Identifying CMOS Battery Opportunities in Aerospace Technologies

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace CMOS Battery Evolution and Objectives

The evolution of CMOS battery technology in aerospace applications has been marked by significant advancements over the past decades. Initially developed for terrestrial applications, CMOS batteries have found their way into aerospace technologies due to their reliability, low power consumption, and ability to retain critical system information during power-off states.

In the early stages of aerospace CMOS battery implementation, the focus was primarily on maintaining basic system configurations and real-time clock functions. As aerospace systems became more complex, the role of CMOS batteries expanded to include supporting a wider range of critical functions, such as flight data recording, navigation system backups, and emergency power systems.

The aerospace industry's stringent requirements have driven continuous improvements in CMOS battery technology. Key areas of development have included enhancing energy density, extending operational life, improving performance under extreme temperature conditions, and increasing resistance to radiation and other harsh environmental factors encountered in aerospace applications.

Recent trends in aerospace CMOS battery evolution have centered on miniaturization and integration. As space and weight constraints become increasingly critical in aircraft and spacecraft design, there is a growing demand for smaller, lighter CMOS battery solutions that can be seamlessly integrated into complex aerospace systems without compromising performance or reliability.

The objectives for future CMOS battery development in aerospace technologies are multifaceted. One primary goal is to further increase energy density, allowing for longer operational lifetimes and reduced maintenance requirements. This is particularly crucial for long-duration space missions and satellite applications where battery replacement is not feasible.

Another key objective is to enhance the environmental resilience of CMOS batteries, enabling them to withstand the extreme conditions encountered in aerospace environments. This includes improving performance at high altitudes, in vacuum conditions, and under intense radiation exposure.

Sustainability and safety are also becoming increasingly important objectives in CMOS battery development for aerospace applications. There is a growing focus on developing more environmentally friendly battery chemistries and improving safety features to mitigate risks associated with battery failures in critical aerospace systems.

Looking ahead, the integration of smart technologies into CMOS batteries represents a significant opportunity. The development of self-monitoring and self-diagnostic capabilities could greatly enhance the reliability and predictive maintenance of aerospace systems, potentially reducing downtime and improving overall safety.

In the early stages of aerospace CMOS battery implementation, the focus was primarily on maintaining basic system configurations and real-time clock functions. As aerospace systems became more complex, the role of CMOS batteries expanded to include supporting a wider range of critical functions, such as flight data recording, navigation system backups, and emergency power systems.

The aerospace industry's stringent requirements have driven continuous improvements in CMOS battery technology. Key areas of development have included enhancing energy density, extending operational life, improving performance under extreme temperature conditions, and increasing resistance to radiation and other harsh environmental factors encountered in aerospace applications.

Recent trends in aerospace CMOS battery evolution have centered on miniaturization and integration. As space and weight constraints become increasingly critical in aircraft and spacecraft design, there is a growing demand for smaller, lighter CMOS battery solutions that can be seamlessly integrated into complex aerospace systems without compromising performance or reliability.

The objectives for future CMOS battery development in aerospace technologies are multifaceted. One primary goal is to further increase energy density, allowing for longer operational lifetimes and reduced maintenance requirements. This is particularly crucial for long-duration space missions and satellite applications where battery replacement is not feasible.

Another key objective is to enhance the environmental resilience of CMOS batteries, enabling them to withstand the extreme conditions encountered in aerospace environments. This includes improving performance at high altitudes, in vacuum conditions, and under intense radiation exposure.

Sustainability and safety are also becoming increasingly important objectives in CMOS battery development for aerospace applications. There is a growing focus on developing more environmentally friendly battery chemistries and improving safety features to mitigate risks associated with battery failures in critical aerospace systems.

Looking ahead, the integration of smart technologies into CMOS batteries represents a significant opportunity. The development of self-monitoring and self-diagnostic capabilities could greatly enhance the reliability and predictive maintenance of aerospace systems, potentially reducing downtime and improving overall safety.

