How to Use Nichrome for Precise Temperature Regulation?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Heating Tech Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in heating technology since its invention in the early 20th century. The evolution of nichrome heating technology has been driven by the increasing demand for precise temperature control across various industries, from household appliances to advanced scientific instruments.

Initially, nichrome was primarily used in simple resistive heating elements, where its high electrical resistance and durability made it ideal for generating heat. However, as technology progressed, the focus shifted towards achieving more accurate and responsive temperature regulation. This shift was necessitated by the growing needs of industries such as semiconductor manufacturing, materials science, and medical equipment, where even slight temperature variations could significantly impact outcomes.

The development of nichrome heating technology has been marked by several key milestones. In the mid-20th century, the introduction of wire-wound nichrome elements allowed for more uniform heat distribution. This was followed by the development of etched-foil elements in the latter half of the century, which provided faster response times and improved temperature uniformity.

Recent advancements have focused on integrating nichrome heating elements with sophisticated control systems. The advent of microprocessor-based controllers and advanced sensors has enabled real-time temperature monitoring and adjustment, pushing the boundaries of precision in temperature regulation.

The current technological objectives in nichrome heating revolve around several key areas. Firstly, there is a drive towards miniaturization, allowing for the integration of precise heating elements in increasingly compact devices. Secondly, researchers are working on improving the energy efficiency of nichrome heating systems, aligning with global efforts towards sustainability.

Another significant objective is enhancing the responsiveness of nichrome heating elements. This involves not only improving the physical properties of the alloy but also developing more advanced control algorithms that can predict and respond to temperature changes more rapidly.

Furthermore, there is a growing interest in exploring new nichrome alloy compositions and manufacturing techniques. These efforts aim to create heating elements with even higher temperature tolerances, longer lifespans, and more precise resistance characteristics.

The ultimate goal of these technological advancements is to achieve near-perfect temperature regulation across a wide range of applications. This includes maintaining ultra-stable temperatures in scientific experiments, providing precise heat control in industrial processes, and enabling more energy-efficient and responsive heating in consumer products.

Initially, nichrome was primarily used in simple resistive heating elements, where its high electrical resistance and durability made it ideal for generating heat. However, as technology progressed, the focus shifted towards achieving more accurate and responsive temperature regulation. This shift was necessitated by the growing needs of industries such as semiconductor manufacturing, materials science, and medical equipment, where even slight temperature variations could significantly impact outcomes.

The development of nichrome heating technology has been marked by several key milestones. In the mid-20th century, the introduction of wire-wound nichrome elements allowed for more uniform heat distribution. This was followed by the development of etched-foil elements in the latter half of the century, which provided faster response times and improved temperature uniformity.

Recent advancements have focused on integrating nichrome heating elements with sophisticated control systems. The advent of microprocessor-based controllers and advanced sensors has enabled real-time temperature monitoring and adjustment, pushing the boundaries of precision in temperature regulation.

The current technological objectives in nichrome heating revolve around several key areas. Firstly, there is a drive towards miniaturization, allowing for the integration of precise heating elements in increasingly compact devices. Secondly, researchers are working on improving the energy efficiency of nichrome heating systems, aligning with global efforts towards sustainability.

Another significant objective is enhancing the responsiveness of nichrome heating elements. This involves not only improving the physical properties of the alloy but also developing more advanced control algorithms that can predict and respond to temperature changes more rapidly.

Furthermore, there is a growing interest in exploring new nichrome alloy compositions and manufacturing techniques. These efforts aim to create heating elements with even higher temperature tolerances, longer lifespans, and more precise resistance characteristics.

The ultimate goal of these technological advancements is to achieve near-perfect temperature regulation across a wide range of applications. This includes maintaining ultra-stable temperatures in scientific experiments, providing precise heat control in industrial processes, and enabling more energy-efficient and responsive heating in consumer products.

Market Demand for Precise Temperature Control

The market demand for precise temperature control has been steadily increasing across various industries, driven by the need for improved efficiency, product quality, and regulatory compliance. In the semiconductor industry, precise temperature regulation is crucial for manufacturing processes such as chemical vapor deposition and ion implantation. The global semiconductor market, valued at $555.9 billion in 2021, is projected to reach $1,380.8 billion by 2029, indicating a significant potential for temperature control technologies.

