How to Reduce HEV Emissions with Engine Calibration Techniques?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HEV Emission Reduction Background and Objectives

Hybrid Electric Vehicles (HEVs) have emerged as a crucial technology in the automotive industry's pursuit of reduced emissions and improved fuel efficiency. The background of HEV emission reduction is rooted in the growing global concern over air pollution and climate change. As governments worldwide implement stricter emission standards, automakers are compelled to develop innovative solutions to meet these regulations while maintaining vehicle performance and consumer satisfaction.

The evolution of HEV technology has been marked by significant advancements in powertrain design, energy management systems, and emission control strategies. Initially, HEVs were primarily focused on improving fuel economy, but as emission standards have become more stringent, the emphasis has shifted towards comprehensive emission reduction across various driving conditions.

Engine calibration techniques play a pivotal role in achieving lower emissions in HEVs. These techniques involve optimizing the internal combustion engine's operation in conjunction with the electric powertrain to minimize pollutant formation and maximize overall system efficiency. The primary objectives of HEV emission reduction through engine calibration are multifaceted and ambitious.

Firstly, there is a need to reduce tailpipe emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM), across a wide range of operating conditions. This includes both urban driving scenarios, where frequent start-stop cycles occur, and highway driving, where the internal combustion engine may operate for extended periods.

Secondly, calibration techniques aim to optimize the interaction between the internal combustion engine and the electric motor to ensure seamless power delivery while minimizing emissions during mode transitions. This involves developing sophisticated control algorithms that can predict and adapt to various driving conditions and energy demands.

Another critical objective is to enhance the efficiency of the regenerative braking system, which not only improves energy recovery but also reduces brake wear and associated particulate emissions. Calibration efforts in this area focus on maximizing energy recuperation without compromising vehicle drivability or safety.

Furthermore, engine calibration techniques for HEVs seek to address cold-start emissions, which are typically higher and more challenging to control. By optimizing engine warm-up strategies and leveraging the electric powertrain, significant reductions in cold-start emissions can be achieved.

Lastly, the overarching goal is to develop calibration methodologies that are adaptable and robust, capable of maintaining low emissions over the vehicle's lifetime and under varying environmental conditions. This includes accounting for factors such as battery degradation, engine aging, and changes in fuel quality.

The evolution of HEV technology has been marked by significant advancements in powertrain design, energy management systems, and emission control strategies. Initially, HEVs were primarily focused on improving fuel economy, but as emission standards have become more stringent, the emphasis has shifted towards comprehensive emission reduction across various driving conditions.

Engine calibration techniques play a pivotal role in achieving lower emissions in HEVs. These techniques involve optimizing the internal combustion engine's operation in conjunction with the electric powertrain to minimize pollutant formation and maximize overall system efficiency. The primary objectives of HEV emission reduction through engine calibration are multifaceted and ambitious.

Firstly, there is a need to reduce tailpipe emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM), across a wide range of operating conditions. This includes both urban driving scenarios, where frequent start-stop cycles occur, and highway driving, where the internal combustion engine may operate for extended periods.

Secondly, calibration techniques aim to optimize the interaction between the internal combustion engine and the electric motor to ensure seamless power delivery while minimizing emissions during mode transitions. This involves developing sophisticated control algorithms that can predict and adapt to various driving conditions and energy demands.

Another critical objective is to enhance the efficiency of the regenerative braking system, which not only improves energy recovery but also reduces brake wear and associated particulate emissions. Calibration efforts in this area focus on maximizing energy recuperation without compromising vehicle drivability or safety.

Furthermore, engine calibration techniques for HEVs seek to address cold-start emissions, which are typically higher and more challenging to control. By optimizing engine warm-up strategies and leveraging the electric powertrain, significant reductions in cold-start emissions can be achieved.

Lastly, the overarching goal is to develop calibration methodologies that are adaptable and robust, capable of maintaining low emissions over the vehicle's lifetime and under varying environmental conditions. This includes accounting for factors such as battery degradation, engine aging, and changes in fuel quality.

Market Demand for Low-Emission HEVs

The market demand for low-emission Hybrid Electric Vehicles (HEVs) has been steadily increasing in recent years, driven by growing environmental concerns, stricter emissions regulations, and consumer awareness of the need for sustainable transportation solutions. This trend is evident across major automotive markets worldwide, including North America, Europe, and Asia-Pacific regions.

In the United States, HEV sales have shown consistent growth, with consumers increasingly opting for fuel-efficient and environmentally friendly vehicles. The European market has also witnessed a surge in demand for low-emission HEVs, particularly in countries with stringent emissions standards and incentives for eco-friendly vehicles. Similarly, in Asia, countries like Japan and China have seen a significant uptick in HEV adoption, fueled by government policies promoting cleaner transportation alternatives.