Market Analysis for Aerospace CMOS Batteries

The aerospace CMOS battery market is experiencing significant growth driven by the increasing demand for reliable power sources in advanced avionics systems and spacecraft. As aerospace technologies continue to evolve, the need for compact, long-lasting, and high-performance batteries has become paramount. CMOS (Complementary Metal-Oxide-Semiconductor) batteries, known for their low power consumption and compatibility with integrated circuits, are emerging as a crucial component in modern aerospace applications.

The market for aerospace CMOS batteries is closely tied to the overall growth of the aerospace industry, which has been steadily expanding despite global economic challenges. The commercial aviation sector, in particular, has been a major driver of demand, with airlines continuously upgrading their fleets with more advanced and fuel-efficient aircraft. These new-generation aircraft rely heavily on sophisticated avionics systems that require stable and reliable power sources, creating a substantial market opportunity for CMOS batteries.

In the space sector, the increasing number of satellite launches and space exploration missions has further bolstered the demand for aerospace CMOS batteries. The trend towards smaller, more efficient satellites, such as CubeSats and nanosatellites, has created a niche market for miniaturized CMOS battery solutions. These batteries are essential for powering onboard systems during eclipse periods when solar panels are ineffective.

The defense aerospace sector also contributes significantly to the CMOS battery market. Military aircraft and unmanned aerial vehicles (UAVs) require advanced power management systems to support their complex electronic warfare and communication systems. CMOS batteries play a critical role in ensuring the reliability and longevity of these mission-critical components.

Geographically, North America and Europe lead the aerospace CMOS battery market, owing to the presence of major aircraft manufacturers and space agencies in these regions. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the expanding aerospace industries in countries like China and India.

Key market players in the aerospace CMOS battery sector include established battery manufacturers and specialized aerospace component suppliers. These companies are investing heavily in research and development to improve battery performance, extend lifespan, and reduce weight – all critical factors in aerospace applications.

The market is also influenced by regulatory standards and certification requirements specific to the aerospace industry. Compliance with these stringent regulations is essential for market entry and sustained growth, creating both challenges and opportunities for manufacturers.

The market for aerospace CMOS batteries is closely tied to the overall growth of the aerospace industry, which has been steadily expanding despite global economic challenges. The commercial aviation sector, in particular, has been a major driver of demand, with airlines continuously upgrading their fleets with more advanced and fuel-efficient aircraft. These new-generation aircraft rely heavily on sophisticated avionics systems that require stable and reliable power sources, creating a substantial market opportunity for CMOS batteries.

In the space sector, the increasing number of satellite launches and space exploration missions has further bolstered the demand for aerospace CMOS batteries. The trend towards smaller, more efficient satellites, such as CubeSats and nanosatellites, has created a niche market for miniaturized CMOS battery solutions. These batteries are essential for powering onboard systems during eclipse periods when solar panels are ineffective.

The defense aerospace sector also contributes significantly to the CMOS battery market. Military aircraft and unmanned aerial vehicles (UAVs) require advanced power management systems to support their complex electronic warfare and communication systems. CMOS batteries play a critical role in ensuring the reliability and longevity of these mission-critical components.

Geographically, North America and Europe lead the aerospace CMOS battery market, owing to the presence of major aircraft manufacturers and space agencies in these regions. However, the Asia-Pacific region is expected to witness the fastest growth, driven by the expanding aerospace industries in countries like China and India.

Key market players in the aerospace CMOS battery sector include established battery manufacturers and specialized aerospace component suppliers. These companies are investing heavily in research and development to improve battery performance, extend lifespan, and reduce weight – all critical factors in aerospace applications.

The market is also influenced by regulatory standards and certification requirements specific to the aerospace industry. Compliance with these stringent regulations is essential for market entry and sustained growth, creating both challenges and opportunities for manufacturers.

