Investigating Magnesium Nitrate in Advanced Ceramic Production

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Ceramics: Background and Objectives

Magnesium nitrate has emerged as a crucial component in advanced ceramic production, revolutionizing the industry with its unique properties and versatile applications. The evolution of ceramic technology has been closely tied to the development of novel materials and processes, with magnesium nitrate playing an increasingly significant role in recent years.

The journey of magnesium nitrate in ceramics began with its use as a precursor in sol-gel synthesis methods, which allowed for the creation of highly pure and homogeneous ceramic materials. As research progressed, scientists discovered that magnesium nitrate could enhance the sintering process, leading to improved densification and mechanical properties of ceramic products.

In the past decade, the focus has shifted towards exploring the potential of magnesium nitrate in advanced functional ceramics. Researchers have found that incorporating magnesium nitrate into ceramic formulations can lead to enhanced electrical, thermal, and optical properties, opening up new possibilities for applications in electronics, energy storage, and photonics.

The current technological landscape is characterized by a growing demand for high-performance ceramics in various industries, including aerospace, automotive, and medical devices. This demand has driven the need for innovative ceramic production techniques that can deliver superior material properties while maintaining cost-effectiveness and scalability.

As we look towards the future, the primary objectives of investigating magnesium nitrate in advanced ceramic production are multifaceted. First and foremost, there is a need to optimize the incorporation of magnesium nitrate into ceramic matrices to achieve specific material properties tailored for different applications. This involves understanding the complex interactions between magnesium nitrate and other ceramic components at the molecular level.

Another key objective is to develop sustainable and environmentally friendly ceramic production processes that leverage the benefits of magnesium nitrate. This includes exploring low-temperature synthesis routes and reducing energy consumption during the manufacturing process, aligning with global efforts towards greener technologies.

Furthermore, researchers aim to expand the range of ceramic materials that can benefit from magnesium nitrate incorporation. This includes investigating its potential in emerging fields such as additive manufacturing of ceramics and the development of novel composite materials with enhanced functionalities.

As we delve deeper into the role of magnesium nitrate in advanced ceramic production, it becomes clear that this field holds immense potential for technological breakthroughs. The ongoing research and development efforts are expected to yield innovative solutions that will shape the future of ceramic technology across various industries.

The journey of magnesium nitrate in ceramics began with its use as a precursor in sol-gel synthesis methods, which allowed for the creation of highly pure and homogeneous ceramic materials. As research progressed, scientists discovered that magnesium nitrate could enhance the sintering process, leading to improved densification and mechanical properties of ceramic products.

In the past decade, the focus has shifted towards exploring the potential of magnesium nitrate in advanced functional ceramics. Researchers have found that incorporating magnesium nitrate into ceramic formulations can lead to enhanced electrical, thermal, and optical properties, opening up new possibilities for applications in electronics, energy storage, and photonics.

The current technological landscape is characterized by a growing demand for high-performance ceramics in various industries, including aerospace, automotive, and medical devices. This demand has driven the need for innovative ceramic production techniques that can deliver superior material properties while maintaining cost-effectiveness and scalability.

As we look towards the future, the primary objectives of investigating magnesium nitrate in advanced ceramic production are multifaceted. First and foremost, there is a need to optimize the incorporation of magnesium nitrate into ceramic matrices to achieve specific material properties tailored for different applications. This involves understanding the complex interactions between magnesium nitrate and other ceramic components at the molecular level.

Another key objective is to develop sustainable and environmentally friendly ceramic production processes that leverage the benefits of magnesium nitrate. This includes exploring low-temperature synthesis routes and reducing energy consumption during the manufacturing process, aligning with global efforts towards greener technologies.

Furthermore, researchers aim to expand the range of ceramic materials that can benefit from magnesium nitrate incorporation. This includes investigating its potential in emerging fields such as additive manufacturing of ceramics and the development of novel composite materials with enhanced functionalities.

As we delve deeper into the role of magnesium nitrate in advanced ceramic production, it becomes clear that this field holds immense potential for technological breakthroughs. The ongoing research and development efforts are expected to yield innovative solutions that will shape the future of ceramic technology across various industries.

Market Analysis for Advanced Ceramic Materials

The advanced ceramics market has been experiencing significant growth in recent years, driven by increasing demand across various industries such as electronics, aerospace, automotive, and healthcare. The global advanced ceramics market size was valued at approximately $75 billion in 2020 and is projected to reach $130 billion by 2027, growing at a CAGR of around 8% during the forecast period.

