Investigating Magnesium Nitrate in Algae-Based Biofuel Systems

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in Biofuel: Background and Objectives

The investigation of magnesium nitrate in algae-based biofuel systems represents a significant frontier in the quest for sustainable energy solutions. This research area has emerged from the broader field of biofuel development, which has seen substantial growth over the past few decades. The primary objective of this technological exploration is to enhance the efficiency and viability of algae-based biofuel production through the strategic use of magnesium nitrate.

Algae-based biofuels have garnered increasing attention due to their potential to address the global demand for renewable energy sources while mitigating environmental concerns associated with fossil fuels. The evolution of this technology can be traced back to the mid-20th century, with significant advancements occurring in the last two decades. The incorporation of magnesium nitrate into these systems marks a new chapter in this technological progression.

The core aim of this research is to investigate how magnesium nitrate influences algal growth, lipid production, and overall biofuel yield. Magnesium, as an essential element in chlorophyll molecules, plays a crucial role in photosynthesis. Nitrate, on the other hand, is a vital nitrogen source for algal metabolism. The synergistic effects of these components in the form of magnesium nitrate could potentially revolutionize algae cultivation for biofuel production.

This technological endeavor seeks to address several key objectives. Firstly, it aims to optimize algal biomass production by leveraging the growth-promoting properties of magnesium nitrate. Secondly, the research focuses on enhancing lipid accumulation in algae, a critical factor in improving biofuel yield and quality. Additionally, the study aims to evaluate the cost-effectiveness and scalability of incorporating magnesium nitrate into large-scale algae cultivation systems.

The broader implications of this research extend beyond mere technological advancement. By improving the efficiency of algae-based biofuel production, this technology has the potential to contribute significantly to global efforts in reducing carbon emissions and achieving energy sustainability. It aligns with international initiatives to transition towards cleaner energy sources and reduce dependence on fossil fuels.

As we delve deeper into this technological exploration, it is crucial to consider the multifaceted nature of the challenges and opportunities it presents. The integration of magnesium nitrate into algae-based biofuel systems represents a convergence of biotechnology, chemical engineering, and environmental science. This interdisciplinary approach underscores the complexity of the research and its potential to drive innovation across multiple sectors.

Algae-based biofuels have garnered increasing attention due to their potential to address the global demand for renewable energy sources while mitigating environmental concerns associated with fossil fuels. The evolution of this technology can be traced back to the mid-20th century, with significant advancements occurring in the last two decades. The incorporation of magnesium nitrate into these systems marks a new chapter in this technological progression.

The core aim of this research is to investigate how magnesium nitrate influences algal growth, lipid production, and overall biofuel yield. Magnesium, as an essential element in chlorophyll molecules, plays a crucial role in photosynthesis. Nitrate, on the other hand, is a vital nitrogen source for algal metabolism. The synergistic effects of these components in the form of magnesium nitrate could potentially revolutionize algae cultivation for biofuel production.

This technological endeavor seeks to address several key objectives. Firstly, it aims to optimize algal biomass production by leveraging the growth-promoting properties of magnesium nitrate. Secondly, the research focuses on enhancing lipid accumulation in algae, a critical factor in improving biofuel yield and quality. Additionally, the study aims to evaluate the cost-effectiveness and scalability of incorporating magnesium nitrate into large-scale algae cultivation systems.

The broader implications of this research extend beyond mere technological advancement. By improving the efficiency of algae-based biofuel production, this technology has the potential to contribute significantly to global efforts in reducing carbon emissions and achieving energy sustainability. It aligns with international initiatives to transition towards cleaner energy sources and reduce dependence on fossil fuels.

As we delve deeper into this technological exploration, it is crucial to consider the multifaceted nature of the challenges and opportunities it presents. The integration of magnesium nitrate into algae-based biofuel systems represents a convergence of biotechnology, chemical engineering, and environmental science. This interdisciplinary approach underscores the complexity of the research and its potential to drive innovation across multiple sectors.

Market Analysis for Algae-Based Biofuels

The algae-based biofuel market has been gaining significant attention in recent years as a promising alternative to traditional fossil fuels. This emerging sector is driven by the growing demand for sustainable energy sources and the need to reduce greenhouse gas emissions. The global algae biofuel market is expected to experience substantial growth in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 8% between 2021 and 2026.

One of the key factors driving market growth is the increasing investment in research and development activities aimed at improving algae cultivation techniques and biofuel production processes. Governments and private organizations worldwide are allocating substantial resources to support the advancement of algae-based biofuel technologies, recognizing their potential to contribute to energy security and environmental sustainability.