Current Challenges in Aerospace CMOS Battery Technology

The aerospace industry faces several critical challenges in CMOS battery technology, which are hindering the advancement of more efficient and reliable power systems for spacecraft and satellites. One of the primary issues is the limited energy density of current CMOS batteries. As space missions become more complex and long-duration, the demand for higher energy storage capacity continues to grow. However, existing CMOS battery technologies struggle to meet these increasing power requirements within the strict weight and size constraints of aerospace applications.

Another significant challenge is the harsh space environment, which poses severe threats to battery performance and longevity. Extreme temperature fluctuations, radiation exposure, and vacuum conditions can significantly degrade battery materials and components. This environmental stress often leads to reduced battery life, decreased efficiency, and potential safety risks. Developing CMOS batteries that can withstand these harsh conditions without compromising performance remains a formidable task for researchers and engineers.

The need for ultra-reliable power sources in aerospace applications presents another hurdle. CMOS batteries must maintain consistent performance over extended periods, often spanning several years, with minimal degradation. This requirement is particularly crucial for missions where battery replacement or maintenance is not feasible. Achieving such high levels of reliability while simultaneously pushing the boundaries of energy density and environmental resilience is a complex balancing act.

Weight reduction is an ongoing challenge in aerospace CMOS battery development. Every gram saved in battery weight translates to potential increases in payload capacity or fuel efficiency. However, reducing weight often comes at the cost of energy density or durability. Finding innovative materials and designs that can minimize battery weight without sacrificing performance is a key focus area for researchers.

The integration of CMOS batteries with other spacecraft systems presents additional challenges. These batteries must be compatible with various power management systems, charging mechanisms, and safety protocols. Ensuring seamless integration while maintaining optimal performance across different spacecraft architectures and mission profiles adds another layer of complexity to battery design and implementation.

Lastly, the aerospace industry faces challenges in scaling up production and reducing costs for advanced CMOS battery technologies. The specialized nature of aerospace applications often results in low production volumes, which can drive up costs and limit widespread adoption of new battery technologies. Bridging the gap between laboratory innovations and cost-effective, large-scale manufacturing remains a significant hurdle in advancing CMOS battery technology for aerospace applications.

Another significant challenge is the harsh space environment, which poses severe threats to battery performance and longevity. Extreme temperature fluctuations, radiation exposure, and vacuum conditions can significantly degrade battery materials and components. This environmental stress often leads to reduced battery life, decreased efficiency, and potential safety risks. Developing CMOS batteries that can withstand these harsh conditions without compromising performance remains a formidable task for researchers and engineers.

The need for ultra-reliable power sources in aerospace applications presents another hurdle. CMOS batteries must maintain consistent performance over extended periods, often spanning several years, with minimal degradation. This requirement is particularly crucial for missions where battery replacement or maintenance is not feasible. Achieving such high levels of reliability while simultaneously pushing the boundaries of energy density and environmental resilience is a complex balancing act.

Weight reduction is an ongoing challenge in aerospace CMOS battery development. Every gram saved in battery weight translates to potential increases in payload capacity or fuel efficiency. However, reducing weight often comes at the cost of energy density or durability. Finding innovative materials and designs that can minimize battery weight without sacrificing performance is a key focus area for researchers.

The integration of CMOS batteries with other spacecraft systems presents additional challenges. These batteries must be compatible with various power management systems, charging mechanisms, and safety protocols. Ensuring seamless integration while maintaining optimal performance across different spacecraft architectures and mission profiles adds another layer of complexity to battery design and implementation.

Lastly, the aerospace industry faces challenges in scaling up production and reducing costs for advanced CMOS battery technologies. The specialized nature of aerospace applications often results in low production volumes, which can drive up costs and limit widespread adoption of new battery technologies. Bridging the gap between laboratory innovations and cost-effective, large-scale manufacturing remains a significant hurdle in advancing CMOS battery technology for aerospace applications.

