Kevlar's Potential in High-Performance Underwater Construction

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kevlar Underwater Applications

Kevlar, a high-strength synthetic fiber developed by DuPont, has shown remarkable potential in underwater construction applications. Its exceptional strength-to-weight ratio, durability, and resistance to corrosion make it an ideal material for various underwater structures and components. In marine environments, Kevlar's properties offer significant advantages over traditional materials like steel and concrete.

One of the primary applications of Kevlar in underwater construction is in the reinforcement of concrete structures. Kevlar fibers can be incorporated into concrete mixtures to enhance their tensile strength and crack resistance. This results in more durable and long-lasting underwater structures, such as bridge piers, offshore platforms, and underwater tunnels. The use of Kevlar-reinforced concrete can significantly reduce maintenance costs and extend the lifespan of these structures in harsh marine environments.

Kevlar's lightweight nature makes it particularly suitable for deep-sea applications where weight is a critical factor. In the construction of underwater habitats, research facilities, and deep-sea exploration vessels, Kevlar composites can be used to create strong yet lightweight structural components. This allows for easier transportation and installation of these structures at great depths, where traditional materials would be impractical or impossible to use.

In the field of underwater cable protection, Kevlar has proven to be an excellent choice. Submarine communication cables and power transmission lines can be reinforced with Kevlar fibers to provide additional strength and protection against environmental stresses. The material's resistance to abrasion and impact makes it ideal for safeguarding these critical infrastructure components from damage caused by underwater currents, marine life, and other potential hazards.

Kevlar's application in underwater construction extends to the development of advanced mooring systems for offshore structures. Kevlar ropes and cables offer superior strength and durability compared to traditional steel cables, while being significantly lighter. This allows for more efficient and reliable anchoring of floating platforms, buoys, and other marine structures, particularly in deep-water environments where weight and tensile strength are crucial factors.

The material's resistance to chemical degradation and its ability to maintain its properties in extreme temperatures make it suitable for use in underwater oil and gas extraction infrastructure. Kevlar composites can be employed in the construction of pipelines, risers, and other components that require high strength and corrosion resistance in challenging underwater environments.

As underwater construction techniques continue to evolve, Kevlar's potential in this field is likely to expand further. Research is ongoing to develop new Kevlar-based composites and hybrid materials that can offer even greater performance in underwater applications. These advancements may lead to the creation of more resilient and efficient underwater structures, pushing the boundaries of what is possible in marine engineering and construction.

One of the primary applications of Kevlar in underwater construction is in the reinforcement of concrete structures. Kevlar fibers can be incorporated into concrete mixtures to enhance their tensile strength and crack resistance. This results in more durable and long-lasting underwater structures, such as bridge piers, offshore platforms, and underwater tunnels. The use of Kevlar-reinforced concrete can significantly reduce maintenance costs and extend the lifespan of these structures in harsh marine environments.

Kevlar's lightweight nature makes it particularly suitable for deep-sea applications where weight is a critical factor. In the construction of underwater habitats, research facilities, and deep-sea exploration vessels, Kevlar composites can be used to create strong yet lightweight structural components. This allows for easier transportation and installation of these structures at great depths, where traditional materials would be impractical or impossible to use.

In the field of underwater cable protection, Kevlar has proven to be an excellent choice. Submarine communication cables and power transmission lines can be reinforced with Kevlar fibers to provide additional strength and protection against environmental stresses. The material's resistance to abrasion and impact makes it ideal for safeguarding these critical infrastructure components from damage caused by underwater currents, marine life, and other potential hazards.

Kevlar's application in underwater construction extends to the development of advanced mooring systems for offshore structures. Kevlar ropes and cables offer superior strength and durability compared to traditional steel cables, while being significantly lighter. This allows for more efficient and reliable anchoring of floating platforms, buoys, and other marine structures, particularly in deep-water environments where weight and tensile strength are crucial factors.

The material's resistance to chemical degradation and its ability to maintain its properties in extreme temperatures make it suitable for use in underwater oil and gas extraction infrastructure. Kevlar composites can be employed in the construction of pipelines, risers, and other components that require high strength and corrosion resistance in challenging underwater environments.

As underwater construction techniques continue to evolve, Kevlar's potential in this field is likely to expand further. Research is ongoing to develop new Kevlar-based composites and hybrid materials that can offer even greater performance in underwater applications. These advancements may lead to the creation of more resilient and efficient underwater structures, pushing the boundaries of what is possible in marine engineering and construction.

Market Analysis

The market for high-performance underwater construction materials is experiencing significant growth, driven by increasing offshore and marine infrastructure development worldwide. Kevlar, a synthetic fiber known for its exceptional strength-to-weight ratio, has emerged as a promising material in this sector. The global underwater construction market, valued at $1.2 trillion in 2020, is projected to reach $1.8 trillion by 2025, with a compound annual growth rate (CAGR) of 8.5%.