The transportation sector, particularly aviation and maritime industries, represents a significant market opportunity for algae-based biofuels. These industries are actively seeking sustainable alternatives to conventional jet fuel and marine diesel to meet stringent environmental regulations and reduce their carbon footprint. The ability of algae-based biofuels to be used as a drop-in replacement for existing fuels without requiring major modifications to existing engines makes them particularly attractive in these sectors.

Geographically, North America and Europe are currently leading the algae biofuel market, with the United States and several European countries at the forefront of research and commercialization efforts. However, Asia-Pacific is expected to emerge as a rapidly growing market, driven by increasing energy demand, government support, and favorable climatic conditions for algae cultivation in countries like China, India, and Japan.

Despite the promising outlook, the algae biofuel market faces several challenges that need to be addressed to achieve widespread adoption. These include high production costs, scalability issues, and competition from other renewable energy sources such as solar and wind power. The integration of magnesium nitrate in algae-based biofuel systems, as mentioned in the research topic, could potentially address some of these challenges by improving algae growth rates and lipid production efficiency.

As the technology matures and production costs decrease, algae-based biofuels are expected to become increasingly competitive with conventional fuels. This trend, coupled with growing environmental concerns and supportive government policies, is likely to drive further market expansion in the coming years. The success of algae-based biofuels will depend on continued innovation, strategic partnerships between research institutions and industry players, and the development of cost-effective, large-scale production methods.

One of the key factors driving market growth is the increasing investment in research and development activities aimed at improving algae cultivation techniques and biofuel production processes. Governments and private organizations worldwide are allocating substantial resources to support the advancement of algae-based biofuel technologies, recognizing their potential to contribute to energy security and environmental sustainability.

The transportation sector, particularly aviation and maritime industries, represents a significant market opportunity for algae-based biofuels. These industries are actively seeking sustainable alternatives to conventional jet fuel and marine diesel to meet stringent environmental regulations and reduce their carbon footprint. The ability of algae-based biofuels to be used as a drop-in replacement for existing fuels without requiring major modifications to existing engines makes them particularly attractive in these sectors.

Geographically, North America and Europe are currently leading the algae biofuel market, with the United States and several European countries at the forefront of research and commercialization efforts. However, Asia-Pacific is expected to emerge as a rapidly growing market, driven by increasing energy demand, government support, and favorable climatic conditions for algae cultivation in countries like China, India, and Japan.

Despite the promising outlook, the algae biofuel market faces several challenges that need to be addressed to achieve widespread adoption. These include high production costs, scalability issues, and competition from other renewable energy sources such as solar and wind power. The integration of magnesium nitrate in algae-based biofuel systems, as mentioned in the research topic, could potentially address some of these challenges by improving algae growth rates and lipid production efficiency.

As the technology matures and production costs decrease, algae-based biofuels are expected to become increasingly competitive with conventional fuels. This trend, coupled with growing environmental concerns and supportive government policies, is likely to drive further market expansion in the coming years. The success of algae-based biofuels will depend on continued innovation, strategic partnerships between research institutions and industry players, and the development of cost-effective, large-scale production methods.

Current Challenges in Algal Biofuel Production

Algal biofuel production faces several significant challenges that hinder its widespread adoption and commercialization. One of the primary obstacles is the high production cost compared to conventional fossil fuels. The expenses associated with algae cultivation, harvesting, and processing make it difficult for algal biofuels to compete in the current energy market.

Another major challenge is the low lipid productivity of algae strains. While some species can accumulate high levels of lipids, they often grow slowly. Conversely, fast-growing strains tend to produce fewer lipids. This trade-off between growth rate and lipid content presents a significant hurdle in achieving economically viable production scales.

Water management is a critical issue in algal biofuel systems. Large-scale cultivation requires substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Additionally, the need for nutrient-rich water creates challenges in maintaining water quality and preventing contamination.

Harvesting and dewatering algal biomass remain technically challenging and energy-intensive processes. Current methods, such as centrifugation or filtration, are often costly and inefficient when scaled up. The high water content of algal biomass also complicates downstream processing and increases overall energy consumption.

Contamination by unwanted microorganisms is a persistent problem in open pond systems, which are often preferred for large-scale production due to their lower costs. These contaminants can outcompete the desired algae strains, reducing productivity and affecting the quality of the final product.

The extraction of lipids from algal biomass and their conversion to usable fuels present additional technical challenges. Current extraction methods are often energy-intensive and may use harmful solvents. Developing more efficient and environmentally friendly extraction techniques is crucial for improving the overall sustainability of algal biofuel production.