Existing Aerospace CMOS Battery Solutions

01 CMOS battery power management

Systems and methods for managing power in CMOS batteries, including techniques for monitoring battery voltage, implementing power-saving modes, and extending battery life through efficient power distribution and consumption in electronic devices.- CMOS battery power management: Systems and methods for managing power in CMOS batteries, including techniques for monitoring battery voltage, implementing power-saving modes, and extending battery life through efficient power distribution and consumption.

- CMOS battery replacement and backup systems: Innovations in CMOS battery replacement procedures and backup power systems to ensure continuous operation of critical components during battery changes or failures, including hot-swappable designs and temporary power storage solutions.

- Integration of CMOS batteries in electronic devices: Advancements in integrating CMOS batteries into various electronic devices, focusing on compact designs, improved connectivity, and enhanced compatibility with different device architectures and form factors.

- CMOS battery monitoring and diagnostics: Development of sophisticated monitoring and diagnostic systems for CMOS batteries, including real-time voltage tracking, predictive maintenance algorithms, and early warning systems for potential battery failures.

- CMOS battery circuit design and optimization: Innovative circuit designs and optimization techniques for CMOS batteries, focusing on improving energy efficiency, reducing power consumption, and enhancing overall performance in various operating conditions.

02 CMOS battery replacement and backup systems

Innovations in CMOS battery replacement procedures and backup power systems to ensure continuous operation of critical components during battery changes or failures, including hot-swappable battery designs and temporary power storage solutions.Expand Specific Solutions03 CMOS battery integration in semiconductor devices

Advancements in integrating CMOS batteries directly into semiconductor devices and integrated circuits, focusing on miniaturization, improved efficiency, and enhanced performance of battery-powered components in electronic systems.Expand Specific Solutions04 CMOS battery charging and monitoring circuits

Development of specialized circuits for charging CMOS batteries and monitoring their status, including voltage regulation, charge level indication, and intelligent charging algorithms to optimize battery performance and lifespan.Expand Specific Solutions05 CMOS battery applications in imaging devices

Utilization of CMOS batteries in imaging devices such as digital cameras and image sensors, focusing on power management techniques to support advanced imaging features while maintaining long battery life and compact device designs.Expand Specific Solutions

Key Aerospace CMOS Battery Manufacturers

The aerospace CMOS battery market is in a growth phase, driven by increasing demand for advanced avionics and electronic systems in aircraft. The market size is expanding, with projections indicating significant growth over the next decade. Technologically, CMOS batteries for aerospace applications are evolving rapidly, with companies like Texas Instruments, Thales SA, and Boeing leading innovation. These firms are developing more efficient, lightweight, and durable batteries to meet the stringent requirements of aerospace environments. While established players dominate, emerging companies like Limatech SAS are introducing novel lithium-ion solutions, indicating a dynamic and competitive landscape in this niche but critical aerospace technology sector.

Texas Instruments Incorporated

Technical Solution: Texas Instruments (TI) has developed CMOS battery management solutions for aerospace applications, focusing on high-precision monitoring and control. Their approach includes the design of ultra-low-power battery fuel gauge ICs that accurately measure state-of-charge and state-of-health in lithium-ion batteries[13]. TI's CMOS battery management systems feature high-resolution analog-to-digital converters (ADCs) and advanced algorithms for cell balancing and protection[14]. The company has also implemented wireless battery management solutions that reduce wiring complexity and weight in aerospace applications[15].

Strengths: Industry-leading precision in battery monitoring, extensive experience in power management ICs, and innovative wireless solutions. Weaknesses: Limited involvement in actual battery cell manufacturing and potential dependencies on third-party battery suppliers.

The Boeing Co.

Technical Solution: Boeing has developed advanced CMOS battery technologies for aerospace applications, focusing on high energy density and long cycle life. Their approach includes the use of lithium-ion chemistry with improved cathode materials and advanced battery management systems. Boeing's CMOS batteries feature integrated temperature sensors and voltage regulators to ensure optimal performance in extreme aerospace conditions[1][3]. The company has also implemented redundant cell designs to enhance reliability and safety, crucial for aircraft operations[5].

