What Are the Key Material Parameters in Self-Assembled Monolayers

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SAM Technology Background and Objectives

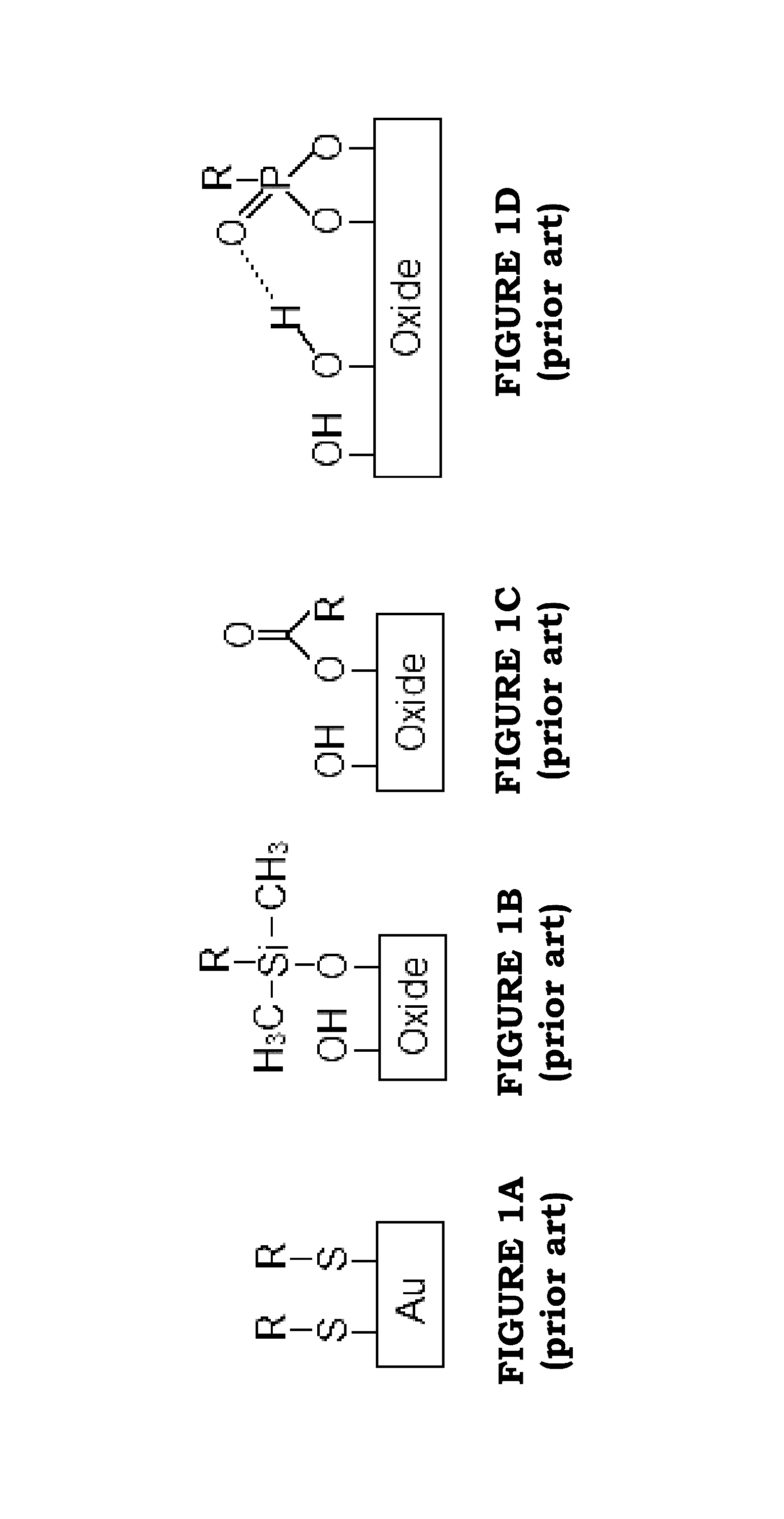

Self-assembled monolayers (SAMs) represent a versatile class of molecular assemblies that have evolved significantly since their initial discovery in the 1980s. These ultrathin organic films form spontaneously on solid surfaces through adsorption and self-organization of molecules from solution or vapor phase. The historical development of SAM technology began with alkanethiols on gold surfaces, which established the fundamental understanding of molecular self-assembly processes at interfaces.

The evolution of SAM technology has been characterized by expanding material combinations, including silanes on oxide surfaces, phosphonates on metal oxides, and more recently, non-conventional substrates such as two-dimensional materials. This progression has been driven by the need for precise control over surface properties across diverse applications spanning electronics, biosensing, and advanced materials science.

Current technological trends in SAM research focus on achieving greater precision in molecular architecture, enhanced stability under various environmental conditions, and expanded functionality through complex molecular designs. The integration of SAMs with other nanofabrication techniques has opened new avenues for creating hierarchical structures with tailored properties at multiple length scales.

The primary objective of SAM technology development is to establish robust structure-property relationships that connect molecular parameters to macroscopic surface properties. This includes understanding how molecular chain length, terminal functional groups, packing density, and substrate interactions collectively determine the physical, chemical, and electronic characteristics of the resulting interfaces.

