Innovations in Nichrome for Cutting-Edge Thermocouples

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Thermocouple Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in thermocouple technology since its inception in the early 20th century. The evolution of nichrome thermocouples has been driven by the increasing demand for more accurate, stable, and durable temperature measurement devices across various industries.

Initially, nichrome was primarily used in heating elements due to its high electrical resistance and oxidation resistance. However, its unique properties soon found application in thermocouple technology. The first nichrome thermocouples were relatively simple, offering moderate accuracy and limited temperature range. As industrial processes became more sophisticated, the need for more precise temperature measurements grew, spurring further development of nichrome-based thermocouples.

Throughout the mid-20th century, significant advancements were made in nichrome alloy composition and manufacturing processes. These improvements led to enhanced thermoelectric properties, increased stability at higher temperatures, and improved longevity. The introduction of various grades of nichrome, each tailored for specific temperature ranges and environmental conditions, marked a significant milestone in thermocouple technology.

In recent decades, the focus has shifted towards developing cutting-edge nichrome thermocouples that can meet the demands of emerging industries such as aerospace, semiconductor manufacturing, and advanced materials processing. These applications require thermocouples capable of operating in extreme conditions, including ultra-high temperatures, corrosive environments, and rapid thermal cycling.

The current objectives in nichrome thermocouple innovation are multifaceted. Researchers and engineers are striving to push the boundaries of temperature measurement range, aiming to develop thermocouples that can accurately measure temperatures beyond 1300°C while maintaining long-term stability. Another key goal is to enhance the response time of nichrome thermocouples, enabling more precise control in rapidly changing thermal environments.

Additionally, there is a growing emphasis on miniaturization and flexibility in thermocouple design. This trend is driven by the need for non-intrusive temperature measurement in compact systems and the integration of thermocouples into smart manufacturing processes. Researchers are exploring novel nichrome alloy compositions and innovative fabrication techniques to achieve these objectives.

Furthermore, the development of self-diagnostic and self-calibrating nichrome thermocouples is an emerging area of focus. These advanced thermocouples aim to reduce maintenance requirements and improve reliability in critical applications where continuous, accurate temperature monitoring is essential.

As we look to the future, the evolution of nichrome thermocouples is expected to continue, with a focus on addressing the challenges posed by Industry 4.0 and the increasing complexity of thermal management in various technological domains. The ultimate goal is to develop nichrome-based thermocouples that offer unparalleled accuracy, durability, and versatility across an ever-expanding range of applications.

Initially, nichrome was primarily used in heating elements due to its high electrical resistance and oxidation resistance. However, its unique properties soon found application in thermocouple technology. The first nichrome thermocouples were relatively simple, offering moderate accuracy and limited temperature range. As industrial processes became more sophisticated, the need for more precise temperature measurements grew, spurring further development of nichrome-based thermocouples.

Throughout the mid-20th century, significant advancements were made in nichrome alloy composition and manufacturing processes. These improvements led to enhanced thermoelectric properties, increased stability at higher temperatures, and improved longevity. The introduction of various grades of nichrome, each tailored for specific temperature ranges and environmental conditions, marked a significant milestone in thermocouple technology.

In recent decades, the focus has shifted towards developing cutting-edge nichrome thermocouples that can meet the demands of emerging industries such as aerospace, semiconductor manufacturing, and advanced materials processing. These applications require thermocouples capable of operating in extreme conditions, including ultra-high temperatures, corrosive environments, and rapid thermal cycling.

The current objectives in nichrome thermocouple innovation are multifaceted. Researchers and engineers are striving to push the boundaries of temperature measurement range, aiming to develop thermocouples that can accurately measure temperatures beyond 1300°C while maintaining long-term stability. Another key goal is to enhance the response time of nichrome thermocouples, enabling more precise control in rapidly changing thermal environments.

Additionally, there is a growing emphasis on miniaturization and flexibility in thermocouple design. This trend is driven by the need for non-intrusive temperature measurement in compact systems and the integration of thermocouples into smart manufacturing processes. Researchers are exploring novel nichrome alloy compositions and innovative fabrication techniques to achieve these objectives.