Strengths: Industry-leading energy density, advanced safety features, and extensive aerospace integration experience. Weaknesses: Higher initial costs and potential supply chain dependencies for specialized materials.

Innovative CMOS Battery Patents for Aerospace Applications

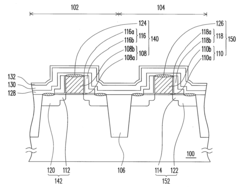

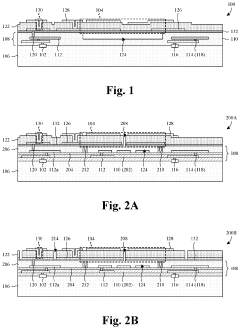

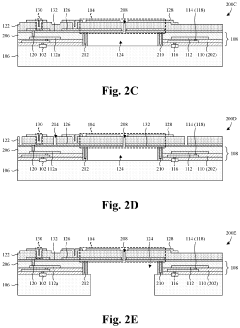

Complementary metal-oxide-semiconductor transistor and method of fabricating the same

PatentInactiveUS20080237734A1

Innovation

- A method involving the formation of device isolation structures, conductive type MOS transistors with specific gate and doped regions, nitride spacers, and stress layers, where the thickness of nitride spacers is reduced through an etching process to increase stress in the channel region, particularly for N-type MOS transistors, to enhance driving current gain and overall device performance.

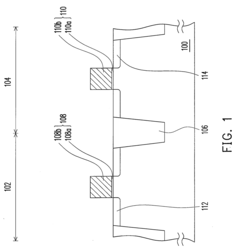

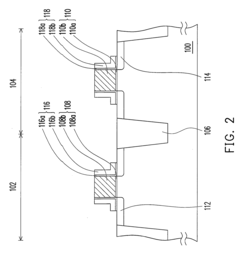

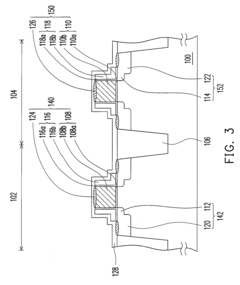

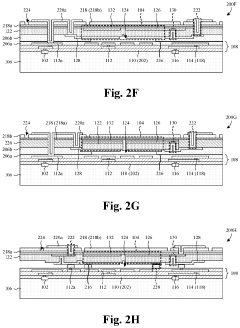

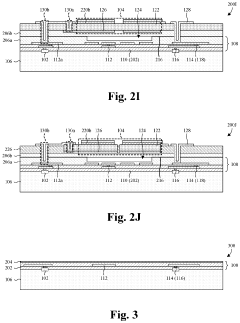

Integration scheme for microelectromechanical systems (MEMS) devices and complementary metal-oxide-semiconductor (CMOS) devices

PatentActiveUS11078074B2

Innovation

- A method involving the formation of a BEOL interconnect structure with a dielectric stack, a lateral etch to create a trench, and a piezoelectric layer over a semiconductor substrate, allowing for electrical coupling of MEMS devices to CMOS devices without wire bonding, performed at the wafer level to reduce packaging time and complexity.

Aerospace CMOS Battery Safety and Reliability Standards

In the aerospace industry, CMOS battery safety and reliability standards are of paramount importance due to the critical nature of aerospace applications. These standards are designed to ensure the consistent performance and longevity of CMOS batteries in extreme conditions, including high altitudes, temperature fluctuations, and vibrations.

The Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent guidelines for CMOS batteries used in aerospace technologies. These regulations cover various aspects, including battery chemistry, construction, testing procedures, and performance requirements. The SAE International's Aerospace Standards (AS) also provide detailed specifications for CMOS batteries, particularly AS8020 for aircraft battery design and performance.

