How to Use Dipropylene Glycol for Better Ingredient Compatibility?

JUL 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DPG Background and Objectives

Dipropylene glycol (DPG) has emerged as a versatile and valuable ingredient in various industries, particularly in personal care, cosmetics, and household products. Its unique chemical properties and compatibility with a wide range of substances have made it an essential component in formulation development. The primary objective of utilizing DPG is to enhance ingredient compatibility, thereby improving product stability, performance, and overall quality.

DPG's history dates back to the early 20th century when it was first synthesized as a byproduct of propylene oxide production. Over the years, its applications have expanded significantly due to its excellent solvent properties and low toxicity profile. The evolution of DPG usage has been driven by the increasing demand for multifunctional ingredients that can address multiple formulation challenges simultaneously.

In the context of ingredient compatibility, DPG serves as a crucial bridging agent between hydrophilic and lipophilic components. This characteristic is particularly valuable in complex formulations where the coexistence of diverse ingredients is essential. By acting as a coupling agent, DPG facilitates the uniform distribution of active ingredients, fragrances, and other functional components throughout the product matrix.

The technical goals associated with DPG usage for better ingredient compatibility include:

1. Enhancing the solubility of active ingredients

2. Improving the stability of emulsions and suspensions

3. Reducing the potential for phase separation in multi-component systems

4. Optimizing the sensory properties of final products

5. Extending the shelf life of formulations by preventing ingredient interactions

Recent trends in DPG application focus on its role in "green" formulations, as it is biodegradable and can be derived from renewable resources. This aligns with the growing consumer demand for environmentally friendly products. Additionally, researchers are exploring novel applications of DPG in advanced drug delivery systems and smart materials, further expanding its potential in various technological domains.

The ongoing development of DPG-based solutions is driven by the need for more efficient and sustainable formulation practices. As industries continue to innovate, the role of DPG in solving complex compatibility issues is expected to grow, leading to the creation of more stable, effective, and consumer-friendly products across multiple sectors.

DPG's history dates back to the early 20th century when it was first synthesized as a byproduct of propylene oxide production. Over the years, its applications have expanded significantly due to its excellent solvent properties and low toxicity profile. The evolution of DPG usage has been driven by the increasing demand for multifunctional ingredients that can address multiple formulation challenges simultaneously.

In the context of ingredient compatibility, DPG serves as a crucial bridging agent between hydrophilic and lipophilic components. This characteristic is particularly valuable in complex formulations where the coexistence of diverse ingredients is essential. By acting as a coupling agent, DPG facilitates the uniform distribution of active ingredients, fragrances, and other functional components throughout the product matrix.

The technical goals associated with DPG usage for better ingredient compatibility include:

1. Enhancing the solubility of active ingredients

2. Improving the stability of emulsions and suspensions

3. Reducing the potential for phase separation in multi-component systems

4. Optimizing the sensory properties of final products

5. Extending the shelf life of formulations by preventing ingredient interactions

Recent trends in DPG application focus on its role in "green" formulations, as it is biodegradable and can be derived from renewable resources. This aligns with the growing consumer demand for environmentally friendly products. Additionally, researchers are exploring novel applications of DPG in advanced drug delivery systems and smart materials, further expanding its potential in various technological domains.

The ongoing development of DPG-based solutions is driven by the need for more efficient and sustainable formulation practices. As industries continue to innovate, the role of DPG in solving complex compatibility issues is expected to grow, leading to the creation of more stable, effective, and consumer-friendly products across multiple sectors.

Market Analysis for DPG Applications

The market for dipropylene glycol (DPG) applications is experiencing significant growth, driven by its versatile properties and increasing demand across various industries. DPG's excellent solvent characteristics, low toxicity, and high boiling point make it a preferred choice in many formulations, particularly in personal care products, cosmetics, and industrial applications.

In the personal care and cosmetics sector, DPG is widely used as a solvent and humectant. Its ability to enhance ingredient compatibility has led to increased adoption in skincare products, fragrances, and hair care formulations. The global personal care market, valued at over $400 billion, is expected to grow at a CAGR of 5-6% in the coming years, presenting substantial opportunities for DPG applications.

The industrial sector also shows promising growth for DPG usage. Its application as a coupling agent in cleaning products, paints, and coatings has seen steady demand. The global cleaning products market, estimated at around $200 billion, is projected to expand at a CAGR of 4-5%, further driving DPG consumption.