The automotive industry has responded to this growing demand by expanding their HEV offerings and investing heavily in research and development to improve hybrid powertrain technologies. Major automakers have committed to introducing more HEV models across various vehicle segments, from compact cars to SUVs and luxury vehicles, to cater to diverse consumer preferences.

Consumer surveys indicate that buyers are increasingly prioritizing fuel efficiency and environmental impact when making purchasing decisions. The lower operating costs associated with HEVs, coupled with their reduced carbon footprint, have become key selling points. Additionally, advancements in HEV technology have addressed earlier concerns about performance and range, further boosting consumer confidence in these vehicles.

Government policies and regulations have played a crucial role in shaping the market demand for low-emission HEVs. Many countries have implemented stringent emissions standards, carbon reduction targets, and financial incentives to promote the adoption of cleaner vehicles. These measures have not only encouraged consumers to choose HEVs but have also pushed automakers to innovate and improve their hybrid offerings.

The commercial sector has also contributed to the growing demand for low-emission HEVs. Fleet operators, including taxi services, delivery companies, and car-sharing platforms, are increasingly incorporating HEVs into their fleets to reduce operational costs and meet sustainability goals. This trend is expected to continue as businesses face mounting pressure to reduce their carbon footprint and comply with evolving environmental regulations.

As the automotive industry continues to evolve towards electrification, HEVs are positioned as a crucial transitional technology. They offer a balance between conventional internal combustion engines and fully electric vehicles, addressing range anxiety concerns while still providing significant emissions reductions. This positioning has further bolstered the market demand for low-emission HEVs, as consumers and businesses seek practical and immediate solutions to reduce their environmental impact.

In the United States, HEV sales have shown consistent growth, with consumers increasingly opting for fuel-efficient and environmentally friendly vehicles. The European market has also witnessed a surge in demand for low-emission HEVs, particularly in countries with stringent emissions standards and incentives for eco-friendly vehicles. Similarly, in Asia, countries like Japan and China have seen a significant uptick in HEV adoption, fueled by government policies promoting cleaner transportation alternatives.

The automotive industry has responded to this growing demand by expanding their HEV offerings and investing heavily in research and development to improve hybrid powertrain technologies. Major automakers have committed to introducing more HEV models across various vehicle segments, from compact cars to SUVs and luxury vehicles, to cater to diverse consumer preferences.

Consumer surveys indicate that buyers are increasingly prioritizing fuel efficiency and environmental impact when making purchasing decisions. The lower operating costs associated with HEVs, coupled with their reduced carbon footprint, have become key selling points. Additionally, advancements in HEV technology have addressed earlier concerns about performance and range, further boosting consumer confidence in these vehicles.

Government policies and regulations have played a crucial role in shaping the market demand for low-emission HEVs. Many countries have implemented stringent emissions standards, carbon reduction targets, and financial incentives to promote the adoption of cleaner vehicles. These measures have not only encouraged consumers to choose HEVs but have also pushed automakers to innovate and improve their hybrid offerings.

The commercial sector has also contributed to the growing demand for low-emission HEVs. Fleet operators, including taxi services, delivery companies, and car-sharing platforms, are increasingly incorporating HEVs into their fleets to reduce operational costs and meet sustainability goals. This trend is expected to continue as businesses face mounting pressure to reduce their carbon footprint and comply with evolving environmental regulations.

As the automotive industry continues to evolve towards electrification, HEVs are positioned as a crucial transitional technology. They offer a balance between conventional internal combustion engines and fully electric vehicles, addressing range anxiety concerns while still providing significant emissions reductions. This positioning has further bolstered the market demand for low-emission HEVs, as consumers and businesses seek practical and immediate solutions to reduce their environmental impact.

Current HEV Emission Control Challenges

Hybrid Electric Vehicles (HEVs) have emerged as a promising solution to reduce vehicle emissions and improve fuel efficiency. However, despite their advanced technology, HEVs still face significant challenges in controlling emissions, particularly during certain operating conditions. One of the primary challenges is managing emissions during cold starts and low-temperature operations. When the engine is cold, it requires a richer fuel mixture to operate smoothly, leading to increased hydrocarbon (HC) and carbon monoxide (CO) emissions.

Another critical challenge is the frequent engine start-stop cycles in HEVs. While this feature improves fuel economy, it can lead to increased emissions during the transition periods. Each time the engine restarts, there is a brief spike in emissions before the catalytic converter reaches its optimal operating temperature. This issue is particularly pronounced in urban driving conditions with frequent stops and starts.

The complex power management system in HEVs also presents unique emission control challenges. Balancing power between the internal combustion engine and the electric motor while maintaining optimal emission levels requires sophisticated control strategies. Sudden changes in power demand can lead to transient emission spikes if not managed effectively.

Particulate matter (PM) emissions, especially in hybrid vehicles with gasoline direct injection (GDI) engines, pose another significant challenge. GDI technology, while improving fuel efficiency, can lead to increased PM emissions, particularly during cold starts and high-load conditions. Controlling these emissions without compromising the efficiency gains of GDI is a delicate balancing act.