Another critical goal is to develop standardized protocols for SAM formation that ensure reproducibility across different laboratory environments and manufacturing settings. This standardization is essential for transitioning SAM technology from research laboratories to industrial applications, where consistency and scalability are paramount.

Looking forward, SAM technology aims to address emerging challenges in advanced electronics, sustainable materials, and biomedical devices. This includes developing SAMs that can function as molecular electronic components, create ultra-low friction surfaces for energy conservation, or serve as biocompatible interfaces for medical implants and diagnostic devices.

The interdisciplinary nature of SAM research necessitates collaboration across chemistry, materials science, physics, and engineering disciplines. By leveraging insights from these diverse fields, researchers seek to unlock the full potential of molecular self-assembly as a bottom-up fabrication strategy for next-generation materials and devices with unprecedented levels of structural control and functional sophistication.

The evolution of SAM technology has been characterized by expanding material combinations, including silanes on oxide surfaces, phosphonates on metal oxides, and more recently, non-conventional substrates such as two-dimensional materials. This progression has been driven by the need for precise control over surface properties across diverse applications spanning electronics, biosensing, and advanced materials science.

Current technological trends in SAM research focus on achieving greater precision in molecular architecture, enhanced stability under various environmental conditions, and expanded functionality through complex molecular designs. The integration of SAMs with other nanofabrication techniques has opened new avenues for creating hierarchical structures with tailored properties at multiple length scales.

The primary objective of SAM technology development is to establish robust structure-property relationships that connect molecular parameters to macroscopic surface properties. This includes understanding how molecular chain length, terminal functional groups, packing density, and substrate interactions collectively determine the physical, chemical, and electronic characteristics of the resulting interfaces.

Another critical goal is to develop standardized protocols for SAM formation that ensure reproducibility across different laboratory environments and manufacturing settings. This standardization is essential for transitioning SAM technology from research laboratories to industrial applications, where consistency and scalability are paramount.

Looking forward, SAM technology aims to address emerging challenges in advanced electronics, sustainable materials, and biomedical devices. This includes developing SAMs that can function as molecular electronic components, create ultra-low friction surfaces for energy conservation, or serve as biocompatible interfaces for medical implants and diagnostic devices.

The interdisciplinary nature of SAM research necessitates collaboration across chemistry, materials science, physics, and engineering disciplines. By leveraging insights from these diverse fields, researchers seek to unlock the full potential of molecular self-assembly as a bottom-up fabrication strategy for next-generation materials and devices with unprecedented levels of structural control and functional sophistication.

Market Applications and Demand Analysis

The market for Self-Assembled Monolayers (SAMs) has experienced significant growth across multiple industries due to their unique properties and versatility. The global SAMs market was valued at approximately 2.3 billion USD in 2022 and is projected to grow at a compound annual growth rate of 9.7% through 2030, driven primarily by expanding applications in electronics, medical devices, and advanced materials.

In the electronics sector, SAMs have become increasingly important for the development of next-generation devices. The miniaturization trend in electronics has created substantial demand for SAMs as interface modifiers and protective coatings. Their ability to form uniform, ultrathin films makes them ideal for applications in organic electronics, where they can significantly improve device performance and longevity by controlling charge transport and surface properties.

The biomedical industry represents another major market for SAMs, particularly in biosensing and drug delivery systems. The growing focus on personalized medicine and point-of-care diagnostics has accelerated the adoption of SAM-based biosensors. These sensors leverage the precise molecular recognition capabilities of functionalized SAMs to detect biomarkers with high sensitivity and specificity, addressing the market need for rapid, accurate diagnostic tools.

Surface engineering applications constitute a rapidly expanding market segment for SAMs. Industries ranging from automotive to aerospace are increasingly utilizing SAMs to modify surface properties such as wettability, friction, and corrosion resistance. The demand for environmentally friendly and energy-efficient manufacturing processes has further boosted interest in SAMs as alternatives to traditional surface treatments that often involve hazardous chemicals or energy-intensive processes.

Regional market analysis reveals that North America and Europe currently dominate the SAMs market, accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization and increasing R&D investments in countries like China, Japan, and South Korea.

Customer requirements are evolving toward SAMs with enhanced stability, reproducibility, and functionality. End-users are particularly interested in SAMs that can maintain their structural integrity under harsh environmental conditions while providing consistent performance. There is also growing demand for SAMs that can be integrated into existing manufacturing processes without significant modifications to equipment or protocols.

Market challenges include the need for standardized characterization methods and quality control procedures to ensure consistent SAM properties across different applications. Additionally, scaling up production while maintaining precise control over key material parameters remains a significant hurdle for widespread commercial adoption in certain high-volume industries.

In the electronics sector, SAMs have become increasingly important for the development of next-generation devices. The miniaturization trend in electronics has created substantial demand for SAMs as interface modifiers and protective coatings. Their ability to form uniform, ultrathin films makes them ideal for applications in organic electronics, where they can significantly improve device performance and longevity by controlling charge transport and surface properties.