Geographically, North America and Europe remain the largest markets for DPG applications, owing to their well-established personal care and industrial sectors. However, the Asia-Pacific region is emerging as a key growth driver, with rapidly expanding manufacturing industries and increasing consumer spending on personal care products.

Environmental regulations and consumer preferences for eco-friendly products are influencing market dynamics. DPG's low volatility and biodegradability align well with these trends, potentially boosting its market share in green formulations.

The fragrance industry represents a particularly promising segment for DPG applications. As a fixative and solvent in perfumes, DPG helps improve scent longevity and overall product performance. The global fragrance market, valued at approximately $50 billion, is expected to grow at a CAGR of 3-4%, offering significant opportunities for DPG usage.

Challenges in the DPG market include price volatility of raw materials and competition from alternative solvents. However, DPG's unique combination of properties and its established position in many formulations provide a competitive edge.

In conclusion, the market for DPG applications shows robust growth potential across multiple industries. Its ability to enhance ingredient compatibility, coupled with favorable market trends, positions DPG as a key component in various formulations for the foreseeable future.

In the personal care and cosmetics sector, DPG is widely used as a solvent and humectant. Its ability to enhance ingredient compatibility has led to increased adoption in skincare products, fragrances, and hair care formulations. The global personal care market, valued at over $400 billion, is expected to grow at a CAGR of 5-6% in the coming years, presenting substantial opportunities for DPG applications.

The industrial sector also shows promising growth for DPG usage. Its application as a coupling agent in cleaning products, paints, and coatings has seen steady demand. The global cleaning products market, estimated at around $200 billion, is projected to expand at a CAGR of 4-5%, further driving DPG consumption.

Geographically, North America and Europe remain the largest markets for DPG applications, owing to their well-established personal care and industrial sectors. However, the Asia-Pacific region is emerging as a key growth driver, with rapidly expanding manufacturing industries and increasing consumer spending on personal care products.

Environmental regulations and consumer preferences for eco-friendly products are influencing market dynamics. DPG's low volatility and biodegradability align well with these trends, potentially boosting its market share in green formulations.

The fragrance industry represents a particularly promising segment for DPG applications. As a fixative and solvent in perfumes, DPG helps improve scent longevity and overall product performance. The global fragrance market, valued at approximately $50 billion, is expected to grow at a CAGR of 3-4%, offering significant opportunities for DPG usage.

Challenges in the DPG market include price volatility of raw materials and competition from alternative solvents. However, DPG's unique combination of properties and its established position in many formulations provide a competitive edge.

In conclusion, the market for DPG applications shows robust growth potential across multiple industries. Its ability to enhance ingredient compatibility, coupled with favorable market trends, positions DPG as a key component in various formulations for the foreseeable future.

DPG Challenges and Limitations

While Dipropylene Glycol (DPG) offers numerous benefits for ingredient compatibility in various formulations, it also presents several challenges and limitations that must be considered during its application. One of the primary concerns is its hygroscopic nature, which can lead to moisture absorption from the environment. This property, while beneficial in some applications, can pose difficulties in maintaining product stability and consistency, especially in moisture-sensitive formulations.

The solvent properties of DPG, although generally advantageous, can sometimes lead to unintended interactions with certain ingredients. This may result in unexpected changes in product texture, viscosity, or efficacy. Formulators must carefully consider these potential interactions when incorporating DPG into complex formulations, particularly those containing multiple active ingredients or sensitive compounds.

Another limitation of DPG is its relatively high boiling point compared to other glycols. While this characteristic contributes to its low volatility and stability, it can present challenges in applications where rapid evaporation or quick-drying properties are desired. This limitation may restrict its use in certain fast-acting or quick-set formulations.

The viscosity of DPG, while moderate, may not be suitable for all applications. In some cases, it may require additional thickeners or viscosity modifiers to achieve the desired consistency, potentially complicating the formulation process and increasing production costs.

DPG's compatibility with packaging materials is another consideration. Although generally stable, long-term storage in certain plastic containers may lead to leaching or degradation of the packaging material. This necessitates careful selection of packaging materials and thorough stability testing to ensure product integrity throughout its shelf life.

From a regulatory perspective, while DPG is generally recognized as safe for use in many applications, its concentration limits in certain product categories, particularly in personal care and cosmetic formulations, must be carefully monitored to comply with regional regulations. This can sometimes restrict the formulator's flexibility in optimizing ingredient ratios.