One of the key safety standards for CMOS batteries in aerospace applications is the UL 1642 certification for lithium batteries. This standard outlines specific tests for electrical, mechanical, and environmental safety, ensuring that batteries can withstand the rigors of aerospace environments without compromising safety or performance.

The DO-311A standard, developed by RTCA, Inc., specifically addresses the airworthiness requirements for rechargeable lithium batteries and battery systems in aerospace. This standard covers aspects such as cell design, battery management systems, and safety mechanisms to prevent thermal runaway and other potential hazards.

Reliability standards for aerospace CMOS batteries focus on factors such as cycle life, capacity retention, and performance under extreme temperatures. The MIL-PRF-32383 specification, for instance, outlines the performance requirements for rechargeable lithium-ion batteries used in military aerospace applications, which often serve as a benchmark for commercial aerospace standards.

To meet these stringent standards, manufacturers employ various techniques and technologies. These include advanced battery management systems (BMS) that monitor and control battery parameters, thermal management solutions to maintain optimal operating temperatures, and robust enclosures to protect against physical damage and environmental factors.

Compliance with these standards often requires extensive testing and certification processes. This includes accelerated life testing, environmental stress screening, and electromagnetic compatibility (EMC) testing to ensure that CMOS batteries can function reliably without interfering with other critical aerospace systems.

As aerospace technologies continue to evolve, these standards are regularly reviewed and updated to address new challenges and incorporate technological advancements. The ongoing development of more energy-dense and safer battery chemistries, such as solid-state batteries, is likely to influence future iterations of these standards, potentially opening new opportunities for CMOS battery applications in aerospace.

The Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent guidelines for CMOS batteries used in aerospace technologies. These regulations cover various aspects, including battery chemistry, construction, testing procedures, and performance requirements. The SAE International's Aerospace Standards (AS) also provide detailed specifications for CMOS batteries, particularly AS8020 for aircraft battery design and performance.

One of the key safety standards for CMOS batteries in aerospace applications is the UL 1642 certification for lithium batteries. This standard outlines specific tests for electrical, mechanical, and environmental safety, ensuring that batteries can withstand the rigors of aerospace environments without compromising safety or performance.

The DO-311A standard, developed by RTCA, Inc., specifically addresses the airworthiness requirements for rechargeable lithium batteries and battery systems in aerospace. This standard covers aspects such as cell design, battery management systems, and safety mechanisms to prevent thermal runaway and other potential hazards.

Reliability standards for aerospace CMOS batteries focus on factors such as cycle life, capacity retention, and performance under extreme temperatures. The MIL-PRF-32383 specification, for instance, outlines the performance requirements for rechargeable lithium-ion batteries used in military aerospace applications, which often serve as a benchmark for commercial aerospace standards.

To meet these stringent standards, manufacturers employ various techniques and technologies. These include advanced battery management systems (BMS) that monitor and control battery parameters, thermal management solutions to maintain optimal operating temperatures, and robust enclosures to protect against physical damage and environmental factors.

Compliance with these standards often requires extensive testing and certification processes. This includes accelerated life testing, environmental stress screening, and electromagnetic compatibility (EMC) testing to ensure that CMOS batteries can function reliably without interfering with other critical aerospace systems.

As aerospace technologies continue to evolve, these standards are regularly reviewed and updated to address new challenges and incorporate technological advancements. The ongoing development of more energy-dense and safer battery chemistries, such as solid-state batteries, is likely to influence future iterations of these standards, potentially opening new opportunities for CMOS battery applications in aerospace.

Environmental Impact of Aerospace CMOS Batteries

The environmental impact of CMOS batteries in aerospace technologies is a critical consideration as the industry strives for sustainability and reduced ecological footprint. These batteries, while essential for maintaining system memory and real-time clock functions in aerospace equipment, pose several environmental challenges throughout their lifecycle.