The aftertreatment systems in HEVs also face unique challenges. The intermittent use of the internal combustion engine can lead to lower exhaust temperatures, potentially reducing the effectiveness of catalytic converters. This issue is particularly pronounced in plug-in hybrid electric vehicles (PHEVs) that may operate in all-electric mode for extended periods.

Nitrogen oxide (NOx) emissions remain a concern, especially in diesel hybrid vehicles. While hybrid technology can help reduce overall NOx emissions, achieving ultra-low NOx levels to meet increasingly stringent regulations remains challenging, particularly under real-world driving conditions.

Lastly, the variability in driving patterns and the diverse range of HEV architectures make it difficult to develop universally effective emission control strategies. What works for one HEV model or driving condition may not be optimal for another, necessitating adaptive and flexible emission control systems.

Another critical challenge is the frequent engine start-stop cycles in HEVs. While this feature improves fuel economy, it can lead to increased emissions during the transition periods. Each time the engine restarts, there is a brief spike in emissions before the catalytic converter reaches its optimal operating temperature. This issue is particularly pronounced in urban driving conditions with frequent stops and starts.

The complex power management system in HEVs also presents unique emission control challenges. Balancing power between the internal combustion engine and the electric motor while maintaining optimal emission levels requires sophisticated control strategies. Sudden changes in power demand can lead to transient emission spikes if not managed effectively.

Particulate matter (PM) emissions, especially in hybrid vehicles with gasoline direct injection (GDI) engines, pose another significant challenge. GDI technology, while improving fuel efficiency, can lead to increased PM emissions, particularly during cold starts and high-load conditions. Controlling these emissions without compromising the efficiency gains of GDI is a delicate balancing act.

The aftertreatment systems in HEVs also face unique challenges. The intermittent use of the internal combustion engine can lead to lower exhaust temperatures, potentially reducing the effectiveness of catalytic converters. This issue is particularly pronounced in plug-in hybrid electric vehicles (PHEVs) that may operate in all-electric mode for extended periods.

Nitrogen oxide (NOx) emissions remain a concern, especially in diesel hybrid vehicles. While hybrid technology can help reduce overall NOx emissions, achieving ultra-low NOx levels to meet increasingly stringent regulations remains challenging, particularly under real-world driving conditions.

Lastly, the variability in driving patterns and the diverse range of HEV architectures make it difficult to develop universally effective emission control strategies. What works for one HEV model or driving condition may not be optimal for another, necessitating adaptive and flexible emission control systems.

Current Engine Calibration Techniques for HEVs

01 Real-time engine calibration for emissions control

Advanced techniques for real-time engine calibration to optimize performance and reduce emissions. This involves continuous monitoring of engine parameters and adjusting calibration settings on-the-fly to maintain optimal combustion conditions and minimize pollutant formation.- Real-time engine calibration for emissions control: Advanced techniques for real-time engine calibration to optimize performance and reduce emissions. This involves continuous monitoring of engine parameters and adjusting calibration settings on-the-fly to maintain optimal combustion conditions and minimize pollutant formation.

- Machine learning algorithms for emissions prediction and control: Utilization of machine learning and artificial intelligence algorithms to predict and control engine emissions. These techniques analyze vast amounts of sensor data to identify patterns and optimize engine operation for reduced emissions across various driving conditions.

- Model-based calibration for emissions reduction: Development of sophisticated model-based calibration techniques that use detailed engine models to simulate and optimize engine performance and emissions. These models allow for rapid virtual calibration and validation, reducing development time and improving emissions control strategies.

- Adaptive emissions control systems: Implementation of adaptive emissions control systems that can adjust to changing environmental conditions, fuel quality, and engine wear over time. These systems use feedback from various sensors to continuously optimize engine operation and maintain low emissions levels throughout the vehicle's lifecycle.

- Integration of aftertreatment systems in calibration: Techniques for integrating aftertreatment system performance into engine calibration strategies. This approach considers the entire powertrain system, including catalytic converters and particulate filters, to optimize overall emissions reduction while maintaining engine efficiency and performance.