Lastly, the cost factor of DPG, while competitive, may still be higher compared to some alternative solvents or compatibility enhancers. This economic consideration can impact its widespread adoption, especially in large-scale industrial applications or cost-sensitive consumer products. Manufacturers must weigh the benefits of improved ingredient compatibility against the overall formulation cost when deciding to incorporate DPG.

The solvent properties of DPG, although generally advantageous, can sometimes lead to unintended interactions with certain ingredients. This may result in unexpected changes in product texture, viscosity, or efficacy. Formulators must carefully consider these potential interactions when incorporating DPG into complex formulations, particularly those containing multiple active ingredients or sensitive compounds.

Another limitation of DPG is its relatively high boiling point compared to other glycols. While this characteristic contributes to its low volatility and stability, it can present challenges in applications where rapid evaporation or quick-drying properties are desired. This limitation may restrict its use in certain fast-acting or quick-set formulations.

The viscosity of DPG, while moderate, may not be suitable for all applications. In some cases, it may require additional thickeners or viscosity modifiers to achieve the desired consistency, potentially complicating the formulation process and increasing production costs.

DPG's compatibility with packaging materials is another consideration. Although generally stable, long-term storage in certain plastic containers may lead to leaching or degradation of the packaging material. This necessitates careful selection of packaging materials and thorough stability testing to ensure product integrity throughout its shelf life.

From a regulatory perspective, while DPG is generally recognized as safe for use in many applications, its concentration limits in certain product categories, particularly in personal care and cosmetic formulations, must be carefully monitored to comply with regional regulations. This can sometimes restrict the formulator's flexibility in optimizing ingredient ratios.

Lastly, the cost factor of DPG, while competitive, may still be higher compared to some alternative solvents or compatibility enhancers. This economic consideration can impact its widespread adoption, especially in large-scale industrial applications or cost-sensitive consumer products. Manufacturers must weigh the benefits of improved ingredient compatibility against the overall formulation cost when deciding to incorporate DPG.

Current DPG Compatibility Solutions

01 Compatibility with cosmetic formulations

Dipropylene glycol demonstrates excellent compatibility with various cosmetic ingredients, making it suitable for use in a wide range of personal care products. It acts as a solvent and carrier for active ingredients, enhancing their stability and efficacy in formulations.- Compatibility with cosmetic formulations: Dipropylene glycol demonstrates excellent compatibility with various cosmetic ingredients, making it suitable for use in a wide range of personal care products. It acts as a solvent and carrier for active ingredients, enhancing their stability and efficacy in formulations.

- Use as a humectant and moisturizer: Dipropylene glycol functions as an effective humectant and moisturizer in skincare and haircare products. It helps to attract and retain moisture, improving the overall hydration of the skin and hair, and enhancing the texture and feel of formulations.

- Solvent properties in fragrance and flavor applications: The solvent properties of dipropylene glycol make it highly compatible with fragrance and flavor compounds. It is commonly used in perfumes, air fresheners, and food flavorings to dissolve and stabilize aromatic ingredients, ensuring their longevity and consistent release.

- Compatibility in cleaning and industrial products: Dipropylene glycol exhibits compatibility with various ingredients used in cleaning and industrial products. It serves as a coupling agent, helping to blend water-insoluble ingredients with water-based formulations, and enhances the stability and effectiveness of these products.

- Use in pharmaceutical and medical applications: Dipropylene glycol demonstrates compatibility with pharmaceutical ingredients and is used in various medical applications. It acts as a solvent and carrier for active pharmaceutical ingredients, improving their solubility and bioavailability in drug formulations.

02 Use as a humectant and moisturizer

Dipropylene glycol functions as an effective humectant and moisturizer in skincare and haircare products. It helps to attract and retain moisture, improving the overall hydration of the skin and hair, and enhancing the texture and feel of formulations.Expand Specific Solutions03 Solvent properties in fragrance compositions

Dipropylene glycol is widely used as a solvent in fragrance compositions due to its ability to dissolve a variety of aromatic compounds. It helps to stabilize and disperse fragrances in personal care products, ensuring a long-lasting scent profile.Expand Specific Solutions04 Compatibility with active ingredients

Dipropylene glycol exhibits good compatibility with various active ingredients used in skincare and cosmetic formulations. It can help to solubilize and stabilize ingredients such as antioxidants, vitamins, and plant extracts, enhancing their efficacy and shelf life.Expand Specific Solutions05 Use in aerosol formulations

