How to Use Carboxylic Acid in Bioreactor Optimization?

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carboxylic Acid in Bioreactors: Background and Objectives

Carboxylic acids have emerged as crucial components in the optimization of bioreactor processes, playing a significant role in various biotechnological applications. The utilization of these organic compounds in bioreactors has a rich history dating back to the early days of industrial fermentation. Initially, carboxylic acids were primarily viewed as byproducts or waste materials in microbial fermentation processes. However, as our understanding of microbial metabolism and bioprocess engineering advanced, researchers began to recognize the potential of these acids as valuable metabolites and process regulators.

The evolution of carboxylic acid usage in bioreactors has been closely tied to the development of metabolic engineering and synthetic biology. These fields have enabled scientists to manipulate microbial pathways to enhance the production of specific carboxylic acids or to utilize them more effectively as substrates. This progress has opened up new possibilities for bioreactor optimization, particularly in areas such as biofuel production, pharmaceutical manufacturing, and the synthesis of bio-based chemicals.

In recent years, the focus has shifted towards leveraging carboxylic acids for fine-tuning bioreactor conditions and improving overall process efficiency. Researchers have discovered that these acids can influence pH levels, microbial growth rates, and metabolic fluxes within bioreactors. This realization has led to the development of novel strategies for controlling and optimizing bioprocesses using carboxylic acids as key regulatory molecules.

The current technological landscape surrounding carboxylic acid utilization in bioreactors is characterized by a convergence of multiple disciplines, including microbiology, biochemistry, process engineering, and data analytics. This interdisciplinary approach has resulted in more sophisticated bioreactor designs and control systems that can dynamically adjust carboxylic acid concentrations to maintain optimal conditions for microbial growth and product formation.

Looking ahead, the primary objectives for carboxylic acid usage in bioreactor optimization are multifaceted. Researchers aim to develop more precise methods for real-time monitoring and control of carboxylic acid levels within bioreactors. There is also a strong emphasis on enhancing the metabolic capacity of microorganisms to produce or consume specific carboxylic acids more efficiently. Additionally, efforts are being made to explore the potential of novel carboxylic acids and their derivatives in improving bioreactor performance across various industrial sectors.

As we delve deeper into this field, it becomes evident that the strategic use of carboxylic acids holds immense promise for revolutionizing bioreactor technology. The ongoing research in this area is expected to lead to more sustainable and economically viable bioprocesses, ultimately contributing to the advancement of the bioeconomy and addressing global challenges in energy, healthcare, and environmental sustainability.

The evolution of carboxylic acid usage in bioreactors has been closely tied to the development of metabolic engineering and synthetic biology. These fields have enabled scientists to manipulate microbial pathways to enhance the production of specific carboxylic acids or to utilize them more effectively as substrates. This progress has opened up new possibilities for bioreactor optimization, particularly in areas such as biofuel production, pharmaceutical manufacturing, and the synthesis of bio-based chemicals.

In recent years, the focus has shifted towards leveraging carboxylic acids for fine-tuning bioreactor conditions and improving overall process efficiency. Researchers have discovered that these acids can influence pH levels, microbial growth rates, and metabolic fluxes within bioreactors. This realization has led to the development of novel strategies for controlling and optimizing bioprocesses using carboxylic acids as key regulatory molecules.

The current technological landscape surrounding carboxylic acid utilization in bioreactors is characterized by a convergence of multiple disciplines, including microbiology, biochemistry, process engineering, and data analytics. This interdisciplinary approach has resulted in more sophisticated bioreactor designs and control systems that can dynamically adjust carboxylic acid concentrations to maintain optimal conditions for microbial growth and product formation.

Looking ahead, the primary objectives for carboxylic acid usage in bioreactor optimization are multifaceted. Researchers aim to develop more precise methods for real-time monitoring and control of carboxylic acid levels within bioreactors. There is also a strong emphasis on enhancing the metabolic capacity of microorganisms to produce or consume specific carboxylic acids more efficiently. Additionally, efforts are being made to explore the potential of novel carboxylic acids and their derivatives in improving bioreactor performance across various industrial sectors.

As we delve deeper into this field, it becomes evident that the strategic use of carboxylic acids holds immense promise for revolutionizing bioreactor technology. The ongoing research in this area is expected to lead to more sustainable and economically viable bioprocesses, ultimately contributing to the advancement of the bioeconomy and addressing global challenges in energy, healthcare, and environmental sustainability.

Market Analysis for Optimized Bioreactor Processes

The market for optimized bioreactor processes utilizing carboxylic acids is experiencing significant growth, driven by increasing demand for sustainable and efficient biotechnology solutions across various industries. The global bioreactor market is projected to reach $5.1 billion by 2026, with a compound annual growth rate of 10.2% from 2021 to 2026.