The healthcare and life sciences sector also presents a substantial market for precise temperature regulation. Laboratory equipment, such as incubators, PCR machines, and ultra-low temperature freezers, require accurate temperature control for reliable research outcomes and sample preservation. The global laboratory equipment market, which includes temperature control devices, was valued at $27.8 billion in 2020 and is expected to grow at a CAGR of 6.7% from 2021 to 2028.

In the automotive industry, the increasing adoption of electric vehicles (EVs) has created a new demand for precise temperature control systems. Battery thermal management is critical for EV performance, safety, and longevity. With the global EV market projected to reach 34 million units by 2030, the demand for advanced temperature regulation technologies is set to surge.

The food and beverage industry relies heavily on precise temperature control for processing, packaging, and storage. The global food processing equipment market, which includes temperature control systems, was valued at $59.5 billion in 2020 and is expected to reach $84.8 billion by 2027. This growth is driven by increasing demand for processed and convenience foods, as well as stricter food safety regulations.

Aerospace and defense applications also require precise temperature regulation for electronic systems, avionics, and satellite components. The global aerospace and defense market, valued at $1,600 billion in 2021, is projected to grow at a CAGR of 5.5% from 2022 to 2030, presenting opportunities for advanced temperature control solutions.

The HVAC industry is another significant market for precise temperature regulation, particularly in commercial and industrial settings. The global HVAC systems market was valued at $240.8 billion in 2020 and is expected to reach $367.5 billion by 2030, driven by increasing demand for energy-efficient and smart climate control solutions.

As industries continue to prioritize precision, efficiency, and sustainability, the market demand for advanced temperature control technologies, including those utilizing nichrome for precise regulation, is expected to grow substantially in the coming years.

The healthcare and life sciences sector also presents a substantial market for precise temperature regulation. Laboratory equipment, such as incubators, PCR machines, and ultra-low temperature freezers, require accurate temperature control for reliable research outcomes and sample preservation. The global laboratory equipment market, which includes temperature control devices, was valued at $27.8 billion in 2020 and is expected to grow at a CAGR of 6.7% from 2021 to 2028.

In the automotive industry, the increasing adoption of electric vehicles (EVs) has created a new demand for precise temperature control systems. Battery thermal management is critical for EV performance, safety, and longevity. With the global EV market projected to reach 34 million units by 2030, the demand for advanced temperature regulation technologies is set to surge.

The food and beverage industry relies heavily on precise temperature control for processing, packaging, and storage. The global food processing equipment market, which includes temperature control systems, was valued at $59.5 billion in 2020 and is expected to reach $84.8 billion by 2027. This growth is driven by increasing demand for processed and convenience foods, as well as stricter food safety regulations.

Aerospace and defense applications also require precise temperature regulation for electronic systems, avionics, and satellite components. The global aerospace and defense market, valued at $1,600 billion in 2021, is projected to grow at a CAGR of 5.5% from 2022 to 2030, presenting opportunities for advanced temperature control solutions.

The HVAC industry is another significant market for precise temperature regulation, particularly in commercial and industrial settings. The global HVAC systems market was valued at $240.8 billion in 2020 and is expected to reach $367.5 billion by 2030, driven by increasing demand for energy-efficient and smart climate control solutions.

As industries continue to prioritize precision, efficiency, and sustainability, the market demand for advanced temperature control technologies, including those utilizing nichrome for precise regulation, is expected to grow substantially in the coming years.

Current Nichrome Tech Challenges

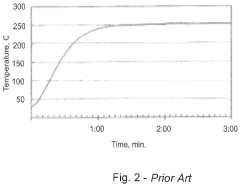

Despite the widespread use of nichrome in temperature regulation applications, several challenges persist in achieving precise and reliable temperature control. One of the primary issues is the inherent thermal inertia of nichrome wire, which can lead to temperature overshooting or undershooting during rapid heating or cooling cycles. This characteristic makes it difficult to maintain exact temperature setpoints, especially in systems requiring quick temperature changes.

Another significant challenge is the degradation of nichrome wire over time due to repeated heating and cooling cycles. This degradation can result in changes to the wire's electrical resistance, affecting its heat generation capabilities and, consequently, the accuracy of temperature regulation. The oxidation of nichrome at high temperatures further compounds this issue, potentially altering the wire's performance characteristics and reducing its lifespan.

The non-linear relationship between electrical current and heat generation in nichrome wire presents additional complexities in precise temperature control. As the wire heats up, its resistance changes, requiring sophisticated control algorithms to maintain consistent heat output. This non-linearity can be particularly problematic in applications demanding high precision across a wide temperature range.