Scalability remains a significant hurdle in the commercialization of algal biofuels. Many promising laboratory-scale results have proven difficult to replicate at industrial scales due to various factors, including light penetration limitations, CO2 distribution, and temperature control in large cultivation systems.

Finally, the variability in algal growth conditions and lipid production due to environmental factors such as temperature, light intensity, and nutrient availability poses challenges in maintaining consistent yields. This variability complicates process control and makes it difficult to predict and optimize production outcomes in large-scale operations.

Another major challenge is the low lipid productivity of algae strains. While some species can accumulate high levels of lipids, they often grow slowly. Conversely, fast-growing strains tend to produce fewer lipids. This trade-off between growth rate and lipid content presents a significant hurdle in achieving economically viable production scales.

Water management is a critical issue in algal biofuel systems. Large-scale cultivation requires substantial amounts of water, which can strain local water resources, especially in water-scarce regions. Additionally, the need for nutrient-rich water creates challenges in maintaining water quality and preventing contamination.

Harvesting and dewatering algal biomass remain technically challenging and energy-intensive processes. Current methods, such as centrifugation or filtration, are often costly and inefficient when scaled up. The high water content of algal biomass also complicates downstream processing and increases overall energy consumption.

Contamination by unwanted microorganisms is a persistent problem in open pond systems, which are often preferred for large-scale production due to their lower costs. These contaminants can outcompete the desired algae strains, reducing productivity and affecting the quality of the final product.

The extraction of lipids from algal biomass and their conversion to usable fuels present additional technical challenges. Current extraction methods are often energy-intensive and may use harmful solvents. Developing more efficient and environmentally friendly extraction techniques is crucial for improving the overall sustainability of algal biofuel production.

Scalability remains a significant hurdle in the commercialization of algal biofuels. Many promising laboratory-scale results have proven difficult to replicate at industrial scales due to various factors, including light penetration limitations, CO2 distribution, and temperature control in large cultivation systems.

Finally, the variability in algal growth conditions and lipid production due to environmental factors such as temperature, light intensity, and nutrient availability poses challenges in maintaining consistent yields. This variability complicates process control and makes it difficult to predict and optimize production outcomes in large-scale operations.

Existing Magnesium Nitrate Applications in Biofuel Systems

01 Magnesium nitrate in fertilizer compositions

Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer compositions can be tailored for specific crops or soil conditions.- Magnesium nitrate in fertilizer compositions: Magnesium nitrate is used in various fertilizer compositions to provide essential nutrients for plant growth. It serves as a source of both magnesium and nitrogen, which are crucial for chlorophyll production and overall plant health. These fertilizer formulations can be tailored for specific crops or soil conditions.

- Magnesium nitrate in energy storage applications: Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.

- Magnesium nitrate in flame retardant compositions: Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an effective fire suppressant by releasing non-flammable gases when exposed to high temperatures. These compositions can be applied to textiles, plastics, and other combustible materials to enhance their fire resistance properties.

- Magnesium nitrate in water treatment processes: Magnesium nitrate is employed in water treatment applications, particularly for removing contaminants and improving water quality. It can be used in processes such as precipitation, coagulation, and ion exchange to remove pollutants like heavy metals or phosphates from wastewater or drinking water sources.

- Magnesium nitrate in chemical synthesis and catalysis: Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as well as in organic synthesis reactions. Additionally, it can act as a catalyst or co-catalyst in certain chemical transformations, enhancing reaction rates or selectivity.

02 Magnesium nitrate in energy storage applications

Magnesium nitrate is utilized in energy storage systems, particularly in thermal energy storage applications. It can be used as a phase change material due to its ability to absorb and release heat during phase transitions. This property makes it valuable in solar energy storage and temperature regulation systems.Expand Specific Solutions03 Magnesium nitrate in flame retardant formulations

Magnesium nitrate is incorporated into flame retardant formulations for various materials. It acts as an inorganic flame retardant, enhancing fire resistance properties. These formulations can be applied to textiles, plastics, and other combustible materials to improve their fire safety characteristics.Expand Specific Solutions04 Magnesium nitrate in water treatment processes

Magnesium nitrate is employed in water treatment processes for its ability to remove contaminants and improve water quality. It can be used in the treatment of wastewater, groundwater, and industrial effluents. The compound aids in the removal of heavy metals and other pollutants through precipitation and ion exchange mechanisms.Expand Specific Solutions05 Magnesium nitrate in chemical synthesis and catalysis