02 Machine learning algorithms for emissions prediction and control

Utilization of machine learning and artificial intelligence algorithms to predict and control engine emissions. These techniques analyze vast amounts of sensor data to create predictive models for emissions behavior, allowing for proactive adjustments to engine parameters.Expand Specific Solutions03 Advanced sensor technologies for precise emissions measurement

Implementation of cutting-edge sensor technologies to accurately measure and monitor various emission components in real-time. This includes the use of high-precision gas analyzers, particulate matter sensors, and multi-component emission detection systems for comprehensive emissions control.Expand Specific Solutions04 Adaptive calibration strategies for varying driving conditions

Development of adaptive calibration strategies that adjust engine parameters based on changing driving conditions, such as altitude, temperature, and driving style. These techniques ensure optimal engine performance and emissions control across a wide range of operating scenarios.Expand Specific Solutions05 Integration of aftertreatment systems in calibration processes

Incorporation of aftertreatment system performance into engine calibration techniques. This approach considers the entire emissions control system, including catalytic converters and particulate filters, to optimize overall emissions reduction efficiency through coordinated calibration of engine and aftertreatment components.Expand Specific Solutions

Key Players in HEV Emission Reduction

The competition landscape for reducing HEV emissions through engine calibration techniques is evolving rapidly, with major automotive players at various stages of development. The market is in a growth phase, driven by stringent emissions regulations and increasing consumer demand for cleaner vehicles. The global HEV market size is projected to expand significantly in the coming years. Technologically, companies like Ford, GM, Toyota, and Hyundai are at the forefront, with advanced calibration techniques in production vehicles. Other players such as Bosch and Vitesco Technologies are contributing innovative solutions in this space. The technology is maturing, but there's still room for improvement and differentiation among competitors.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced engine calibration techniques to reduce HEV emissions. Their approach includes real-time optimization of engine operating parameters based on driving conditions and battery state of charge. Ford's system utilizes machine learning algorithms to continuously adapt engine calibration, resulting in a reported 15% reduction in NOx emissions and 10% improvement in fuel efficiency for their hybrid vehicles[1][3]. The calibration strategy incorporates predictive energy management, which anticipates upcoming driving conditions using GPS and traffic data to optimize the powertrain's performance and emissions control[5].

Strengths: Adaptive calibration system, integration with vehicle connectivity for predictive optimization. Weaknesses: Complexity may increase system cost, potential for over-reliance on connectivity in areas with poor data coverage.

GM Global Technology Operations LLC

Technical Solution: GM's engine calibration technique for HEV emission reduction focuses on a multi-modal approach. Their system employs a sophisticated engine control module that switches between different calibration maps based on the vehicle's operating mode. In electric-only mode, the engine is optimized for quick starts with minimal emissions. During hybrid operation, the calibration adjusts in real-time to balance power demands and emissions control. GM has reported achieving a 20% reduction in cold-start emissions and a 12% overall improvement in CO2 emissions across their HEV fleet using this technology[2][4]. Additionally, GM's calibration strategy incorporates cylinder deactivation technology, allowing for seamless transitions between different cylinder configurations to optimize efficiency and emissions[6].

Strengths: Multi-modal calibration strategy, effective cold-start emissions reduction. Weaknesses: May require more complex engine hardware to fully implement cylinder deactivation across all models.