Kevlar's potential in underwater construction stems from its unique properties, including high tensile strength, low weight, and excellent resistance to corrosion and fatigue. These characteristics make it particularly suitable for applications such as reinforcing concrete structures, creating durable protective coatings, and manufacturing lightweight yet strong components for underwater equipment and structures.

The offshore oil and gas industry, a major driver of underwater construction, has shown increasing interest in Kevlar-based solutions. With the global offshore oil and gas market expected to reach $145 billion by 2026, growing at a CAGR of 6.2%, the demand for advanced materials like Kevlar is set to rise. Kevlar's ability to withstand harsh underwater environments while providing superior strength makes it an attractive option for deep-sea exploration and production facilities.

Another significant market segment for Kevlar in underwater construction is marine infrastructure development. As coastal cities expand and invest in sea defenses, ports, and underwater tunnels, the need for durable and corrosion-resistant materials grows. The global marine construction market, valued at $465 billion in 2020, is expected to reach $625 billion by 2025, presenting substantial opportunities for Kevlar-based solutions.

Renewable energy projects, particularly offshore wind farms, represent an emerging market for Kevlar in underwater construction. The global offshore wind market is projected to grow from $36.1 billion in 2020 to $87.5 billion by 2026, with a CAGR of 15.9%. Kevlar's potential applications in this sector include reinforcing wind turbine foundations and manufacturing durable cable protection systems.

Despite the promising market outlook, challenges remain in widespread adoption of Kevlar in underwater construction. These include the relatively high cost of Kevlar compared to traditional materials and the need for specialized manufacturing and installation techniques. However, as the demand for high-performance materials in challenging underwater environments continues to grow, investments in research and development are likely to address these barriers and expand Kevlar's market penetration in the underwater construction industry.

Kevlar's potential in underwater construction stems from its unique properties, including high tensile strength, low weight, and excellent resistance to corrosion and fatigue. These characteristics make it particularly suitable for applications such as reinforcing concrete structures, creating durable protective coatings, and manufacturing lightweight yet strong components for underwater equipment and structures.

The offshore oil and gas industry, a major driver of underwater construction, has shown increasing interest in Kevlar-based solutions. With the global offshore oil and gas market expected to reach $145 billion by 2026, growing at a CAGR of 6.2%, the demand for advanced materials like Kevlar is set to rise. Kevlar's ability to withstand harsh underwater environments while providing superior strength makes it an attractive option for deep-sea exploration and production facilities.

Another significant market segment for Kevlar in underwater construction is marine infrastructure development. As coastal cities expand and invest in sea defenses, ports, and underwater tunnels, the need for durable and corrosion-resistant materials grows. The global marine construction market, valued at $465 billion in 2020, is expected to reach $625 billion by 2025, presenting substantial opportunities for Kevlar-based solutions.

Renewable energy projects, particularly offshore wind farms, represent an emerging market for Kevlar in underwater construction. The global offshore wind market is projected to grow from $36.1 billion in 2020 to $87.5 billion by 2026, with a CAGR of 15.9%. Kevlar's potential applications in this sector include reinforcing wind turbine foundations and manufacturing durable cable protection systems.

Despite the promising market outlook, challenges remain in widespread adoption of Kevlar in underwater construction. These include the relatively high cost of Kevlar compared to traditional materials and the need for specialized manufacturing and installation techniques. However, as the demand for high-performance materials in challenging underwater environments continues to grow, investments in research and development are likely to address these barriers and expand Kevlar's market penetration in the underwater construction industry.

Technical Challenges

The application of Kevlar in high-performance underwater construction faces several significant technical challenges. One of the primary obstacles is the material's susceptibility to water absorption, which can lead to degradation of its mechanical properties over time. When exposed to prolonged underwater conditions, Kevlar fibers may experience swelling and weakening, potentially compromising the structural integrity of the construction.

Another challenge lies in the difficulty of achieving effective bonding between Kevlar and other materials commonly used in underwater construction, such as concrete or metal. The smooth surface of Kevlar fibers can result in poor adhesion, necessitating the development of specialized bonding agents or surface treatments to ensure proper integration with other construction materials.

The high cost of Kevlar production and processing presents an economic hurdle for its widespread adoption in underwater construction. The complex manufacturing process and limited availability of raw materials contribute to the elevated expenses, making it challenging to justify its use in large-scale projects where cost-effectiveness is a crucial factor.

Kevlar's sensitivity to ultraviolet (UV) radiation poses a significant concern for its application in shallow underwater environments or areas with high UV exposure. Prolonged UV exposure can lead to degradation of the material's properties, potentially reducing its lifespan and effectiveness in underwater structures.