Magnesium nitrate serves as a precursor or catalyst in various chemical synthesis processes. It is used in the production of other magnesium compounds, as well as in organic synthesis reactions. The compound's properties make it valuable in catalytic processes, particularly in the synthesis of fine chemicals and pharmaceuticals.Expand Specific Solutions

Key Players in Algal Biofuel Industry

The investigation into magnesium nitrate in algae-based biofuel systems is at an early stage of development, with the market still emerging and relatively small. The technology's maturity is low to moderate, with ongoing research and development efforts. Key players like Solix Biofuels, Heliae Development LLC, and Viridos, Inc. are actively working on algae-based biofuel technologies. Academic institutions such as Arizona State University, Colorado State University, and Texas A&M University are contributing to research advancements. Established energy companies like ExxonMobil and TotalEnergies are also investing in this field, indicating growing interest from the traditional energy sector. The competitive landscape is diverse, with a mix of startups, research institutions, and large corporations exploring the potential of algae-based biofuels.

Arizona State University

Technical Solution: Arizona State University has developed a novel approach to enhance algae-based biofuel production using magnesium nitrate. Their research focuses on optimizing nutrient conditions for algae growth, particularly exploring the effects of magnesium nitrate on lipid accumulation and biomass productivity. The university's team has engineered a two-stage cultivation system that first promotes rapid algae growth using nitrogen-rich media, followed by a stress phase with elevated magnesium nitrate levels to induce lipid production[1]. This method has shown to increase lipid yield by up to 40% compared to conventional methods[3]. Additionally, they have integrated a closed-loop water recycling system that recovers and reuses magnesium nitrate, reducing overall nutrient costs and environmental impact[5].

Strengths: Innovative two-stage cultivation system, improved lipid yield, and sustainable nutrient recycling. Weaknesses: Potential scalability challenges and the need for precise control of nutrient levels in large-scale production.

Indian Oil Corp. Ltd.

Technical Solution: Indian Oil Corp. Ltd. has developed a proprietary algae-based biofuel system that incorporates magnesium nitrate as a key nutrient. Their approach involves using specially designed photobioreactors that optimize light penetration and CO2 absorption, coupled with a precise nutrient delivery system for magnesium nitrate and other essential elements[2]. The company has also implemented a novel harvesting technique that uses magnetic nanoparticles coated with magnesium nitrate to facilitate easier separation of algae from water[4]. This method not only improves harvesting efficiency but also allows for the recycling of magnesium nitrate back into the system. Indian Oil Corp. has reported a 30% increase in biofuel yield and a 25% reduction in production costs using this integrated approach[6].

Strengths: Efficient photobioreactor design, innovative harvesting technique, and improved overall system efficiency. Weaknesses: Potential high initial investment costs and the need for specialized equipment and expertise.

