Innovations in Acoustic Wave-based Piezoelectric Sensors

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Objectives

Piezoelectric sensors have undergone significant evolution since their inception, driven by advancements in materials science, fabrication techniques, and signal processing. The journey began with the discovery of the piezoelectric effect by Jacques and Pierre Curie in 1880, which laid the foundation for the development of these sensors. Initially, natural crystals like quartz were used, but the field has since expanded to include a wide range of synthetic materials with enhanced piezoelectric properties.

The evolution of acoustic wave-based piezoelectric sensors has been marked by several key milestones. In the 1960s, the introduction of surface acoustic wave (SAW) devices revolutionized the field, enabling the development of compact, highly sensitive sensors. The 1980s saw the emergence of bulk acoustic wave (BAW) sensors, which offered improved frequency stability and higher operating frequencies. More recently, the development of film bulk acoustic resonators (FBAR) has pushed the boundaries of miniaturization and performance.

Throughout this evolution, the objectives of piezoelectric sensor development have remained focused on improving sensitivity, selectivity, and reliability while reducing size and power consumption. Recent innovations aim to address the growing demand for real-time, in-situ sensing capabilities in various applications, from environmental monitoring to biomedical diagnostics.

Current research objectives in acoustic wave-based piezoelectric sensors include enhancing their performance in harsh environments, improving their integration with other sensing modalities, and expanding their applicability in emerging fields such as Internet of Things (IoT) and wearable technologies. There is also a strong focus on developing sensors with multi-parameter sensing capabilities, allowing for simultaneous measurement of various physical and chemical parameters.

Another key objective is the development of self-powered piezoelectric sensors, leveraging the energy harvesting capabilities of piezoelectric materials to create autonomous sensing systems. This aligns with the broader trend towards sustainable and energy-efficient technologies.

As we look to the future, the objectives for piezoelectric sensor innovation are increasingly centered around enhancing their adaptability and intelligence. This includes the integration of machine learning algorithms for improved signal processing and pattern recognition, as well as the development of reconfigurable sensor arrays that can dynamically adjust their properties based on environmental conditions or specific sensing requirements.

The evolution of acoustic wave-based piezoelectric sensors has been marked by several key milestones. In the 1960s, the introduction of surface acoustic wave (SAW) devices revolutionized the field, enabling the development of compact, highly sensitive sensors. The 1980s saw the emergence of bulk acoustic wave (BAW) sensors, which offered improved frequency stability and higher operating frequencies. More recently, the development of film bulk acoustic resonators (FBAR) has pushed the boundaries of miniaturization and performance.

Throughout this evolution, the objectives of piezoelectric sensor development have remained focused on improving sensitivity, selectivity, and reliability while reducing size and power consumption. Recent innovations aim to address the growing demand for real-time, in-situ sensing capabilities in various applications, from environmental monitoring to biomedical diagnostics.

Current research objectives in acoustic wave-based piezoelectric sensors include enhancing their performance in harsh environments, improving their integration with other sensing modalities, and expanding their applicability in emerging fields such as Internet of Things (IoT) and wearable technologies. There is also a strong focus on developing sensors with multi-parameter sensing capabilities, allowing for simultaneous measurement of various physical and chemical parameters.

Another key objective is the development of self-powered piezoelectric sensors, leveraging the energy harvesting capabilities of piezoelectric materials to create autonomous sensing systems. This aligns with the broader trend towards sustainable and energy-efficient technologies.

As we look to the future, the objectives for piezoelectric sensor innovation are increasingly centered around enhancing their adaptability and intelligence. This includes the integration of machine learning algorithms for improved signal processing and pattern recognition, as well as the development of reconfigurable sensor arrays that can dynamically adjust their properties based on environmental conditions or specific sensing requirements.