The anisotropic nature of Kevlar fibers presents challenges in designing structures that can withstand multidirectional stresses commonly encountered in underwater environments. Engineers must carefully consider the orientation and arrangement of Kevlar reinforcements to optimize their performance under various loading conditions.

Furthermore, the long-term durability of Kevlar in aggressive marine environments remains a concern. Exposure to saltwater, marine organisms, and varying temperatures can potentially accelerate the degradation of Kevlar fibers, necessitating the development of protective coatings or treatments to enhance its resistance to these environmental factors.

The integration of Kevlar into existing underwater construction techniques and methodologies presents another technical challenge. Traditional construction practices may need to be adapted or entirely redesigned to accommodate the unique properties and handling requirements of Kevlar-based materials.

Lastly, the limited availability of comprehensive long-term performance data for Kevlar in underwater applications creates uncertainty in predicting its behavior over extended periods. This lack of historical data makes it challenging for engineers and designers to confidently incorporate Kevlar into critical underwater structures without extensive testing and validation.

Another challenge lies in the difficulty of achieving effective bonding between Kevlar and other materials commonly used in underwater construction, such as concrete or metal. The smooth surface of Kevlar fibers can result in poor adhesion, necessitating the development of specialized bonding agents or surface treatments to ensure proper integration with other construction materials.

The high cost of Kevlar production and processing presents an economic hurdle for its widespread adoption in underwater construction. The complex manufacturing process and limited availability of raw materials contribute to the elevated expenses, making it challenging to justify its use in large-scale projects where cost-effectiveness is a crucial factor.

Kevlar's sensitivity to ultraviolet (UV) radiation poses a significant concern for its application in shallow underwater environments or areas with high UV exposure. Prolonged UV exposure can lead to degradation of the material's properties, potentially reducing its lifespan and effectiveness in underwater structures.

The anisotropic nature of Kevlar fibers presents challenges in designing structures that can withstand multidirectional stresses commonly encountered in underwater environments. Engineers must carefully consider the orientation and arrangement of Kevlar reinforcements to optimize their performance under various loading conditions.

Furthermore, the long-term durability of Kevlar in aggressive marine environments remains a concern. Exposure to saltwater, marine organisms, and varying temperatures can potentially accelerate the degradation of Kevlar fibers, necessitating the development of protective coatings or treatments to enhance its resistance to these environmental factors.

The integration of Kevlar into existing underwater construction techniques and methodologies presents another technical challenge. Traditional construction practices may need to be adapted or entirely redesigned to accommodate the unique properties and handling requirements of Kevlar-based materials.

Lastly, the limited availability of comprehensive long-term performance data for Kevlar in underwater applications creates uncertainty in predicting its behavior over extended periods. This lack of historical data makes it challenging for engineers and designers to confidently incorporate Kevlar into critical underwater structures without extensive testing and validation.

Current Solutions

01 Kevlar-reinforced composite materials

Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries.- Kevlar-reinforced composite materials: Kevlar fibers are used to reinforce various composite materials, enhancing their strength, durability, and impact resistance. These composites find applications in aerospace, automotive, and protective equipment industries. The incorporation of Kevlar fibers significantly improves the mechanical properties of the resulting materials.

- Kevlar-based protective gear: Kevlar is extensively used in the development of personal protective equipment, including bulletproof vests, helmets, and other safety gear. Its high tensile strength and lightweight properties make it ideal for creating protective clothing and accessories that offer superior protection against ballistic threats and other hazards.

- Kevlar in automotive applications: The automotive industry utilizes Kevlar in various components to improve vehicle performance and safety. Kevlar-reinforced parts, such as tires, belts, and body panels, contribute to weight reduction, increased fuel efficiency, and enhanced crash protection. The material's high strength-to-weight ratio makes it particularly valuable in this sector.

- Kevlar-enhanced sporting goods: Kevlar is incorporated into various sporting goods and equipment to improve their performance and durability. Applications include tennis rackets, bicycle frames, and high-performance sails. The material's lightweight nature and excellent strength properties contribute to enhanced athletic performance and equipment longevity.

- Kevlar in aerospace and marine applications: The aerospace and marine industries utilize Kevlar in the construction of aircraft and watercraft components. Kevlar-reinforced structures offer significant weight savings while maintaining high strength and durability. Applications include aircraft fuselage panels, boat hulls, and satellite components, where the material's resistance to fatigue and corrosion is particularly beneficial.