The use of magnesium nitrate in advanced ceramic production is gaining traction due to its potential to enhance material properties and manufacturing processes. This trend is particularly evident in the development of high-performance ceramics for specialized applications. The market for magnesium nitrate-based advanced ceramics is expected to grow in tandem with the overall advanced ceramics market, albeit at a slightly higher rate due to its emerging applications.

Key market drivers for advanced ceramics include the growing demand for lightweight and high-strength materials in aerospace and automotive industries, increasing use of ceramics in electronics and semiconductor manufacturing, and the rising adoption of ceramic-based medical implants and devices. The market for magnesium nitrate in advanced ceramic production is specifically benefiting from the need for improved thermal and electrical properties in certain ceramic applications.

Geographically, Asia-Pacific dominates the advanced ceramics market, accounting for over 40% of the global market share. This is primarily due to the strong presence of electronics and automotive industries in countries like China, Japan, and South Korea. North America and Europe follow, with significant contributions from aerospace and healthcare sectors.

The market landscape is characterized by intense competition among key players such as Kyocera Corporation, CeramTec GmbH, Saint-Gobain Ceramic Materials, and Morgan Advanced Materials. These companies are investing heavily in research and development to innovate new ceramic materials and production techniques, including those involving magnesium nitrate.

Challenges in the market include high production costs, complex manufacturing processes, and the need for specialized skills and equipment. However, ongoing technological advancements and increasing investments in research and development are expected to address these challenges and drive market growth.

In conclusion, the market analysis for advanced ceramic materials, particularly those involving magnesium nitrate, indicates a promising future with substantial growth potential. As industries continue to demand high-performance materials with superior properties, the role of magnesium nitrate in advanced ceramic production is likely to expand, creating new opportunities for market players and driving innovation in the field.

The use of magnesium nitrate in advanced ceramic production is gaining traction due to its potential to enhance material properties and manufacturing processes. This trend is particularly evident in the development of high-performance ceramics for specialized applications. The market for magnesium nitrate-based advanced ceramics is expected to grow in tandem with the overall advanced ceramics market, albeit at a slightly higher rate due to its emerging applications.

Key market drivers for advanced ceramics include the growing demand for lightweight and high-strength materials in aerospace and automotive industries, increasing use of ceramics in electronics and semiconductor manufacturing, and the rising adoption of ceramic-based medical implants and devices. The market for magnesium nitrate in advanced ceramic production is specifically benefiting from the need for improved thermal and electrical properties in certain ceramic applications.

Geographically, Asia-Pacific dominates the advanced ceramics market, accounting for over 40% of the global market share. This is primarily due to the strong presence of electronics and automotive industries in countries like China, Japan, and South Korea. North America and Europe follow, with significant contributions from aerospace and healthcare sectors.

The market landscape is characterized by intense competition among key players such as Kyocera Corporation, CeramTec GmbH, Saint-Gobain Ceramic Materials, and Morgan Advanced Materials. These companies are investing heavily in research and development to innovate new ceramic materials and production techniques, including those involving magnesium nitrate.

Challenges in the market include high production costs, complex manufacturing processes, and the need for specialized skills and equipment. However, ongoing technological advancements and increasing investments in research and development are expected to address these challenges and drive market growth.

In conclusion, the market analysis for advanced ceramic materials, particularly those involving magnesium nitrate, indicates a promising future with substantial growth potential. As industries continue to demand high-performance materials with superior properties, the role of magnesium nitrate in advanced ceramic production is likely to expand, creating new opportunities for market players and driving innovation in the field.

Current Challenges in Magnesium Nitrate Utilization

The utilization of magnesium nitrate in advanced ceramic production faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the hygroscopic nature of magnesium nitrate, which makes it highly susceptible to moisture absorption from the environment. This property can lead to difficulties in storage, handling, and precise dosing during the ceramic manufacturing process.

Another challenge lies in the thermal decomposition behavior of magnesium nitrate. When exposed to high temperatures during ceramic sintering, magnesium nitrate undergoes complex decomposition reactions, potentially resulting in the formation of undesired intermediate compounds or gas evolution. These phenomena can adversely affect the microstructure and properties of the final ceramic product, necessitating careful control of the thermal processing parameters.

