Innovative PHEV cooling techniques for enhanced performance

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHEV Cooling Evolution

The evolution of cooling techniques for Plug-in Hybrid Electric Vehicles (PHEVs) has been a critical factor in enhancing their performance and efficiency. This technological progression can be traced through several key stages, each marked by significant advancements and innovative solutions.

In the early days of PHEV development, cooling systems were primarily adapted from conventional internal combustion engine vehicles. These systems relied heavily on liquid cooling for the engine and simple air cooling for the battery pack. However, as PHEV technology advanced, it became clear that more sophisticated cooling solutions were necessary to manage the complex thermal challenges posed by the integration of electric and combustion powertrains.

The next phase saw the introduction of dedicated battery thermal management systems. These systems utilized a combination of air and liquid cooling to maintain optimal battery temperature, crucial for maximizing battery life and performance. Manufacturers began implementing more advanced heat exchangers and intelligent control systems to efficiently distribute cooling across different vehicle components.

As PHEVs became more powerful and energy-dense, the industry witnessed a shift towards more integrated cooling approaches. This phase was characterized by the development of unified cooling loops that managed heat across the entire powertrain, including the engine, electric motors, power electronics, and battery pack. These systems often incorporated smart valves and pumps to dynamically adjust coolant flow based on real-time thermal demands.

Recent years have seen a focus on innovative materials and designs to enhance cooling efficiency. The use of phase-change materials for battery thermal management, advanced heat spreaders, and micro-channel cooling for power electronics have emerged as promising technologies. Additionally, the integration of predictive thermal management algorithms, leveraging artificial intelligence and real-time data analysis, has allowed for more proactive and efficient cooling strategies.

The latest frontier in PHEV cooling evolution involves the exploration of novel cooling mediums and techniques. This includes the investigation of dielectric fluids for direct battery immersion cooling, the use of thermoelectric devices for localized cooling, and the development of advanced heat pump systems that can provide both cabin and powertrain thermal management.

Throughout this evolution, there has been a consistent trend towards greater integration, efficiency, and intelligence in PHEV cooling systems. The goal has remained constant: to optimize vehicle performance, extend range, improve battery longevity, and enhance overall system reliability. As PHEVs continue to play a crucial role in the transition to electrified transportation, the evolution of their cooling technologies remains a key area of innovation and research in the automotive industry.

In the early days of PHEV development, cooling systems were primarily adapted from conventional internal combustion engine vehicles. These systems relied heavily on liquid cooling for the engine and simple air cooling for the battery pack. However, as PHEV technology advanced, it became clear that more sophisticated cooling solutions were necessary to manage the complex thermal challenges posed by the integration of electric and combustion powertrains.

The next phase saw the introduction of dedicated battery thermal management systems. These systems utilized a combination of air and liquid cooling to maintain optimal battery temperature, crucial for maximizing battery life and performance. Manufacturers began implementing more advanced heat exchangers and intelligent control systems to efficiently distribute cooling across different vehicle components.

As PHEVs became more powerful and energy-dense, the industry witnessed a shift towards more integrated cooling approaches. This phase was characterized by the development of unified cooling loops that managed heat across the entire powertrain, including the engine, electric motors, power electronics, and battery pack. These systems often incorporated smart valves and pumps to dynamically adjust coolant flow based on real-time thermal demands.

Recent years have seen a focus on innovative materials and designs to enhance cooling efficiency. The use of phase-change materials for battery thermal management, advanced heat spreaders, and micro-channel cooling for power electronics have emerged as promising technologies. Additionally, the integration of predictive thermal management algorithms, leveraging artificial intelligence and real-time data analysis, has allowed for more proactive and efficient cooling strategies.

The latest frontier in PHEV cooling evolution involves the exploration of novel cooling mediums and techniques. This includes the investigation of dielectric fluids for direct battery immersion cooling, the use of thermoelectric devices for localized cooling, and the development of advanced heat pump systems that can provide both cabin and powertrain thermal management.

Throughout this evolution, there has been a consistent trend towards greater integration, efficiency, and intelligence in PHEV cooling systems. The goal has remained constant: to optimize vehicle performance, extend range, improve battery longevity, and enhance overall system reliability. As PHEVs continue to play a crucial role in the transition to electrified transportation, the evolution of their cooling technologies remains a key area of innovation and research in the automotive industry.