The biomedical industry represents another major market for SAMs, particularly in biosensing and drug delivery systems. The growing focus on personalized medicine and point-of-care diagnostics has accelerated the adoption of SAM-based biosensors. These sensors leverage the precise molecular recognition capabilities of functionalized SAMs to detect biomarkers with high sensitivity and specificity, addressing the market need for rapid, accurate diagnostic tools.

Surface engineering applications constitute a rapidly expanding market segment for SAMs. Industries ranging from automotive to aerospace are increasingly utilizing SAMs to modify surface properties such as wettability, friction, and corrosion resistance. The demand for environmentally friendly and energy-efficient manufacturing processes has further boosted interest in SAMs as alternatives to traditional surface treatments that often involve hazardous chemicals or energy-intensive processes.

Regional market analysis reveals that North America and Europe currently dominate the SAMs market, accounting for approximately 60% of global demand. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization and increasing R&D investments in countries like China, Japan, and South Korea.

Customer requirements are evolving toward SAMs with enhanced stability, reproducibility, and functionality. End-users are particularly interested in SAMs that can maintain their structural integrity under harsh environmental conditions while providing consistent performance. There is also growing demand for SAMs that can be integrated into existing manufacturing processes without significant modifications to equipment or protocols.

Market challenges include the need for standardized characterization methods and quality control procedures to ensure consistent SAM properties across different applications. Additionally, scaling up production while maintaining precise control over key material parameters remains a significant hurdle for widespread commercial adoption in certain high-volume industries.

Current State and Challenges in SAM Development

Self-assembled monolayers (SAMs) have emerged as a critical technology in various fields including electronics, biosensors, and surface engineering. The current state of SAM development reflects significant advancements in understanding molecular self-assembly processes, yet several challenges persist that limit their widespread industrial application.

Globally, research institutions and companies have made substantial progress in developing SAMs with diverse functionalities. The United States and European countries lead in fundamental research, while Asian countries, particularly Japan and South Korea, excel in application-oriented developments. This geographical distribution of expertise creates a complex landscape of technological capabilities.

One of the primary challenges in SAM development is achieving consistent molecular ordering and packing density across large surface areas. Current fabrication methods often result in defects and domain boundaries that compromise the functional properties of the monolayer. These imperfections become particularly problematic when scaling up from laboratory demonstrations to industrial applications.

The stability of SAMs under various environmental conditions remains another significant hurdle. Many SAMs exhibit degradation when exposed to elevated temperatures, humidity, or ultraviolet radiation, limiting their practical applications in real-world settings. Research efforts are increasingly focused on enhancing the thermal and oxidative stability of SAMs through molecular design and surface engineering approaches.

Control over the kinetics of self-assembly presents another technical challenge. The formation of high-quality SAMs often requires extended deposition times, which is incompatible with high-throughput manufacturing processes. Accelerating the assembly process without compromising structural quality remains an active area of research.

The characterization of SAMs at the molecular level continues to be technically demanding. While techniques such as scanning tunneling microscopy, atomic force microscopy, and X-ray photoelectron spectroscopy provide valuable insights, they often require specialized equipment and expertise. The development of more accessible and rapid characterization methods would significantly advance the field.

Material selection for SAMs presents both opportunities and challenges. While thiol-based SAMs on gold surfaces are well-established, expanding the repertoire of substrate-adsorbate combinations would enable broader applications. Recent research has explored silane-based SAMs on oxide surfaces and phosphonate-based systems, but each comes with specific limitations in terms of stability, ordering, or processing requirements.

The integration of SAMs with other materials and technologies represents a frontier challenge. Creating hybrid systems that combine SAMs with polymers, nanoparticles, or biological molecules requires precise control over interfacial properties and interactions, demanding interdisciplinary approaches and new methodological developments.

Globally, research institutions and companies have made substantial progress in developing SAMs with diverse functionalities. The United States and European countries lead in fundamental research, while Asian countries, particularly Japan and South Korea, excel in application-oriented developments. This geographical distribution of expertise creates a complex landscape of technological capabilities.

One of the primary challenges in SAM development is achieving consistent molecular ordering and packing density across large surface areas. Current fabrication methods often result in defects and domain boundaries that compromise the functional properties of the monolayer. These imperfections become particularly problematic when scaling up from laboratory demonstrations to industrial applications.

The stability of SAMs under various environmental conditions remains another significant hurdle. Many SAMs exhibit degradation when exposed to elevated temperatures, humidity, or ultraviolet radiation, limiting their practical applications in real-world settings. Research efforts are increasingly focused on enhancing the thermal and oxidative stability of SAMs through molecular design and surface engineering approaches.

Control over the kinetics of self-assembly presents another technical challenge. The formation of high-quality SAMs often requires extended deposition times, which is incompatible with high-throughput manufacturing processes. Accelerating the assembly process without compromising structural quality remains an active area of research.

The characterization of SAMs at the molecular level continues to be technically demanding. While techniques such as scanning tunneling microscopy, atomic force microscopy, and X-ray photoelectron spectroscopy provide valuable insights, they often require specialized equipment and expertise. The development of more accessible and rapid characterization methods would significantly advance the field.