The reactivity of magnesium nitrate with other ceramic precursors and additives presents additional complications. Interactions between magnesium nitrate and other components in the ceramic formulation may lead to unexpected phase formations or alterations in the intended composition. This challenge requires extensive research and optimization to develop compatible material systems that can harness the benefits of magnesium nitrate without compromising the desired ceramic properties.

Furthermore, the environmental and safety concerns associated with the use of nitrate compounds in industrial processes pose regulatory and operational challenges. Stringent regulations regarding the handling, storage, and disposal of nitrate-containing materials necessitate the implementation of robust safety protocols and waste management strategies, potentially increasing production costs and complexity.

The scalability of magnesium nitrate-based ceramic production processes also presents hurdles for industrial implementation. Achieving consistent quality and properties in large-scale production requires precise control over reaction kinetics, mixing uniformity, and processing conditions. Developing scalable manufacturing techniques that maintain the advantages of magnesium nitrate while ensuring reproducibility and cost-effectiveness remains a significant challenge for researchers and industry practitioners.

Lastly, the limited understanding of the exact mechanisms by which magnesium nitrate influences the microstructure and properties of advanced ceramics hinders the optimization of material systems and processing techniques. Further fundamental research is needed to elucidate the complex relationships between magnesium nitrate incorporation, ceramic microstructure evolution, and resultant material properties, enabling more targeted and efficient utilization of this promising precursor in advanced ceramic production.

Another challenge lies in the thermal decomposition behavior of magnesium nitrate. When exposed to high temperatures during ceramic sintering, magnesium nitrate undergoes complex decomposition reactions, potentially resulting in the formation of undesired intermediate compounds or gas evolution. These phenomena can adversely affect the microstructure and properties of the final ceramic product, necessitating careful control of the thermal processing parameters.

The reactivity of magnesium nitrate with other ceramic precursors and additives presents additional complications. Interactions between magnesium nitrate and other components in the ceramic formulation may lead to unexpected phase formations or alterations in the intended composition. This challenge requires extensive research and optimization to develop compatible material systems that can harness the benefits of magnesium nitrate without compromising the desired ceramic properties.

Furthermore, the environmental and safety concerns associated with the use of nitrate compounds in industrial processes pose regulatory and operational challenges. Stringent regulations regarding the handling, storage, and disposal of nitrate-containing materials necessitate the implementation of robust safety protocols and waste management strategies, potentially increasing production costs and complexity.

The scalability of magnesium nitrate-based ceramic production processes also presents hurdles for industrial implementation. Achieving consistent quality and properties in large-scale production requires precise control over reaction kinetics, mixing uniformity, and processing conditions. Developing scalable manufacturing techniques that maintain the advantages of magnesium nitrate while ensuring reproducibility and cost-effectiveness remains a significant challenge for researchers and industry practitioners.

Lastly, the limited understanding of the exact mechanisms by which magnesium nitrate influences the microstructure and properties of advanced ceramics hinders the optimization of material systems and processing techniques. Further fundamental research is needed to elucidate the complex relationships between magnesium nitrate incorporation, ceramic microstructure evolution, and resultant material properties, enabling more targeted and efficient utilization of this promising precursor in advanced ceramic production.

Existing Applications of Magnesium Nitrate in Ceramics

01 Magnesium nitrate in fertilizer compositions

Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer formulations can be tailored for specific crops or soil conditions.- Magnesium nitrate in fertilizer compositions: Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.

- Magnesium nitrate in energy storage applications: Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.

- Magnesium nitrate in flame retardant formulations: Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an effective fire suppressant by releasing non-flammable gases when exposed to high temperatures. These formulations can be applied to textiles, plastics, and other combustible materials to enhance their fire resistance properties.

- Magnesium nitrate in water treatment processes: Magnesium nitrate is employed in water treatment processes for its ability to remove contaminants and improve water quality. It can be used in the treatment of wastewater, groundwater, and industrial effluents. The compound helps in the precipitation of certain pollutants and can also be used in the regeneration of ion exchange resins.

- Magnesium nitrate in chemical synthesis: Magnesium nitrate serves as a versatile reagent in various chemical synthesis processes. It is used as a precursor in the production of other magnesium compounds, as a catalyst in certain organic reactions, and as a source of nitrate ions in inorganic synthesis. Its applications extend to the production of ceramics, pigments, and other industrial materials.