Market Demand Analysis

The market demand for innovative PHEV cooling techniques is experiencing significant growth, driven by the increasing adoption of plug-in hybrid electric vehicles (PHEVs) worldwide. As automotive manufacturers strive to meet stringent emissions regulations and consumer demands for fuel efficiency, PHEVs have emerged as a crucial transitional technology between conventional internal combustion engines and fully electric vehicles.

The global PHEV market is projected to expand at a compound annual growth rate (CAGR) of over 30% in the next five years, with sales expected to reach several million units annually by 2025. This rapid growth is creating a substantial demand for advanced cooling solutions that can enhance PHEV performance, efficiency, and reliability.

One of the primary drivers for innovative cooling techniques is the need to manage the complex thermal challenges posed by PHEVs. These vehicles combine both electric and combustion powertrains, resulting in higher heat generation and more intricate cooling requirements compared to conventional vehicles. Efficient thermal management is crucial for optimizing battery performance, extending electric range, and ensuring the longevity of critical components.

Consumer expectations for improved electric range and overall vehicle performance are also fueling the demand for advanced cooling solutions. As PHEVs continue to evolve, customers are seeking vehicles that can operate in electric-only mode for longer distances while maintaining optimal performance in hybrid mode. This necessitates cooling systems that can effectively manage heat dissipation across various driving conditions and power demands.

The automotive industry's focus on lightweighting and space optimization is another factor driving the need for innovative cooling techniques. Manufacturers are seeking compact, lightweight cooling solutions that can efficiently manage thermal loads without compromising vehicle design or adding excessive weight. This trend is particularly relevant for PHEVs, where space is at a premium due to the presence of both electric and combustion powertrains.

Furthermore, the growing emphasis on fast charging capabilities for PHEVs is creating additional thermal management challenges. As charging speeds increase, so does the heat generated during the charging process. This has led to a demand for cooling solutions that can effectively manage battery temperatures during rapid charging, ensuring safety and preserving battery life.

The market for PHEV cooling techniques is also being influenced by the broader shift towards electrification in the automotive industry. As automakers invest heavily in electric vehicle technologies, there is a spillover effect on PHEV development, with innovations in EV cooling systems being adapted and optimized for hybrid applications.

In conclusion, the market demand for innovative PHEV cooling techniques is robust and multifaceted, driven by the rapid growth of the PHEV market, the need for enhanced performance and efficiency, consumer expectations, design constraints, and the broader trends in vehicle electrification. This demand is expected to continue growing as PHEVs play an increasingly important role in the transition to sustainable mobility.

The global PHEV market is projected to expand at a compound annual growth rate (CAGR) of over 30% in the next five years, with sales expected to reach several million units annually by 2025. This rapid growth is creating a substantial demand for advanced cooling solutions that can enhance PHEV performance, efficiency, and reliability.

One of the primary drivers for innovative cooling techniques is the need to manage the complex thermal challenges posed by PHEVs. These vehicles combine both electric and combustion powertrains, resulting in higher heat generation and more intricate cooling requirements compared to conventional vehicles. Efficient thermal management is crucial for optimizing battery performance, extending electric range, and ensuring the longevity of critical components.

Consumer expectations for improved electric range and overall vehicle performance are also fueling the demand for advanced cooling solutions. As PHEVs continue to evolve, customers are seeking vehicles that can operate in electric-only mode for longer distances while maintaining optimal performance in hybrid mode. This necessitates cooling systems that can effectively manage heat dissipation across various driving conditions and power demands.

The automotive industry's focus on lightweighting and space optimization is another factor driving the need for innovative cooling techniques. Manufacturers are seeking compact, lightweight cooling solutions that can efficiently manage thermal loads without compromising vehicle design or adding excessive weight. This trend is particularly relevant for PHEVs, where space is at a premium due to the presence of both electric and combustion powertrains.

Furthermore, the growing emphasis on fast charging capabilities for PHEVs is creating additional thermal management challenges. As charging speeds increase, so does the heat generated during the charging process. This has led to a demand for cooling solutions that can effectively manage battery temperatures during rapid charging, ensuring safety and preserving battery life.