Material selection for SAMs presents both opportunities and challenges. While thiol-based SAMs on gold surfaces are well-established, expanding the repertoire of substrate-adsorbate combinations would enable broader applications. Recent research has explored silane-based SAMs on oxide surfaces and phosphonate-based systems, but each comes with specific limitations in terms of stability, ordering, or processing requirements.

The integration of SAMs with other materials and technologies represents a frontier challenge. Creating hybrid systems that combine SAMs with polymers, nanoparticles, or biological molecules requires precise control over interfacial properties and interactions, demanding interdisciplinary approaches and new methodological developments.

Current Methodologies for SAM Characterization

01 Composition and formation of self-assembled monolayers

Self-assembled monolayers (SAMs) can be formed using various materials including thiols, silanes, and phosphonic acids on different substrates. The formation process involves spontaneous organization of molecules on surfaces through chemisorption, resulting in well-ordered molecular structures. Key parameters affecting SAM formation include molecular concentration, solvent selection, temperature, and substrate preparation. These factors influence the packing density, orientation, and overall quality of the resulting monolayer.- Composition and structure of self-assembled monolayers: Self-assembled monolayers (SAMs) are composed of specific molecular structures that can spontaneously organize on surfaces. The composition typically includes a head group that binds to the substrate, a tail group that provides functionality, and a spacer chain that connects them. The molecular structure parameters such as chain length, functional groups, and packing density significantly influence the properties and performance of the resulting monolayer. These structural parameters can be controlled during synthesis to achieve desired surface properties.

- Electronic and optical properties of SAMs: Self-assembled monolayers exhibit unique electronic and optical properties that make them valuable for various applications. The electronic properties include conductivity, electron transfer rates, and energy level alignment, which can be tuned by selecting appropriate molecular components. Optical properties such as refractive index, absorption, and fluorescence can be engineered by incorporating specific chromophores or functional groups. These properties are critical for applications in sensors, displays, and electronic devices where precise control of material parameters is essential.

- Surface modification and functionalization techniques: Various techniques can be employed to modify and functionalize self-assembled monolayers to achieve specific material parameters. These include chemical modification of terminal groups, post-assembly reactions, and incorporation of bioactive molecules. Parameters such as surface energy, wettability, and chemical reactivity can be precisely controlled through these functionalization methods. The ability to tailor surface properties makes SAMs valuable for applications in biosensors, microfluidics, and biomedical devices where specific surface interactions are required.

- Fabrication methods and process parameters: The fabrication of self-assembled monolayers involves various methods and process parameters that significantly influence the quality and properties of the resulting structures. Key parameters include solution concentration, immersion time, temperature, solvent selection, and substrate preparation. Advanced techniques such as microcontact printing, vapor deposition, and electrochemical methods can be used to create patterned SAMs with controlled spatial distribution. Optimization of these process parameters is essential for achieving reproducible and high-quality monolayers with desired characteristics.

- Applications and performance metrics of SAMs: Self-assembled monolayers find applications in various fields including electronics, sensors, biomedical devices, and protective coatings. The performance metrics for these applications include stability under different environmental conditions, resistance to degradation, binding specificity, and functional efficiency. Material parameters such as thickness uniformity, defect density, and molecular orientation significantly impact the performance in specific applications. Understanding the relationship between material parameters and application performance is crucial for designing SAMs with optimal properties for targeted uses.

02 Electronic and optical properties of SAMs

Self-assembled monolayers exhibit unique electronic and optical properties that can be tuned through molecular design. Parameters such as molecular dipole moment, electronic coupling between molecules, and interaction with the substrate affect the electronic structure of SAMs. These properties are crucial for applications in molecular electronics, sensors, and optical devices. The thickness, refractive index, and dielectric constant of SAMs can be controlled by selecting appropriate molecular components and formation conditions.Expand Specific Solutions03 Surface modification and functionalization of SAMs

Self-assembled monolayers can be functionalized with various chemical groups to tailor surface properties for specific applications. The terminal functional groups of SAM molecules determine surface characteristics such as wettability, adhesion, and biocompatibility. Post-assembly modification techniques allow for the introduction of complex functionalities while maintaining the structural integrity of the monolayer. Parameters such as functional group density, spatial distribution, and accessibility significantly impact the performance of functionalized SAMs in applications like biosensing and surface patterning.Expand Specific Solutions04 Stability and durability parameters of SAMs

The stability of self-assembled monolayers is influenced by various parameters including thermal stability, oxidative resistance, and mechanical durability. Environmental factors such as temperature, humidity, pH, and exposure to solvents can affect the long-term performance of SAMs. The strength of the head group-substrate bond, intermolecular interactions within the monolayer, and protection against oxidation are critical parameters determining SAM stability. Various stabilization strategies, including cross-linking between adjacent molecules and protective overlayers, can enhance the durability of SAMs for practical applications.Expand Specific Solutions05 Characterization techniques for SAM material parameters

Various analytical techniques are employed to characterize the material parameters of self-assembled monolayers. Surface-sensitive methods such as X-ray photoelectron spectroscopy (XPS), atomic force microscopy (AFM), and ellipsometry provide information about composition, thickness, and surface morphology. Contact angle measurements reveal wettability properties, while infrared spectroscopy and Raman spectroscopy offer insights into molecular orientation and packing. Electrical characterization techniques, including impedance spectroscopy and scanning tunneling microscopy, help evaluate the electronic properties of SAMs. These characterization methods are essential for optimizing SAM formation and ensuring reproducibility in various applications.Expand Specific Solutions