Carboxylic acids play a crucial role in bioreactor optimization, particularly in fermentation processes for the production of biofuels, pharmaceuticals, and specialty chemicals. The use of carboxylic acids in bioreactors enhances metabolic pathways, improves product yields, and reduces production costs, making it an attractive option for manufacturers seeking to improve their bioprocesses.

The pharmaceutical industry is a major driver of demand for optimized bioreactor processes. With the growing focus on biopharmaceuticals and personalized medicine, there is an increasing need for efficient and scalable production methods. Carboxylic acid-based bioreactor optimization offers improved productivity and product quality, making it particularly valuable in this sector.

In the biofuels industry, the use of carboxylic acids in bioreactor optimization is gaining traction as companies seek to enhance the efficiency of microbial fermentation processes. This approach allows for higher yields of biofuels such as ethanol and butanol, contributing to the overall growth of the renewable energy market.

The food and beverage industry is another significant market for optimized bioreactor processes. Carboxylic acids are used to improve the production of various food additives, flavors, and nutritional supplements. As consumer demand for natural and clean-label products continues to rise, the adoption of these optimized bioprocesses is expected to increase.

Geographically, North America and Europe are the leading markets for optimized bioreactor processes, owing to their well-established biotechnology and pharmaceutical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in biotechnology research and development, particularly in countries like China and India.

The market for optimized bioreactor processes faces some challenges, including high initial investment costs and regulatory hurdles. However, the long-term benefits of improved efficiency, reduced production costs, and enhanced product quality are expected to outweigh these challenges, driving continued market growth and innovation in the field of bioreactor optimization using carboxylic acids.

Carboxylic acids play a crucial role in bioreactor optimization, particularly in fermentation processes for the production of biofuels, pharmaceuticals, and specialty chemicals. The use of carboxylic acids in bioreactors enhances metabolic pathways, improves product yields, and reduces production costs, making it an attractive option for manufacturers seeking to improve their bioprocesses.

The pharmaceutical industry is a major driver of demand for optimized bioreactor processes. With the growing focus on biopharmaceuticals and personalized medicine, there is an increasing need for efficient and scalable production methods. Carboxylic acid-based bioreactor optimization offers improved productivity and product quality, making it particularly valuable in this sector.

In the biofuels industry, the use of carboxylic acids in bioreactor optimization is gaining traction as companies seek to enhance the efficiency of microbial fermentation processes. This approach allows for higher yields of biofuels such as ethanol and butanol, contributing to the overall growth of the renewable energy market.

The food and beverage industry is another significant market for optimized bioreactor processes. Carboxylic acids are used to improve the production of various food additives, flavors, and nutritional supplements. As consumer demand for natural and clean-label products continues to rise, the adoption of these optimized bioprocesses is expected to increase.

Geographically, North America and Europe are the leading markets for optimized bioreactor processes, owing to their well-established biotechnology and pharmaceutical industries. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing investments in biotechnology research and development, particularly in countries like China and India.

The market for optimized bioreactor processes faces some challenges, including high initial investment costs and regulatory hurdles. However, the long-term benefits of improved efficiency, reduced production costs, and enhanced product quality are expected to outweigh these challenges, driving continued market growth and innovation in the field of bioreactor optimization using carboxylic acids.

Current Challenges in Carboxylic Acid Utilization

The utilization of carboxylic acids in bioreactor optimization faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the inherent toxicity of carboxylic acids to microorganisms at high concentrations. This toxicity can severely impact cell growth and metabolic activities, leading to reduced productivity and yield in bioreactor systems.

Another major challenge is the difficulty in maintaining optimal pH levels within the bioreactor. Carboxylic acids tend to lower the pH of the medium, which can create an unfavorable environment for microbial growth and enzyme activity. Continuous pH adjustment is often necessary, adding complexity to the process control and potentially increasing operational costs.

The recovery and purification of carboxylic acids from the fermentation broth present additional hurdles. Traditional separation methods, such as distillation or extraction, can be energy-intensive and may require large volumes of organic solvents, raising environmental concerns and production costs.

Furthermore, the low solubility of many carboxylic acids in aqueous solutions limits their concentration in the fermentation medium. This constraint necessitates the development of novel strategies for in situ product removal or the engineering of more tolerant microbial strains.

The metabolic burden imposed on microorganisms for carboxylic acid production is another significant challenge. Overproduction of these compounds can divert cellular resources from growth and other essential functions, potentially leading to reduced overall productivity and strain instability over time.

Scaling up carboxylic acid production in bioreactors also presents difficulties. Maintaining consistent performance and product quality across different scales, from laboratory to industrial production, remains a complex task due to changes in mixing, mass transfer, and heat dissipation characteristics.