Furthermore, the thermal distribution along nichrome heating elements is often uneven, leading to hot spots and cold spots. This non-uniform heating can compromise the overall temperature regulation accuracy, especially in larger-scale applications or when heating irregularly shaped objects. Addressing this issue often requires complex design considerations and may involve the use of multiple heating zones or advanced heat distribution techniques.

The environmental sensitivity of nichrome-based heating systems also poses challenges. Factors such as ambient temperature fluctuations, air currents, and varying thermal loads can significantly impact the performance of these systems. Compensating for these external influences requires advanced sensing and control mechanisms, adding complexity and cost to temperature regulation solutions.

Lastly, the power efficiency of nichrome heating elements remains a concern, particularly in applications requiring prolonged operation or those with energy constraints. The relatively high electrical resistance of nichrome, while beneficial for heat generation, can result in significant power consumption. Balancing the need for precise temperature control with energy efficiency considerations continues to be a challenge for engineers and designers working with nichrome-based systems.

Another significant challenge is the degradation of nichrome wire over time due to repeated heating and cooling cycles. This degradation can result in changes to the wire's electrical resistance, affecting its heat generation capabilities and, consequently, the accuracy of temperature regulation. The oxidation of nichrome at high temperatures further compounds this issue, potentially altering the wire's performance characteristics and reducing its lifespan.

The non-linear relationship between electrical current and heat generation in nichrome wire presents additional complexities in precise temperature control. As the wire heats up, its resistance changes, requiring sophisticated control algorithms to maintain consistent heat output. This non-linearity can be particularly problematic in applications demanding high precision across a wide temperature range.

Furthermore, the thermal distribution along nichrome heating elements is often uneven, leading to hot spots and cold spots. This non-uniform heating can compromise the overall temperature regulation accuracy, especially in larger-scale applications or when heating irregularly shaped objects. Addressing this issue often requires complex design considerations and may involve the use of multiple heating zones or advanced heat distribution techniques.

The environmental sensitivity of nichrome-based heating systems also poses challenges. Factors such as ambient temperature fluctuations, air currents, and varying thermal loads can significantly impact the performance of these systems. Compensating for these external influences requires advanced sensing and control mechanisms, adding complexity and cost to temperature regulation solutions.

Lastly, the power efficiency of nichrome heating elements remains a concern, particularly in applications requiring prolonged operation or those with energy constraints. The relatively high electrical resistance of nichrome, while beneficial for heat generation, can result in significant power consumption. Balancing the need for precise temperature control with energy efficiency considerations continues to be a challenge for engineers and designers working with nichrome-based systems.

Existing Nichrome Temp Regulation Solutions

01 Nichrome heating elements in electronic devices

Nichrome is commonly used as a heating element in various electronic devices due to its high resistance and ability to withstand high temperatures. It is utilized in applications such as electric heaters, ovens, and other heating appliances to generate controlled heat.- Nichrome heating elements in electronic devices: Nichrome is commonly used as a heating element in various electronic devices due to its high resistance and ability to withstand high temperatures. It is utilized in applications such as electric heaters, ovens, and other heating appliances to generate controlled heat.

- Temperature control and measurement in nichrome applications: Precise temperature control and measurement are crucial in nichrome-based systems. Various methods and devices are employed to monitor and regulate the temperature of nichrome elements, ensuring optimal performance and safety in different applications.

- Nichrome alloy composition and properties: The composition and properties of nichrome alloys are tailored for specific temperature requirements. Different ratios of nickel and chromium, along with other elements, are used to achieve desired characteristics such as resistance to oxidation and stability at high temperatures.

- Nichrome wire applications in sensors and detectors: Nichrome wire is utilized in various sensors and detectors due to its temperature-dependent resistance properties. It is employed in devices such as temperature sensors, flow meters, and gas detectors, where precise temperature measurement or heat generation is required.

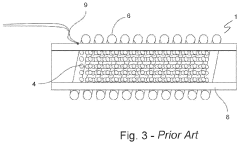

- Thermal management and insulation for nichrome components: Effective thermal management and insulation are essential for nichrome-based systems to ensure efficient heat distribution, prevent heat loss, and protect surrounding components. Various materials and designs are employed to achieve optimal thermal performance and safety in high-temperature applications.