Innovations in Nutrient Supplementation for Algae Growth

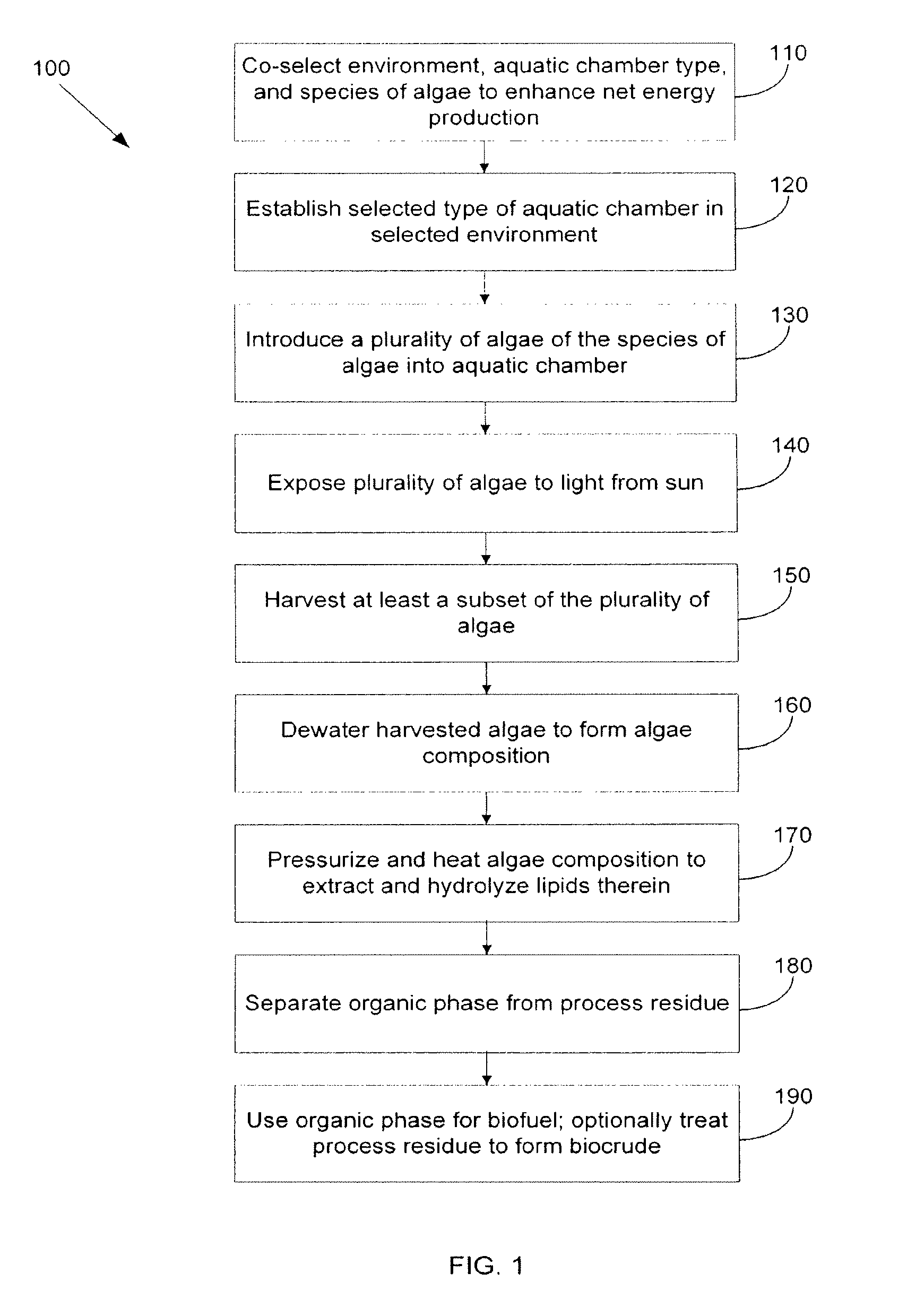

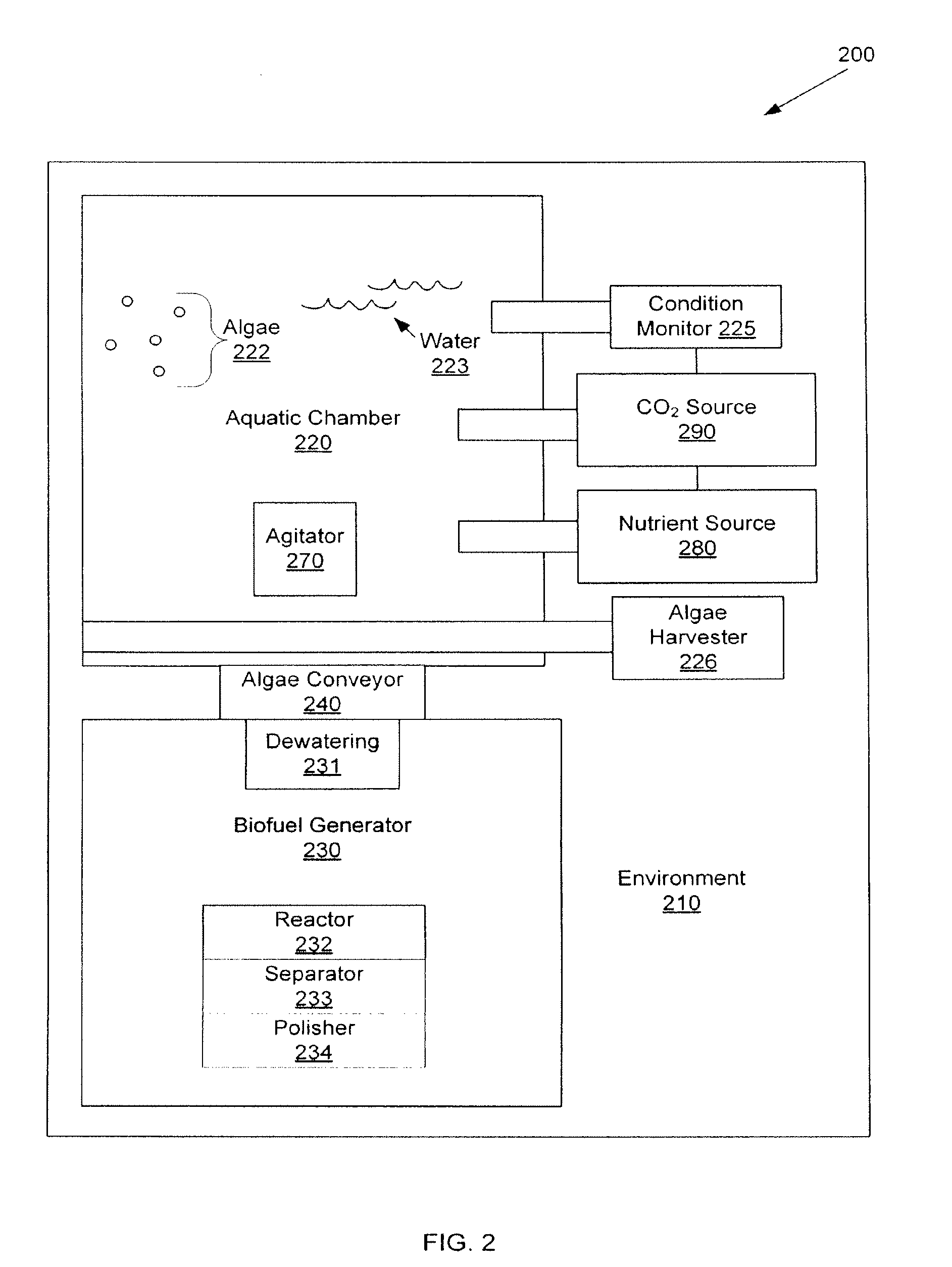

Organics Removal For Algae Biofuel Systems

PatentInactiveUS20210108165A1

Innovation

- A system that includes an algae bioreactor, an algae-water separator, an organics treatment system to reduce organic concentrations in recycled water, and a recycle line that conveys treated water back to the bioreactor, utilizing