Innovative Integration of Piezoelectric Sensors in Consumer Electronics

JUL 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Sensor Evolution and Integration Goals

Piezoelectric sensors have undergone significant evolution since their discovery in the late 19th century. Initially utilized in sonar technology during World War I, these sensors have progressively found their way into various applications, including consumer electronics. The journey from rudimentary quartz crystals to sophisticated multi-layered piezoelectric materials marks a century of technological advancement.

In recent years, the miniaturization and improved sensitivity of piezoelectric sensors have opened up new possibilities for integration into consumer electronics. The goal is to seamlessly incorporate these sensors into everyday devices, enhancing user experience and device functionality without compromising design aesthetics or increasing device bulk.

One primary objective is to develop ultra-thin, flexible piezoelectric sensors that can be integrated into the structure of electronic devices. This would allow for pressure-sensitive surfaces on smartphones, tablets, and wearables, enabling new forms of user interaction and input methods. Another aim is to improve energy harvesting capabilities, potentially using the piezoelectric effect to extend battery life in low-power devices or even create self-powered sensors for IoT applications.

Enhancing the durability and reliability of piezoelectric sensors in consumer environments is crucial. The goal is to create sensors that can withstand daily wear and tear, extreme temperatures, and exposure to various environmental factors without degradation in performance. This includes developing new materials and manufacturing processes that increase the longevity and consistency of piezoelectric components.

Integration goals also focus on expanding the sensing capabilities of piezoelectric technology. This involves developing multi-modal sensors that can detect not only pressure but also vibration, acceleration, and even sound. Such advancements could lead to more sophisticated health monitoring in wearables, improved audio capture in mobile devices, and enhanced gesture recognition in smart home products.

Another key objective is to reduce the cost and complexity of integrating piezoelectric sensors into mass-produced consumer electronics. This requires innovations in manufacturing processes, such as roll-to-roll printing of piezoelectric materials, which could significantly lower production costs and increase scalability.

Lastly, there is a push towards developing standardized interfaces and protocols for piezoelectric sensors in consumer electronics. This would facilitate easier integration across different devices and platforms, encouraging wider adoption and fostering an ecosystem of compatible applications and services.

In recent years, the miniaturization and improved sensitivity of piezoelectric sensors have opened up new possibilities for integration into consumer electronics. The goal is to seamlessly incorporate these sensors into everyday devices, enhancing user experience and device functionality without compromising design aesthetics or increasing device bulk.

One primary objective is to develop ultra-thin, flexible piezoelectric sensors that can be integrated into the structure of electronic devices. This would allow for pressure-sensitive surfaces on smartphones, tablets, and wearables, enabling new forms of user interaction and input methods. Another aim is to improve energy harvesting capabilities, potentially using the piezoelectric effect to extend battery life in low-power devices or even create self-powered sensors for IoT applications.

Enhancing the durability and reliability of piezoelectric sensors in consumer environments is crucial. The goal is to create sensors that can withstand daily wear and tear, extreme temperatures, and exposure to various environmental factors without degradation in performance. This includes developing new materials and manufacturing processes that increase the longevity and consistency of piezoelectric components.

Integration goals also focus on expanding the sensing capabilities of piezoelectric technology. This involves developing multi-modal sensors that can detect not only pressure but also vibration, acceleration, and even sound. Such advancements could lead to more sophisticated health monitoring in wearables, improved audio capture in mobile devices, and enhanced gesture recognition in smart home products.

Another key objective is to reduce the cost and complexity of integrating piezoelectric sensors into mass-produced consumer electronics. This requires innovations in manufacturing processes, such as roll-to-roll printing of piezoelectric materials, which could significantly lower production costs and increase scalability.

Lastly, there is a push towards developing standardized interfaces and protocols for piezoelectric sensors in consumer electronics. This would facilitate easier integration across different devices and platforms, encouraging wider adoption and fostering an ecosystem of compatible applications and services.