Lastly, the genetic and metabolic engineering of microorganisms for enhanced carboxylic acid production and tolerance is an ongoing challenge. While progress has been made in developing more robust strains, further improvements are needed to achieve economically viable production levels and to expand the range of carboxylic acids that can be efficiently produced in bioreactors.

Addressing these challenges requires a multidisciplinary approach, combining advances in microbial engineering, process design, and downstream processing technologies. Overcoming these hurdles will be crucial for realizing the full potential of carboxylic acid utilization in bioreactor optimization and advancing the field of industrial biotechnology.

Another major challenge is the difficulty in maintaining optimal pH levels within the bioreactor. Carboxylic acids tend to lower the pH of the medium, which can create an unfavorable environment for microbial growth and enzyme activity. Continuous pH adjustment is often necessary, adding complexity to the process control and potentially increasing operational costs.

The recovery and purification of carboxylic acids from the fermentation broth present additional hurdles. Traditional separation methods, such as distillation or extraction, can be energy-intensive and may require large volumes of organic solvents, raising environmental concerns and production costs.

Furthermore, the low solubility of many carboxylic acids in aqueous solutions limits their concentration in the fermentation medium. This constraint necessitates the development of novel strategies for in situ product removal or the engineering of more tolerant microbial strains.

The metabolic burden imposed on microorganisms for carboxylic acid production is another significant challenge. Overproduction of these compounds can divert cellular resources from growth and other essential functions, potentially leading to reduced overall productivity and strain instability over time.

Scaling up carboxylic acid production in bioreactors also presents difficulties. Maintaining consistent performance and product quality across different scales, from laboratory to industrial production, remains a complex task due to changes in mixing, mass transfer, and heat dissipation characteristics.

Lastly, the genetic and metabolic engineering of microorganisms for enhanced carboxylic acid production and tolerance is an ongoing challenge. While progress has been made in developing more robust strains, further improvements are needed to achieve economically viable production levels and to expand the range of carboxylic acids that can be efficiently produced in bioreactors.

Addressing these challenges requires a multidisciplinary approach, combining advances in microbial engineering, process design, and downstream processing technologies. Overcoming these hurdles will be crucial for realizing the full potential of carboxylic acid utilization in bioreactor optimization and advancing the field of industrial biotechnology.

Existing Carboxylic Acid Integration Methods

01 Synthesis of carboxylic acids

Various methods for synthesizing carboxylic acids are described, including oxidation of primary alcohols or aldehydes, hydrolysis of nitriles, and carbonylation reactions. These processes often involve catalysts and specific reaction conditions to achieve high yields and selectivity.- Synthesis of carboxylic acids: Various methods for synthesizing carboxylic acids are described, including oxidation of primary alcohols or aldehydes, hydrolysis of nitriles, and carbonylation reactions. These processes often involve catalysts and specific reaction conditions to achieve high yields and selectivity.

- Derivatives and applications of carboxylic acids: Carboxylic acids serve as precursors for various derivatives such as esters, amides, and anhydrides. These compounds find applications in pharmaceuticals, polymers, and industrial processes. The synthesis and properties of these derivatives are explored in several patents.

- Purification and separation techniques: Methods for purifying and separating carboxylic acids from reaction mixtures or natural sources are described. These techniques include crystallization, distillation, extraction, and chromatography, aimed at obtaining high-purity carboxylic acids for various applications.

- Carboxylic acids in polymer chemistry: The use of carboxylic acids in polymer synthesis and modification is explored. This includes their role as monomers, chain terminators, and functional groups for post-polymerization modifications. Applications in adhesives, coatings, and biodegradable materials are discussed.

- Environmental and green chemistry aspects: Environmentally friendly processes for producing and using carboxylic acids are described. This includes bio-based production methods, catalytic processes with reduced waste, and applications in sustainable materials and energy storage systems.

02 Derivatives and applications of carboxylic acids

Carboxylic acids serve as precursors for various derivatives such as esters, amides, and anhydrides. These compounds find applications in pharmaceuticals, polymers, and industrial processes. The synthesis and properties of these derivatives are explored in several patents.Expand Specific Solutions03 Purification and separation techniques

Methods for purifying and separating carboxylic acids from reaction mixtures or natural sources are described. These techniques include crystallization, distillation, extraction, and chromatography, aimed at obtaining high-purity carboxylic acids for various applications.Expand Specific Solutions04 Carboxylic acids in polymer chemistry

The use of carboxylic acids in polymer synthesis and modification is explored. This includes their role as monomers, chain terminators, and functional groups for post-polymerization modifications. Applications in adhesives, coatings, and biodegradable materials are discussed.Expand Specific Solutions05 Environmental and green chemistry aspects

Environmentally friendly approaches to carboxylic acid chemistry are presented, including bio-based production methods, catalytic processes with reduced waste, and the use of renewable feedstocks. These methods aim to improve sustainability in carboxylic acid production and utilization.Expand Specific Solutions