Acoustic Wave Sensor Market Analysis

The acoustic wave sensor market has been experiencing significant growth in recent years, driven by the increasing demand for advanced sensing technologies across various industries. This market segment is characterized by its diverse applications, ranging from automotive and healthcare to industrial process control and environmental monitoring. The global acoustic wave sensor market was valued at approximately $450 million in 2020 and is projected to reach $1.2 billion by 2026, growing at a CAGR of around 15% during the forecast period.

One of the key factors contributing to this market growth is the rising adoption of Internet of Things (IoT) and smart devices, which require sophisticated sensing capabilities. Acoustic wave sensors, particularly those based on piezoelectric technology, offer advantages such as high sensitivity, reliability, and the ability to operate in harsh environments. These attributes make them ideal for integration into IoT devices and smart systems, further driving market expansion.

The automotive sector represents a significant portion of the acoustic wave sensor market, with applications in tire pressure monitoring systems, engine management, and advanced driver assistance systems (ADAS). The increasing focus on vehicle safety and efficiency has led to a surge in demand for these sensors in the automotive industry. Additionally, the healthcare sector is emerging as a promising market for acoustic wave sensors, with applications in medical diagnostics, drug discovery, and biosensing.

Geographically, North America and Europe currently dominate the acoustic wave sensor market, owing to their advanced technological infrastructure and early adoption of innovative sensing solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing investments in healthcare and environmental monitoring technologies.

The market landscape is characterized by intense competition among key players, including Honeywell International Inc., Siemens AG, Raytheon Technologies Corporation, and Broadcom Inc. These companies are focusing on research and development activities to enhance sensor performance, reduce costs, and expand their product portfolios. Collaborations and partnerships with technology providers and end-users are also becoming increasingly common as companies seek to strengthen their market positions and address evolving customer needs.

Despite the positive growth outlook, the acoustic wave sensor market faces challenges such as high initial costs and technical complexities associated with sensor integration. However, ongoing technological advancements, including the development of miniaturized sensors and improved signal processing techniques, are expected to address these challenges and further drive market growth in the coming years.

One of the key factors contributing to this market growth is the rising adoption of Internet of Things (IoT) and smart devices, which require sophisticated sensing capabilities. Acoustic wave sensors, particularly those based on piezoelectric technology, offer advantages such as high sensitivity, reliability, and the ability to operate in harsh environments. These attributes make them ideal for integration into IoT devices and smart systems, further driving market expansion.

The automotive sector represents a significant portion of the acoustic wave sensor market, with applications in tire pressure monitoring systems, engine management, and advanced driver assistance systems (ADAS). The increasing focus on vehicle safety and efficiency has led to a surge in demand for these sensors in the automotive industry. Additionally, the healthcare sector is emerging as a promising market for acoustic wave sensors, with applications in medical diagnostics, drug discovery, and biosensing.

Geographically, North America and Europe currently dominate the acoustic wave sensor market, owing to their advanced technological infrastructure and early adoption of innovative sensing solutions. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing investments in healthcare and environmental monitoring technologies.

The market landscape is characterized by intense competition among key players, including Honeywell International Inc., Siemens AG, Raytheon Technologies Corporation, and Broadcom Inc. These companies are focusing on research and development activities to enhance sensor performance, reduce costs, and expand their product portfolios. Collaborations and partnerships with technology providers and end-users are also becoming increasingly common as companies seek to strengthen their market positions and address evolving customer needs.

Despite the positive growth outlook, the acoustic wave sensor market faces challenges such as high initial costs and technical complexities associated with sensor integration. However, ongoing technological advancements, including the development of miniaturized sensors and improved signal processing techniques, are expected to address these challenges and further drive market growth in the coming years.

Acoustic Wave Sensor Challenges

Acoustic wave-based piezoelectric sensors face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the sensitivity to environmental factors, particularly temperature fluctuations. These sensors often exhibit temperature-dependent frequency shifts, which can lead to inaccurate measurements and reduced reliability in real-world applications. Developing compensation techniques or materials with improved temperature stability remains an ongoing challenge.