Consumer Electronics Market Demand Analysis

The consumer electronics market has witnessed a significant surge in demand for innovative and multifunctional devices, creating a fertile ground for the integration of piezoelectric sensors. This technology offers unique capabilities that align well with current consumer preferences and industry trends.

Smartphones, being the cornerstone of personal electronics, present a prime opportunity for piezoelectric sensor integration. The global smartphone market, valued at over $400 billion, continues to grow, with consumers increasingly seeking devices that offer enhanced user experiences. Piezoelectric sensors can enable advanced haptic feedback, improved touch sensitivity, and even energy harvesting capabilities, addressing the ever-present demand for longer battery life and more intuitive interfaces.

Wearable technology, another rapidly expanding segment, is projected to reach a market value exceeding $100 billion by 2025. Fitness trackers, smartwatches, and health monitoring devices can greatly benefit from piezoelectric sensors' ability to detect minute movements and pressures. This aligns with the growing health consciousness among consumers and their desire for more accurate and comprehensive biometric data.

The smart home sector, expected to surpass $150 billion by 2024, presents another significant opportunity. Piezoelectric sensors can enhance security systems, improve energy management, and enable more responsive home automation. Consumers are increasingly looking for seamless integration of technology into their living spaces, and these sensors can provide the sensitivity and reliability required for such applications.

In the automotive industry, which is rapidly embracing consumer electronics features, piezoelectric sensors can play a crucial role. With the global connected car market projected to reach $225 billion by 2027, there is a growing demand for advanced driver assistance systems, touchless controls, and improved vehicle diagnostics. Piezoelectric sensors can contribute to all these areas, enhancing safety, comfort, and user experience.

The gaming and virtual reality markets, collectively valued at over $150 billion, are also potential beneficiaries of piezoelectric sensor technology. These sensors can provide more immersive experiences through improved haptic feedback in controllers and VR equipment, meeting the demand for increasingly realistic and interactive gaming environments.

Audio equipment, including headphones and speakers, represents another significant market segment where piezoelectric sensors can make a substantial impact. With the global headphone market alone expected to exceed $20 billion by 2025, there is a clear demand for enhanced sound quality and noise-cancellation features, both areas where piezoelectric technology can excel.

In conclusion, the integration of piezoelectric sensors in consumer electronics addresses multiple market needs across various segments. From improving user interfaces and enhancing device functionality to enabling new features in smart homes and vehicles, this technology aligns well with current consumer demands for more intuitive, efficient, and feature-rich electronic products.

Smartphones, being the cornerstone of personal electronics, present a prime opportunity for piezoelectric sensor integration. The global smartphone market, valued at over $400 billion, continues to grow, with consumers increasingly seeking devices that offer enhanced user experiences. Piezoelectric sensors can enable advanced haptic feedback, improved touch sensitivity, and even energy harvesting capabilities, addressing the ever-present demand for longer battery life and more intuitive interfaces.

Wearable technology, another rapidly expanding segment, is projected to reach a market value exceeding $100 billion by 2025. Fitness trackers, smartwatches, and health monitoring devices can greatly benefit from piezoelectric sensors' ability to detect minute movements and pressures. This aligns with the growing health consciousness among consumers and their desire for more accurate and comprehensive biometric data.

The smart home sector, expected to surpass $150 billion by 2024, presents another significant opportunity. Piezoelectric sensors can enhance security systems, improve energy management, and enable more responsive home automation. Consumers are increasingly looking for seamless integration of technology into their living spaces, and these sensors can provide the sensitivity and reliability required for such applications.

In the automotive industry, which is rapidly embracing consumer electronics features, piezoelectric sensors can play a crucial role. With the global connected car market projected to reach $225 billion by 2027, there is a growing demand for advanced driver assistance systems, touchless controls, and improved vehicle diagnostics. Piezoelectric sensors can contribute to all these areas, enhancing safety, comfort, and user experience.

The gaming and virtual reality markets, collectively valued at over $150 billion, are also potential beneficiaries of piezoelectric sensor technology. These sensors can provide more immersive experiences through improved haptic feedback in controllers and VR equipment, meeting the demand for increasingly realistic and interactive gaming environments.