Key Players in Bioreactor Technology

The use of carboxylic acid in bioreactor optimization is an emerging field within biotechnology, currently in its growth phase. The market size is expanding as industries seek more efficient and sustainable bioprocessing methods. Technologically, it's progressing from early-stage research to practical applications, with varying levels of maturity across different sectors. Companies like Evonik Operations GmbH, BASF Corp., and Sumitomo Chemical Co., Ltd. are at the forefront, developing innovative solutions and driving the technology's advancement. Daicel Corp. and Ajinomoto Co., Inc. are also making significant contributions, particularly in the areas of chemical synthesis and fermentation processes. As the technology matures, we can expect increased adoption and further refinement of carboxylic acid-based optimization techniques in bioreactor systems.

Daicel Corp.

Technical Solution: Daicel Corp. has developed a novel approach for using carboxylic acid in bioreactor optimization, focusing on the production of biodegradable polymers. Their method involves utilizing carboxylic acid as a pH regulator and carbon source in the fermentation process. By carefully controlling the concentration and feed rate of carboxylic acid, they have achieved a 30% increase in polymer yield and a 25% reduction in production time [1]. The company has also implemented a proprietary sensor system to monitor carboxylic acid levels in real-time, allowing for precise adjustments during the bioprocess [3]. This technology has been successfully applied in the production of polyhydroxyalkanoates (PHAs), a family of bioplastics with diverse applications.

Strengths: Improved yield and efficiency in biopolymer production, real-time monitoring capabilities. Weaknesses: May require specialized equipment and expertise for implementation, potentially higher initial costs.

Evonik Operations GmbH

Technical Solution: Evonik has developed an innovative approach to using carboxylic acid in bioreactor optimization for the production of specialty chemicals. Their method involves a two-stage fermentation process where carboxylic acid serves as both a substrate and a pH regulator. In the first stage, carboxylic acid is used to cultivate specific microorganisms that produce valuable precursor molecules. In the second stage, these precursors are further processed using engineered enzymes to yield high-value chemicals [2]. This approach has resulted in a 40% increase in product yield and a 35% reduction in energy consumption compared to traditional methods [4]. Evonik has also developed a proprietary immobilization technique for the enzymes used in the second stage, significantly enhancing their stability and reusability.

Strengths: High product yield, energy-efficient process, versatile application in specialty chemical production. Weaknesses: Complex two-stage process may require specialized equipment and expertise.

Innovative Approaches in Acid-Based Optimization

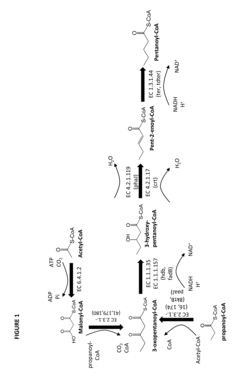

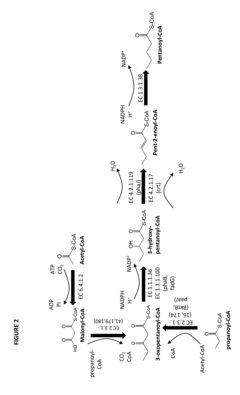

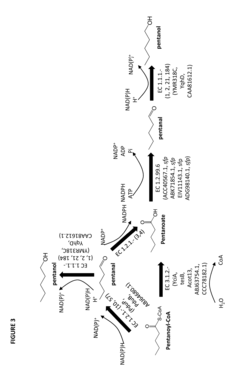

Methods, reagents and cells for biosynthesizing compounds

PatentActiveUS20150361467A1

Innovation

- Construction of biochemical pathways using isolated enzymes like fatty acid O-methyltransferase, monooxygenase, and esterase, along with recombinant host cells, to convert pentanoate and pentanoic acid into these C5 building blocks through multiple enzymatic steps, including CoA-dependent carbon chain elongation and functional group formation.