Furthermore, the development of self-diagnostic and self-calibrating nichrome thermocouples is an emerging area of focus. These advanced thermocouples aim to reduce maintenance requirements and improve reliability in critical applications where continuous, accurate temperature monitoring is essential.

As we look to the future, the evolution of nichrome thermocouples is expected to continue, with a focus on addressing the challenges posed by Industry 4.0 and the increasing complexity of thermal management in various technological domains. The ultimate goal is to develop nichrome-based thermocouples that offer unparalleled accuracy, durability, and versatility across an ever-expanding range of applications.

Market Analysis for Advanced Thermocouples

The advanced thermocouple market is experiencing significant growth driven by increasing demand for precise temperature measurement across various industries. The global thermocouple market size was valued at $1.6 billion in 2020 and is projected to reach $2.3 billion by 2027, growing at a CAGR of 5.2% during the forecast period. This growth is primarily attributed to the expanding applications of thermocouples in automotive, aerospace, energy, and industrial sectors.

In the automotive industry, the adoption of advanced thermocouples is rising due to stringent emission regulations and the need for improved engine performance monitoring. The aerospace sector is another key driver, with thermocouples being essential for monitoring critical temperatures in aircraft engines and systems. The energy sector, particularly in power generation and oil & gas industries, relies heavily on thermocouples for process control and safety applications.

The industrial sector, including manufacturing, chemical processing, and food & beverage industries, represents a significant market for advanced thermocouples. These industries require high-precision temperature measurement for quality control, process optimization, and compliance with regulatory standards. The growing emphasis on Industry 4.0 and smart manufacturing is further boosting the demand for advanced thermocouples integrated with IoT and data analytics capabilities.

Geographically, North America and Europe are the leading markets for advanced thermocouples, owing to their well-established industrial base and technological advancements. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing investments in aerospace and energy sectors.

The market for nichrome-based thermocouples, specifically, is showing promising growth prospects. Nichrome alloys offer excellent stability, high temperature resistance, and good thermoelectric properties, making them ideal for cutting-edge thermocouple applications. The innovations in nichrome composition and manufacturing techniques are enabling the development of thermocouples with enhanced accuracy, durability, and response times.

Key market trends include the miniaturization of thermocouples for use in compact electronic devices and medical equipment, the development of wireless and smart thermocouples for remote monitoring applications, and the integration of advanced materials to extend the temperature range and longevity of thermocouples. These trends are opening new opportunities for market players and driving further innovation in the field.

In the automotive industry, the adoption of advanced thermocouples is rising due to stringent emission regulations and the need for improved engine performance monitoring. The aerospace sector is another key driver, with thermocouples being essential for monitoring critical temperatures in aircraft engines and systems. The energy sector, particularly in power generation and oil & gas industries, relies heavily on thermocouples for process control and safety applications.

The industrial sector, including manufacturing, chemical processing, and food & beverage industries, represents a significant market for advanced thermocouples. These industries require high-precision temperature measurement for quality control, process optimization, and compliance with regulatory standards. The growing emphasis on Industry 4.0 and smart manufacturing is further boosting the demand for advanced thermocouples integrated with IoT and data analytics capabilities.

Geographically, North America and Europe are the leading markets for advanced thermocouples, owing to their well-established industrial base and technological advancements. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and growing investments in aerospace and energy sectors.

The market for nichrome-based thermocouples, specifically, is showing promising growth prospects. Nichrome alloys offer excellent stability, high temperature resistance, and good thermoelectric properties, making them ideal for cutting-edge thermocouple applications. The innovations in nichrome composition and manufacturing techniques are enabling the development of thermocouples with enhanced accuracy, durability, and response times.

Key market trends include the miniaturization of thermocouples for use in compact electronic devices and medical equipment, the development of wireless and smart thermocouples for remote monitoring applications, and the integration of advanced materials to extend the temperature range and longevity of thermocouples. These trends are opening new opportunities for market players and driving further innovation in the field.

Nichrome Thermocouple Technology Landscape

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in thermocouple technology for decades. Its unique properties, including high electrical resistivity and excellent temperature stability, have made it an ideal material for temperature sensing applications. The evolution of nichrome in thermocouples has been marked by continuous improvements in composition, manufacturing processes, and application techniques.