02 Kevlar in protective gear and clothing

Kevlar is extensively used in the manufacture of protective gear and clothing, including bulletproof vests, helmets, and cut-resistant gloves. Its high tensile strength and lightweight properties make it ideal for personal protection equipment.Expand Specific Solutions03 Kevlar-based fire-resistant materials

Kevlar is utilized in the development of fire-resistant materials and fabrics. These materials are used in firefighting equipment, industrial safety gear, and other applications requiring high heat resistance.Expand Specific Solutions04 Kevlar in automotive and aerospace applications

Kevlar is employed in various automotive and aerospace components to reduce weight while maintaining strength. It is used in tires, body panels, and structural parts to improve fuel efficiency and performance.Expand Specific Solutions05 Kevlar in sporting goods and recreational equipment

Kevlar is incorporated into sporting goods and recreational equipment to enhance durability and performance. Applications include bicycle tires, tennis rackets, and kayaks, where its lightweight and high-strength properties are beneficial.Expand Specific Solutions

Industry Leaders

The development of Kevlar's potential in high-performance underwater construction is in its early stages, with a growing market driven by increasing demand for durable and lightweight materials in marine applications. The technology's maturity is still evolving, as research institutions like Woods Hole Oceanographic Institution and universities such as Ocean University of China lead the way in exploring its underwater capabilities. Major players in the oil and gas industry, including ExxonMobil Upstream Research Co., Schlumberger, and Saudi Aramco, are likely to be key adopters and contributors to this technology's advancement. The competitive landscape is diverse, with materials science companies, defense organizations, and engineering firms all vying to capitalize on Kevlar's unique properties for underwater construction applications.

Exxonmobil Upstream Research Co.

Technical Solution: Exxonmobil has developed a Kevlar-reinforced composite material for underwater pipelines and structures. This innovative solution combines the high strength-to-weight ratio of Kevlar with advanced polymer matrices, resulting in a material that exhibits exceptional durability and corrosion resistance in harsh marine environments. The company has implemented a proprietary manufacturing process that allows for the precise alignment of Kevlar fibers within the composite, optimizing its mechanical properties for underwater applications[1]. Additionally, Exxonmobil has conducted extensive testing of this material in simulated deep-sea conditions, demonstrating its ability to withstand high pressures and resist degradation from prolonged exposure to saltwater[3].

Strengths: Superior strength-to-weight ratio, excellent corrosion resistance, and proven performance in deep-sea environments. Weaknesses: Potentially higher production costs compared to traditional materials and limited long-term data on in-situ performance.

Schlumberger Canada Ltd.

Technical Solution: Schlumberger has pioneered the use of Kevlar-enhanced cement composites for underwater well construction and completion. Their proprietary technology incorporates Kevlar fibers into specially formulated cement slurries, significantly improving the tensile strength and impact resistance of underwater concrete structures. This innovative approach addresses the challenges of high-pressure environments and potential seismic activities in offshore drilling operations. Schlumberger's Kevlar-reinforced cement has been successfully deployed in several deep-water projects, demonstrating improved well integrity and longevity[2]. The company has also developed advanced placement techniques to ensure optimal distribution of Kevlar fibers within the cement matrix, maximizing the material's performance in critical underwater applications[4].

Strengths: Enhanced well integrity, improved resistance to high-pressure environments, and increased longevity of underwater structures. Weaknesses: Higher initial costs and potential complexity in mixing and placement procedures.