The market for PHEV cooling techniques is also being influenced by the broader shift towards electrification in the automotive industry. As automakers invest heavily in electric vehicle technologies, there is a spillover effect on PHEV development, with innovations in EV cooling systems being adapted and optimized for hybrid applications.

In conclusion, the market demand for innovative PHEV cooling techniques is robust and multifaceted, driven by the rapid growth of the PHEV market, the need for enhanced performance and efficiency, consumer expectations, design constraints, and the broader trends in vehicle electrification. This demand is expected to continue growing as PHEVs play an increasingly important role in the transition to sustainable mobility.

Current Challenges

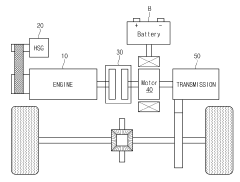

Plug-in Hybrid Electric Vehicles (PHEVs) face several significant challenges in their cooling systems, which directly impact their overall performance and efficiency. One of the primary issues is the complexity of managing multiple heat sources within a compact space. PHEVs incorporate both an internal combustion engine and an electric powertrain, each with distinct thermal management requirements. This dual-system architecture creates a more intricate cooling demand compared to conventional vehicles or pure electric vehicles.

The battery pack in PHEVs is a critical component that requires precise temperature control. Lithium-ion batteries, commonly used in PHEVs, operate optimally within a narrow temperature range. Overheating can lead to reduced battery life, decreased performance, and potential safety hazards. Conversely, excessively low temperatures can result in diminished power output and reduced electric range. Developing cooling techniques that can maintain the battery pack within its ideal temperature range across various driving conditions and ambient temperatures remains a significant challenge.

Another hurdle is the need for efficient heat recovery and utilization. PHEVs generate waste heat from multiple sources, including the engine, electric motors, and power electronics. Capturing and repurposing this waste heat effectively could significantly improve overall vehicle efficiency. However, designing a system that can seamlessly integrate heat recovery with the vehicle's heating, ventilation, and air conditioning (HVAC) system, as well as the powertrain cooling, presents considerable engineering challenges.

The varying power demands in PHEVs also pose a challenge for cooling system design. The vehicle may switch between electric-only mode, hybrid mode, and engine-only mode, each with different cooling requirements. Developing a cooling system that can adapt quickly and efficiently to these changing demands while maintaining optimal performance across all operating modes is a complex task.

Weight and space constraints further complicate the cooling system design in PHEVs. The addition of electric components already increases the vehicle's weight and occupies valuable space. Integrating an advanced cooling system without significantly impacting the vehicle's weight or interior space requires innovative solutions and materials.

Energy efficiency is another critical challenge. The cooling system itself consumes energy, which can impact the vehicle's overall efficiency and range. Balancing the power consumption of the cooling system with its effectiveness in maintaining optimal operating temperatures across all components is a delicate engineering task.

Lastly, cost considerations play a crucial role in PHEV cooling system development. While advanced cooling technologies can offer significant performance benefits, they must also be economically viable for mass production. Finding cost-effective solutions that meet the complex cooling demands of PHEVs without substantially increasing the vehicle's price point remains an ongoing challenge for manufacturers and engineers in the automotive industry.

The battery pack in PHEVs is a critical component that requires precise temperature control. Lithium-ion batteries, commonly used in PHEVs, operate optimally within a narrow temperature range. Overheating can lead to reduced battery life, decreased performance, and potential safety hazards. Conversely, excessively low temperatures can result in diminished power output and reduced electric range. Developing cooling techniques that can maintain the battery pack within its ideal temperature range across various driving conditions and ambient temperatures remains a significant challenge.

Another hurdle is the need for efficient heat recovery and utilization. PHEVs generate waste heat from multiple sources, including the engine, electric motors, and power electronics. Capturing and repurposing this waste heat effectively could significantly improve overall vehicle efficiency. However, designing a system that can seamlessly integrate heat recovery with the vehicle's heating, ventilation, and air conditioning (HVAC) system, as well as the powertrain cooling, presents considerable engineering challenges.