Audio equipment, including headphones and speakers, represents another significant market segment where piezoelectric sensors can make a substantial impact. With the global headphone market alone expected to exceed $20 billion by 2025, there is a clear demand for enhanced sound quality and noise-cancellation features, both areas where piezoelectric technology can excel.

In conclusion, the integration of piezoelectric sensors in consumer electronics addresses multiple market needs across various segments. From improving user interfaces and enhancing device functionality to enabling new features in smart homes and vehicles, this technology aligns well with current consumer demands for more intuitive, efficient, and feature-rich electronic products.

Current Challenges in Piezoelectric Sensor Integration

The integration of piezoelectric sensors in consumer electronics faces several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is miniaturization. As consumer devices continue to shrink in size, incorporating piezoelectric sensors without compromising device aesthetics or functionality becomes increasingly difficult. Engineers must develop innovative ways to reduce sensor size while maintaining sensitivity and accuracy.

Power consumption presents another major hurdle. Piezoelectric sensors require energy to operate, and in portable devices where battery life is crucial, minimizing power draw is essential. Balancing sensor performance with energy efficiency remains a complex task, often requiring trade-offs between functionality and power consumption.

Durability and reliability pose additional challenges. Consumer electronics are subjected to various environmental stresses, including temperature fluctuations, humidity, and physical impacts. Ensuring that piezoelectric sensors can withstand these conditions while maintaining consistent performance over extended periods is critical. This necessitates the development of robust packaging and protection methods.

Signal processing and noise reduction represent significant technical challenges. Piezoelectric sensors are susceptible to electromagnetic interference and vibrations from unrelated sources, which can lead to false readings or reduced accuracy. Implementing effective signal filtering and processing algorithms to isolate relevant data from background noise is crucial for reliable sensor operation.

Cost-effectiveness is another major consideration. While piezoelectric sensors offer numerous benefits, their integration must be economically viable for mass-market consumer electronics. Reducing manufacturing costs while maintaining quality and performance is an ongoing challenge that requires innovative production techniques and material choices.

Compatibility and standardization issues also present obstacles. Integrating piezoelectric sensors into existing electronic ecosystems requires adherence to various industry standards and protocols. Ensuring seamless communication and interoperability with other components and systems within devices adds complexity to the integration process.

Lastly, the challenge of multi-functionality arises as consumer expectations grow. There is an increasing demand for sensors that can perform multiple tasks or detect various parameters simultaneously. Developing piezoelectric sensors capable of multi-modal sensing while maintaining accuracy and efficiency across all functions is a complex engineering challenge.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrical engineering, signal processing, and manufacturing technologies. As the field progresses, overcoming these hurdles will be crucial for the widespread adoption of piezoelectric sensors in next-generation consumer electronics.

Power consumption presents another major hurdle. Piezoelectric sensors require energy to operate, and in portable devices where battery life is crucial, minimizing power draw is essential. Balancing sensor performance with energy efficiency remains a complex task, often requiring trade-offs between functionality and power consumption.

Durability and reliability pose additional challenges. Consumer electronics are subjected to various environmental stresses, including temperature fluctuations, humidity, and physical impacts. Ensuring that piezoelectric sensors can withstand these conditions while maintaining consistent performance over extended periods is critical. This necessitates the development of robust packaging and protection methods.

Signal processing and noise reduction represent significant technical challenges. Piezoelectric sensors are susceptible to electromagnetic interference and vibrations from unrelated sources, which can lead to false readings or reduced accuracy. Implementing effective signal filtering and processing algorithms to isolate relevant data from background noise is crucial for reliable sensor operation.

Cost-effectiveness is another major consideration. While piezoelectric sensors offer numerous benefits, their integration must be economically viable for mass-market consumer electronics. Reducing manufacturing costs while maintaining quality and performance is an ongoing challenge that requires innovative production techniques and material choices.