Leading Research Groups and Industry Players

The self-assembled monolayers (SAMs) technology market is currently in a growth phase, with increasing applications across semiconductor, electronics, and biomedical industries. The global market size for SAM technologies is expanding at approximately 15% annually, driven by miniaturization demands in electronics and advanced surface engineering requirements. From a technical maturity perspective, the landscape shows varied development levels among key players. Industry leaders like Taiwan Semiconductor Manufacturing Co., GLOBALFOUNDRIES, and SK hynix have established advanced SAM integration capabilities for semiconductor applications, while research-focused organizations including MIT, Harvard, and CEA are pioneering next-generation SAM materials with enhanced stability and functionality. Companies like 3M, Seiko Epson, and Merck Patent GmbH are commercializing specialized SAM solutions for industrial applications, creating a competitive ecosystem balancing fundamental research with practical implementation.

President & Fellows of Harvard College

Technical Solution: Harvard researchers have developed sophisticated approaches to controlling SAM material parameters through innovative molecular design and assembly strategies. Their technical solution involves synthesizing SAM precursors with complex architectures including branched backbones, multiple anchoring groups, and biomimetic functional elements that enable unprecedented control over surface properties. Harvard has pioneered techniques for creating responsive SAMs that change their configuration in response to external stimuli (pH, light, electrical potential), enabling dynamic control of surface properties. Their research has established fundamental relationships between molecular packing parameters and resulting collective properties including mechanical stiffness, charge transport, and wettability. Harvard's approach includes advanced characterization methods combining synchrotron techniques, neutron reflectometry, and scanning probe microscopies to resolve structural details at the molecular level. They've developed computational models that predict SAM formation energetics and final configurations based on molecular structure and substrate properties, enabling rational design of SAM systems with targeted performance parameters.

Strengths: Cutting-edge molecular designs enabling novel functionalities; sophisticated multi-technique characterization capabilities; strong theoretical foundation supporting experimental work. Weaknesses: Some advanced SAM systems require complex multi-step synthesis; highly specialized characterization techniques limit widespread adoption of quality control methods.

The Regents of the University of California

Technical Solution: UC researchers have developed comprehensive approaches to SAM formation focusing on key material parameters that determine performance in electronic and biomedical applications. Their technical solution involves systematic investigation of substrate preparation methods, demonstrating that atomically flat surfaces with controlled crystallographic orientation significantly enhance SAM quality. They've pioneered techniques for real-time monitoring of SAM formation kinetics using quartz crystal microbalance with dissipation (QCM-D) and surface plasmon resonance (SPR), enabling precise control over assembly conditions. UC's approach emphasizes understanding the relationship between molecular structure (chain length, terminal functionality, backbone rigidity) and resulting SAM properties. Their research has established quantitative correlations between deposition parameters and critical SAM metrics including packing density, tilt angle, and defect concentration. They've developed specialized post-deposition treatments including thermal annealing and UV-ozone exposure to enhance SAM stability and performance.

Strengths: Comprehensive understanding of structure-property relationships; advanced in-situ monitoring capabilities; innovative post-processing techniques. Weaknesses: Some approaches require ultra-high vacuum or specialized surface science equipment; challenges in translating fundamental insights to industrial-scale processes.