02 Magnesium nitrate in energy storage applications

Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.Expand Specific Solutions03 Magnesium nitrate in water treatment processes

Magnesium nitrate finds applications in water treatment processes. It can be used as a coagulant or flocculant to remove impurities from water. Additionally, it may be employed in the treatment of wastewater or in the preparation of drinking water to adjust mineral content.Expand Specific Solutions04 Magnesium nitrate in flame retardant formulations

Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an inorganic flame retardant, enhancing the fire resistance of products such as textiles, plastics, and wood-based materials. These formulations can improve the safety of consumer goods and construction materials.Expand Specific Solutions05 Magnesium nitrate in chemical synthesis and catalysis

Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It can be used in the production of other magnesium compounds, as a catalyst support, or as a reagent in organic synthesis reactions. Its applications extend to the manufacturing of pharmaceuticals, fine chemicals, and advanced materials.Expand Specific Solutions

Key Players in Advanced Ceramic Industry

The investigation of magnesium nitrate in advanced ceramic production is currently in a growth phase, with increasing market demand and technological advancements. The global market for advanced ceramics is expanding, driven by applications in electronics, aerospace, and energy sectors. The technology's maturity varies among key players, with companies like FUJIFILM Corp., Sumitomo Chemical Co., Ltd., and NGK Insulators, Ltd. leading in research and development. These firms are leveraging their expertise in materials science to enhance magnesium nitrate's role in ceramic production. Universities and research institutions, such as the University of Seville and Korea Institute of Machinery & Materials, are also contributing to the field's progress, indicating a collaborative ecosystem for innovation in this technology.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed an innovative approach to using magnesium nitrate in advanced ceramic production. Their method involves a sol-gel process where magnesium nitrate is used as a precursor for synthesizing high-purity magnesium oxide nanoparticles[1]. These nanoparticles are then incorporated into ceramic matrices to enhance mechanical properties and thermal stability. The company has also explored the use of magnesium nitrate in the production of magnesium aluminate spinel ceramics, which offer excellent optical and mechanical properties[2]. Their research has shown that controlling the decomposition of magnesium nitrate during the ceramic sintering process can lead to improved microstructure and reduced porosity in the final product[3].

Strengths: High-purity precursor synthesis, enhanced mechanical properties, improved thermal stability. Weaknesses: Complex process control required, potential for nitrate residues in final product.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a proprietary method for utilizing magnesium nitrate in the production of advanced ceramics for electrical insulation and energy storage applications. Their approach involves a modified solution combustion synthesis technique, where magnesium nitrate serves as both the oxidizer and the magnesium source[4]. This method allows for precise control over the ceramic composition and microstructure. NGK has successfully applied this technique to produce high-performance magnesium oxide-based ceramics with enhanced dielectric properties and improved thermal conductivity[5]. The company has also investigated the use of magnesium nitrate in the fabrication of ceramic-metal composites, which exhibit superior mechanical strength and electrical conductivity compared to traditional ceramics[6].

Strengths: Precise composition control, enhanced dielectric properties, improved thermal conductivity. Weaknesses: Energy-intensive combustion process, potential for non-uniform particle size distribution.

Innovative Magnesium Nitrate Formulations

Novel ceramic materials having improved mechanical properties & process for their preparation

PatentUndeterminedIN3396DEL2005A

Innovation

- A process involving the preparation of alumina with nano-sized MgO particles less than 15 nm, using a method that includes dissolving magnesium nitrate and sucrose in water, dehydration to form a gel, calcination to produce nano MgO, and subsequent blending with alumina followed by spark plasma sintering to enhance mechanical properties.

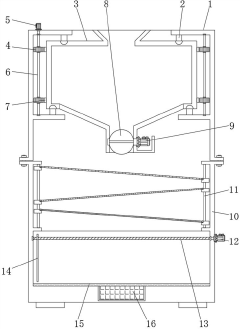

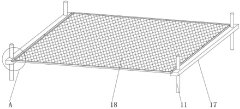

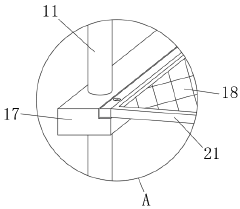

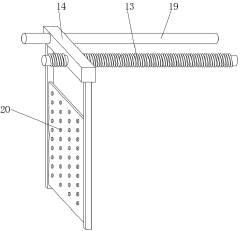

Magnesium nitrate production filtering device

PatentActiveCN218188154U

Innovation

- The melting box can rotate smoothly through the meshing of the tooth block and gear, allowing for thorough melting and filtration of magnesium nitrate solution.