02 Temperature control and measurement in nichrome applications

Precise temperature control and measurement are crucial in nichrome-based systems. Various methods and devices are employed to monitor and regulate the temperature of nichrome elements, ensuring optimal performance and safety in different applications.Expand Specific Solutions03 Nichrome alloy composition and properties

The composition and properties of nichrome alloys are tailored for specific temperature requirements. Different ratios of nickel and chromium, along with other elements, are used to achieve desired characteristics such as resistance to oxidation and stability at high temperatures.Expand Specific Solutions04 Nichrome wire in sensor and measurement devices

Nichrome wire is utilized in various sensor and measurement devices due to its stable electrical properties at different temperatures. It is employed in thermocouples, strain gauges, and other instruments for accurate temperature and physical property measurements.Expand Specific Solutions05 High-temperature applications of nichrome

Nichrome's ability to withstand extreme temperatures makes it suitable for high-temperature applications. It is used in industrial furnaces, laboratory equipment, and aerospace components where materials need to maintain stability and performance under intense heat conditions.Expand Specific Solutions

Key Players in Nichrome Heating Industry

The market for precise temperature regulation using nichrome is in a mature stage, with a global market size estimated in the billions of dollars. The technology is well-established, with applications across various industries including aerospace, electronics, and manufacturing. Key players like Gaona Aero Material Co., Ltd. and Shandong Roitie New Material Science and Technology Co., Ltd. are driving innovation in high-temperature alloys and materials. Academic institutions such as the University of Science & Technology Beijing and Dresden University of Technology contribute to ongoing research and development. The competitive landscape is diverse, with companies like Tokyo Electron Ltd. and Panasonic Holdings Corp. offering advanced temperature control solutions for industrial applications. As the demand for precise temperature regulation continues to grow in emerging technologies, the market is expected to expand further.

Tokyo Electron Ltd.

Technical Solution: Tokyo Electron Ltd. has developed advanced temperature regulation systems using nichrome for semiconductor manufacturing processes. Their approach involves precise control of nichrome heating elements in wafer processing equipment. The company utilizes a closed-loop feedback system that continuously monitors and adjusts the temperature based on real-time measurements[1]. This system incorporates multiple thermocouples strategically placed to detect temperature variations across the wafer surface. The nichrome elements are segmented to allow for zone-specific heating, enabling uniform temperature distribution even in large wafers[3]. Additionally, Tokyo Electron has implemented rapid thermal processing (RTP) techniques using nichrome, allowing for quick temperature ramps and precise control in the range of ±0.1°C[5].

Strengths: Highly precise temperature control suitable for advanced semiconductor processes. Weaknesses: May require complex control systems and regular calibration to maintain accuracy.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed a range of nichrome-based heating solutions with precise temperature regulation capabilities. Their approach combines thin-film nichrome elements with advanced control systems for applications in consumer electronics, automotive, and industrial sectors. Panasonic's technology utilizes a multi-layer design where nichrome is sandwiched between insulating materials, allowing for rapid heat transfer and improved durability[8]. The company has implemented fuzzy logic control systems that adapt to varying load conditions, maintaining temperature accuracy within ±2°C even under fluctuating environmental conditions[10]. Panasonic has also developed a unique etching process for nichrome elements, creating intricate patterns that optimize heat distribution and reduce hot spots[12].

Strengths: Versatile solutions applicable across multiple industries with good temperature stability. Weaknesses: May have higher initial costs compared to simpler heating systems.

Core Nichrome Heating Innovations

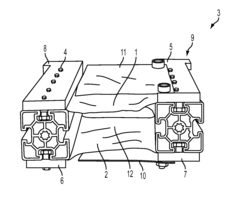

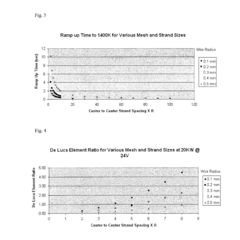

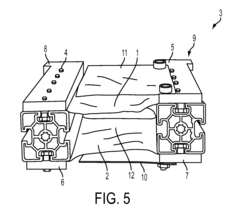

Wire mesh thermal radiative element and use in a radiative oven

PatentInactiveUS20150184867A1

Innovation

- A resistive mesh element with a calibrated De Luca Element Ratio, using nichrome wire with a specific strand diameter and spacing, operates at 24V to achieve efficient heat distribution and rapid temperature rise, allowing for quick cooking times while being cost-effective and easy to assemble.