Critical Material Parameters and Their Significance

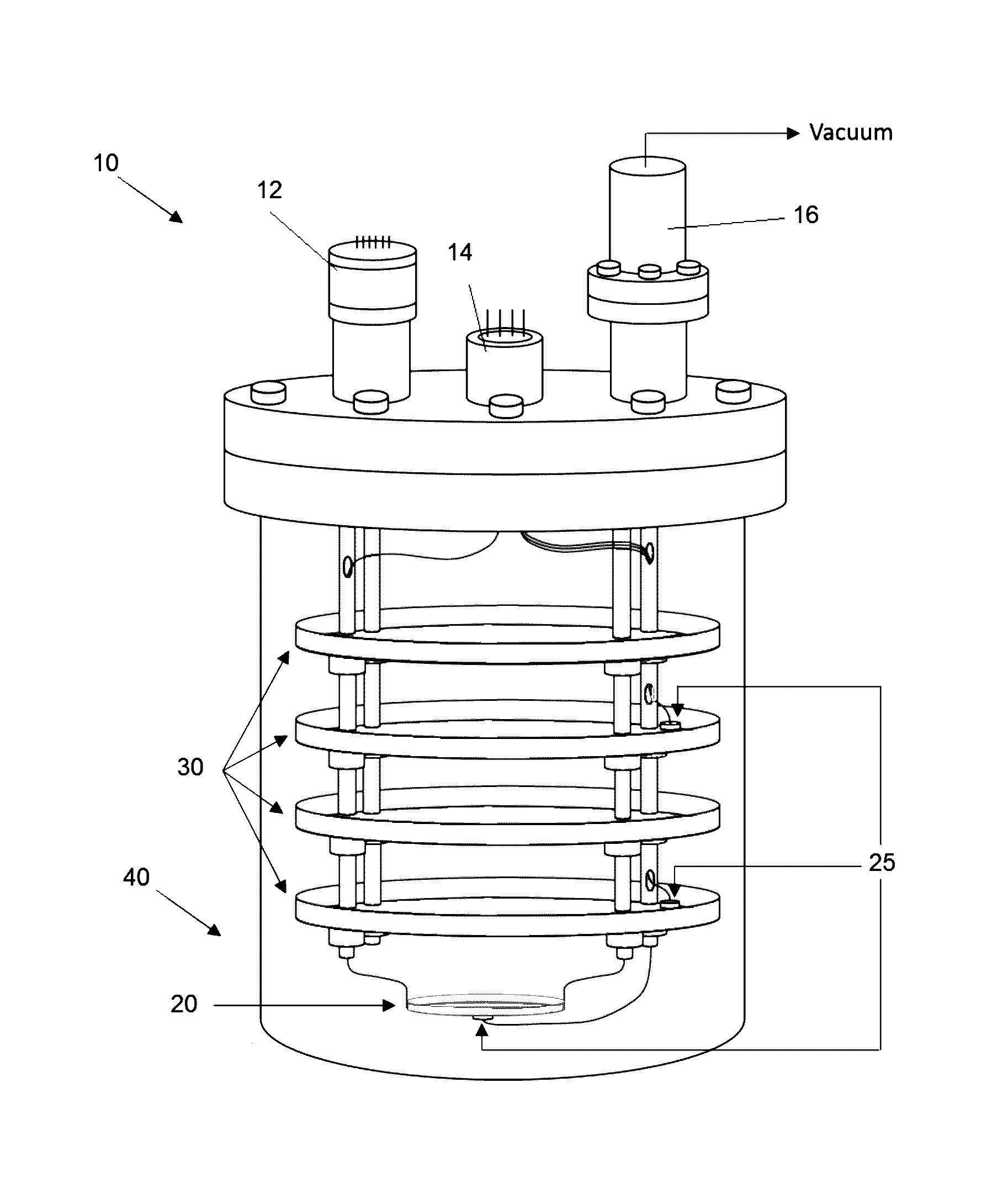

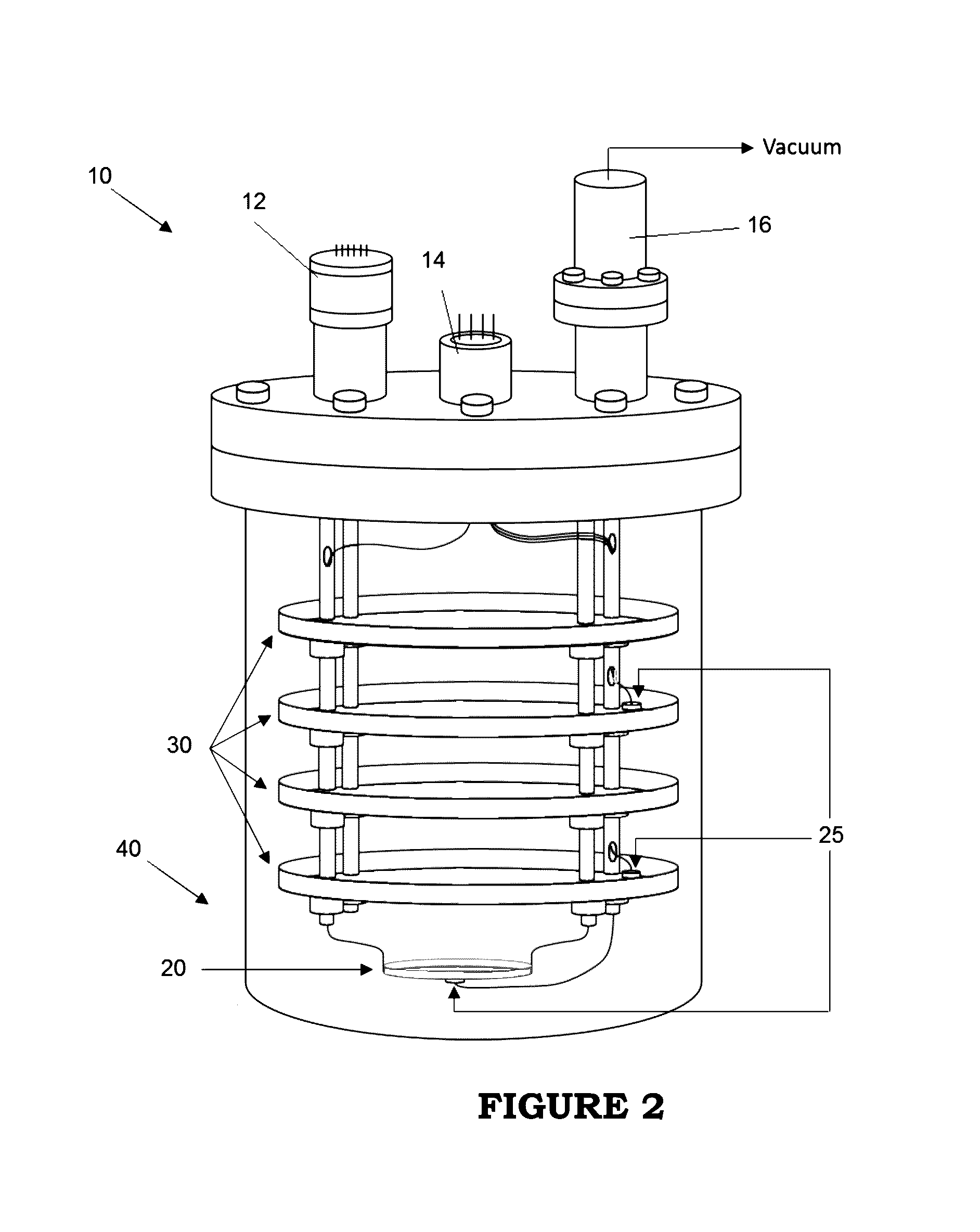

Self-assembled organic monolayer hybrid materials and methods thereof

PatentInactiveUS9478361B2

Innovation

- A novel method involving the molecular vapor deposition of functionalized carboxylic acid derivatives in a gas phase, forming a substrate-carboxylic acid derivative ester linkage, which enables rapid and efficient uni-dentate, bi-dentate, or tri-dentate bonding to the substrate, enhancing electron transfer and surface passivation.

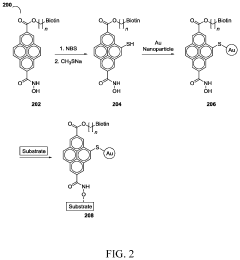

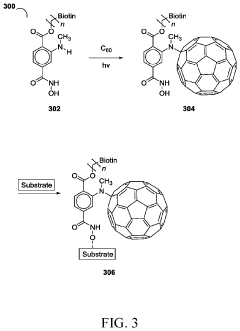

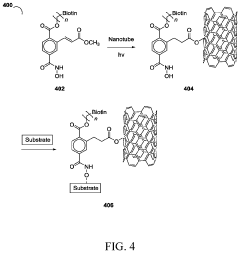

Molecular design to suppress desorption of self-assembled monolayers

PatentInactiveUS11002730B2

Innovation

- Incorporating a mass altering unit, such as polymers, fullerenes, or nanoparticles, into the self-assembled monolayer on metal, metal oxide, or silicon-containing substrates to increase the mass of the SAM, thereby reducing desorption without interfering with analyte binding, forming a molecular detector system.

Scalability and Manufacturing Considerations

The scalability of self-assembled monolayer (SAM) technologies represents a critical challenge for their widespread industrial adoption. Current laboratory-scale production methods, primarily based on solution-phase deposition or vapor-phase processes, face significant barriers when transitioning to mass manufacturing environments. Solution-based methods offer cost advantages but struggle with uniformity across large surface areas, while vapor deposition provides better uniformity but at substantially higher equipment costs and reduced throughput rates.

Manufacturing considerations must address several key parameters simultaneously. Surface preparation emerges as a fundamental prerequisite, as even nanoscale contaminants can disrupt the molecular ordering critical to SAM performance. Industrial implementation requires standardized cleaning protocols compatible with high-volume production lines while maintaining pristine substrate conditions. The development of in-line quality control methods presents another challenge, as traditional laboratory characterization techniques like ellipsometry and X-ray photoelectron spectroscopy are poorly suited to real-time manufacturing environments.