- The threaded connection between the swing frame and threaded rod enables left-right sliding, facilitating solution paddling and improving dissolution.

- Integration of a heater with a heat conducting plate for rapid crystallization of the magnesium nitrate solution.

Environmental Impact of Magnesium Nitrate Production

The production of magnesium nitrate for advanced ceramic manufacturing has significant environmental implications that warrant careful consideration. The primary environmental concerns stem from the extraction of raw materials, energy consumption during production, and potential pollution from waste products.

Raw material extraction, particularly magnesium mining, can lead to habitat destruction, soil erosion, and water pollution. Open-pit mining, a common method for magnesium extraction, often results in large-scale land disturbance and can impact local ecosystems. Additionally, the processing of magnesium ore typically involves the use of strong acids, which can contaminate soil and water sources if not properly managed.

The production process of magnesium nitrate is energy-intensive, contributing to greenhouse gas emissions and climate change. The Nitric Acid process, commonly used for magnesium nitrate synthesis, requires high temperatures and pressures, resulting in substantial energy consumption. This energy demand is often met through fossil fuel combustion, further exacerbating the carbon footprint of the production process.

Waste management is another critical environmental concern. The production of magnesium nitrate generates various by-products and effluents that require proper treatment and disposal. Improper handling of these wastes can lead to soil and water contamination, potentially affecting both terrestrial and aquatic ecosystems. Of particular concern are nitrate-rich effluents, which can contribute to eutrophication in water bodies if released untreated.

Air pollution is also a significant issue associated with magnesium nitrate production. The process can release nitrogen oxides (NOx) and particulate matter into the atmosphere. These emissions can contribute to smog formation, acid rain, and respiratory health issues in nearby communities.

However, it's important to note that the environmental impact of magnesium nitrate production can be mitigated through various strategies. Implementing cleaner production technologies, such as closed-loop systems and energy-efficient equipment, can significantly reduce resource consumption and waste generation. Additionally, adopting renewable energy sources for powering production facilities can help decrease the carbon footprint of the manufacturing process.

Recycling and recovery of magnesium and nitrate compounds from waste streams can also play a crucial role in minimizing environmental impact. This not only reduces the demand for raw materials but also decreases the volume of waste requiring disposal. Furthermore, implementing stringent environmental management systems and adhering to regulatory standards can help ensure that production facilities operate in an environmentally responsible manner.

In conclusion, while the production of magnesium nitrate for advanced ceramic manufacturing does pose several environmental challenges, proactive measures and technological advancements can help mitigate these impacts. As the demand for advanced ceramics continues to grow, it is crucial for the industry to prioritize sustainable production methods and invest in eco-friendly technologies to minimize its environmental footprint.

Raw material extraction, particularly magnesium mining, can lead to habitat destruction, soil erosion, and water pollution. Open-pit mining, a common method for magnesium extraction, often results in large-scale land disturbance and can impact local ecosystems. Additionally, the processing of magnesium ore typically involves the use of strong acids, which can contaminate soil and water sources if not properly managed.

The production process of magnesium nitrate is energy-intensive, contributing to greenhouse gas emissions and climate change. The Nitric Acid process, commonly used for magnesium nitrate synthesis, requires high temperatures and pressures, resulting in substantial energy consumption. This energy demand is often met through fossil fuel combustion, further exacerbating the carbon footprint of the production process.

Waste management is another critical environmental concern. The production of magnesium nitrate generates various by-products and effluents that require proper treatment and disposal. Improper handling of these wastes can lead to soil and water contamination, potentially affecting both terrestrial and aquatic ecosystems. Of particular concern are nitrate-rich effluents, which can contribute to eutrophication in water bodies if released untreated.

Air pollution is also a significant issue associated with magnesium nitrate production. The process can release nitrogen oxides (NOx) and particulate matter into the atmosphere. These emissions can contribute to smog formation, acid rain, and respiratory health issues in nearby communities.