Another critical hurdle is the need for improved selectivity and specificity. In complex environments with multiple analytes, acoustic wave sensors may struggle to distinguish between target molecules and interfering substances. This limitation can result in false positives or negatives, compromising the sensor's effectiveness in fields such as medical diagnostics and environmental monitoring.

Miniaturization presents both opportunities and challenges for acoustic wave sensors. While smaller devices offer advantages in portability and integration, reducing sensor size can lead to decreased sensitivity and signal-to-noise ratio. Balancing these factors to create compact yet high-performance sensors is a significant engineering challenge.

The fabrication process for acoustic wave sensors also poses difficulties. Achieving consistent and reproducible sensor performance requires precise control over material properties and device geometry. Variations in manufacturing can lead to discrepancies in sensor behavior, making large-scale production and quality control challenging.

Power consumption is another area of concern, particularly for wireless and portable applications. Reducing the energy requirements of acoustic wave sensors while maintaining their performance is crucial for extending battery life and enabling long-term deployment in remote or inaccessible locations.

Durability and longevity of acoustic wave sensors in harsh environments remain significant challenges. Exposure to corrosive chemicals, high humidity, or extreme temperatures can degrade sensor performance over time. Developing robust packaging and protective coatings that do not interfere with sensor operation is an ongoing area of research.

Integration with other sensing modalities and electronic systems presents both technical and standardization challenges. Ensuring compatibility with existing technologies and developing efficient data processing algorithms are essential for realizing the full potential of acoustic wave sensors in complex sensing systems.

Lastly, the cost of production and implementation remains a barrier to widespread adoption in some applications. Developing more cost-effective manufacturing processes and materials without compromising sensor performance is crucial for expanding the use of acoustic wave-based piezoelectric sensors across various industries.

Another critical hurdle is the need for improved selectivity and specificity. In complex environments with multiple analytes, acoustic wave sensors may struggle to distinguish between target molecules and interfering substances. This limitation can result in false positives or negatives, compromising the sensor's effectiveness in fields such as medical diagnostics and environmental monitoring.

Miniaturization presents both opportunities and challenges for acoustic wave sensors. While smaller devices offer advantages in portability and integration, reducing sensor size can lead to decreased sensitivity and signal-to-noise ratio. Balancing these factors to create compact yet high-performance sensors is a significant engineering challenge.

The fabrication process for acoustic wave sensors also poses difficulties. Achieving consistent and reproducible sensor performance requires precise control over material properties and device geometry. Variations in manufacturing can lead to discrepancies in sensor behavior, making large-scale production and quality control challenging.

Power consumption is another area of concern, particularly for wireless and portable applications. Reducing the energy requirements of acoustic wave sensors while maintaining their performance is crucial for extending battery life and enabling long-term deployment in remote or inaccessible locations.

Durability and longevity of acoustic wave sensors in harsh environments remain significant challenges. Exposure to corrosive chemicals, high humidity, or extreme temperatures can degrade sensor performance over time. Developing robust packaging and protective coatings that do not interfere with sensor operation is an ongoing area of research.

Integration with other sensing modalities and electronic systems presents both technical and standardization challenges. Ensuring compatibility with existing technologies and developing efficient data processing algorithms are essential for realizing the full potential of acoustic wave sensors in complex sensing systems.

Lastly, the cost of production and implementation remains a barrier to widespread adoption in some applications. Developing more cost-effective manufacturing processes and materials without compromising sensor performance is crucial for expanding the use of acoustic wave-based piezoelectric sensors across various industries.