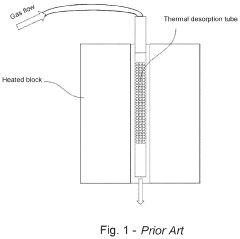

Thermal Desorption Tube for Portable, Battery-Powered Field Analyzer or Line-Powered Analyzer

PatentActiveUS20210088425A1

Innovation

- A thermal desorption tube with an embedded heating element made from a metal with a high Resistance Temperature Coefficient (RTC) value, allowing for precise temperature control by measuring electrical current and voltage drop, ensuring rapid and energy-efficient heating of the sorbent material without overheating.

Energy Efficiency in Nichrome Heating

Nichrome, an alloy of nickel and chromium, has been widely used in heating applications due to its high electrical resistance and ability to withstand high temperatures. When it comes to energy efficiency in nichrome heating, several factors come into play that can significantly impact the overall performance and cost-effectiveness of heating systems.

One of the primary advantages of nichrome in energy-efficient heating is its rapid heat-up time. The material's high electrical resistance allows it to quickly reach desired temperatures, reducing the overall energy consumption during the initial heating phase. This characteristic is particularly beneficial in applications where frequent on-off cycles are required, as it minimizes energy waste during the warm-up period.

The durability of nichrome also contributes to its energy efficiency. The alloy's resistance to oxidation and corrosion at high temperatures ensures a longer lifespan for heating elements, reducing the need for frequent replacements. This longevity not only saves on material costs but also reduces the energy required for manufacturing and installing replacement parts.

Precise temperature control is another aspect where nichrome excels in energy efficiency. By carefully designing nichrome heating elements and implementing advanced control systems, it is possible to achieve highly accurate temperature regulation. This precision allows for optimal energy usage by preventing overheating and unnecessary power consumption.

The thermal conductivity of nichrome plays a crucial role in its energy efficiency. While not as conductive as some other materials, nichrome's moderate thermal conductivity allows for even heat distribution across the heating element. This property helps to eliminate hot spots and ensures uniform heating, which can lead to more efficient energy utilization and improved overall system performance.

In recent years, advancements in nichrome alloy compositions have further enhanced its energy efficiency. By fine-tuning the ratio of nickel to chromium and incorporating small amounts of other elements, researchers have developed nichrome variants with improved electrical and thermal properties. These innovations have resulted in heating elements that offer even better energy efficiency and temperature stability.

The design of nichrome heating systems also plays a significant role in maximizing energy efficiency. Optimizing the geometry and arrangement of nichrome elements can improve heat transfer and reduce energy losses. For instance, using coiled or folded nichrome wire configurations can increase the surface area for heat dissipation, leading to more efficient heating processes.

When considering energy efficiency in nichrome heating, it is essential to account for the entire system, including insulation and heat recovery mechanisms. Proper insulation around nichrome heating elements can significantly reduce heat loss to the environment, while heat recovery systems can capture and reuse waste heat, further improving overall energy efficiency.

One of the primary advantages of nichrome in energy-efficient heating is its rapid heat-up time. The material's high electrical resistance allows it to quickly reach desired temperatures, reducing the overall energy consumption during the initial heating phase. This characteristic is particularly beneficial in applications where frequent on-off cycles are required, as it minimizes energy waste during the warm-up period.

The durability of nichrome also contributes to its energy efficiency. The alloy's resistance to oxidation and corrosion at high temperatures ensures a longer lifespan for heating elements, reducing the need for frequent replacements. This longevity not only saves on material costs but also reduces the energy required for manufacturing and installing replacement parts.

Precise temperature control is another aspect where nichrome excels in energy efficiency. By carefully designing nichrome heating elements and implementing advanced control systems, it is possible to achieve highly accurate temperature regulation. This precision allows for optimal energy usage by preventing overheating and unnecessary power consumption.

The thermal conductivity of nichrome plays a crucial role in its energy efficiency. While not as conductive as some other materials, nichrome's moderate thermal conductivity allows for even heat distribution across the heating element. This property helps to eliminate hot spots and ensures uniform heating, which can lead to more efficient energy utilization and improved overall system performance.

In recent years, advancements in nichrome alloy compositions have further enhanced its energy efficiency. By fine-tuning the ratio of nickel to chromium and incorporating small amounts of other elements, researchers have developed nichrome variants with improved electrical and thermal properties. These innovations have resulted in heating elements that offer even better energy efficiency and temperature stability.