During the production phase, the manufacturing of CMOS batteries involves the use of potentially hazardous materials, including lithium, thionyl chloride, and various heavy metals. The extraction and processing of these raw materials can lead to habitat destruction, water pollution, and increased carbon emissions. Additionally, the energy-intensive production processes contribute to the overall carbon footprint of aerospace technologies.

In the operational phase, CMOS batteries in aerospace applications generally have a long lifespan, which helps minimize waste generation. However, the extreme conditions experienced in aerospace environments, such as temperature fluctuations and radiation exposure, can accelerate battery degradation. This may lead to more frequent replacements, potentially increasing the environmental burden.

The end-of-life stage presents significant environmental concerns. Improper disposal of CMOS batteries can result in the release of toxic substances into soil and water systems. The lithium content, in particular, poses fire hazards and can contaminate groundwater if not handled correctly. Recycling these batteries is challenging due to their small size and the complexity of separating the various components.

To address these environmental issues, the aerospace industry is exploring several avenues. One approach is the development of more environmentally friendly battery chemistries that reduce or eliminate the use of hazardous materials. Research into bio-based electrolytes and organic electrode materials shows promise in creating more sustainable CMOS battery alternatives.

Another focus area is improving the recycling and disposal processes for aerospace CMOS batteries. Advanced recycling technologies are being developed to more efficiently recover valuable materials and safely neutralize hazardous components. Some aerospace companies are also implementing take-back programs to ensure proper handling of end-of-life batteries.

The industry is also investigating ways to extend the lifespan of CMOS batteries in aerospace applications. This includes developing more robust battery designs that can withstand harsh environments for longer periods, as well as implementing smart power management systems that optimize battery usage and reduce the frequency of replacements.

As environmental regulations become more stringent, aerospace manufacturers are increasingly adopting lifecycle assessment approaches to quantify and minimize the environmental impact of their CMOS battery usage. This holistic view helps in identifying opportunities for improvement across the entire product lifecycle, from raw material sourcing to end-of-life management.

During the production phase, the manufacturing of CMOS batteries involves the use of potentially hazardous materials, including lithium, thionyl chloride, and various heavy metals. The extraction and processing of these raw materials can lead to habitat destruction, water pollution, and increased carbon emissions. Additionally, the energy-intensive production processes contribute to the overall carbon footprint of aerospace technologies.

In the operational phase, CMOS batteries in aerospace applications generally have a long lifespan, which helps minimize waste generation. However, the extreme conditions experienced in aerospace environments, such as temperature fluctuations and radiation exposure, can accelerate battery degradation. This may lead to more frequent replacements, potentially increasing the environmental burden.

The end-of-life stage presents significant environmental concerns. Improper disposal of CMOS batteries can result in the release of toxic substances into soil and water systems. The lithium content, in particular, poses fire hazards and can contaminate groundwater if not handled correctly. Recycling these batteries is challenging due to their small size and the complexity of separating the various components.

To address these environmental issues, the aerospace industry is exploring several avenues. One approach is the development of more environmentally friendly battery chemistries that reduce or eliminate the use of hazardous materials. Research into bio-based electrolytes and organic electrode materials shows promise in creating more sustainable CMOS battery alternatives.

Another focus area is improving the recycling and disposal processes for aerospace CMOS batteries. Advanced recycling technologies are being developed to more efficiently recover valuable materials and safely neutralize hazardous components. Some aerospace companies are also implementing take-back programs to ensure proper handling of end-of-life batteries.

The industry is also investigating ways to extend the lifespan of CMOS batteries in aerospace applications. This includes developing more robust battery designs that can withstand harsh environments for longer periods, as well as implementing smart power management systems that optimize battery usage and reduce the frequency of replacements.

As environmental regulations become more stringent, aerospace manufacturers are increasingly adopting lifecycle assessment approaches to quantify and minimize the environmental impact of their CMOS battery usage. This holistic view helps in identifying opportunities for improvement across the entire product lifecycle, from raw material sourcing to end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!