Current Acoustic Wave Sensing Solutions

01 Piezoelectric sensor design and structure

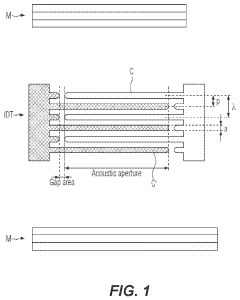

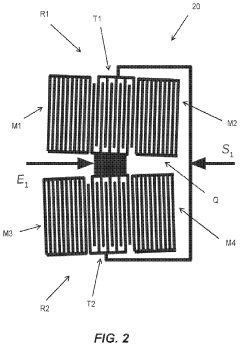

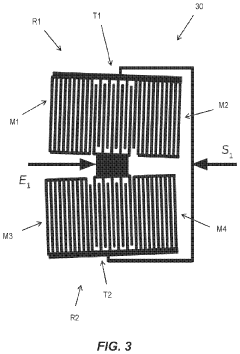

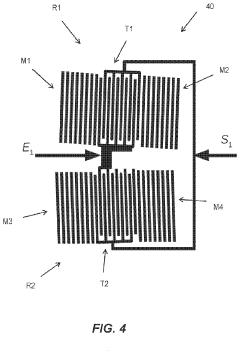

Acoustic wave-based piezoelectric sensors utilize specific designs and structures to enhance sensitivity and performance. These may include optimized electrode configurations, substrate materials, and resonator geometries. The sensors can be designed as surface acoustic wave (SAW) or bulk acoustic wave (BAW) devices, each with unique characteristics for different applications.- Piezoelectric sensor design and structure: Acoustic wave-based piezoelectric sensors utilize specific designs and structures to enhance sensitivity and performance. These may include optimized electrode configurations, substrate materials, and resonator geometries. Advanced designs can incorporate multiple layers or arrays of piezoelectric elements to improve detection capabilities and frequency response.

- Signal processing and noise reduction techniques: Various signal processing methods are employed to enhance the performance of acoustic wave-based piezoelectric sensors. These techniques may include digital filtering, adaptive noise cancellation, and advanced algorithms for signal extraction. Such methods improve the sensor's ability to detect weak signals in noisy environments and increase overall sensitivity.

- Integration with other sensing technologies: Acoustic wave-based piezoelectric sensors can be integrated with other sensing technologies to create multi-modal sensing systems. This integration may involve combining piezoelectric sensors with MEMS devices, optical sensors, or other types of transducers. Such hybrid systems can provide more comprehensive and accurate measurements in various applications.

- Application-specific sensor designs: Piezoelectric sensors based on acoustic waves are tailored for specific applications such as biomedical sensing, environmental monitoring, and industrial process control. These specialized designs may incorporate unique materials, geometries, or operating frequencies to optimize performance for the intended use case.

- Fabrication and manufacturing techniques: Advanced fabrication methods are crucial for producing high-performance acoustic wave-based piezoelectric sensors. These techniques may include precision deposition of piezoelectric materials, microfabrication processes, and novel bonding methods. Improved manufacturing processes can lead to sensors with better uniformity, reliability, and cost-effectiveness.

02 Frequency control and signal processing

Advanced frequency control techniques and signal processing methods are employed to improve the accuracy and reliability of acoustic wave-based piezoelectric sensors. This includes the use of phase-locked loops, frequency synthesizers, and digital signal processing algorithms to extract meaningful data from the sensor output and reduce noise.Expand Specific Solutions03 Integration with MEMS technology

Acoustic wave-based piezoelectric sensors are increasingly integrated with Micro-Electro-Mechanical Systems (MEMS) technology. This integration allows for miniaturization, improved performance, and the development of multi-functional sensing platforms. MEMS-based piezoelectric sensors can be used in various applications, including pressure sensing, accelerometers, and chemical detection.Expand Specific Solutions04 Environmental and biomedical applications

Acoustic wave-based piezoelectric sensors find applications in environmental monitoring and biomedical fields. These sensors can detect various analytes, measure physical parameters, and monitor biological processes. They are used in gas sensing, liquid analysis, and biosensors for medical diagnostics and environmental monitoring.Expand Specific Solutions05 Wireless and energy harvesting capabilities

Recent developments in acoustic wave-based piezoelectric sensors include wireless operation and energy harvesting features. These advancements enable remote sensing applications and self-powered operation, making the sensors suitable for use in hard-to-reach locations or in scenarios where frequent battery replacement is impractical.Expand Specific Solutions