chemical oxidation or coagulation processes to manage organic buildup.

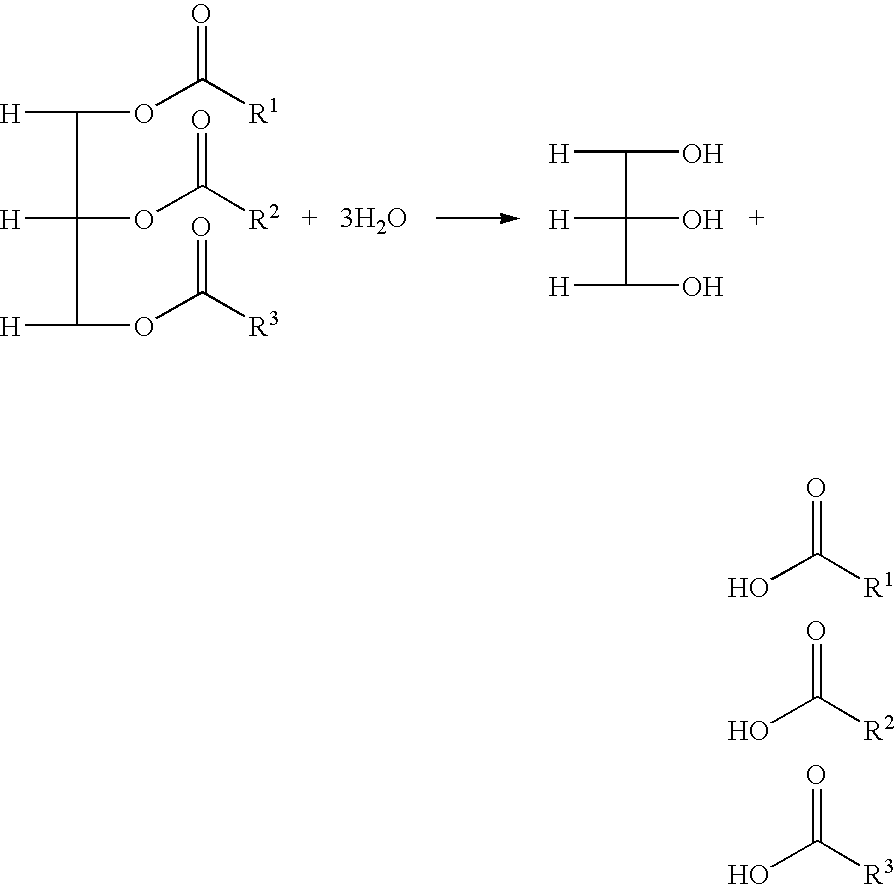

Systems and methods for hydrothermal conversion of algae into biofuel

PatentInactiveUS20100050502A1

Innovation

- The use of near-critical or supercritical water to extract and hydrolyze lipids from algae, eliminating the need for drying and enhancing the extraction of both polar and neutral lipids, thereby increasing the yield of biofuel.