Key Innovations

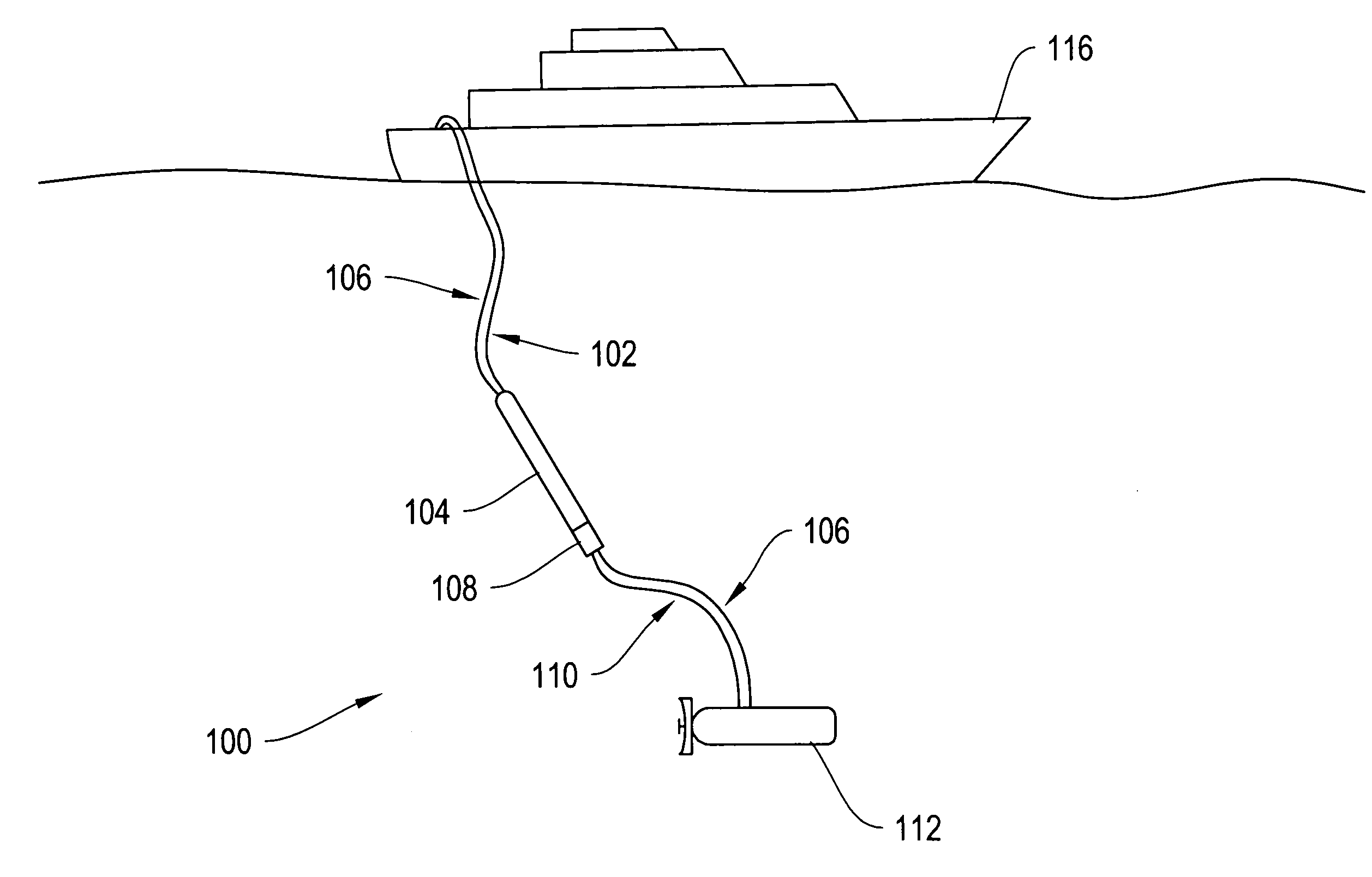

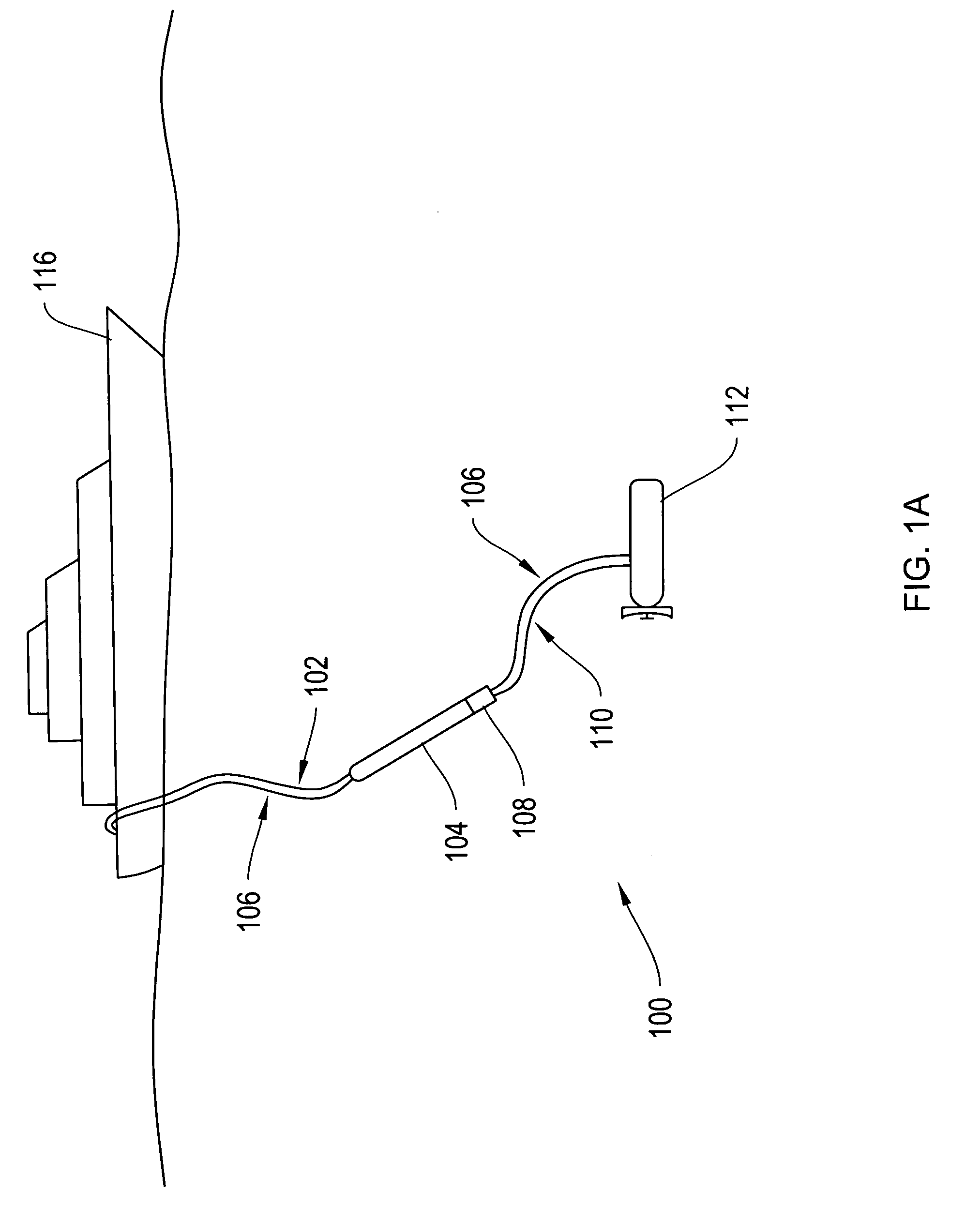

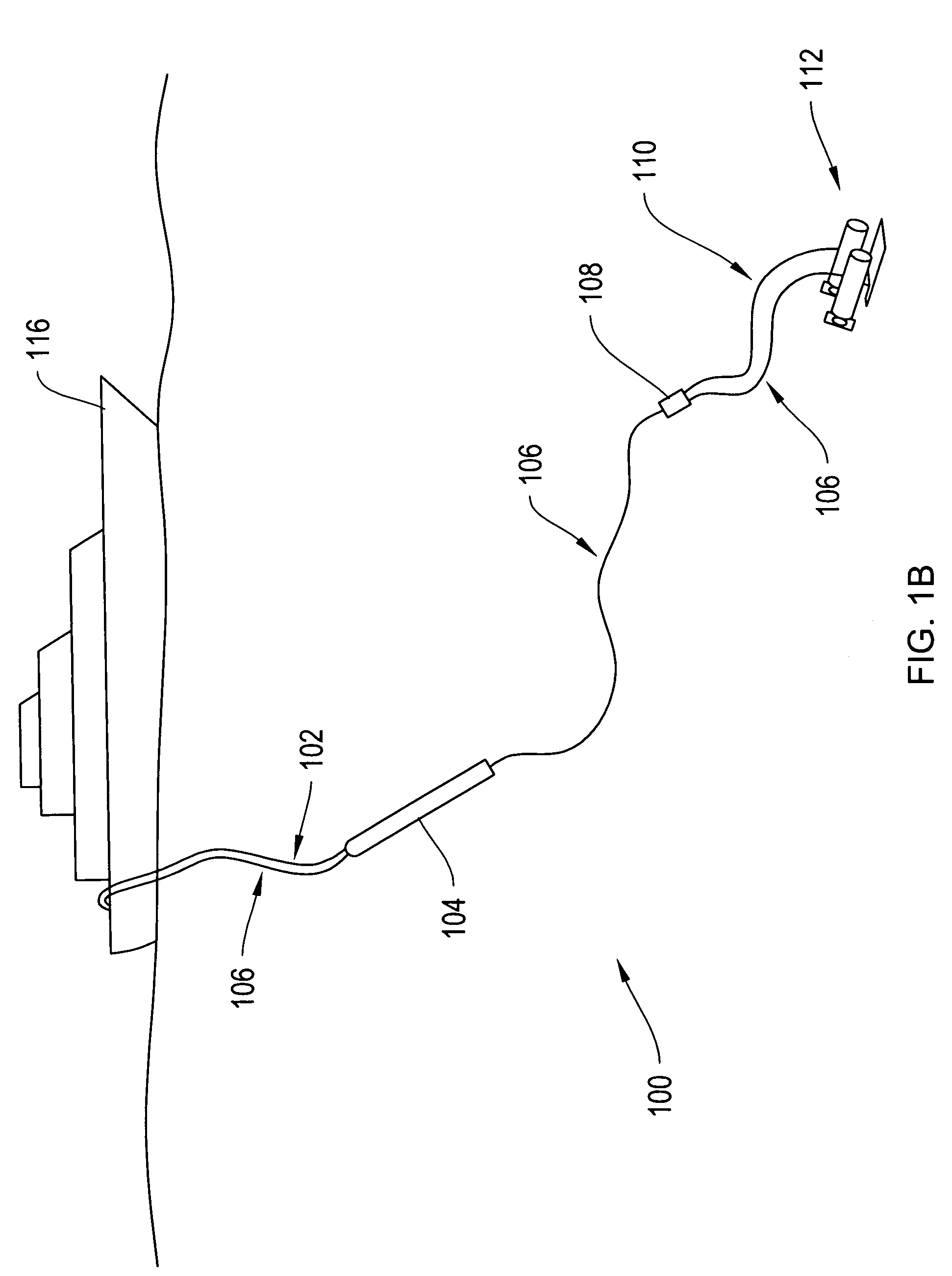

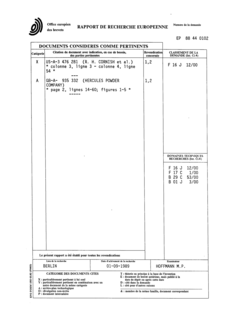

Systems and methods for tethering underwater vehicles

PatentInactiveUS7621229B2

Innovation

- A lightweight glass fiber optic tether system with an adjustable mechanical fuse and constant tension fiber optic payout mechanism, allowing the tether to separate under predetermined loads and extend up to 60 km, providing a communication link and reducing the weight and drag of the cable.

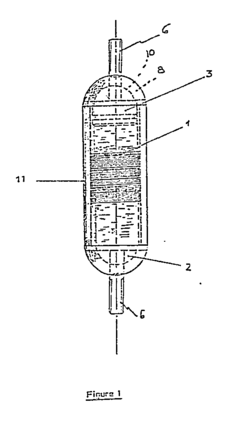

Vessel for liquids under high pression

PatentInactiveEP0319439A3

Innovation

- The design features semi-cylindrical plugs with grooves housing flexible bundles of Kevlar fibers outside the tank body, distributing mechanical stresses evenly and eliminating the need for internal tie rods, allowing for efficient force transmission and reduced material costs.

Environmental Impact

The use of Kevlar in high-performance underwater construction presents both potential benefits and environmental concerns. As a synthetic fiber, Kevlar's production process involves chemical synthesis, which can have environmental implications. However, its exceptional strength-to-weight ratio and durability may lead to reduced material consumption and longer-lasting structures, potentially offsetting some of these impacts.

In underwater environments, Kevlar's resistance to corrosion and degradation is a significant advantage. Unlike traditional materials such as steel or concrete, Kevlar does not rust or deteriorate in saltwater, reducing the need for frequent maintenance or replacement. This longevity can minimize disturbances to marine ecosystems caused by construction activities and reduce the overall environmental footprint of underwater structures.