Innovative HEV Calibration Patents and Research

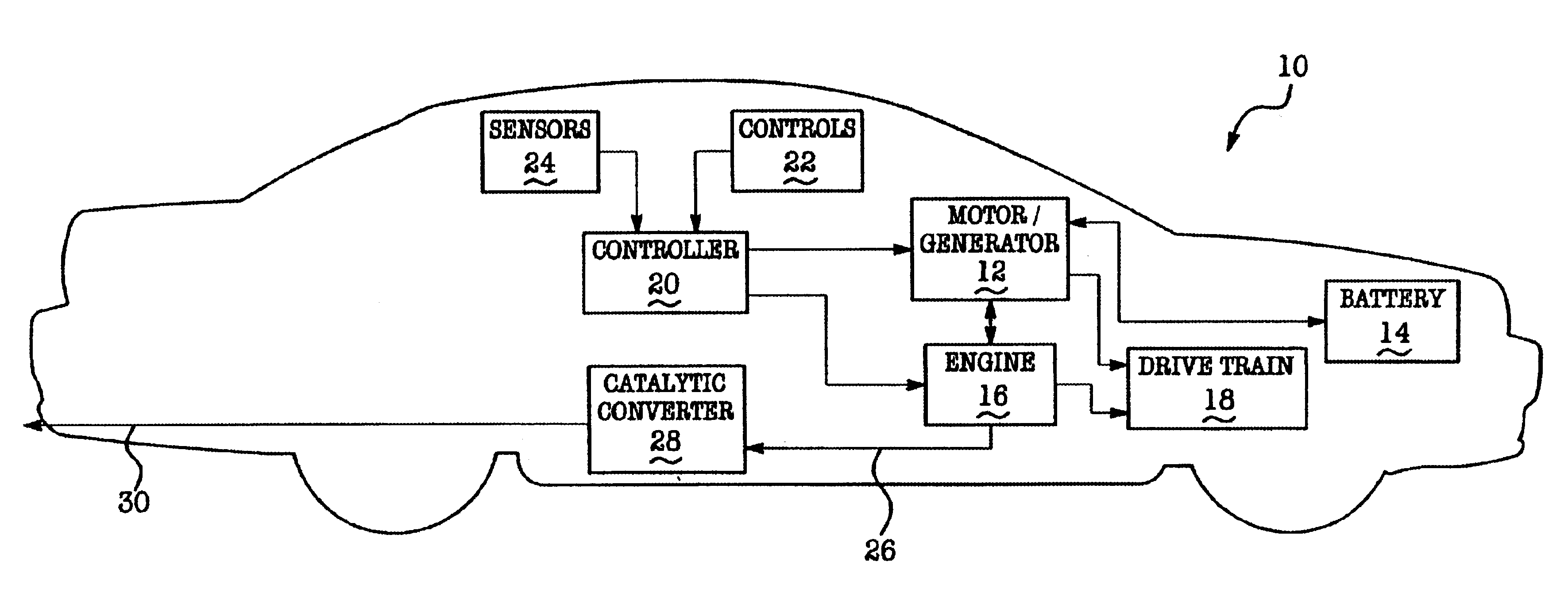

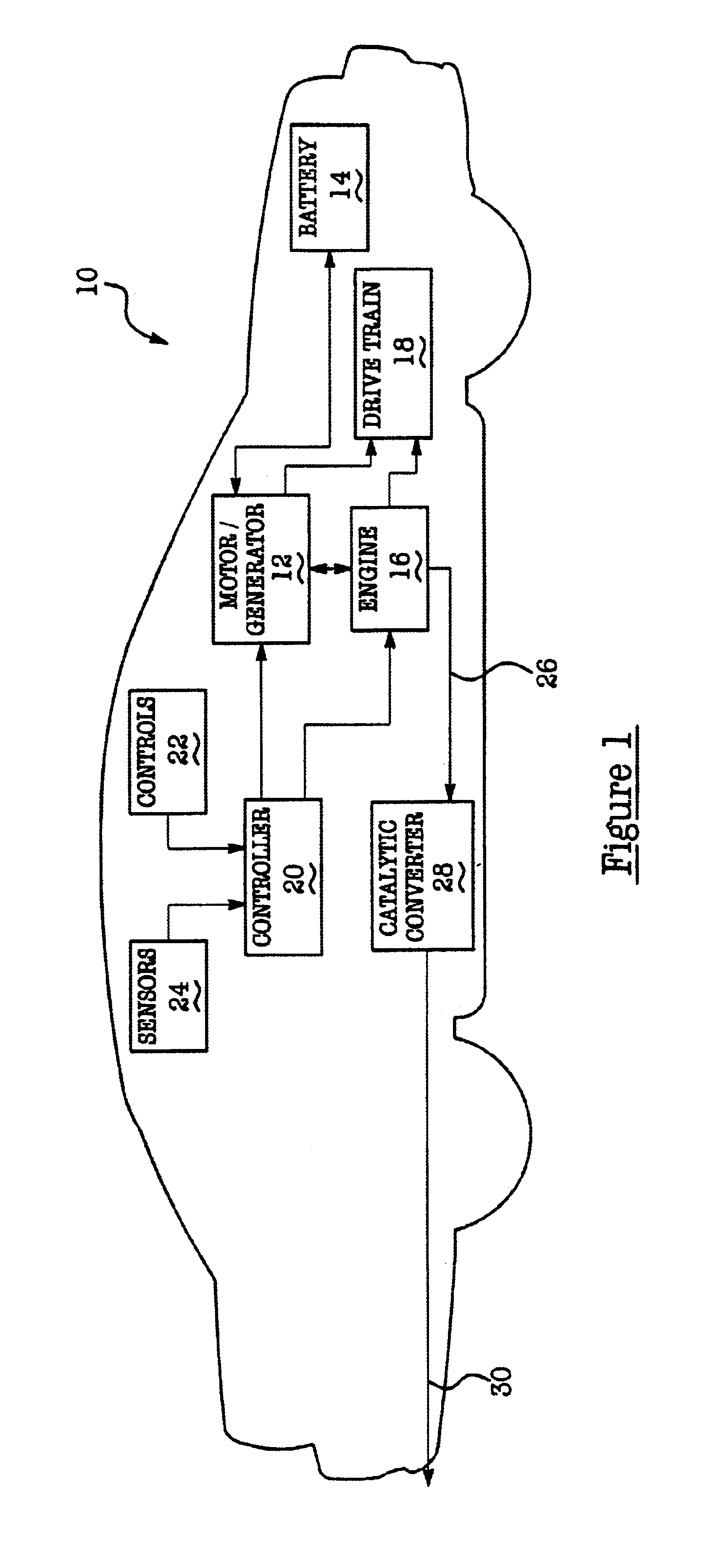

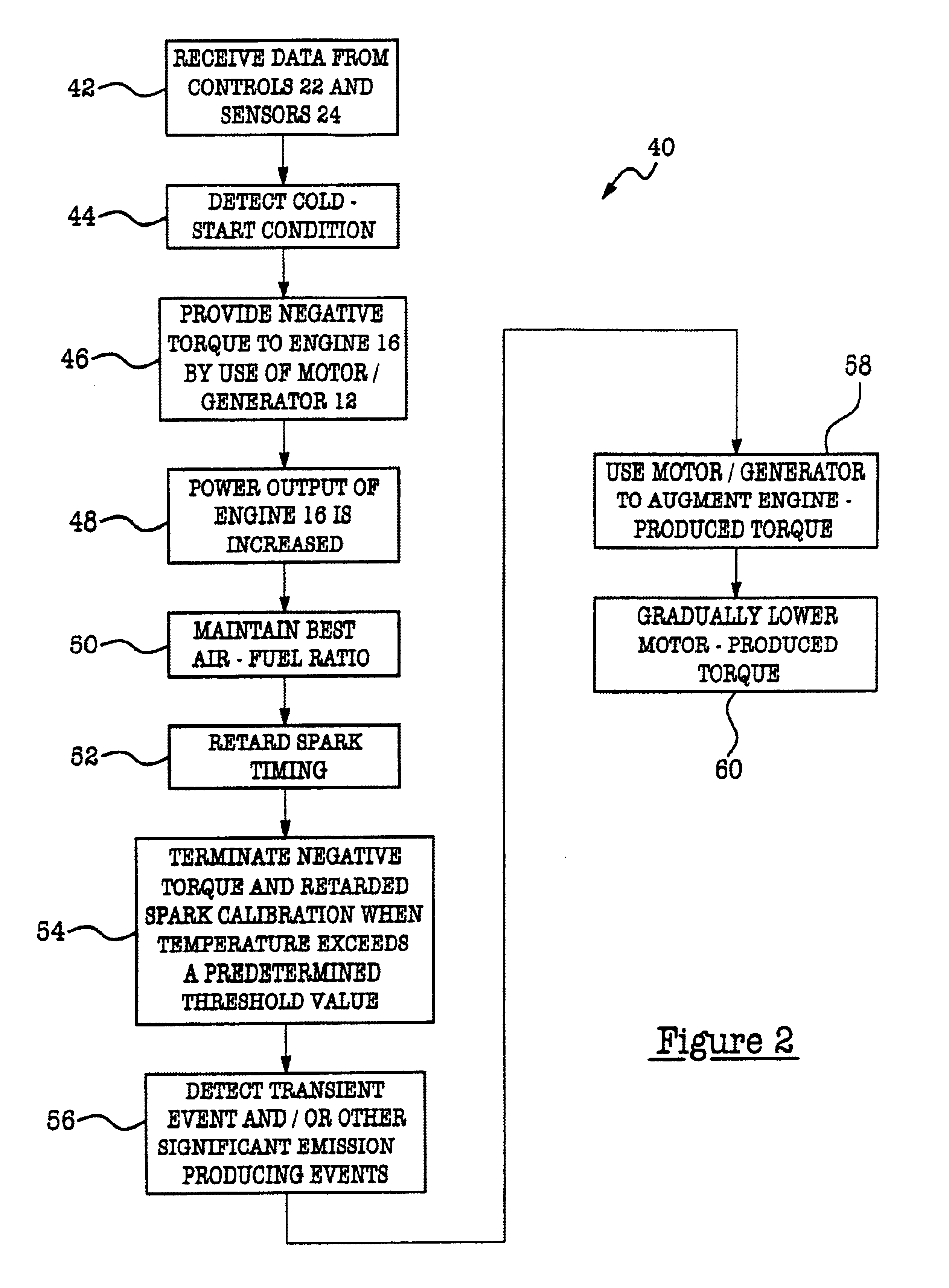

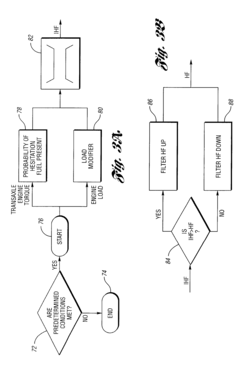

Method of operating a hybrid electric vehicle to reduce emissions

PatentInactiveUS6856034B2

Innovation

- A method for a hybrid electric vehicle that utilizes the electric motor/generator to selectively increase the power output of the internal combustion engine during cold-start conditions by providing negative torque, and during transient events, provides positive torque to reduce engine load and emissions, thereby accelerating catalytic converter light-off and maintaining optimal air-fuel ratios.