Environmental Impact Assessment

The environmental impact assessment of incorporating magnesium nitrate in algae-based biofuel systems reveals both potential benefits and challenges. This analysis is crucial for understanding the sustainability and long-term viability of this innovative approach to biofuel production.

One of the primary environmental advantages of using magnesium nitrate in algae-based biofuel systems is the potential reduction in overall nutrient requirements. Magnesium nitrate serves as a dual-purpose nutrient, providing both magnesium and nitrogen, which are essential for algal growth. This can lead to a more efficient use of resources and potentially reduce the environmental footprint associated with nutrient production and transportation.

However, the introduction of magnesium nitrate into these systems also raises concerns about potential water pollution. If not properly managed, excess magnesium and nitrate could leach into surrounding water bodies, contributing to eutrophication and potentially harming aquatic ecosystems. Careful monitoring and control of nutrient levels in the algae cultivation systems are essential to mitigate these risks.

The use of magnesium nitrate may also impact the carbon footprint of the biofuel production process. On one hand, it could potentially enhance algal growth rates, leading to increased carbon sequestration during the cultivation phase. Conversely, the production and transportation of magnesium nitrate itself may contribute to greenhouse gas emissions, necessitating a comprehensive life cycle assessment to determine the net environmental impact.

Land use considerations are another important aspect of the environmental impact assessment. While algae-based biofuel systems generally have a smaller land footprint compared to traditional crop-based biofuels, the incorporation of magnesium nitrate may influence land requirements. If it leads to increased productivity, it could potentially reduce the overall land area needed for cultivation, thereby minimizing habitat disruption and land-use changes.

Water consumption is a critical factor in the environmental sustainability of algae-based biofuel systems. The addition of magnesium nitrate may affect water requirements and quality. It is essential to evaluate whether this nutrient supplement alters water usage patterns or influences the potential for water recycling within the system.

Biodiversity impacts must also be considered, particularly in open pond cultivation systems. The altered nutrient profile resulting from magnesium nitrate use could potentially affect local ecosystems if released into the environment. Assessing the potential for invasive species proliferation or changes in local microbial communities is crucial for maintaining ecological balance.

In conclusion, while magnesium nitrate shows promise in enhancing algae-based biofuel systems, a thorough environmental impact assessment is necessary to ensure its sustainable implementation. This assessment should encompass nutrient management, water quality, carbon footprint, land use, water consumption, and biodiversity considerations to provide a comprehensive understanding of its environmental implications.

One of the primary environmental advantages of using magnesium nitrate in algae-based biofuel systems is the potential reduction in overall nutrient requirements. Magnesium nitrate serves as a dual-purpose nutrient, providing both magnesium and nitrogen, which are essential for algal growth. This can lead to a more efficient use of resources and potentially reduce the environmental footprint associated with nutrient production and transportation.

However, the introduction of magnesium nitrate into these systems also raises concerns about potential water pollution. If not properly managed, excess magnesium and nitrate could leach into surrounding water bodies, contributing to eutrophication and potentially harming aquatic ecosystems. Careful monitoring and control of nutrient levels in the algae cultivation systems are essential to mitigate these risks.

The use of magnesium nitrate may also impact the carbon footprint of the biofuel production process. On one hand, it could potentially enhance algal growth rates, leading to increased carbon sequestration during the cultivation phase. Conversely, the production and transportation of magnesium nitrate itself may contribute to greenhouse gas emissions, necessitating a comprehensive life cycle assessment to determine the net environmental impact.

Land use considerations are another important aspect of the environmental impact assessment. While algae-based biofuel systems generally have a smaller land footprint compared to traditional crop-based biofuels, the incorporation of magnesium nitrate may influence land requirements. If it leads to increased productivity, it could potentially reduce the overall land area needed for cultivation, thereby minimizing habitat disruption and land-use changes.

Water consumption is a critical factor in the environmental sustainability of algae-based biofuel systems. The addition of magnesium nitrate may affect water requirements and quality. It is essential to evaluate whether this nutrient supplement alters water usage patterns or influences the potential for water recycling within the system.