The varying power demands in PHEVs also pose a challenge for cooling system design. The vehicle may switch between electric-only mode, hybrid mode, and engine-only mode, each with different cooling requirements. Developing a cooling system that can adapt quickly and efficiently to these changing demands while maintaining optimal performance across all operating modes is a complex task.

Weight and space constraints further complicate the cooling system design in PHEVs. The addition of electric components already increases the vehicle's weight and occupies valuable space. Integrating an advanced cooling system without significantly impacting the vehicle's weight or interior space requires innovative solutions and materials.

Energy efficiency is another critical challenge. The cooling system itself consumes energy, which can impact the vehicle's overall efficiency and range. Balancing the power consumption of the cooling system with its effectiveness in maintaining optimal operating temperatures across all components is a delicate engineering task.

Lastly, cost considerations play a crucial role in PHEV cooling system development. While advanced cooling technologies can offer significant performance benefits, they must also be economically viable for mass production. Finding cost-effective solutions that meet the complex cooling demands of PHEVs without substantially increasing the vehicle's price point remains an ongoing challenge for manufacturers and engineers in the automotive industry.

Existing Cooling Solutions

01 Advanced thermal management systems

PHEVs employ sophisticated thermal management systems to optimize cooling performance. These systems integrate various components such as heat exchangers, coolant circuits, and temperature sensors to efficiently regulate the temperature of the powertrain, battery pack, and other critical components. Advanced control algorithms are used to manage heat distribution and dissipation, enhancing overall vehicle efficiency and performance.- Advanced thermal management systems: PHEVs employ sophisticated thermal management systems to optimize cooling performance. These systems often include multiple cooling circuits, intelligent control strategies, and heat exchangers to efficiently manage heat from various components such as the engine, electric motor, and battery pack. Advanced thermal management helps maintain optimal operating temperatures, improving overall vehicle efficiency and performance.

- Battery cooling techniques: Effective battery cooling is crucial for PHEV performance and longevity. Various cooling methods are employed, including liquid cooling systems, air cooling, and phase-change materials. These techniques help maintain optimal battery temperature, prevent overheating, and ensure consistent performance across different operating conditions.

- Integrated cooling for power electronics: Power electronics in PHEVs, such as inverters and converters, require efficient cooling to maintain performance. Integrated cooling solutions, including direct liquid cooling and advanced heat sink designs, are used to manage heat generated by these components. This integration helps reduce overall system complexity and improves cooling efficiency.

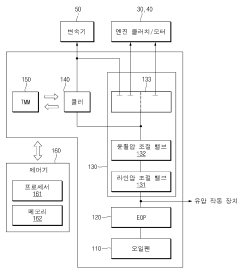

- Intelligent cooling control strategies: PHEVs utilize intelligent control strategies to optimize cooling performance. These strategies may include predictive algorithms, real-time temperature monitoring, and adaptive cooling based on driving conditions and component loads. Such advanced control systems help balance cooling needs with energy efficiency, enhancing overall vehicle performance.

- Waste heat recovery and utilization: To improve overall efficiency, PHEVs incorporate waste heat recovery systems. These systems capture and repurpose heat generated by various components, such as the engine and electric drivetrain. The recovered heat can be used for cabin heating, battery temperature management, or even converted back into usable energy, contributing to improved vehicle performance and efficiency.

02 Battery cooling techniques

Effective battery cooling is crucial for PHEV performance and longevity. Various cooling methods are employed, including liquid cooling systems, air cooling, and phase-change materials. These techniques help maintain optimal battery temperature during charging and discharging cycles, preventing overheating and ensuring consistent performance across different operating conditions.Expand Specific Solutions03 Integrated cooling for electric drive components

PHEVs utilize integrated cooling solutions for electric drive components such as motors, inverters, and power electronics. These systems often combine multiple cooling circuits or use shared coolant loops to efficiently manage heat generated by various components. This integration helps reduce system complexity, weight, and improves overall cooling performance.Expand Specific Solutions04 Intelligent cooling control strategies

Advanced control strategies are implemented in PHEVs to optimize cooling performance. These strategies use real-time data from various sensors to adjust cooling system parameters dynamically. Machine learning algorithms and predictive models are employed to anticipate cooling needs based on driving conditions, ambient temperature, and vehicle operating mode, ensuring efficient and proactive thermal management.Expand Specific Solutions05 Waste heat recovery and utilization