Kevlar's lightweight nature also offers environmental benefits during transportation and installation. Reduced weight means less fuel consumption during shipping and fewer emissions from construction vessels. Additionally, the ease of handling lighter materials can lead to shorter construction periods, further minimizing the impact on marine life and habitats.

However, the potential release of microfibers from Kevlar-based materials into aquatic environments is a concern that requires careful consideration. While Kevlar is generally inert, the long-term effects of its presence in marine ecosystems are not fully understood. Research is needed to assess the potential bioaccumulation of Kevlar particles in marine organisms and their impact on food chains.

The use of Kevlar in underwater construction may also contribute to noise reduction during installation and operation of structures. Its vibration-damping properties could help mitigate the impact of anthropogenic noise on marine life, which is a growing concern in ocean conservation efforts.

From a lifecycle perspective, the recyclability of Kevlar-based materials is an important factor. While Kevlar itself is not biodegradable, advancements in recycling technologies may provide opportunities for the recovery and reuse of Kevlar fibers from decommissioned underwater structures, reducing waste and resource consumption.

In conclusion, the environmental impact of Kevlar in high-performance underwater construction is multifaceted. Its durability and performance characteristics offer potential environmental benefits, but careful consideration must be given to its production process, long-term presence in marine environments, and end-of-life management to ensure sustainable use in underwater applications.

In underwater environments, Kevlar's resistance to corrosion and degradation is a significant advantage. Unlike traditional materials such as steel or concrete, Kevlar does not rust or deteriorate in saltwater, reducing the need for frequent maintenance or replacement. This longevity can minimize disturbances to marine ecosystems caused by construction activities and reduce the overall environmental footprint of underwater structures.

Kevlar's lightweight nature also offers environmental benefits during transportation and installation. Reduced weight means less fuel consumption during shipping and fewer emissions from construction vessels. Additionally, the ease of handling lighter materials can lead to shorter construction periods, further minimizing the impact on marine life and habitats.

However, the potential release of microfibers from Kevlar-based materials into aquatic environments is a concern that requires careful consideration. While Kevlar is generally inert, the long-term effects of its presence in marine ecosystems are not fully understood. Research is needed to assess the potential bioaccumulation of Kevlar particles in marine organisms and their impact on food chains.

The use of Kevlar in underwater construction may also contribute to noise reduction during installation and operation of structures. Its vibration-damping properties could help mitigate the impact of anthropogenic noise on marine life, which is a growing concern in ocean conservation efforts.