The development of nichrome for thermocouples can be traced back to the early 20th century when the need for accurate temperature measurement in industrial processes became increasingly critical. Initially, the focus was on achieving a stable alloy composition that could withstand high temperatures while maintaining consistent electrical properties. Over time, researchers and engineers have refined the nickel-chromium ratio and introduced trace elements to enhance performance characteristics.

In recent years, the landscape of nichrome thermocouple technology has been shaped by several key innovations. One significant advancement has been the development of nano-structured nichrome materials. These materials exhibit enhanced thermoelectric properties, resulting in improved sensitivity and faster response times. The use of nanotechnology has also led to the creation of thin-film nichrome thermocouples, which offer superior performance in miniaturized applications.

Another notable trend in the nichrome thermocouple technology landscape is the integration of smart features. Modern thermocouples incorporating nichrome elements are now being equipped with built-in signal processing capabilities, wireless connectivity, and self-diagnostic functions. This integration allows for real-time temperature monitoring, remote data access, and predictive maintenance, significantly enhancing the utility of these devices across various industries.

The push for higher temperature capabilities has also driven innovations in nichrome thermocouple technology. Advanced manufacturing techniques, such as powder metallurgy and precision alloying, have enabled the production of nichrome alloys capable of operating at temperatures exceeding 1200°C. These high-temperature variants find applications in aerospace, nuclear power, and advanced materials processing sectors.

Environmental considerations have also influenced the nichrome thermocouple landscape. Efforts are underway to develop lead-free nichrome alloys that maintain the desirable properties of traditional compositions while complying with stringent environmental regulations. Additionally, research into recyclable and sustainable manufacturing processes for nichrome thermocouples is gaining traction, aligning with global sustainability goals.

The development of nichrome for thermocouples can be traced back to the early 20th century when the need for accurate temperature measurement in industrial processes became increasingly critical. Initially, the focus was on achieving a stable alloy composition that could withstand high temperatures while maintaining consistent electrical properties. Over time, researchers and engineers have refined the nickel-chromium ratio and introduced trace elements to enhance performance characteristics.

In recent years, the landscape of nichrome thermocouple technology has been shaped by several key innovations. One significant advancement has been the development of nano-structured nichrome materials. These materials exhibit enhanced thermoelectric properties, resulting in improved sensitivity and faster response times. The use of nanotechnology has also led to the creation of thin-film nichrome thermocouples, which offer superior performance in miniaturized applications.

Another notable trend in the nichrome thermocouple technology landscape is the integration of smart features. Modern thermocouples incorporating nichrome elements are now being equipped with built-in signal processing capabilities, wireless connectivity, and self-diagnostic functions. This integration allows for real-time temperature monitoring, remote data access, and predictive maintenance, significantly enhancing the utility of these devices across various industries.

The push for higher temperature capabilities has also driven innovations in nichrome thermocouple technology. Advanced manufacturing techniques, such as powder metallurgy and precision alloying, have enabled the production of nichrome alloys capable of operating at temperatures exceeding 1200°C. These high-temperature variants find applications in aerospace, nuclear power, and advanced materials processing sectors.

Environmental considerations have also influenced the nichrome thermocouple landscape. Efforts are underway to develop lead-free nichrome alloys that maintain the desirable properties of traditional compositions while complying with stringent environmental regulations. Additionally, research into recyclable and sustainable manufacturing processes for nichrome thermocouples is gaining traction, aligning with global sustainability goals.

Current Nichrome Thermocouple Designs

01 Nichrome wire cutting devices

Cutting devices utilizing nichrome wire for precise and efficient cutting of various materials. These devices often incorporate heating elements to enhance cutting performance and may be used in applications such as foam cutting, plastic cutting, or food processing.- Nichrome wire cutting devices: Cutting devices utilizing nichrome wire for precise and efficient cutting of various materials. These devices often incorporate heating elements to enhance cutting performance and may be used in applications such as foam cutting, plastic cutting, or food processing.

- Nichrome alloy composition and properties: Specific compositions and properties of nichrome alloys used in cutting-edge applications. These alloys are designed to provide high resistance, durability, and heat tolerance, making them suitable for use in cutting tools and heating elements.