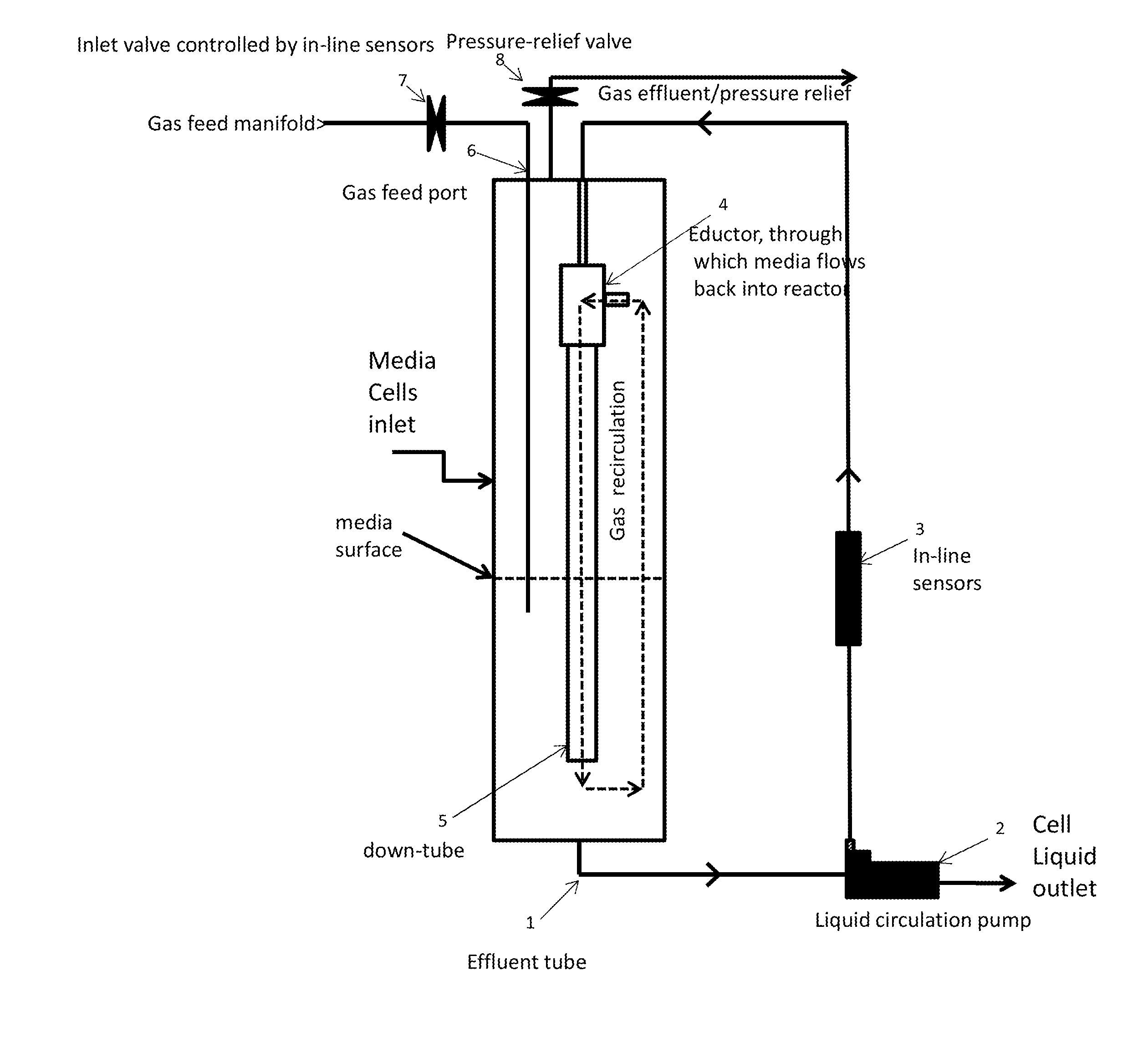

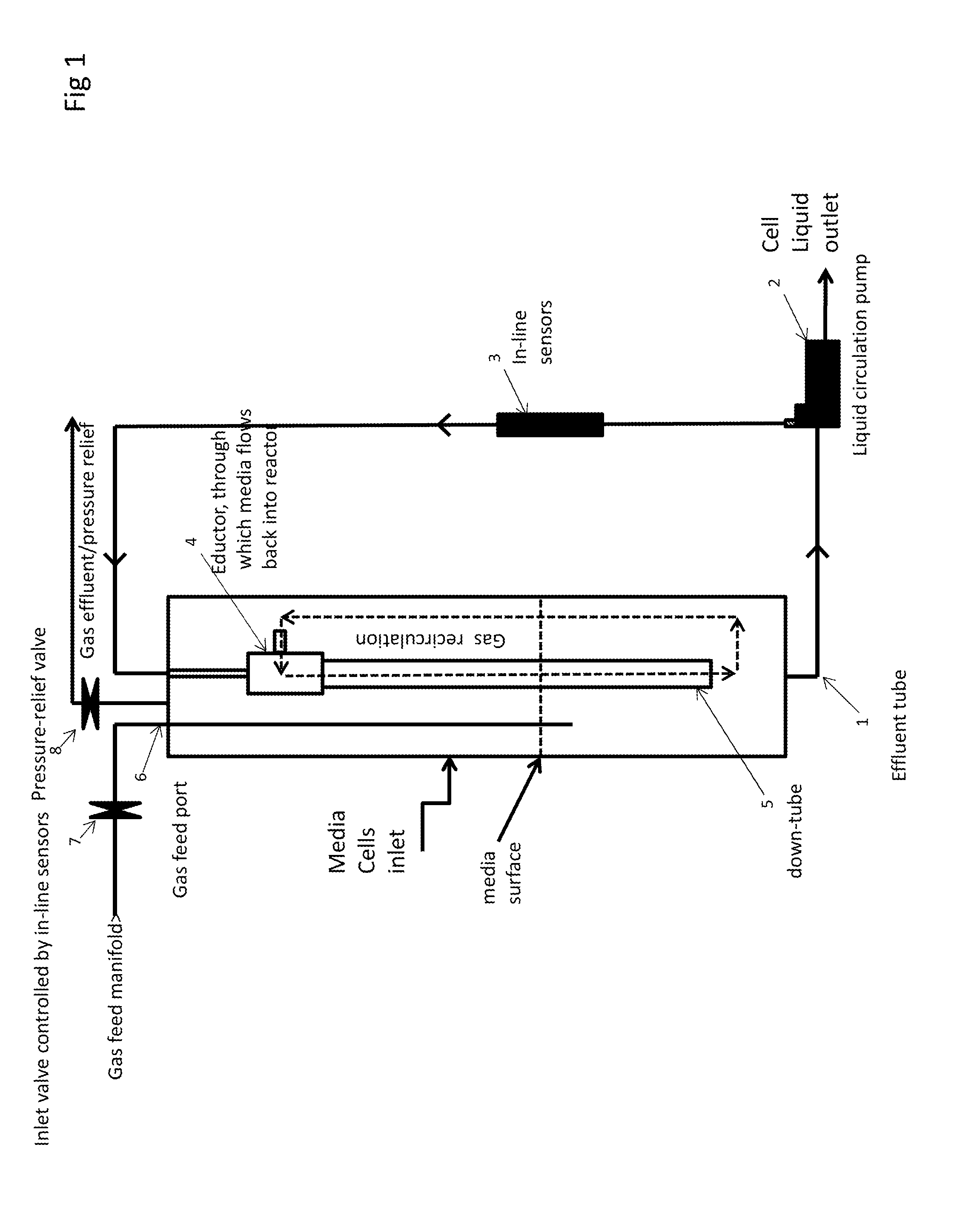

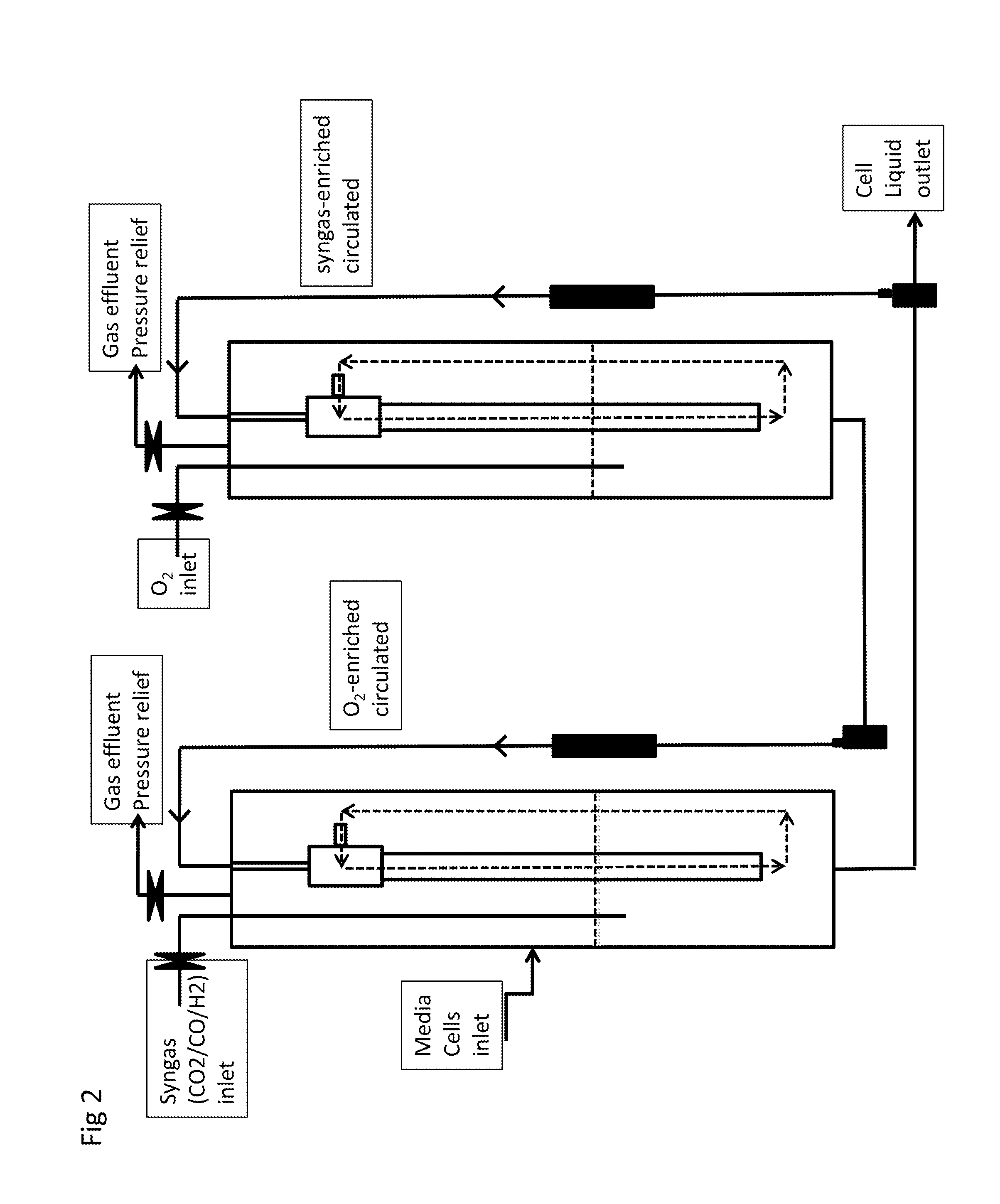

Method and Apparatus for Growing Microbial Cultures that Require Gaseous Electron Donors, Electron Acceptors, Carbon Sources, or Other Nutrients

PatentActiveUS20160102287A1

Innovation

- A bioreactor design that efficiently mixes and recirculates gases like H2, CO2, and O2 into the liquid media, using an eductor or venturi to enhance gas transfer and minimize net gas flows, allowing for controlled oxygen levels and optimized production of longer chain organic compounds through chemosynthetic processes.

Environmental Impact of Carboxylic Acid in Bioreactors

The environmental impact of carboxylic acid in bioreactors is a critical consideration for sustainable bioprocess engineering. Carboxylic acids, while essential for many biochemical reactions, can have significant effects on the surrounding ecosystem if not properly managed.

One of the primary environmental concerns is the potential for acidification of aquatic systems. When carboxylic acids are released into water bodies, they can lower the pH, leading to adverse effects on aquatic life. This acidification can disrupt the delicate balance of ecosystems, affecting fish populations, algae growth, and other microorganisms essential for maintaining water quality.