Compatibility and standardization issues also present obstacles. Integrating piezoelectric sensors into existing electronic ecosystems requires adherence to various industry standards and protocols. Ensuring seamless communication and interoperability with other components and systems within devices adds complexity to the integration process.

Lastly, the challenge of multi-functionality arises as consumer expectations grow. There is an increasing demand for sensors that can perform multiple tasks or detect various parameters simultaneously. Developing piezoelectric sensors capable of multi-modal sensing while maintaining accuracy and efficiency across all functions is a complex engineering challenge.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrical engineering, signal processing, and manufacturing technologies. As the field progresses, overcoming these hurdles will be crucial for the widespread adoption of piezoelectric sensors in next-generation consumer electronics.

Existing Integration Solutions for Consumer Electronics

01 Piezoelectric sensor design and fabrication

This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity, durability, and performance. These advancements aim to improve the overall efficiency and reliability of piezoelectric sensors for various applications.- Piezoelectric sensor design and fabrication: This category focuses on the design and manufacturing processes of piezoelectric sensors. It includes innovative approaches to sensor construction, material selection, and fabrication techniques to enhance sensitivity and performance. The designs may incorporate novel structures or layering methods to optimize the piezoelectric effect for specific applications.

- Applications of piezoelectric sensors: Piezoelectric sensors find diverse applications across various industries. This category covers the use of these sensors in areas such as automotive systems, consumer electronics, industrial monitoring, and medical devices. The sensors can be employed for pressure measurement, vibration detection, force sensing, and other physical parameter measurements.

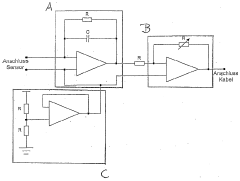

- Signal processing and data analysis for piezoelectric sensors: This category encompasses methods and systems for processing and analyzing signals from piezoelectric sensors. It includes techniques for noise reduction, signal amplification, and data interpretation. Advanced algorithms and software solutions may be employed to extract meaningful information from sensor outputs and improve overall system performance.

- Integration of piezoelectric sensors with other technologies: This point focuses on the integration of piezoelectric sensors with other technologies to create more comprehensive sensing systems. It may include combining piezoelectric sensors with MEMS devices, incorporating them into IoT platforms, or integrating them with wireless communication technologies for remote monitoring and control applications.

- Energy harvesting and self-powered piezoelectric sensors: This category explores the use of piezoelectric materials for energy harvesting applications and the development of self-powered sensors. It includes designs that utilize the piezoelectric effect to generate electricity from ambient vibrations or mechanical stress, potentially eliminating the need for external power sources in certain sensing applications.

02 Applications of piezoelectric sensors

Piezoelectric sensors find diverse applications across multiple industries. This category explores their use in areas such as automotive systems, consumer electronics, industrial monitoring, and medical devices. The sensors' ability to convert mechanical stress into electrical signals makes them valuable for measuring pressure, acceleration, and vibration in various environments.Expand Specific Solutions03 Signal processing and data analysis for piezoelectric sensors

This category covers techniques for processing and analyzing signals from piezoelectric sensors. It includes methods for noise reduction, signal amplification, and data interpretation. Advanced algorithms and software solutions are developed to extract meaningful information from sensor outputs, enabling more accurate and reliable measurements in complex environments.Expand Specific Solutions04 Integration of piezoelectric sensors in smart systems

The integration of piezoelectric sensors into smart systems and Internet of Things (IoT) devices is a growing trend. This category explores how these sensors are incorporated into larger networks and systems for real-time monitoring, predictive maintenance, and automated decision-making. It includes developments in sensor networking, wireless communication, and data management for connected sensor systems.Expand Specific Solutions05 Enhancements in piezoelectric materials and structures

This category focuses on advancements in piezoelectric materials and structural designs to improve sensor performance. It includes research into novel piezoelectric compounds, nanostructured materials, and composite structures that offer enhanced sensitivity, broader frequency response, or improved temperature stability. These material innovations aim to expand the capabilities and applications of piezoelectric sensors.Expand Specific Solutions