- Nichrome-based heating elements: Heating elements made from nichrome wire or alloys, used in various cutting and heating applications. These elements are designed to provide uniform and controlled heat distribution, making them ideal for precision cutting and thermal processing.

- Nichrome wire in medical cutting devices: Application of nichrome wire in medical cutting devices, such as surgical tools or biopsy instruments. These devices utilize the properties of nichrome to achieve precise and controlled cutting in medical procedures.

- Manufacturing processes for nichrome cutting edges: Specialized manufacturing processes for producing nichrome cutting edges with enhanced performance characteristics. These processes may involve specific heat treatments, shaping techniques, or surface modifications to optimize the cutting properties of nichrome alloys.

02 Nichrome alloy composition and properties

Specific compositions and properties of nichrome alloys used in cutting-edge applications. These alloys are designed to provide high resistance, durability, and heat tolerance, making them suitable for use in cutting tools and heating elements.Expand Specific Solutions03 Nichrome-based heating elements

Heating elements made from nichrome wire or alloys, used in various applications such as industrial heating, domestic appliances, and scientific instruments. These elements provide efficient and controlled heating for cutting or other thermal processes.Expand Specific Solutions04 Nichrome wire in surgical instruments

Application of nichrome wire in surgical cutting instruments, providing precise and controlled cutting in medical procedures. These instruments may incorporate features such as adjustable temperature control and specialized coatings for improved performance.Expand Specific Solutions05 Nichrome-based sensors and actuators

Utilization of nichrome in sensors and actuators for various applications, including temperature sensing, flow measurement, and micro-electromechanical systems (MEMS). The unique properties of nichrome allow for accurate and responsive sensing and actuation in diverse environments.Expand Specific Solutions

Key Manufacturers in Thermocouple Industry

The market for innovative nichrome-based thermocouples is in a growth phase, driven by increasing demand for high-precision temperature measurement in various industries. The global thermocouple market size is projected to expand significantly, with a CAGR of around 6% over the next five years. Technologically, nichrome thermocouples are advancing rapidly, with companies like Xi'an Thermal Power Research Institute, Okazaki Manufacturing, and Topcon Corp leading innovations. These firms are developing more accurate, durable, and versatile thermocouple designs, incorporating advanced materials and manufacturing techniques. The competitive landscape is diverse, with established players and emerging startups vying for market share through R&D investments and strategic partnerships.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed advanced nichrome-based thermocouples for high-temperature applications in thermal power plants. Their innovation focuses on improving the stability and longevity of thermocouples in extreme environments. The institute has implemented a proprietary alloying process that enhances the oxidation resistance of nichrome wires, resulting in thermocouples that can maintain accuracy at temperatures up to 1300°C for extended periods[1]. Additionally, they have developed a unique protective sheath coating that further extends the lifespan of the thermocouples in corrosive environments commonly found in power generation facilities[2].

Strengths: Excellent high-temperature stability and longevity, specifically tailored for power plant environments. Weaknesses: May be less cost-effective for lower temperature applications, limited versatility outside of thermal power industry.

Okazaki Manufacturing Co.

Technical Solution: Okazaki Manufacturing Co. has pioneered the development of ultra-thin nichrome wire thermocouples for precision temperature measurement in miniaturized devices. Their innovative approach involves a proprietary drawing process that produces nichrome wires as thin as 0.01 mm in diameter while maintaining uniform composition and electrical properties[3]. These micro-thermocouples offer rapid response times, typically under 0.1 seconds, making them ideal for dynamic temperature monitoring in microelectronics and medical devices. Okazaki has also developed a unique insulation technique using nano-ceramic coatings, which allows for high-density thermocouple arrays without signal interference[4].

Strengths: Unparalleled miniaturization capabilities, fast response times, suitable for high-density applications. Weaknesses: Higher production costs, potentially more fragile than standard thermocouples.