Process integration represents another significant hurdle. SAMs must withstand subsequent manufacturing steps, including thermal cycling, solvent exposure, and mechanical stresses. The stability of the formed monolayers under these conditions varies dramatically based on the binding chemistry and molecular structure. Thiol-based SAMs on gold, while extensively studied in research settings, exhibit limited thermal stability that restricts their integration with standard semiconductor processing techniques requiring elevated temperatures.

Environmental and economic factors also influence scalability. Traditional SAM formation often involves hazardous solvents like toluene or chlorinated hydrocarbons, creating regulatory challenges for large-scale implementation. Recent advances in green chemistry approaches, utilizing aqueous or bio-based solvents, show promise but frequently result in longer processing times or reduced monolayer quality. The economic viability of scaled SAM production depends heavily on precursor costs, which currently remain high for specialized molecules with complex functional groups.

Recent innovations addressing these challenges include roll-to-roll processing techniques for flexible electronics applications, automated spray deposition systems with precise environmental controls, and microfluidic delivery methods that minimize precursor waste. Additionally, computational modeling tools are increasingly employed to predict optimal processing parameters, reducing empirical optimization cycles and accelerating industrial implementation timelines.

Manufacturing considerations must address several key parameters simultaneously. Surface preparation emerges as a fundamental prerequisite, as even nanoscale contaminants can disrupt the molecular ordering critical to SAM performance. Industrial implementation requires standardized cleaning protocols compatible with high-volume production lines while maintaining pristine substrate conditions. The development of in-line quality control methods presents another challenge, as traditional laboratory characterization techniques like ellipsometry and X-ray photoelectron spectroscopy are poorly suited to real-time manufacturing environments.