Acoustic Sensor Industry Leaders

The acoustic wave-based piezoelectric sensor market is in a growth phase, driven by increasing demand for high-precision sensing technologies across various industries. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Honeywell International Technologies Ltd., Soitec SA, and MACOM Technology Solutions Holdings, Inc. leading innovation. These firms are developing more sensitive, miniaturized, and versatile sensors. Academic institutions such as Xi'an Jiaotong University and the Industrial Technology Research Institute are contributing to fundamental research, pushing the boundaries of piezoelectric materials and sensor designs. The collaboration between industry and academia is accelerating the technology's maturation, promising enhanced performance and new applications in sectors ranging from healthcare to industrial automation.

Chinese Academy of Sciences Institute of Acoustics

Technical Solution: The Chinese Academy of Sciences Institute of Acoustics has made significant advancements in acoustic wave-based piezoelectric sensors through their research on novel materials and device structures. They have developed high-performance sensors using lithium niobate (LiNbO3) and aluminum nitride (AlN) thin films, which offer excellent piezoelectric properties[1][4]. The institute has also pioneered the use of phononic crystals in sensor design, creating acoustic wave guides that enhance sensor sensitivity and selectivity[2]. Their innovations include the development of flexible piezoelectric sensors using organic materials, opening up new applications in wearable technology and soft robotics[3][6]. Additionally, the institute has made progress in integrating these sensors with wireless communication systems for remote sensing applications[5].

Strengths: Cutting-edge materials research, innovative device structures, wide range of potential applications. Weaknesses: Some technologies may still be in early stages of development, potential challenges in mass production.

Industrial Technology Research Institute

Technical Solution: The Industrial Technology Research Institute (ITRI) has made significant contributions to acoustic wave-based piezoelectric sensor technology through their interdisciplinary research approach. ITRI has developed novel sensor designs that utilize shear horizontal surface acoustic waves (SH-SAW) for enhanced sensitivity in liquid environments[1][3]. They have also pioneered the use of composite piezoelectric materials, combining different materials to optimize sensor performance for specific applications[2]. ITRI's innovations include the development of temperature-compensated sensors that maintain accuracy across a wide range of operating conditions[4]. Additionally, they have made advancements in sensor packaging and integration, creating robust solutions for harsh industrial environments[5]. ITRI has also focused on developing low-cost fabrication techniques to make these advanced sensors more accessible for widespread adoption[6].

Strengths: Interdisciplinary approach, focus on practical applications, advancements in sensor robustness. Weaknesses: May face challenges in competing with large multinational corporations in terms of resources and market reach.

Key Piezoelectric Sensor Innovations

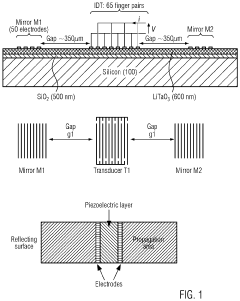

Two-port acoustic wave sensor device

PatentPendingUS20240154603A1

Innovation

- A two-port acoustic wave sensor device with a quartz material layer featuring a specific crystal cut and tilted transducer configuration, utilizing Bragg mirrors and reflection structures to enhance signal propagation and resonance frequency differences, thereby improving measurement accuracy and reliability.

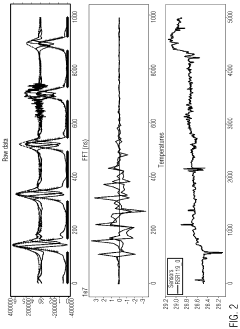

Acoustic wave sensor and interrogation of the same

PatentActiveUS20220173721A1

Innovation

- A method and system for interrogating acoustic wave sensors that process received response radiofrequency signals in both time and frequency domains, determining in-phase and quadrature components, and excising defective frames based on predetermined thresholds to improve signal quality and account for sensor motion.