Biodiversity impacts must also be considered, particularly in open pond cultivation systems. The altered nutrient profile resulting from magnesium nitrate use could potentially affect local ecosystems if released into the environment. Assessing the potential for invasive species proliferation or changes in local microbial communities is crucial for maintaining ecological balance.

In conclusion, while magnesium nitrate shows promise in enhancing algae-based biofuel systems, a thorough environmental impact assessment is necessary to ensure its sustainable implementation. This assessment should encompass nutrient management, water quality, carbon footprint, land use, water consumption, and biodiversity considerations to provide a comprehensive understanding of its environmental implications.

Regulatory Framework for Biofuel Production

The regulatory framework for biofuel production plays a crucial role in shaping the development and implementation of algae-based biofuel systems, including those investigating the use of magnesium nitrate. This framework encompasses a complex web of policies, standards, and guidelines established by various governmental bodies and international organizations.

At the federal level in the United States, the Environmental Protection Agency (EPA) oversees the Renewable Fuel Standard (RFS) program, which mandates the blending of renewable fuels into transportation fuels. The RFS program includes specific provisions for advanced biofuels, under which algae-based biofuels may qualify. The EPA also regulates the environmental impacts of biofuel production facilities, including air and water quality standards.

The Department of Energy (DOE) and the United States Department of Agriculture (USDA) also play significant roles in shaping biofuel regulations. The DOE's Bioenergy Technologies Office provides funding and support for research and development in algae-based biofuels, while the USDA oversees regulations related to feedstock cultivation and land use.

Internationally, organizations such as the International Organization for Standardization (ISO) have developed standards for sustainable biofuel production. These standards address issues such as greenhouse gas emissions, biodiversity, and social impacts associated with biofuel production.

The European Union has implemented the Renewable Energy Directive (RED), which sets targets for renewable energy use in transportation and includes sustainability criteria for biofuels. This directive has implications for algae-based biofuel systems seeking to enter the European market.

Specific to the use of magnesium nitrate in algae-based biofuel systems, regulations may address the handling, storage, and disposal of this compound. The Occupational Safety and Health Administration (OSHA) in the United States provides guidelines for the safe handling of magnesium nitrate in industrial settings.

As the field of algae-based biofuels continues to evolve, regulatory frameworks are likely to adapt. Policymakers are increasingly focusing on life cycle assessments of biofuel production, considering factors such as water usage, nutrient inputs, and overall environmental impact. This holistic approach may lead to more comprehensive regulations that specifically address the unique aspects of algae cultivation and processing.

Researchers and industry stakeholders working on magnesium nitrate applications in algae-based biofuel systems must navigate this complex regulatory landscape. Compliance with existing regulations, as well as anticipation of future policy changes, is essential for the successful development and commercialization of these technologies.

At the federal level in the United States, the Environmental Protection Agency (EPA) oversees the Renewable Fuel Standard (RFS) program, which mandates the blending of renewable fuels into transportation fuels. The RFS program includes specific provisions for advanced biofuels, under which algae-based biofuels may qualify. The EPA also regulates the environmental impacts of biofuel production facilities, including air and water quality standards.

The Department of Energy (DOE) and the United States Department of Agriculture (USDA) also play significant roles in shaping biofuel regulations. The DOE's Bioenergy Technologies Office provides funding and support for research and development in algae-based biofuels, while the USDA oversees regulations related to feedstock cultivation and land use.

Internationally, organizations such as the International Organization for Standardization (ISO) have developed standards for sustainable biofuel production. These standards address issues such as greenhouse gas emissions, biodiversity, and social impacts associated with biofuel production.

The European Union has implemented the Renewable Energy Directive (RED), which sets targets for renewable energy use in transportation and includes sustainability criteria for biofuels. This directive has implications for algae-based biofuel systems seeking to enter the European market.

Specific to the use of magnesium nitrate in algae-based biofuel systems, regulations may address the handling, storage, and disposal of this compound. The Occupational Safety and Health Administration (OSHA) in the United States provides guidelines for the safe handling of magnesium nitrate in industrial settings.

As the field of algae-based biofuels continues to evolve, regulatory frameworks are likely to adapt. Policymakers are increasingly focusing on life cycle assessments of biofuel production, considering factors such as water usage, nutrient inputs, and overall environmental impact. This holistic approach may lead to more comprehensive regulations that specifically address the unique aspects of algae cultivation and processing.

Researchers and industry stakeholders working on magnesium nitrate applications in algae-based biofuel systems must navigate this complex regulatory landscape. Compliance with existing regulations, as well as anticipation of future policy changes, is essential for the successful development and commercialization of these technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!