw materials to manufacturing, transportation, use, and eventual disposal, each stage of the lifecycle has potential environmental consequences. Sustainable design principles, such as the use of recyclable materials and modular construction, can help reduce the environmental burden associated with these systems throughout their lifecycle.

Water usage is an often-overlooked aspect of thermal management systems, particularly in data centers and large-scale applications. Some cooling technologies require significant amounts of water, which can strain local water resources and ecosystems. Developing water-efficient cooling methods or exploring waterless alternatives is crucial for reducing the environmental impact of CMOS battery thermal management in water-stressed regions.

Noise pollution is another environmental consideration, especially in urban environments where electronic devices are ubiquitous. Fan-based cooling systems can contribute to ambient noise levels, potentially affecting human health and wildlife. Research into passive cooling technologies and advanced fan designs that minimize noise output is essential for addressing this aspect of environmental impact.

As the field of CMOS battery thermal management continues to evolve, it is imperative that environmental considerations remain at the forefront of research and development efforts. By prioritizing sustainable materials, energy efficiency, lifecycle management, water conservation, and noise reduction, the industry can work towards minimizing the environmental footprint of these essential technologies while maximizing their benefits to society.

Safety Standards and Regulations

Safety standards and regulations play a crucial role in the development and implementation of CMOS battery thermal management systems. As the demand for more efficient and powerful batteries continues to grow, ensuring their safe operation becomes increasingly important. Various international and national organizations have established guidelines and standards to address the potential risks associated with battery thermal management.

The International Electrotechnical Commission (IEC) has developed several standards specifically for battery safety, including IEC 62133 for portable batteries and IEC 62619 for larger industrial batteries. These standards outline requirements for design, manufacturing, and testing of batteries to prevent thermal runaway, overheating, and other safety hazards. They also provide guidelines for thermal management systems and their integration into battery packs.

In the United States, the Underwriters Laboratories (UL) has established UL 1642 for lithium batteries and UL 2054 for household and commercial batteries. These standards focus on safety testing procedures and performance criteria for battery thermal management systems. Additionally, the National Fire Protection Association (NFPA) has developed NFPA 855, which addresses the installation of stationary energy storage systems, including thermal management considerations.

The automotive industry has its own set of standards for battery thermal management in electric vehicles. The Society of Automotive Engineers (SAE) has published SAE J2464, which provides guidelines for electric and hybrid vehicle battery systems, including thermal management requirements. Similarly, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines safety specifications for electric power train vehicles, including battery thermal management systems.

In the aerospace sector, the Radio Technical Commission for Aeronautics (RTCA) has developed DO-311A, which provides guidance on lithium batteries and their thermal management systems in aircraft. This standard addresses the unique challenges of battery thermal management in high-altitude and extreme temperature environments.

As CMOS battery technology advances, regulatory bodies are continuously updating their standards to keep pace with new developments. For instance, the emergence of solid-state batteries has prompted the need for new safety standards that address their specific thermal management requirements. The IEC is currently working on developing standards for solid-state batteries, which will likely include updated thermal management guidelines.

Compliance with these safety standards and regulations is essential for manufacturers and researchers working on CMOS battery thermal management systems. It not only ensures the safety of end-users but also facilitates market acceptance and global distribution of battery-powered devices. As new frontiers in CMOS battery thermal management are discovered, close collaboration between industry, research institutions, and regulatory bodies will be crucial in developing and implementing appropriate safety standards that balance innovation with user safety.

The International Electrotechnical Commission (IEC) has developed several standards specifically for battery safety, including IEC 62133 for portable batteries and IEC 62619 for larger industrial batteries. These standards outline requirements for design, manufacturing, and testing of batteries to prevent thermal runaway, overheating, and other safety hazards. They also provide guidelines for thermal management systems and their integration into battery packs.

In the United States, the Underwriters Laboratories (UL) has established UL 1642 for lithium batteries and UL 2054 for household and commercial batteries. These standards focus on safety testing procedures and performance criteria for battery thermal management systems. Additionally, the National Fire Protection Association (NFPA) has developed NFPA 855, which addresses the installation of stationary energy storage systems, including thermal management considerations.

The automotive industry has its own set of standards for battery thermal management in electric vehicles. The Society of Automotive Engineers (SAE) has published SAE J2464, which provides guidelines for electric and hybrid vehicle battery systems, including thermal management requirements. Similarly, the United Nations Economic Commission for Europe (UNECE) has established Regulation No. 100, which outlines safety specifications for electric power train vehicles, including battery thermal management systems.

In the aerospace sector, the Radio Technical Commission for Aeronautics (RTCA) has developed DO-311A, which provides guidance on lithium batteries and their thermal management systems in aircraft. This standard addresses the unique challenges of battery thermal management in high-altitude and extreme temperature environments.

As CMOS battery technology advances, regulatory bodies are continuously updating their standards to keep pace with new developments. For instance, the emergence of solid-state batteries has prompted the need for new safety standards that address their specific thermal management requirements. The IEC is currently working on developing standards for solid-state batteries, which will likely include updated thermal management guidelines.

Compliance with these safety standards and regulations is essential for manufacturers and researchers working on CMOS battery thermal management systems. It not only ensures the safety of end-users but also facilitates market acceptance and global distribution of battery-powered devices. As new frontiers in CMOS battery thermal management are discovered, close collaboration between industry, research institutions, and regulatory bodies will be crucial in developing and implementing appropriate safety standards that balance innovation with user safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!