Piezoelectric Material Advancements

Piezoelectric materials have undergone significant advancements in recent years, particularly in the context of acoustic wave-based sensors. These materials, which convert mechanical stress into electrical signals and vice versa, form the foundation of many sensing technologies. The evolution of piezoelectric materials has been driven by the need for improved sensitivity, stability, and performance in diverse applications.

One of the key areas of progress has been the development of new piezoelectric compositions. Traditional materials like quartz and lead zirconate titanate (PZT) are being complemented by novel compounds that offer enhanced properties. For instance, relaxor-based ferroelectric single crystals, such as PMN-PT (lead magnesium niobate-lead titanate), have shown exceptional piezoelectric coefficients and electromechanical coupling factors. These materials enable the creation of sensors with higher sensitivity and broader bandwidth.

Nanostructured piezoelectric materials have also emerged as a promising avenue for advancement. By manipulating the material at the nanoscale, researchers have achieved improved electromechanical properties and increased surface-to-volume ratios. Piezoelectric nanowires, nanofibers, and nanocomposites have demonstrated enhanced sensing capabilities due to their unique structural characteristics. These nanostructures allow for the fabrication of highly sensitive and miniaturized acoustic wave sensors.

Another significant development has been the pursuit of lead-free piezoelectric materials. Environmental concerns and regulatory pressures have driven research into alternatives to lead-based piezoelectrics. Materials such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) have shown promising piezoelectric properties while addressing the need for eco-friendly solutions. These lead-free options are becoming increasingly viable for acoustic wave sensor applications.

The integration of piezoelectric materials with flexible substrates has opened up new possibilities for wearable and conformable sensors. Thin-film deposition techniques and innovative material processing methods have enabled the creation of bendable and stretchable piezoelectric devices. These flexible sensors can adapt to complex geometries and maintain their performance under deformation, making them suitable for a wide range of applications, from healthcare monitoring to structural health assessment.

Advancements in piezoelectric material design have also focused on improving temperature stability and reducing aging effects. This has led to the development of engineered domain structures and doping strategies that enhance the long-term reliability of acoustic wave sensors. By mitigating temperature-induced variations and minimizing performance degradation over time, these improvements contribute to more robust and dependable sensing systems.

One of the key areas of progress has been the development of new piezoelectric compositions. Traditional materials like quartz and lead zirconate titanate (PZT) are being complemented by novel compounds that offer enhanced properties. For instance, relaxor-based ferroelectric single crystals, such as PMN-PT (lead magnesium niobate-lead titanate), have shown exceptional piezoelectric coefficients and electromechanical coupling factors. These materials enable the creation of sensors with higher sensitivity and broader bandwidth.

Nanostructured piezoelectric materials have also emerged as a promising avenue for advancement. By manipulating the material at the nanoscale, researchers have achieved improved electromechanical properties and increased surface-to-volume ratios. Piezoelectric nanowires, nanofibers, and nanocomposites have demonstrated enhanced sensing capabilities due to their unique structural characteristics. These nanostructures allow for the fabrication of highly sensitive and miniaturized acoustic wave sensors.

Another significant development has been the pursuit of lead-free piezoelectric materials. Environmental concerns and regulatory pressures have driven research into alternatives to lead-based piezoelectrics. Materials such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) have shown promising piezoelectric properties while addressing the need for eco-friendly solutions. These lead-free options are becoming increasingly viable for acoustic wave sensor applications.

The integration of piezoelectric materials with flexible substrates has opened up new possibilities for wearable and conformable sensors. Thin-film deposition techniques and innovative material processing methods have enabled the creation of bendable and stretchable piezoelectric devices. These flexible sensors can adapt to complex geometries and maintain their performance under deformation, making them suitable for a wide range of applications, from healthcare monitoring to structural health assessment.

Advancements in piezoelectric material design have also focused on improving temperature stability and reducing aging effects. This has led to the development of engineered domain structures and doping strategies that enhance the long-term reliability of acoustic wave sensors. By mitigating temperature-induced variations and minimizing performance degradation over time, these improvements contribute to more robust and dependable sensing systems.