Process integration represents another significant hurdle. SAMs must withstand subsequent manufacturing steps, including thermal cycling, solvent exposure, and mechanical stresses. The stability of the formed monolayers under these conditions varies dramatically based on the binding chemistry and molecular structure. Thiol-based SAMs on gold, while extensively studied in research settings, exhibit limited thermal stability that restricts their integration with standard semiconductor processing techniques requiring elevated temperatures.

Environmental and economic factors also influence scalability. Traditional SAM formation often involves hazardous solvents like toluene or chlorinated hydrocarbons, creating regulatory challenges for large-scale implementation. Recent advances in green chemistry approaches, utilizing aqueous or bio-based solvents, show promise but frequently result in longer processing times or reduced monolayer quality. The economic viability of scaled SAM production depends heavily on precursor costs, which currently remain high for specialized molecules with complex functional groups.

Recent innovations addressing these challenges include roll-to-roll processing techniques for flexible electronics applications, automated spray deposition systems with precise environmental controls, and microfluidic delivery methods that minimize precursor waste. Additionally, computational modeling tools are increasingly employed to predict optimal processing parameters, reducing empirical optimization cycles and accelerating industrial implementation timelines.

Environmental Impact and Sustainability Aspects

The environmental impact of self-assembled monolayers (SAMs) extends beyond their technical applications, encompassing sustainability considerations throughout their lifecycle. The production processes for SAM precursor molecules often involve organic synthesis routes that may utilize hazardous solvents and reagents. Recent research has focused on developing greener synthesis pathways that reduce toxic waste generation and energy consumption, with particular emphasis on replacing traditional organic solvents with more environmentally benign alternatives such as water, supercritical CO2, or bio-derived solvents.

The application of SAMs in various industries presents both environmental challenges and opportunities. While some SAM formation processes require ultra-high vacuum conditions or specialized equipment with significant energy demands, others can be performed under ambient conditions with minimal resource requirements. The choice of substrate materials and functional groups significantly influences the environmental footprint, with noble metal substrates raising sustainability concerns due to resource scarcity and mining impacts.

Biodegradability and end-of-life considerations for SAM-modified surfaces remain underexplored areas. The persistence of certain thiol-based SAMs in the environment raises potential ecotoxicological concerns, particularly when incorporating heavy metals or fluorinated compounds. Research into bio-derived SAM precursors, such as those based on naturally occurring fatty acids or amino acids, offers promising alternatives with improved environmental compatibility and reduced bioaccumulation potential.

From a lifecycle assessment perspective, SAMs can contribute to sustainability through their enabling functions in various technologies. Their application in anti-fouling coatings reduces the need for toxic biocides in marine environments. Similarly, SAM-based sensors enable more efficient environmental monitoring systems, while their use in catalysis can improve reaction efficiency and reduce waste generation in chemical manufacturing processes.

The durability and stability parameters of SAMs directly impact their sustainability profile. Longer-lasting SAM coatings reduce replacement frequency and associated material consumption, though this benefit must be balanced against potential accumulation in the environment. Recent advances in stimuli-responsive SAMs that can be selectively removed or degraded under controlled conditions represent an important step toward more sustainable surface modification technologies.

Regulatory frameworks increasingly influence SAM development, with restrictions on certain perfluorinated compounds and heavy metals driving innovation toward more environmentally compatible alternatives. This regulatory landscape, combined with growing industry commitment to green chemistry principles, is accelerating the transition toward SAM technologies with reduced environmental impact and enhanced sustainability credentials.

The application of SAMs in various industries presents both environmental challenges and opportunities. While some SAM formation processes require ultra-high vacuum conditions or specialized equipment with significant energy demands, others can be performed under ambient conditions with minimal resource requirements. The choice of substrate materials and functional groups significantly influences the environmental footprint, with noble metal substrates raising sustainability concerns due to resource scarcity and mining impacts.

Biodegradability and end-of-life considerations for SAM-modified surfaces remain underexplored areas. The persistence of certain thiol-based SAMs in the environment raises potential ecotoxicological concerns, particularly when incorporating heavy metals or fluorinated compounds. Research into bio-derived SAM precursors, such as those based on naturally occurring fatty acids or amino acids, offers promising alternatives with improved environmental compatibility and reduced bioaccumulation potential.

From a lifecycle assessment perspective, SAMs can contribute to sustainability through their enabling functions in various technologies. Their application in anti-fouling coatings reduces the need for toxic biocides in marine environments. Similarly, SAM-based sensors enable more efficient environmental monitoring systems, while their use in catalysis can improve reaction efficiency and reduce waste generation in chemical manufacturing processes.

The durability and stability parameters of SAMs directly impact their sustainability profile. Longer-lasting SAM coatings reduce replacement frequency and associated material consumption, though this benefit must be balanced against potential accumulation in the environment. Recent advances in stimuli-responsive SAMs that can be selectively removed or degraded under controlled conditions represent an important step toward more sustainable surface modification technologies.

Regulatory frameworks increasingly influence SAM development, with restrictions on certain perfluorinated compounds and heavy metals driving innovation toward more environmentally compatible alternatives. This regulatory landscape, combined with growing industry commitment to green chemistry principles, is accelerating the transition toward SAM technologies with reduced environmental impact and enhanced sustainability credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!