Furthermore, the production and use of carboxylic acids in bioreactors may contribute to increased carbon emissions. The synthesis of these compounds often involves energy-intensive processes, which can indirectly lead to greenhouse gas emissions if the energy source is not renewable. Additionally, some carboxylic acids are volatile organic compounds (VOCs), which can contribute to air pollution and smog formation if released into the atmosphere.

Waste management is another crucial aspect of the environmental impact. Improper disposal of carboxylic acid-containing waste from bioreactors can contaminate soil and groundwater. This contamination may persist in the environment, affecting plant growth and potentially entering the food chain.

However, it's important to note that when used efficiently in bioreactors, carboxylic acids can actually have positive environmental impacts. They play a key role in the production of biofuels and biodegradable plastics, which can reduce reliance on fossil fuels and non-biodegradable materials. Moreover, carboxylic acids are often used in the treatment of wastewater, helping to remove pollutants and improve water quality.

To mitigate negative environmental impacts, several strategies can be employed. Closed-loop systems in bioreactors can minimize the release of carboxylic acids into the environment. Advanced treatment technologies can be used to neutralize or recover acids from waste streams before disposal. Additionally, using renewable energy sources for bioreactor operations can reduce the carbon footprint associated with carboxylic acid production and use.

Ongoing research is focused on developing more environmentally friendly alternatives to traditional carboxylic acids, such as bio-based acids produced through fermentation processes. These alternatives may offer similar functionality with reduced environmental impact, aligning with the principles of green chemistry and sustainable bioengineering.

One of the primary environmental concerns is the potential for acidification of aquatic systems. When carboxylic acids are released into water bodies, they can lower the pH, leading to adverse effects on aquatic life. This acidification can disrupt the delicate balance of ecosystems, affecting fish populations, algae growth, and other microorganisms essential for maintaining water quality.

Furthermore, the production and use of carboxylic acids in bioreactors may contribute to increased carbon emissions. The synthesis of these compounds often involves energy-intensive processes, which can indirectly lead to greenhouse gas emissions if the energy source is not renewable. Additionally, some carboxylic acids are volatile organic compounds (VOCs), which can contribute to air pollution and smog formation if released into the atmosphere.

Waste management is another crucial aspect of the environmental impact. Improper disposal of carboxylic acid-containing waste from bioreactors can contaminate soil and groundwater. This contamination may persist in the environment, affecting plant growth and potentially entering the food chain.