Acoustic Wave Sensor Applications

Acoustic wave sensors have found widespread applications across various industries due to their unique properties and versatility. In the field of environmental monitoring, these sensors play a crucial role in detecting air and water pollutants with high sensitivity and accuracy. They are particularly effective in measuring particulate matter, volatile organic compounds, and heavy metals in real-time, enabling rapid response to environmental hazards.

In the healthcare sector, acoustic wave sensors have revolutionized point-of-care diagnostics. These sensors can detect biomarkers associated with various diseases, including cancer and infectious diseases, at extremely low concentrations. Their ability to provide quick and accurate results has made them invaluable in early disease detection and monitoring.

The automotive industry has embraced acoustic wave sensors for tire pressure monitoring systems and engine diagnostics. These sensors offer improved reliability and durability compared to traditional pressure sensors, contributing to enhanced vehicle safety and performance. Additionally, they are being explored for advanced driver assistance systems, particularly in detecting obstacles and improving parking assistance technologies.

In the realm of industrial process control, acoustic wave sensors have proven indispensable for monitoring viscosity, density, and temperature of fluids in real-time. This capability allows for precise control of manufacturing processes, leading to improved product quality and reduced waste. The sensors' resistance to harsh environments makes them particularly suitable for use in chemical and petrochemical industries.

The telecommunications sector utilizes acoustic wave sensors in frequency control applications, such as in mobile phones and base stations. These sensors provide stable frequency references, essential for maintaining signal quality and network synchronization. Their compact size and low power consumption make them ideal for integration into modern communication devices.

In the field of security and defense, acoustic wave sensors are employed in chemical and biological warfare agent detection systems. Their high sensitivity and rapid response time enable early warning in potentially hazardous environments. Furthermore, these sensors are being developed for use in explosive detection at airports and other high-security areas, enhancing public safety measures.

The food and beverage industry has also benefited from acoustic wave sensor technology. These sensors are used for quality control, detecting contaminants, and monitoring fermentation processes. Their non-invasive nature allows for continuous monitoring without compromising product integrity, ensuring food safety and consistency.

In the healthcare sector, acoustic wave sensors have revolutionized point-of-care diagnostics. These sensors can detect biomarkers associated with various diseases, including cancer and infectious diseases, at extremely low concentrations. Their ability to provide quick and accurate results has made them invaluable in early disease detection and monitoring.

The automotive industry has embraced acoustic wave sensors for tire pressure monitoring systems and engine diagnostics. These sensors offer improved reliability and durability compared to traditional pressure sensors, contributing to enhanced vehicle safety and performance. Additionally, they are being explored for advanced driver assistance systems, particularly in detecting obstacles and improving parking assistance technologies.

In the realm of industrial process control, acoustic wave sensors have proven indispensable for monitoring viscosity, density, and temperature of fluids in real-time. This capability allows for precise control of manufacturing processes, leading to improved product quality and reduced waste. The sensors' resistance to harsh environments makes them particularly suitable for use in chemical and petrochemical industries.

The telecommunications sector utilizes acoustic wave sensors in frequency control applications, such as in mobile phones and base stations. These sensors provide stable frequency references, essential for maintaining signal quality and network synchronization. Their compact size and low power consumption make them ideal for integration into modern communication devices.

In the field of security and defense, acoustic wave sensors are employed in chemical and biological warfare agent detection systems. Their high sensitivity and rapid response time enable early warning in potentially hazardous environments. Furthermore, these sensors are being developed for use in explosive detection at airports and other high-security areas, enhancing public safety measures.

The food and beverage industry has also benefited from acoustic wave sensor technology. These sensors are used for quality control, detecting contaminants, and monitoring fermentation processes. Their non-invasive nature allows for continuous monitoring without compromising product integrity, ensuring food safety and consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!