PHEVs incorporate waste heat recovery systems to improve overall energy efficiency. These systems capture and repurpose heat generated by the internal combustion engine, electric components, and braking systems. The recovered heat can be used for cabin heating, battery temperature regulation, or converted into electrical energy, contributing to improved vehicle range and performance.Expand Specific Solutions

Key PHEV Manufacturers

The innovative PHEV cooling techniques market is in a growth phase, with increasing demand driven by the automotive industry's shift towards electrification. The market size is expanding rapidly, fueled by stringent emissions regulations and consumer interest in eco-friendly vehicles. Technologically, the field is advancing quickly, with major players like Hyundai, Toyota, and BYD leading the way. These companies are investing heavily in R&D to develop more efficient and effective cooling systems for PHEVs. Other significant contributors include Ford, Honda, and Volkswagen Group (through Audi), who are also making strides in this area. The competition is fierce, with both established automakers and newer entrants like Polestar vying for market share and technological leadership.

Toyota Motor Corp.

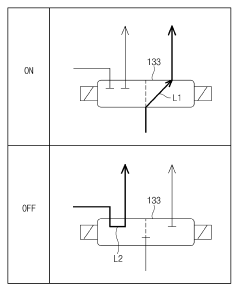

Technical Solution: Toyota has developed an innovative PHEV cooling system that utilizes a heat pump for both cabin and battery temperature management. This system integrates the air conditioning and heat pump functions, allowing for efficient cooling of the battery pack and cabin simultaneously. The heat pump can extract heat from the ambient air or the vehicle's powertrain components to warm the cabin in cold weather, reducing the load on the battery[1]. Additionally, Toyota has implemented a two-way cooling circuit that can switch between series and parallel flow configurations, optimizing cooling efficiency based on driving conditions and battery temperature[3]. The system also incorporates a pre-cooling function that can cool the battery while the vehicle is charging, ensuring optimal battery temperature at the start of a journey[5].

Strengths: Highly efficient integrated cooling system, reduced energy consumption, improved battery life and performance. Weaknesses: Potentially higher initial cost, increased system complexity.

Ford Global Technologies LLC

Technical Solution: Ford has developed a advanced thermal management system for PHEVs that utilizes a combination of liquid cooling and phase-change materials. The liquid cooling system circulates a specially formulated coolant through channels in the battery pack and power electronics, efficiently removing heat. The phase-change materials are strategically placed within the battery pack to absorb excess heat during high-load conditions and release it when temperatures drop[2]. Ford's system also incorporates an intelligent control algorithm that predicts cooling needs based on driving patterns, weather conditions, and battery state of charge[4]. This predictive cooling approach allows for more efficient use of the cooling system, reducing overall energy consumption. Additionally, Ford has implemented a waste heat recovery system that captures heat from the electric motor and power electronics to warm the cabin, further improving overall system efficiency[6].

Strengths: Efficient heat management, improved battery longevity, reduced energy consumption for cooling. Weaknesses: Increased system complexity, potential for higher maintenance costs.

Core Cooling Innovations

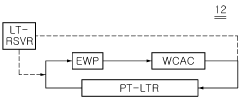

Cooling system for hybrid vehicle and method for controlling of temperature of battery

PatentPendingKR1020240035029A

Innovation

- An integrated cooling system that combines the low-temperature cooling circuit of the powertrain with the battery cooling circuit, using a heating line to raise battery temperature and a coolant return line to manage temperature, with control valves and direction switching valves to optimize coolant flow.

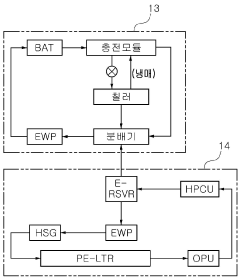

Cooling system and method for hybrid electric vehicle

PatentPendingKR1020210153798A

Innovation

- A cooling system with an Electronic Oil Pump (EOP) and flow control valves adjusts cooling flow rates based on engine clutch and motor temperatures, using a controller to manage lubricating oil supply and cooling flow to maintain optimal temperatures.