Key Players in Piezoelectric Sensor Industry

The integration of piezoelectric sensors in consumer electronics is in a growth phase, with the market expanding rapidly due to increasing demand for smart devices and IoT applications. The global market size for piezoelectric sensors is projected to reach several billion dollars by 2025. Technologically, the field is advancing quickly, with companies like Murata Manufacturing, Kyocera, and TDK Electronics leading innovation. These firms are developing more sensitive, miniaturized sensors with improved energy efficiency and durability. Emerging players such as Fraunhofer-Gesellschaft and university research centers are also contributing to technological advancements, focusing on novel materials and fabrication techniques to enhance sensor performance and integration capabilities in consumer electronics.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced piezoelectric sensors for consumer electronics, focusing on miniaturization and high sensitivity. Their MEMS (Micro-Electro-Mechanical Systems) piezoelectric sensors offer ultra-compact designs, with some models as small as 1.0 x 0.5 x 0.5 mm[1]. These sensors utilize a proprietary piezoelectric ceramic material that provides excellent stability and reliability. Murata's innovative integration approach includes multi-functional sensors that combine accelerometers, gyroscopes, and pressure sensors in a single package, reducing overall device size and power consumption[2]. They have also developed flexible piezoelectric film sensors that can be easily integrated into curved or irregular surfaces of consumer devices[3].

Strengths: Industry-leading miniaturization, high sensitivity, and multi-functional integration. Weaknesses: Potentially higher cost compared to traditional sensors, may require specialized manufacturing processes.

Robert Bosch GmbH

Technical Solution: Bosch has made significant strides in integrating piezoelectric sensors into consumer electronics, focusing on automotive and smart home applications. Their MEMS-based piezoelectric sensors are used in advanced driver assistance systems (ADAS) for crash detection and airbag deployment[11]. In smart home devices, Bosch has developed piezoelectric sensors for security systems, detecting glass breakage and vibrations with high accuracy[12]. Their innovative approach includes the development of self-powered wireless sensors using piezoelectric energy harvesting, enabling long-term operation without battery replacement[13]. Bosch has also created piezoelectric-based microphones for voice-controlled devices, offering improved noise cancellation and directionality compared to traditional electret microphones[14].

Strengths: Strong focus on automotive and smart home applications, self-powered sensor solutions. Weaknesses: Less presence in personal consumer electronics like smartphones or wearables.

Core Innovations in Piezoelectric Sensor Technology

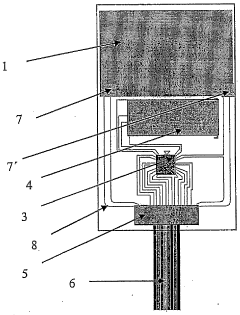

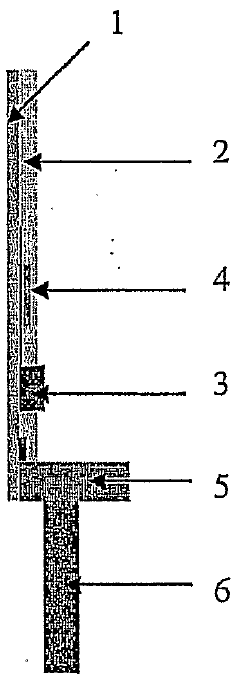

Piezoelectric sensor comprising a thermal sensor and an amplifier circuit

PatentInactiveEP1848973A1

Innovation

- Integration of a thermal sensor within the piezoelectric sensor system, combined with a semiconductor-based amplifier circuit that includes temperature compensation, allowing the system to operate effectively under different temperature conditions and enabling miniaturization and cost-effectiveness.

Piezoelectric sensor comprising a thermal sensor and an amplifier circuit

PatentWO2006084767A1

Innovation

- Integration of a thermal sensor and a temperature-compensated amplifier circuit within a miniaturized piezoelectric sensor system, utilizing semiconductor technology to ensure mechanical flexibility and cost-effectiveness, allowing the sensor to operate under different temperature conditions without significant mechanical or shape influence on the measurement object.