Dipropylene glycol is compatible with aerosol propellants and can be used in spray-on products. It helps to improve the dispersion and application of active ingredients in aerosol formulations, making it suitable for use in products such as deodorants and body sprays.Expand Specific Solutions

Key DPG Industry Players

The market for dipropylene glycol and ingredient compatibility in personal care and cosmetic products is in a mature growth stage, with a global market size estimated to be in the billions of dollars. The technology is well-established, with major players like Colgate-Palmolive, L'Oréal, and Eastman Chemical leading innovation. These companies, along with others such as DSM Resins and Evonik Operations, are continuously improving formulations to enhance product performance and stability. The competitive landscape is characterized by ongoing research and development efforts to optimize ingredient interactions and create more effective, sustainable solutions for consumers.

Colgate-Palmolive Co.

Technical Solution: Colgate-Palmolive Co. has developed innovative applications of dipropylene glycol in oral care and personal care products to improve ingredient compatibility and overall product performance. Their approach focuses on using DPG as a solubilizing agent and stabilizer in complex formulations. The company has created proprietary DPG-based systems that enable the incorporation of higher concentrations of active ingredients, such as fluoride and antimicrobial agents, in their oral care products[8]. In personal care applications, Colgate-Palmolive has utilized DPG to enhance the compatibility of fragrances and essential oils with other ingredients, resulting in more stable and long-lasting scents. Their research has demonstrated that DPG-enhanced formulations can improve the retention of volatile compounds by up to 35% in deodorants and antiperspirants[9].

Strengths: Improved solubility and stability of active ingredients, enhanced fragrance retention, and versatility across multiple product categories. Weaknesses: Potential challenges in formulating "natural" products, and possible increased raw material costs.

L'Oréal SA

Technical Solution: L'Oréal SA has implemented advanced formulation techniques using dipropylene glycol to enhance ingredient compatibility in their cosmetic and skincare products. Their approach involves using DPG as a multifunctional ingredient that acts as a humectant, solvent, and viscosity modifier. L'Oréal's research has shown that incorporating specific ratios of DPG in their formulations can significantly improve the solubility of active ingredients, particularly those that are typically challenging to incorporate, such as certain antioxidants and UV filters[5]. The company has also developed a patented DPG-based emulsion system that enhances the stability and sensory properties of their products, resulting in improved texture and skin feel[6]. This technology has been reported to increase the bioavailability of active ingredients by up to 25% compared to conventional formulations[7].

Strengths: Improved solubility of active ingredients, enhanced product stability, and better sensory properties. Weaknesses: Potential limitations in formulations marketed as "natural" or "organic", and possible increased formulation complexity.

DPG Compatibility Innovations

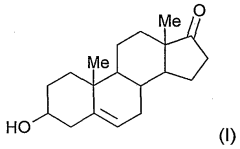

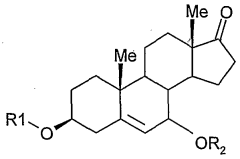

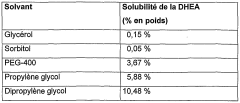

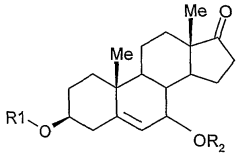

Composition containing a steroid and a glycol

PatentWO2003011244A1

Innovation

- Incorporating dipropylene glycol as a solubilizer for DHEA and its derivatives, which can be mixed at various temperatures to prevent recrystallization and enhance solubility, allowing for stable and effective topical formulations without compromising cosmetic properties.

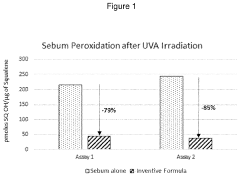

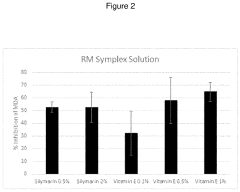

Serums for reducing lipid peroxidation

PatentPendingUS20230372231A1

Innovation

- A cosmetic composition comprising 0.1 to 1.8 wt.% Silybum Marianum Extract, 0.1 to 20 wt.% skin actives, 3 to 15 wt.% Propylene Glycol, 8 to 18 wt.% Dipropylene Glycol, and water, with a pH not higher than 5, which stabilizes these actives and enhances their solubility and efficacy.