Environmental Impact

The environmental impact of innovative PHEV cooling techniques is a critical consideration in the development and implementation of these technologies. As automotive manufacturers strive to enhance the performance of plug-in hybrid electric vehicles (PHEVs), the cooling systems play a crucial role in maintaining optimal operating conditions for both the internal combustion engine and the electric powertrain components.

Advanced cooling techniques in PHEVs contribute to improved energy efficiency, which directly translates to reduced fuel consumption and lower greenhouse gas emissions. By effectively managing heat dissipation, these innovative cooling systems allow the vehicle to operate at peak efficiency for longer periods, maximizing the use of electric power and minimizing reliance on the internal combustion engine.

One of the key environmental benefits of enhanced PHEV cooling techniques is the potential for extended electric-only driving range. By maintaining optimal temperatures for the battery pack and electric motor, these systems can help increase the distance a PHEV can travel on electric power alone, reducing overall emissions and fossil fuel consumption.

Moreover, innovative cooling solutions often incorporate environmentally friendly refrigerants and coolants with lower global warming potential. This shift away from traditional, high-impact refrigerants aligns with global efforts to reduce the automotive industry's contribution to climate change and ozone depletion.

The use of advanced materials and designs in PHEV cooling systems can also lead to weight reduction and improved aerodynamics. Lighter vehicles require less energy to operate, further reducing fuel consumption and emissions. Additionally, more efficient cooling systems may allow for smaller radiators and heat exchangers, potentially improving the vehicle's overall aerodynamic profile.

Another environmental consideration is the lifecycle impact of these cooling technologies. Manufacturers are increasingly focusing on the use of recyclable and sustainable materials in cooling system components, aiming to reduce the environmental footprint of PHEVs from production through to end-of-life disposal.

Innovative cooling techniques also contribute to the longevity and reliability of PHEV components, particularly the battery pack. By maintaining optimal operating temperatures, these systems can help extend the lifespan of batteries, reducing the need for premature replacements and the associated environmental impacts of battery production and disposal.

In conclusion, the environmental impact of innovative PHEV cooling techniques extends beyond immediate performance enhancements. These technologies play a crucial role in improving overall vehicle efficiency, reducing emissions, and supporting the transition towards more sustainable transportation solutions. As the automotive industry continues to evolve, the development of environmentally conscious cooling systems will remain a key focus in the pursuit of greener mobility options.

Advanced cooling techniques in PHEVs contribute to improved energy efficiency, which directly translates to reduced fuel consumption and lower greenhouse gas emissions. By effectively managing heat dissipation, these innovative cooling systems allow the vehicle to operate at peak efficiency for longer periods, maximizing the use of electric power and minimizing reliance on the internal combustion engine.

One of the key environmental benefits of enhanced PHEV cooling techniques is the potential for extended electric-only driving range. By maintaining optimal temperatures for the battery pack and electric motor, these systems can help increase the distance a PHEV can travel on electric power alone, reducing overall emissions and fossil fuel consumption.

Moreover, innovative cooling solutions often incorporate environmentally friendly refrigerants and coolants with lower global warming potential. This shift away from traditional, high-impact refrigerants aligns with global efforts to reduce the automotive industry's contribution to climate change and ozone depletion.

The use of advanced materials and designs in PHEV cooling systems can also lead to weight reduction and improved aerodynamics. Lighter vehicles require less energy to operate, further reducing fuel consumption and emissions. Additionally, more efficient cooling systems may allow for smaller radiators and heat exchangers, potentially improving the vehicle's overall aerodynamic profile.

Another environmental consideration is the lifecycle impact of these cooling technologies. Manufacturers are increasingly focusing on the use of recyclable and sustainable materials in cooling system components, aiming to reduce the environmental footprint of PHEVs from production through to end-of-life disposal.

Innovative cooling techniques also contribute to the longevity and reliability of PHEV components, particularly the battery pack. By maintaining optimal operating temperatures, these systems can help extend the lifespan of batteries, reducing the need for premature replacements and the associated environmental impacts of battery production and disposal.

In conclusion, the environmental impact of innovative PHEV cooling techniques extends beyond immediate performance enhancements. These technologies play a crucial role in improving overall vehicle efficiency, reducing emissions, and supporting the transition towards more sustainable transportation solutions. As the automotive industry continues to evolve, the development of environmentally conscious cooling systems will remain a key focus in the pursuit of greener mobility options.