Environmental Impact of Piezoelectric Materials

The integration of piezoelectric sensors in consumer electronics has raised concerns about the environmental impact of piezoelectric materials. As these sensors become more prevalent in everyday devices, it is crucial to assess their lifecycle environmental footprint and potential long-term ecological consequences.

Piezoelectric materials, commonly used in these sensors, are typically composed of lead zirconate titanate (PZT) or other lead-based compounds. The production of these materials involves mining and processing of raw materials, which can lead to habitat disruption and resource depletion. Furthermore, the manufacturing process of piezoelectric components often requires high temperatures and energy-intensive procedures, contributing to increased carbon emissions and energy consumption.

The use phase of piezoelectric sensors in consumer electronics generally has a minimal direct environmental impact. However, the increasing miniaturization and integration of these sensors into various devices may lead to challenges in product repairability and recyclability. This could potentially shorten the lifespan of electronic products, exacerbating the growing issue of electronic waste (e-waste).

End-of-life management of piezoelectric sensors presents significant environmental concerns. The presence of lead and other heavy metals in these materials poses risks of soil and water contamination if not properly disposed of or recycled. Current recycling technologies for piezoelectric materials are limited, and the small size of these components in consumer electronics makes their recovery and separation challenging.

Efforts are being made to develop more environmentally friendly alternatives to traditional piezoelectric materials. Research into lead-free piezoelectric compounds, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), shows promise in reducing the environmental impact of these sensors. However, these alternatives often face challenges in matching the performance and cost-effectiveness of lead-based materials.

The increasing adoption of piezoelectric sensors in consumer electronics also raises questions about the long-term accumulation of these materials in the environment. As more devices containing these sensors reach their end-of-life, there is a growing need for improved recycling technologies and infrastructure to handle this specific type of electronic waste.

To address these environmental concerns, manufacturers and researchers are exploring various strategies. These include designing products for easier disassembly and recycling, developing more efficient recycling processes for piezoelectric materials, and investing in the research and development of eco-friendly piezoelectric alternatives. Additionally, there is a growing emphasis on implementing extended producer responsibility programs to ensure proper end-of-life management of products containing piezoelectric sensors.

Piezoelectric materials, commonly used in these sensors, are typically composed of lead zirconate titanate (PZT) or other lead-based compounds. The production of these materials involves mining and processing of raw materials, which can lead to habitat disruption and resource depletion. Furthermore, the manufacturing process of piezoelectric components often requires high temperatures and energy-intensive procedures, contributing to increased carbon emissions and energy consumption.

The use phase of piezoelectric sensors in consumer electronics generally has a minimal direct environmental impact. However, the increasing miniaturization and integration of these sensors into various devices may lead to challenges in product repairability and recyclability. This could potentially shorten the lifespan of electronic products, exacerbating the growing issue of electronic waste (e-waste).

End-of-life management of piezoelectric sensors presents significant environmental concerns. The presence of lead and other heavy metals in these materials poses risks of soil and water contamination if not properly disposed of or recycled. Current recycling technologies for piezoelectric materials are limited, and the small size of these components in consumer electronics makes their recovery and separation challenging.

Efforts are being made to develop more environmentally friendly alternatives to traditional piezoelectric materials. Research into lead-free piezoelectric compounds, such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), shows promise in reducing the environmental impact of these sensors. However, these alternatives often face challenges in matching the performance and cost-effectiveness of lead-based materials.

The increasing adoption of piezoelectric sensors in consumer electronics also raises questions about the long-term accumulation of these materials in the environment. As more devices containing these sensors reach their end-of-life, there is a growing need for improved recycling technologies and infrastructure to handle this specific type of electronic waste.

To address these environmental concerns, manufacturers and researchers are exploring various strategies. These include designing products for easier disassembly and recycling, developing more efficient recycling processes for piezoelectric materials, and investing in the research and development of eco-friendly piezoelectric alternatives. Additionally, there is a growing emphasis on implementing extended producer responsibility programs to ensure proper end-of-life management of products containing piezoelectric sensors.