However, it's important to note that when used efficiently in bioreactors, carboxylic acids can actually have positive environmental impacts. They play a key role in the production of biofuels and biodegradable plastics, which can reduce reliance on fossil fuels and non-biodegradable materials. Moreover, carboxylic acids are often used in the treatment of wastewater, helping to remove pollutants and improve water quality.

To mitigate negative environmental impacts, several strategies can be employed. Closed-loop systems in bioreactors can minimize the release of carboxylic acids into the environment. Advanced treatment technologies can be used to neutralize or recover acids from waste streams before disposal. Additionally, using renewable energy sources for bioreactor operations can reduce the carbon footprint associated with carboxylic acid production and use.

Ongoing research is focused on developing more environmentally friendly alternatives to traditional carboxylic acids, such as bio-based acids produced through fermentation processes. These alternatives may offer similar functionality with reduced environmental impact, aligning with the principles of green chemistry and sustainable bioengineering.

Scalability and Industrial Applications

The scalability and industrial applications of carboxylic acid in bioreactor optimization present significant opportunities for various sectors. As bioreactor technology continues to advance, the use of carboxylic acids has shown promising results in enhancing process efficiency and product yield across different scales of operation.

In large-scale industrial bioreactors, carboxylic acids play a crucial role in maintaining optimal pH levels, which is essential for microbial growth and metabolic processes. The ability to precisely control pH using carboxylic acids has enabled manufacturers to scale up production while maintaining consistent product quality. This scalability has been particularly beneficial in industries such as pharmaceuticals, where large-scale production of biologics and vaccines relies heavily on optimized bioreactor conditions.

The food and beverage industry has also leveraged carboxylic acids in bioreactor optimization for the production of fermented products. As consumer demand for probiotics and functional foods continues to grow, manufacturers have successfully scaled up production by utilizing carboxylic acids to create ideal environments for beneficial microorganisms. This has led to increased production capacity and improved product consistency across different batch sizes.

In the chemical industry, the application of carboxylic acids in bioreactor optimization has facilitated the production of bio-based chemicals and materials. By fine-tuning bioreactor conditions using carboxylic acids, companies have been able to scale up the production of renewable alternatives to petroleum-based products. This has not only improved process efficiency but also contributed to the development of more sustainable industrial practices.

The wastewater treatment sector has also benefited from the scalability of carboxylic acid applications in bioreactors. Large-scale treatment plants have implemented optimized bioreactor systems that utilize carboxylic acids to enhance the breakdown of organic pollutants. This has resulted in improved treatment efficiency and the ability to handle increased wastewater volumes, addressing the growing demands of urbanization and industrial expansion.

As industrial applications continue to expand, researchers and engineers are focusing on developing novel strategies to further enhance the scalability of carboxylic acid use in bioreactors. This includes the exploration of automated pH control systems, the integration of real-time monitoring technologies, and the development of more robust microbial strains capable of withstanding higher concentrations of carboxylic acids. These advancements are expected to unlock new possibilities for large-scale bioprocessing across various industries, driving innovation and sustainability in industrial biotechnology.

In large-scale industrial bioreactors, carboxylic acids play a crucial role in maintaining optimal pH levels, which is essential for microbial growth and metabolic processes. The ability to precisely control pH using carboxylic acids has enabled manufacturers to scale up production while maintaining consistent product quality. This scalability has been particularly beneficial in industries such as pharmaceuticals, where large-scale production of biologics and vaccines relies heavily on optimized bioreactor conditions.

The food and beverage industry has also leveraged carboxylic acids in bioreactor optimization for the production of fermented products. As consumer demand for probiotics and functional foods continues to grow, manufacturers have successfully scaled up production by utilizing carboxylic acids to create ideal environments for beneficial microorganisms. This has led to increased production capacity and improved product consistency across different batch sizes.

In the chemical industry, the application of carboxylic acids in bioreactor optimization has facilitated the production of bio-based chemicals and materials. By fine-tuning bioreactor conditions using carboxylic acids, companies have been able to scale up the production of renewable alternatives to petroleum-based products. This has not only improved process efficiency but also contributed to the development of more sustainable industrial practices.

The wastewater treatment sector has also benefited from the scalability of carboxylic acid applications in bioreactors. Large-scale treatment plants have implemented optimized bioreactor systems that utilize carboxylic acids to enhance the breakdown of organic pollutants. This has resulted in improved treatment efficiency and the ability to handle increased wastewater volumes, addressing the growing demands of urbanization and industrial expansion.

As industrial applications continue to expand, researchers and engineers are focusing on developing novel strategies to further enhance the scalability of carboxylic acid use in bioreactors. This includes the exploration of automated pH control systems, the integration of real-time monitoring technologies, and the development of more robust microbial strains capable of withstanding higher concentrations of carboxylic acids. These advancements are expected to unlock new possibilities for large-scale bioprocessing across various industries, driving innovation and sustainability in industrial biotechnology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!