Breakthrough Nichrome Alloy Compositions

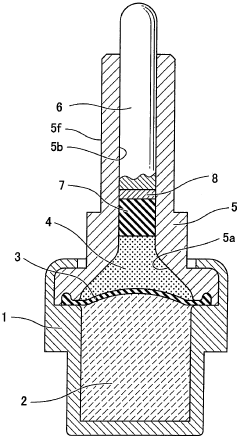

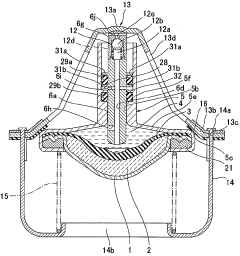

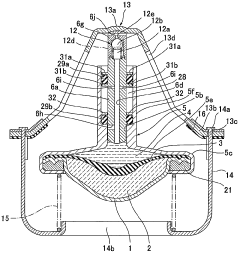

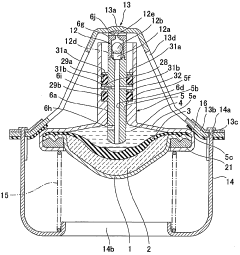

thermocouple and thermostat

PatentInactiveDE102012108693A1

Innovation

- Incorporation of a check valve within the piston to allow fluid flow in one direction and prevent leakage, using a deformable incompressible fluid with better fluidity, such as oil, and eliminating the need for hermetic sealing, allowing for a larger liquid chamber and reduced shape restrictions.

Thermocouple Calibration Standards

Thermocouple calibration standards play a crucial role in ensuring the accuracy and reliability of temperature measurements across various industries. These standards are meticulously developed and maintained to provide a consistent reference point for calibrating thermocouples, which are essential components in many temperature measurement applications. The International Temperature Scale of 1990 (ITS-90) serves as the foundation for modern thermocouple calibration standards, providing a unified framework for temperature measurements worldwide.

Calibration standards for thermocouples are typically established and maintained by national metrology institutes, such as the National Institute of Standards and Technology (NIST) in the United States or the National Physical Laboratory (NPL) in the United Kingdom. These institutions develop and disseminate primary standards, which are used to calibrate secondary standards and working standards used in industry and research laboratories.

The calibration process involves comparing the output of a thermocouple under test to a reference standard at various temperature points. This comparison allows for the determination of errors and uncertainties in the thermocouple's performance. The calibration data is then used to generate correction factors or calibration curves, which can be applied to improve the accuracy of temperature measurements in practical applications.

Thermocouple calibration standards encompass a range of temperature points and reference materials. Fixed points, such as the freezing or melting points of pure metals, are commonly used as they provide highly stable and reproducible temperature references. For example, the freezing point of pure zinc (419.527°C) and the melting point of pure gold (1064.18°C) are widely used fixed points in thermocouple calibration.

In addition to fixed points, calibration standards also include interpolation instruments and techniques. These allow for accurate temperature measurements between fixed points, ensuring comprehensive coverage across the entire operating range of thermocouples. Precision resistance thermometers, such as standard platinum resistance thermometers (SPRTs), are often used as interpolation instruments due to their high accuracy and stability.

The development of thermocouple calibration standards is an ongoing process, with continuous efforts to improve accuracy, extend temperature ranges, and address emerging technological needs. Innovations in materials science, measurement techniques, and data analysis contribute to the evolution of these standards, ensuring that they remain relevant and effective in supporting advanced temperature measurement applications.

Calibration standards for thermocouples are typically established and maintained by national metrology institutes, such as the National Institute of Standards and Technology (NIST) in the United States or the National Physical Laboratory (NPL) in the United Kingdom. These institutions develop and disseminate primary standards, which are used to calibrate secondary standards and working standards used in industry and research laboratories.

The calibration process involves comparing the output of a thermocouple under test to a reference standard at various temperature points. This comparison allows for the determination of errors and uncertainties in the thermocouple's performance. The calibration data is then used to generate correction factors or calibration curves, which can be applied to improve the accuracy of temperature measurements in practical applications.

Thermocouple calibration standards encompass a range of temperature points and reference materials. Fixed points, such as the freezing or melting points of pure metals, are commonly used as they provide highly stable and reproducible temperature references. For example, the freezing point of pure zinc (419.527°C) and the melting point of pure gold (1064.18°C) are widely used fixed points in thermocouple calibration.