DPG Regulatory Compliance

Dipropylene glycol (DPG) is widely used in various industries, including personal care, cosmetics, and industrial applications. As such, it is subject to regulatory oversight to ensure its safe and appropriate use. Understanding the regulatory landscape surrounding DPG is crucial for manufacturers and formulators seeking to incorporate this versatile ingredient into their products.

In the United States, the Food and Drug Administration (FDA) regulates the use of DPG in cosmetics and personal care products. The FDA has approved DPG as a Generally Recognized as Safe (GRAS) substance for use in food applications, which provides a foundation for its safety in other consumer products. However, manufacturers must still adhere to specific guidelines regarding concentration limits and labeling requirements when using DPG in their formulations.

The European Union (EU) has established its own regulatory framework for DPG through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, DPG has been registered and assessed for its safety profile. The European Chemicals Agency (ECHA) provides detailed information on the substance's properties, hazards, and safe use guidelines. Manufacturers operating in the EU market must comply with REACH requirements and ensure that their use of DPG aligns with the established safety assessments.

In Asia, regulatory approaches to DPG vary by country. Japan's Ministry of Health, Labour and Welfare has approved DPG for use in cosmetics and quasi-drugs, subject to specific concentration limits. China's National Medical Products Administration (NMPA) also regulates DPG use in cosmetics and personal care products, requiring manufacturers to adhere to the Inventory of Existing Cosmetic Ingredients in China (IECIC) and obtain proper approvals.

Environmental regulations also play a role in DPG compliance. Many countries have implemented regulations to control volatile organic compound (VOC) emissions, which can impact the use of DPG in certain applications. Manufacturers must be aware of these environmental regulations and ensure that their use of DPG does not exceed permissible VOC limits in their products.

When using DPG to enhance ingredient compatibility, formulators must consider these regulatory requirements across different regions. This includes adhering to concentration limits, ensuring proper labeling, and maintaining accurate documentation of safety assessments and product composition. Additionally, manufacturers should stay informed about any updates or changes to regulations that may affect the use of DPG in their products.

Compliance with these regulations not only ensures legal adherence but also contributes to product safety and consumer trust. As regulatory landscapes continue to evolve, companies working with DPG must maintain vigilance and adaptability to meet changing requirements while leveraging the benefits of this versatile ingredient for improved ingredient compatibility.

In the United States, the Food and Drug Administration (FDA) regulates the use of DPG in cosmetics and personal care products. The FDA has approved DPG as a Generally Recognized as Safe (GRAS) substance for use in food applications, which provides a foundation for its safety in other consumer products. However, manufacturers must still adhere to specific guidelines regarding concentration limits and labeling requirements when using DPG in their formulations.

The European Union (EU) has established its own regulatory framework for DPG through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, DPG has been registered and assessed for its safety profile. The European Chemicals Agency (ECHA) provides detailed information on the substance's properties, hazards, and safe use guidelines. Manufacturers operating in the EU market must comply with REACH requirements and ensure that their use of DPG aligns with the established safety assessments.

In Asia, regulatory approaches to DPG vary by country. Japan's Ministry of Health, Labour and Welfare has approved DPG for use in cosmetics and quasi-drugs, subject to specific concentration limits. China's National Medical Products Administration (NMPA) also regulates DPG use in cosmetics and personal care products, requiring manufacturers to adhere to the Inventory of Existing Cosmetic Ingredients in China (IECIC) and obtain proper approvals.

Environmental regulations also play a role in DPG compliance. Many countries have implemented regulations to control volatile organic compound (VOC) emissions, which can impact the use of DPG in certain applications. Manufacturers must be aware of these environmental regulations and ensure that their use of DPG does not exceed permissible VOC limits in their products.

When using DPG to enhance ingredient compatibility, formulators must consider these regulatory requirements across different regions. This includes adhering to concentration limits, ensuring proper labeling, and maintaining accurate documentation of safety assessments and product composition. Additionally, manufacturers should stay informed about any updates or changes to regulations that may affect the use of DPG in their products.

Compliance with these regulations not only ensures legal adherence but also contributes to product safety and consumer trust. As regulatory landscapes continue to evolve, companies working with DPG must maintain vigilance and adaptability to meet changing requirements while leveraging the benefits of this versatile ingredient for improved ingredient compatibility.