However, it's important to note that the environmental impact of magnesium nitrate production can be mitigated through various strategies. Implementing cleaner production technologies, such as closed-loop systems and energy-efficient equipment, can significantly reduce resource consumption and waste generation. Additionally, adopting renewable energy sources for powering production facilities can help decrease the carbon footprint of the manufacturing process.

Recycling and recovery of magnesium and nitrate compounds from waste streams can also play a crucial role in minimizing environmental impact. This not only reduces the demand for raw materials but also decreases the volume of waste requiring disposal. Furthermore, implementing stringent environmental management systems and adhering to regulatory standards can help ensure that production facilities operate in an environmentally responsible manner.

In conclusion, while the production of magnesium nitrate for advanced ceramic manufacturing does pose several environmental challenges, proactive measures and technological advancements can help mitigate these impacts. As the demand for advanced ceramics continues to grow, it is crucial for the industry to prioritize sustainable production methods and invest in eco-friendly technologies to minimize its environmental footprint.

Regulatory Framework for Ceramic Manufacturing

The regulatory framework for ceramic manufacturing, particularly in the context of using magnesium nitrate in advanced ceramic production, encompasses a complex set of guidelines and standards designed to ensure product safety, environmental protection, and quality control. These regulations vary across different regions and countries, but generally share common objectives.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating ceramic manufacturing processes. The Clean Air Act and Clean Water Act are particularly relevant, as they set limits on emissions and effluents from ceramic production facilities. The Occupational Safety and Health Administration (OSHA) also imposes strict guidelines on workplace safety, especially concerning the handling of potentially hazardous materials like magnesium nitrate.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which directly impacts the use of chemicals in ceramic manufacturing. Under REACH, manufacturers must register chemicals used in their processes and demonstrate their safe use. This regulation has significant implications for the use of magnesium nitrate in advanced ceramic production within the EU.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Environmental Protection has introduced stringent environmental protection laws that affect ceramic manufacturing. Japan's regulatory approach focuses on product quality and safety, with the Japan Industrial Standards (JIS) playing a key role in setting specifications for ceramic products.

Specific to magnesium nitrate use in advanced ceramics, regulations often focus on its storage, handling, and disposal due to its oxidizing properties. Many jurisdictions classify it as a hazardous material, requiring special permits for its use and transportation. Manufacturers must adhere to strict protocols for its storage and handling to prevent accidents and environmental contamination.

The regulatory landscape also extends to product certification and quality standards. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines and standards for ceramic products, which manufacturers must meet to ensure market acceptance and compliance.

As the ceramic industry evolves, particularly with the integration of advanced materials like magnesium nitrate, regulatory bodies are continuously updating their frameworks. This dynamic regulatory environment requires manufacturers to stay informed and adaptable, often necessitating significant investments in compliance measures and technologies.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating ceramic manufacturing processes. The Clean Air Act and Clean Water Act are particularly relevant, as they set limits on emissions and effluents from ceramic production facilities. The Occupational Safety and Health Administration (OSHA) also imposes strict guidelines on workplace safety, especially concerning the handling of potentially hazardous materials like magnesium nitrate.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which directly impacts the use of chemicals in ceramic manufacturing. Under REACH, manufacturers must register chemicals used in their processes and demonstrate their safe use. This regulation has significant implications for the use of magnesium nitrate in advanced ceramic production within the EU.

In Asia, countries like China and Japan have their own regulatory frameworks. China's Ministry of Environmental Protection has introduced stringent environmental protection laws that affect ceramic manufacturing. Japan's regulatory approach focuses on product quality and safety, with the Japan Industrial Standards (JIS) playing a key role in setting specifications for ceramic products.

Specific to magnesium nitrate use in advanced ceramics, regulations often focus on its storage, handling, and disposal due to its oxidizing properties. Many jurisdictions classify it as a hazardous material, requiring special permits for its use and transportation. Manufacturers must adhere to strict protocols for its storage and handling to prevent accidents and environmental contamination.

The regulatory landscape also extends to product certification and quality standards. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide guidelines and standards for ceramic products, which manufacturers must meet to ensure market acceptance and compliance.

As the ceramic industry evolves, particularly with the integration of advanced materials like magnesium nitrate, regulatory bodies are continuously updating their frameworks. This dynamic regulatory environment requires manufacturers to stay informed and adaptable, often necessitating significant investments in compliance measures and technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!