From a lifecycle perspective, the recyclability of Kevlar-based materials is an important factor. While Kevlar itself is not biodegradable, advancements in recycling technologies may provide opportunities for the recovery and reuse of Kevlar fibers from decommissioned underwater structures, reducing waste and resource consumption.

In conclusion, the environmental impact of Kevlar in high-performance underwater construction is multifaceted. Its durability and performance characteristics offer potential environmental benefits, but careful consideration must be given to its production process, long-term presence in marine environments, and end-of-life management to ensure sustainable use in underwater applications.

Regulatory Framework

The regulatory framework surrounding the use of Kevlar in high-performance underwater construction is complex and multifaceted, involving various international and national bodies. The International Maritime Organization (IMO) plays a crucial role in setting global standards for marine safety and environmental protection. Their guidelines on the use of advanced materials in underwater structures directly impact the adoption of Kevlar-based solutions.

At the national level, agencies such as the United States Coast Guard and the European Maritime Safety Agency enforce stringent regulations on materials used in underwater construction. These regulations often focus on durability, fire resistance, and environmental impact. Kevlar's unique properties, including its high strength-to-weight ratio and resistance to corrosion, make it an attractive option, but also necessitate careful consideration of its long-term performance under extreme conditions.

Environmental regulations pose both challenges and opportunities for Kevlar in underwater construction. Many countries have implemented strict laws to protect marine ecosystems, requiring construction materials to be non-toxic and biodegradable. While Kevlar is not biodegradable, its durability can lead to reduced maintenance and replacement cycles, potentially lowering the overall environmental impact of underwater structures.

Safety standards for underwater construction workers also influence the regulatory landscape. Occupational safety organizations, such as OSHA in the United States, mandate specific requirements for personal protective equipment and construction methodologies. Kevlar's lightweight nature and high strength could potentially enhance worker safety, but must be thoroughly tested and certified for underwater use.

The regulatory framework also extends to intellectual property rights and patent laws. As Kevlar is a proprietary material developed by DuPont, its use in underwater construction may be subject to licensing agreements and patent restrictions. This aspect of the regulatory environment can significantly impact the cost and availability of Kevlar-based solutions in the marine construction industry.

Standardization bodies, such as ASTM International and the International Organization for Standardization (ISO), play a crucial role in developing testing methods and performance criteria for advanced materials in underwater applications. These standards ensure consistency and reliability in the use of Kevlar across different projects and geographical regions.

As the potential of Kevlar in underwater construction continues to grow, regulatory bodies are likely to adapt and evolve their frameworks. This may include the development of new testing protocols, performance benchmarks, and environmental impact assessments specifically tailored to Kevlar-based underwater structures. Industry stakeholders, including material scientists, engineers, and construction companies, will need to actively engage with regulatory authorities to shape these evolving standards and ensure they reflect the latest technological advancements and safety considerations.

At the national level, agencies such as the United States Coast Guard and the European Maritime Safety Agency enforce stringent regulations on materials used in underwater construction. These regulations often focus on durability, fire resistance, and environmental impact. Kevlar's unique properties, including its high strength-to-weight ratio and resistance to corrosion, make it an attractive option, but also necessitate careful consideration of its long-term performance under extreme conditions.

Environmental regulations pose both challenges and opportunities for Kevlar in underwater construction. Many countries have implemented strict laws to protect marine ecosystems, requiring construction materials to be non-toxic and biodegradable. While Kevlar is not biodegradable, its durability can lead to reduced maintenance and replacement cycles, potentially lowering the overall environmental impact of underwater structures.

Safety standards for underwater construction workers also influence the regulatory landscape. Occupational safety organizations, such as OSHA in the United States, mandate specific requirements for personal protective equipment and construction methodologies. Kevlar's lightweight nature and high strength could potentially enhance worker safety, but must be thoroughly tested and certified for underwater use.

The regulatory framework also extends to intellectual property rights and patent laws. As Kevlar is a proprietary material developed by DuPont, its use in underwater construction may be subject to licensing agreements and patent restrictions. This aspect of the regulatory environment can significantly impact the cost and availability of Kevlar-based solutions in the marine construction industry.

Standardization bodies, such as ASTM International and the International Organization for Standardization (ISO), play a crucial role in developing testing methods and performance criteria for advanced materials in underwater applications. These standards ensure consistency and reliability in the use of Kevlar across different projects and geographical regions.

As the potential of Kevlar in underwater construction continues to grow, regulatory bodies are likely to adapt and evolve their frameworks. This may include the development of new testing protocols, performance benchmarks, and environmental impact assessments specifically tailored to Kevlar-based underwater structures. Industry stakeholders, including material scientists, engineers, and construction companies, will need to actively engage with regulatory authorities to shape these evolving standards and ensure they reflect the latest technological advancements and safety considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!