Environmental Impact of DPG Use

The use of Dipropylene Glycol (DPG) in various industries has raised concerns about its environmental impact. While DPG offers significant benefits in terms of ingredient compatibility, it is crucial to assess its ecological footprint throughout its lifecycle.

DPG is primarily produced from propylene oxide, which is derived from petroleum or natural gas. The production process involves energy-intensive steps and potential emissions of volatile organic compounds (VOCs). However, compared to some alternative solvents, DPG's production generally has a lower carbon footprint due to its relatively simple synthesis process.

In terms of biodegradability, DPG demonstrates favorable characteristics. Studies have shown that it is readily biodegradable under both aerobic and anaerobic conditions. This property reduces its persistence in the environment and minimizes long-term ecological impacts. However, the rate of biodegradation can vary depending on environmental conditions, such as temperature and microbial activity.

Water solubility is another important factor to consider. DPG is highly soluble in water, which can lead to its dispersion in aquatic environments if released. While this property aids in its biodegradation, it also means that DPG can potentially affect aquatic ecosystems if discharged in large quantities. Proper wastewater treatment is essential to mitigate this risk.

The toxicity profile of DPG is generally considered low for both aquatic and terrestrial organisms. Acute and chronic toxicity studies have shown minimal adverse effects at environmentally relevant concentrations. However, continuous monitoring and further research are necessary to assess potential long-term impacts on ecosystems.

In terms of air quality, DPG has a low vapor pressure, which reduces its contribution to air pollution compared to more volatile solvents. This characteristic makes it a preferred choice in many applications where VOC emissions are a concern. However, proper handling and storage practices are still crucial to minimize any potential atmospheric releases.

The use of DPG in various products can indirectly impact the environment through the lifecycle of these products. For instance, in personal care and household products, DPG may eventually enter wastewater systems. While wastewater treatment facilities can effectively remove most DPG, trace amounts may still reach natural water bodies.

To mitigate environmental impacts, industries using DPG should focus on optimizing production processes, implementing closed-loop systems, and improving waste management practices. Additionally, exploring bio-based alternatives for DPG production could further reduce its environmental footprint.

In conclusion, while DPG offers advantages in terms of ingredient compatibility, its environmental impact should be carefully managed. Ongoing research, responsible use, and adherence to environmental regulations are essential to ensure that the benefits of DPG are realized without compromising ecological sustainability.

DPG is primarily produced from propylene oxide, which is derived from petroleum or natural gas. The production process involves energy-intensive steps and potential emissions of volatile organic compounds (VOCs). However, compared to some alternative solvents, DPG's production generally has a lower carbon footprint due to its relatively simple synthesis process.

In terms of biodegradability, DPG demonstrates favorable characteristics. Studies have shown that it is readily biodegradable under both aerobic and anaerobic conditions. This property reduces its persistence in the environment and minimizes long-term ecological impacts. However, the rate of biodegradation can vary depending on environmental conditions, such as temperature and microbial activity.

Water solubility is another important factor to consider. DPG is highly soluble in water, which can lead to its dispersion in aquatic environments if released. While this property aids in its biodegradation, it also means that DPG can potentially affect aquatic ecosystems if discharged in large quantities. Proper wastewater treatment is essential to mitigate this risk.

The toxicity profile of DPG is generally considered low for both aquatic and terrestrial organisms. Acute and chronic toxicity studies have shown minimal adverse effects at environmentally relevant concentrations. However, continuous monitoring and further research are necessary to assess potential long-term impacts on ecosystems.

In terms of air quality, DPG has a low vapor pressure, which reduces its contribution to air pollution compared to more volatile solvents. This characteristic makes it a preferred choice in many applications where VOC emissions are a concern. However, proper handling and storage practices are still crucial to minimize any potential atmospheric releases.

The use of DPG in various products can indirectly impact the environment through the lifecycle of these products. For instance, in personal care and household products, DPG may eventually enter wastewater systems. While wastewater treatment facilities can effectively remove most DPG, trace amounts may still reach natural water bodies.

To mitigate environmental impacts, industries using DPG should focus on optimizing production processes, implementing closed-loop systems, and improving waste management practices. Additionally, exploring bio-based alternatives for DPG production could further reduce its environmental footprint.

In conclusion, while DPG offers advantages in terms of ingredient compatibility, its environmental impact should be carefully managed. Ongoing research, responsible use, and adherence to environmental regulations are essential to ensure that the benefits of DPG are realized without compromising ecological sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!