Miniaturization Trends in Sensor Technology

The miniaturization trend in sensor technology has been a driving force behind the innovative integration of piezoelectric sensors in consumer electronics. Over the past decade, significant advancements have been made in reducing the size of piezoelectric sensors while maintaining or even improving their performance characteristics. This trend has been crucial in enabling the widespread adoption of these sensors in various consumer electronic devices.

One of the key factors contributing to the miniaturization of piezoelectric sensors is the development of advanced materials and fabrication techniques. Researchers have been exploring novel piezoelectric materials with enhanced properties, such as higher sensitivity and lower power consumption, which allow for smaller sensor designs. Additionally, advancements in microfabrication technologies have enabled the production of ultra-thin piezoelectric films and nanostructures, further reducing the overall size of the sensors.

The miniaturization of piezoelectric sensors has also been facilitated by improvements in packaging and integration techniques. Manufacturers have developed innovative ways to incorporate these sensors into compact form factors, often utilizing 3D packaging and system-in-package (SiP) technologies. These approaches allow for the seamless integration of piezoelectric sensors with other electronic components, resulting in more compact and efficient device designs.

Another significant trend in sensor miniaturization is the development of multifunctional sensors. By combining multiple sensing capabilities into a single, compact package, manufacturers can reduce the overall footprint of sensing components in consumer electronics. For example, some piezoelectric sensors now incorporate temperature sensing or accelerometer functionalities, eliminating the need for separate sensors and further contributing to device miniaturization.

The push for smaller sensors has also led to advancements in signal processing and data analysis techniques. As sensors become smaller, the challenge of maintaining signal quality and accuracy increases. To address this, researchers have developed sophisticated algorithms and signal conditioning circuits that can extract meaningful data from miniaturized sensors, ensuring reliable performance even as the physical size of the sensors decreases.

The ongoing miniaturization trend in sensor technology has opened up new possibilities for the integration of piezoelectric sensors in consumer electronics. From wearable devices to smartphones and smart home appliances, these compact sensors are enabling new features and functionalities that were previously impractical due to size constraints. As the trend continues, we can expect to see even more innovative applications of piezoelectric sensors in increasingly compact and sophisticated consumer electronic devices.

One of the key factors contributing to the miniaturization of piezoelectric sensors is the development of advanced materials and fabrication techniques. Researchers have been exploring novel piezoelectric materials with enhanced properties, such as higher sensitivity and lower power consumption, which allow for smaller sensor designs. Additionally, advancements in microfabrication technologies have enabled the production of ultra-thin piezoelectric films and nanostructures, further reducing the overall size of the sensors.

The miniaturization of piezoelectric sensors has also been facilitated by improvements in packaging and integration techniques. Manufacturers have developed innovative ways to incorporate these sensors into compact form factors, often utilizing 3D packaging and system-in-package (SiP) technologies. These approaches allow for the seamless integration of piezoelectric sensors with other electronic components, resulting in more compact and efficient device designs.

Another significant trend in sensor miniaturization is the development of multifunctional sensors. By combining multiple sensing capabilities into a single, compact package, manufacturers can reduce the overall footprint of sensing components in consumer electronics. For example, some piezoelectric sensors now incorporate temperature sensing or accelerometer functionalities, eliminating the need for separate sensors and further contributing to device miniaturization.

The push for smaller sensors has also led to advancements in signal processing and data analysis techniques. As sensors become smaller, the challenge of maintaining signal quality and accuracy increases. To address this, researchers have developed sophisticated algorithms and signal conditioning circuits that can extract meaningful data from miniaturized sensors, ensuring reliable performance even as the physical size of the sensors decreases.

The ongoing miniaturization trend in sensor technology has opened up new possibilities for the integration of piezoelectric sensors in consumer electronics. From wearable devices to smartphones and smart home appliances, these compact sensors are enabling new features and functionalities that were previously impractical due to size constraints. As the trend continues, we can expect to see even more innovative applications of piezoelectric sensors in increasingly compact and sophisticated consumer electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!