Thermal Management ROI

The return on investment (ROI) for thermal management in plug-in hybrid electric vehicles (PHEVs) is a critical consideration for manufacturers and consumers alike. Effective thermal management systems can significantly enhance vehicle performance, efficiency, and longevity, ultimately leading to substantial cost savings and improved customer satisfaction.

One of the primary benefits of advanced cooling techniques in PHEVs is the optimization of battery performance. By maintaining optimal operating temperatures, these systems can extend battery life, reduce degradation, and improve overall efficiency. This translates to longer driving ranges, reduced charging frequency, and lower replacement costs over the vehicle's lifetime. Studies have shown that proper thermal management can extend battery life by up to 15%, potentially saving thousands of dollars in replacement costs.

Moreover, innovative cooling techniques can enhance the performance of electric motors and power electronics. By efficiently dissipating heat, these systems allow for higher power outputs and improved efficiency, resulting in better acceleration, higher top speeds, and increased overall vehicle performance. This performance boost not only improves the driving experience but also contributes to the vehicle's marketability and competitive edge.

From an energy efficiency standpoint, advanced thermal management systems can significantly reduce the power consumption of climate control systems. By integrating waste heat recovery and intelligent cooling strategies, PHEVs can minimize the energy required for cabin heating and cooling. This efficiency gain directly translates to extended electric driving range and reduced fuel consumption in hybrid mode, offering tangible cost savings to the end-user.

The ROI of thermal management innovations extends beyond direct cost savings. Enhanced reliability and reduced maintenance requirements contribute to lower total cost of ownership. Additionally, improved thermal management can lead to weight reduction in cooling systems, further boosting vehicle efficiency and performance.

From a manufacturer's perspective, investing in innovative cooling techniques can yield substantial returns through increased market share, brand reputation, and customer loyalty. As consumers become more aware of the importance of thermal management in electric and hybrid vehicles, advanced cooling systems can serve as a key differentiator in a competitive market.

In conclusion, the ROI of thermal management in PHEVs is multifaceted, encompassing direct cost savings, performance improvements, and market advantages. As the technology continues to evolve, the potential for returns is likely to grow, making it a crucial area for ongoing research and development in the automotive industry.

One of the primary benefits of advanced cooling techniques in PHEVs is the optimization of battery performance. By maintaining optimal operating temperatures, these systems can extend battery life, reduce degradation, and improve overall efficiency. This translates to longer driving ranges, reduced charging frequency, and lower replacement costs over the vehicle's lifetime. Studies have shown that proper thermal management can extend battery life by up to 15%, potentially saving thousands of dollars in replacement costs.

Moreover, innovative cooling techniques can enhance the performance of electric motors and power electronics. By efficiently dissipating heat, these systems allow for higher power outputs and improved efficiency, resulting in better acceleration, higher top speeds, and increased overall vehicle performance. This performance boost not only improves the driving experience but also contributes to the vehicle's marketability and competitive edge.

From an energy efficiency standpoint, advanced thermal management systems can significantly reduce the power consumption of climate control systems. By integrating waste heat recovery and intelligent cooling strategies, PHEVs can minimize the energy required for cabin heating and cooling. This efficiency gain directly translates to extended electric driving range and reduced fuel consumption in hybrid mode, offering tangible cost savings to the end-user.

The ROI of thermal management innovations extends beyond direct cost savings. Enhanced reliability and reduced maintenance requirements contribute to lower total cost of ownership. Additionally, improved thermal management can lead to weight reduction in cooling systems, further boosting vehicle efficiency and performance.

From a manufacturer's perspective, investing in innovative cooling techniques can yield substantial returns through increased market share, brand reputation, and customer loyalty. As consumers become more aware of the importance of thermal management in electric and hybrid vehicles, advanced cooling systems can serve as a key differentiator in a competitive market.

In conclusion, the ROI of thermal management in PHEVs is multifaceted, encompassing direct cost savings, performance improvements, and market advantages. As the technology continues to evolve, the potential for returns is likely to grow, making it a crucial area for ongoing research and development in the automotive industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!