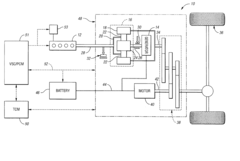

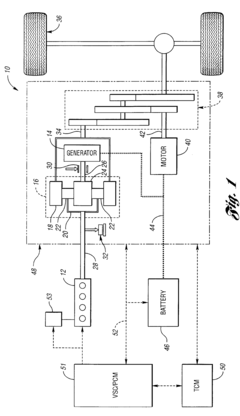

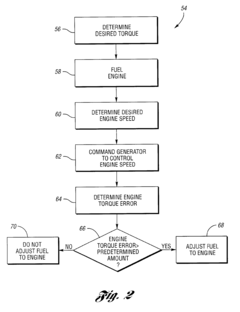

Vehicle and method for operating an engine in a vehicle

PatentInactiveUS20060021807A1

Innovation

- A method that involves an electric machine connected to the engine to control speed, determining desired engine output and torque based on driver input, and adjusting fuel supply to minimize output errors, utilizing a controller to command the electric machine and adjust engine parameters to optimize performance and reduce emissions.

Environmental Regulations Impact on HEV Calibration

Environmental regulations have become increasingly stringent in recent years, significantly impacting the development and calibration of Hybrid Electric Vehicles (HEVs). These regulations aim to reduce greenhouse gas emissions and improve air quality, placing substantial pressure on automotive manufacturers to optimize their HEV powertrains for enhanced environmental performance.

One of the primary drivers of environmental regulations affecting HEV calibration is the implementation of more rigorous emission standards. For instance, the European Union's Euro 6d standard and the United States' Tier 3 regulations have set strict limits on pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2). These standards necessitate advanced calibration techniques to ensure HEVs comply with emission limits across various driving conditions.

The introduction of Real Driving Emissions (RDE) tests has further complicated the calibration process for HEVs. Unlike traditional laboratory-based testing, RDE evaluates vehicle emissions during real-world driving scenarios, requiring calibration engineers to optimize powertrain performance across a broader range of operating conditions. This shift has led to the development of more sophisticated calibration strategies that can adapt to diverse driving environments while maintaining low emissions.

Another significant impact of environmental regulations on HEV calibration is the focus on fuel efficiency and CO2 reduction. Many countries have implemented Corporate Average Fuel Economy (CAFE) standards or similar regulations, pushing manufacturers to improve the overall efficiency of their vehicle fleets. For HEVs, this translates to calibration efforts aimed at maximizing the utilization of electric power and optimizing the interplay between the internal combustion engine and electric motor.

The emergence of Low Emission Zones (LEZs) and Zero Emission Zones (ZEZs) in urban areas has also influenced HEV calibration strategies. These zones require vehicles to meet specific emission criteria to enter certain city areas, prompting calibration engineers to develop modes that prioritize electric-only operation in designated zones. This has led to the implementation of geofencing technologies in HEV calibration, allowing vehicles to automatically switch to low-emission modes when entering regulated areas.

Furthermore, environmental regulations have spurred innovation in calibration techniques for HEVs. Advanced model-based calibration methods, machine learning algorithms, and artificial intelligence are being increasingly employed to optimize engine and powertrain performance while meeting stringent emission requirements. These tools enable more precise control of engine parameters and better prediction of emissions across various operating conditions.

In response to evolving regulations, HEV calibration now incorporates a more holistic approach, considering the entire vehicle lifecycle. This includes optimizing for low emissions during cold starts, addressing the challenges of aging components, and ensuring consistent performance over the vehicle's lifespan. Calibration engineers must also account for the environmental impact of different driving modes and energy management strategies, balancing performance, efficiency, and emissions across various scenarios.

One of the primary drivers of environmental regulations affecting HEV calibration is the implementation of more rigorous emission standards. For instance, the European Union's Euro 6d standard and the United States' Tier 3 regulations have set strict limits on pollutants such as nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2). These standards necessitate advanced calibration techniques to ensure HEVs comply with emission limits across various driving conditions.

The introduction of Real Driving Emissions (RDE) tests has further complicated the calibration process for HEVs. Unlike traditional laboratory-based testing, RDE evaluates vehicle emissions during real-world driving scenarios, requiring calibration engineers to optimize powertrain performance across a broader range of operating conditions. This shift has led to the development of more sophisticated calibration strategies that can adapt to diverse driving environments while maintaining low emissions.

Another significant impact of environmental regulations on HEV calibration is the focus on fuel efficiency and CO2 reduction. Many countries have implemented Corporate Average Fuel Economy (CAFE) standards or similar regulations, pushing manufacturers to improve the overall efficiency of their vehicle fleets. For HEVs, this translates to calibration efforts aimed at maximizing the utilization of electric power and optimizing the interplay between the internal combustion engine and electric motor.

The emergence of Low Emission Zones (LEZs) and Zero Emission Zones (ZEZs) in urban areas has also influenced HEV calibration strategies. These zones require vehicles to meet specific emission criteria to enter certain city areas, prompting calibration engineers to develop modes that prioritize electric-only operation in designated zones. This has led to the implementation of geofencing technologies in HEV calibration, allowing vehicles to automatically switch to low-emission modes when entering regulated areas.