The design of nichrome heating systems also plays a significant role in maximizing energy efficiency. Optimizing the geometry and arrangement of nichrome elements can improve heat transfer and reduce energy losses. For instance, using coiled or folded nichrome wire configurations can increase the surface area for heat dissipation, leading to more efficient heating processes.

When considering energy efficiency in nichrome heating, it is essential to account for the entire system, including insulation and heat recovery mechanisms. Proper insulation around nichrome heating elements can significantly reduce heat loss to the environment, while heat recovery systems can capture and reuse waste heat, further improving overall energy efficiency.

Safety Standards for Nichrome Applications

The implementation of nichrome for precise temperature regulation necessitates adherence to stringent safety standards to mitigate potential risks associated with its use. These standards encompass various aspects of nichrome applications, including electrical safety, thermal management, and material compatibility.

Electrical safety standards for nichrome applications focus on preventing electrical hazards such as short circuits, overheating, and electrical shocks. These standards typically require proper insulation of nichrome elements, appropriate grounding mechanisms, and the use of circuit protection devices like fuses or circuit breakers. Additionally, they may specify maximum voltage and current ratings for different nichrome wire gauges and configurations.

Thermal management safety standards address the potential fire hazards and overheating risks associated with nichrome heating elements. These standards often mandate the use of temperature-limiting devices, such as thermostats or thermal fuses, to prevent excessive heating. They may also specify minimum clearances between nichrome elements and surrounding materials, as well as requirements for heat-resistant enclosures or insulation.

Material compatibility standards ensure that nichrome elements are used in conjunction with appropriate materials that can withstand the high temperatures generated. These standards may outline suitable substrate materials, insulation types, and protective coatings that are compatible with nichrome and can maintain their integrity under operating conditions.

Operational safety standards for nichrome applications typically include guidelines for proper installation, maintenance, and regular inspection of nichrome-based heating systems. These standards may require the implementation of fail-safe mechanisms, emergency shut-off systems, and proper labeling of hot surfaces or potential hazards.

Environmental safety considerations are also addressed in nichrome application standards, particularly in terms of emissions and waste management. These may include regulations on the release of potentially harmful substances during nichrome operation and guidelines for the proper disposal of nichrome-containing components at the end of their lifecycle.

Specific industry standards may apply to nichrome applications in different sectors, such as food processing, medical equipment, or aerospace. These standards often incorporate additional safety requirements tailored to the unique challenges and risks associated with each industry.

Compliance with international safety standards and certifications, such as those issued by IEC, UL, or CE, is often required for nichrome-based products to ensure global market acceptance and regulatory compliance. These standards provide a framework for consistent safety practices across different regions and applications.

Electrical safety standards for nichrome applications focus on preventing electrical hazards such as short circuits, overheating, and electrical shocks. These standards typically require proper insulation of nichrome elements, appropriate grounding mechanisms, and the use of circuit protection devices like fuses or circuit breakers. Additionally, they may specify maximum voltage and current ratings for different nichrome wire gauges and configurations.

Thermal management safety standards address the potential fire hazards and overheating risks associated with nichrome heating elements. These standards often mandate the use of temperature-limiting devices, such as thermostats or thermal fuses, to prevent excessive heating. They may also specify minimum clearances between nichrome elements and surrounding materials, as well as requirements for heat-resistant enclosures or insulation.

Material compatibility standards ensure that nichrome elements are used in conjunction with appropriate materials that can withstand the high temperatures generated. These standards may outline suitable substrate materials, insulation types, and protective coatings that are compatible with nichrome and can maintain their integrity under operating conditions.

Operational safety standards for nichrome applications typically include guidelines for proper installation, maintenance, and regular inspection of nichrome-based heating systems. These standards may require the implementation of fail-safe mechanisms, emergency shut-off systems, and proper labeling of hot surfaces or potential hazards.

Environmental safety considerations are also addressed in nichrome application standards, particularly in terms of emissions and waste management. These may include regulations on the release of potentially harmful substances during nichrome operation and guidelines for the proper disposal of nichrome-containing components at the end of their lifecycle.

Specific industry standards may apply to nichrome applications in different sectors, such as food processing, medical equipment, or aerospace. These standards often incorporate additional safety requirements tailored to the unique challenges and risks associated with each industry.

Compliance with international safety standards and certifications, such as those issued by IEC, UL, or CE, is often required for nichrome-based products to ensure global market acceptance and regulatory compliance. These standards provide a framework for consistent safety practices across different regions and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!