In addition to fixed points, calibration standards also include interpolation instruments and techniques. These allow for accurate temperature measurements between fixed points, ensuring comprehensive coverage across the entire operating range of thermocouples. Precision resistance thermometers, such as standard platinum resistance thermometers (SPRTs), are often used as interpolation instruments due to their high accuracy and stability.

The development of thermocouple calibration standards is an ongoing process, with continuous efforts to improve accuracy, extend temperature ranges, and address emerging technological needs. Innovations in materials science, measurement techniques, and data analysis contribute to the evolution of these standards, ensuring that they remain relevant and effective in supporting advanced temperature measurement applications.

Environmental Impact of Nichrome Production

The production of nichrome, a crucial alloy in thermocouple technology, has significant environmental implications that warrant careful consideration. The manufacturing process involves the extraction and processing of nickel and chromium, both of which can have substantial ecological impacts. Mining operations for these metals often lead to habitat destruction, soil erosion, and water pollution. The energy-intensive smelting and refining processes contribute to greenhouse gas emissions and air pollution.

Nichrome production also generates hazardous waste materials, including heavy metals and toxic chemicals, which require proper disposal to prevent environmental contamination. The use of water in cooling and cleaning processes during manufacturing can strain local water resources and potentially lead to water pollution if not properly managed. Additionally, the transportation of raw materials and finished products contributes to carbon emissions and air pollution.

However, the industry has been making strides in mitigating these environmental impacts. Many manufacturers are implementing more sustainable practices, such as using recycled materials, improving energy efficiency in production processes, and adopting cleaner technologies. Some companies are investing in closed-loop water systems to reduce water consumption and minimize wastewater discharge. There is also a growing trend towards the development of more environmentally friendly alloys that can partially or fully replace nichrome in certain applications.

The long lifespan and recyclability of nichrome products somewhat offset the environmental costs of production. Thermocouples made with nichrome can operate for extended periods, reducing the need for frequent replacements and thus lowering the overall environmental impact over time. At the end of their lifecycle, nichrome components can be recycled, further reducing the demand for new raw materials.

As environmental regulations become more stringent globally, nichrome producers are increasingly focusing on sustainability. This includes efforts to reduce emissions, improve waste management, and enhance overall environmental performance. Some companies are exploring alternative energy sources for their manufacturing processes, such as solar or wind power, to decrease their carbon footprint.

The environmental impact of nichrome production also extends to the supply chain. Responsible sourcing of raw materials is becoming a priority, with companies seeking to ensure that their nickel and chromium are obtained from mines with good environmental practices. This shift is driving improvements in mining operations and encouraging more sustainable extraction methods throughout the industry.

Nichrome production also generates hazardous waste materials, including heavy metals and toxic chemicals, which require proper disposal to prevent environmental contamination. The use of water in cooling and cleaning processes during manufacturing can strain local water resources and potentially lead to water pollution if not properly managed. Additionally, the transportation of raw materials and finished products contributes to carbon emissions and air pollution.

However, the industry has been making strides in mitigating these environmental impacts. Many manufacturers are implementing more sustainable practices, such as using recycled materials, improving energy efficiency in production processes, and adopting cleaner technologies. Some companies are investing in closed-loop water systems to reduce water consumption and minimize wastewater discharge. There is also a growing trend towards the development of more environmentally friendly alloys that can partially or fully replace nichrome in certain applications.

The long lifespan and recyclability of nichrome products somewhat offset the environmental costs of production. Thermocouples made with nichrome can operate for extended periods, reducing the need for frequent replacements and thus lowering the overall environmental impact over time. At the end of their lifecycle, nichrome components can be recycled, further reducing the demand for new raw materials.

As environmental regulations become more stringent globally, nichrome producers are increasingly focusing on sustainability. This includes efforts to reduce emissions, improve waste management, and enhance overall environmental performance. Some companies are exploring alternative energy sources for their manufacturing processes, such as solar or wind power, to decrease their carbon footprint.

The environmental impact of nichrome production also extends to the supply chain. Responsible sourcing of raw materials is becoming a priority, with companies seeking to ensure that their nickel and chromium are obtained from mines with good environmental practices. This shift is driving improvements in mining operations and encouraging more sustainable extraction methods throughout the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!