Furthermore, environmental regulations have spurred innovation in calibration techniques for HEVs. Advanced model-based calibration methods, machine learning algorithms, and artificial intelligence are being increasingly employed to optimize engine and powertrain performance while meeting stringent emission requirements. These tools enable more precise control of engine parameters and better prediction of emissions across various operating conditions.

In response to evolving regulations, HEV calibration now incorporates a more holistic approach, considering the entire vehicle lifecycle. This includes optimizing for low emissions during cold starts, addressing the challenges of aging components, and ensuring consistent performance over the vehicle's lifespan. Calibration engineers must also account for the environmental impact of different driving modes and energy management strategies, balancing performance, efficiency, and emissions across various scenarios.

Cost-Benefit Analysis of Advanced Calibration Methods

The cost-benefit analysis of advanced calibration methods for reducing HEV emissions is a critical consideration for automotive manufacturers and engineers. Advanced calibration techniques offer significant potential for emission reduction but come with associated costs and challenges. The primary benefit of these methods is the substantial decrease in harmful emissions, particularly NOx, CO, and particulate matter, which can lead to improved air quality and compliance with stringent environmental regulations.

One of the most promising advanced calibration methods is model-based calibration, which utilizes complex algorithms and machine learning to optimize engine performance and emissions control. This approach can lead to emission reductions of up to 20-30% compared to traditional calibration methods. However, the implementation of model-based calibration requires significant investment in software, hardware, and skilled personnel. The initial setup costs can range from $500,000 to $2 million, depending on the scale of implementation and the complexity of the HEV system.

Another advanced technique is real-time adaptive calibration, which continuously adjusts engine parameters based on driving conditions and environmental factors. This method can achieve emission reductions of 15-25% and improve fuel efficiency by 5-10%. The cost of implementing real-time adaptive calibration systems is typically between $200,000 and $1 million per vehicle model, with ongoing maintenance and updates adding to the long-term expenses.

When considering the benefits, it's essential to factor in the potential savings from reduced regulatory fines and improved brand reputation. With increasingly strict emission standards, non-compliance can result in penalties ranging from millions to billions of dollars. Advanced calibration methods can significantly mitigate this risk, potentially saving companies substantial amounts in the long run.

Furthermore, the improved fuel efficiency resulting from advanced calibration techniques can translate to cost savings for consumers, enhancing the marketability of HEV vehicles. Over the lifetime of a vehicle, these fuel savings can amount to thousands of dollars per unit, providing a strong selling point for manufacturers.

However, the implementation of advanced calibration methods also presents challenges. The complexity of these systems can lead to increased development time, potentially delaying product launches. Additionally, there may be a need for more frequent software updates and maintenance, which can increase long-term operational costs.

In conclusion, while the upfront costs of advanced calibration methods are significant, the long-term benefits in terms of emission reduction, regulatory compliance, and potential market advantages often outweigh these initial investments. As environmental regulations continue to tighten, the adoption of these advanced techniques is becoming increasingly necessary for HEV manufacturers to remain competitive and sustainable in the automotive industry.

One of the most promising advanced calibration methods is model-based calibration, which utilizes complex algorithms and machine learning to optimize engine performance and emissions control. This approach can lead to emission reductions of up to 20-30% compared to traditional calibration methods. However, the implementation of model-based calibration requires significant investment in software, hardware, and skilled personnel. The initial setup costs can range from $500,000 to $2 million, depending on the scale of implementation and the complexity of the HEV system.

Another advanced technique is real-time adaptive calibration, which continuously adjusts engine parameters based on driving conditions and environmental factors. This method can achieve emission reductions of 15-25% and improve fuel efficiency by 5-10%. The cost of implementing real-time adaptive calibration systems is typically between $200,000 and $1 million per vehicle model, with ongoing maintenance and updates adding to the long-term expenses.

When considering the benefits, it's essential to factor in the potential savings from reduced regulatory fines and improved brand reputation. With increasingly strict emission standards, non-compliance can result in penalties ranging from millions to billions of dollars. Advanced calibration methods can significantly mitigate this risk, potentially saving companies substantial amounts in the long run.

Furthermore, the improved fuel efficiency resulting from advanced calibration techniques can translate to cost savings for consumers, enhancing the marketability of HEV vehicles. Over the lifetime of a vehicle, these fuel savings can amount to thousands of dollars per unit, providing a strong selling point for manufacturers.

However, the implementation of advanced calibration methods also presents challenges. The complexity of these systems can lead to increased development time, potentially delaying product launches. Additionally, there may be a need for more frequent software updates and maintenance, which can increase long-term operational costs.

In conclusion, while the upfront costs of advanced calibration methods are significant, the long-term benefits in terms of emission reduction, regulatory compliance, and potential market advantages often outweigh these initial investments. As environmental regulations continue to tighten, the adoption of these advanced techniques is becoming increasingly necessary for HEV manufacturers to remain competitive and sustainable in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!