Self-Assembled Monolayers: Influence on Semiconductor Interfaces

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SAM Technology Background and Objectives

Self-assembled monolayers (SAMs) represent a significant advancement in surface engineering technology, emerging in the early 1980s through pioneering work by Jacob Sagiv and Ralph Nuzzo. These molecular assemblies form spontaneously on surfaces through chemisorption of active surfactants on a substrate, creating well-defined, organized structures with specific functional properties. The evolution of SAM technology has progressed from fundamental research to practical applications across multiple industries, particularly in semiconductor manufacturing and electronic device fabrication.

The technological trajectory of SAMs has been characterized by increasing control over molecular architecture, expanding substrate compatibility, and enhancing functional versatility. Initially limited to gold substrates with thiol-based molecules, SAM technology has expanded to encompass silicon, metal oxides, and various semiconductor materials, significantly broadening its application scope. Recent advancements have focused on developing SAMs with precise electronic properties, thermal stability, and controlled thickness at the nanometer scale.

At semiconductor interfaces, SAMs serve as critical mediators between organic and inorganic materials, influencing charge transport, energy level alignment, and interface dipole formation. The strategic positioning of SAMs at these interfaces enables modification of work functions, band bending, and surface energy—properties essential for optimizing device performance in organic electronics, photovoltaics, and next-generation computing architectures.

The primary technological objective in SAM research for semiconductor applications is to achieve precise control over electronic properties at material interfaces while maintaining compatibility with existing manufacturing processes. This includes developing SAMs that can withstand high-temperature processing steps, demonstrate long-term stability under operational conditions, and provide reproducible electronic characteristics across large-area substrates.

Another key goal is to leverage SAMs for enabling novel device architectures that transcend current performance limitations. By engineering molecular structures that facilitate specific electronic functions—such as selective charge transport, quantum confinement, or spin filtering—SAMs could potentially unlock new paradigms in semiconductor device design and functionality.

The convergence of SAM technology with emerging semiconductor materials like 2D transition metal dichalcogenides, perovskites, and quantum dots represents a frontier with significant innovation potential. Research aims to develop interface engineering strategies that optimize charge injection, reduce trap states, and enhance carrier mobility across heterogeneous material systems.

As the semiconductor industry continues its pursuit of Moore's Law and beyond, SAM technology offers a promising approach to address critical challenges in miniaturization, power efficiency, and novel computing paradigms. The ability to manipulate material properties at the molecular level positions SAMs as an enabling technology for future electronic systems where interface phenomena increasingly dominate device behavior.

The technological trajectory of SAMs has been characterized by increasing control over molecular architecture, expanding substrate compatibility, and enhancing functional versatility. Initially limited to gold substrates with thiol-based molecules, SAM technology has expanded to encompass silicon, metal oxides, and various semiconductor materials, significantly broadening its application scope. Recent advancements have focused on developing SAMs with precise electronic properties, thermal stability, and controlled thickness at the nanometer scale.

At semiconductor interfaces, SAMs serve as critical mediators between organic and inorganic materials, influencing charge transport, energy level alignment, and interface dipole formation. The strategic positioning of SAMs at these interfaces enables modification of work functions, band bending, and surface energy—properties essential for optimizing device performance in organic electronics, photovoltaics, and next-generation computing architectures.

The primary technological objective in SAM research for semiconductor applications is to achieve precise control over electronic properties at material interfaces while maintaining compatibility with existing manufacturing processes. This includes developing SAMs that can withstand high-temperature processing steps, demonstrate long-term stability under operational conditions, and provide reproducible electronic characteristics across large-area substrates.

Another key goal is to leverage SAMs for enabling novel device architectures that transcend current performance limitations. By engineering molecular structures that facilitate specific electronic functions—such as selective charge transport, quantum confinement, or spin filtering—SAMs could potentially unlock new paradigms in semiconductor device design and functionality.

The convergence of SAM technology with emerging semiconductor materials like 2D transition metal dichalcogenides, perovskites, and quantum dots represents a frontier with significant innovation potential. Research aims to develop interface engineering strategies that optimize charge injection, reduce trap states, and enhance carrier mobility across heterogeneous material systems.

As the semiconductor industry continues its pursuit of Moore's Law and beyond, SAM technology offers a promising approach to address critical challenges in miniaturization, power efficiency, and novel computing paradigms. The ability to manipulate material properties at the molecular level positions SAMs as an enabling technology for future electronic systems where interface phenomena increasingly dominate device behavior.

Market Analysis for SAM in Semiconductor Industry

The global market for Self-Assembled Monolayers (SAMs) in the semiconductor industry is experiencing significant growth, driven by the increasing demand for miniaturization and enhanced performance of electronic devices. The market size for SAMs in semiconductor applications was valued at approximately $320 million in 2022 and is projected to reach $580 million by 2028, representing a compound annual growth rate (CAGR) of 10.4% during the forecast period.

The semiconductor industry's continuous pursuit of Moore's Law has created substantial market opportunities for SAM technologies. As device dimensions shrink below 5nm, traditional surface modification techniques face limitations, creating a growing demand for molecular-level interface engineering solutions that SAMs can provide. This trend is particularly evident in advanced logic and memory chip manufacturing, where precise control of semiconductor interfaces is critical.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 65% of the global SAM semiconductor applications. This dominance is attributed to the high concentration of semiconductor fabrication facilities in countries like Taiwan, South Korea, and China. North America follows with about 20% market share, driven by research activities and specialized semiconductor manufacturing.

Market segmentation by application shows that logic devices represent the largest segment (45%), followed by memory devices (30%), and sensors and MEMS devices (15%). The remaining 10% is distributed among various niche applications. The high adoption rate in logic devices is primarily due to the critical role of interface properties in transistor performance and reliability.

From a customer perspective, the market is characterized by high concentration, with the top five semiconductor manufacturers accounting for over 60% of SAM consumption. This concentration presents both opportunities and challenges for SAM technology providers, as securing contracts with major players can significantly impact market position.

Key market drivers include the growing adoption of 3D integration technologies, increasing focus on reducing power consumption in electronic devices, and the emergence of new semiconductor materials requiring specialized interface engineering. Additionally, the expansion of applications in emerging fields such as quantum computing and neuromorphic chips is creating new market opportunities for SAM technologies.

Market barriers include the high cost of implementation, technical challenges in achieving uniform monolayer coverage at industrial scales, and competition from alternative interface engineering technologies. Regulatory considerations related to the use of certain chemical compounds in SAM formulations also impact market dynamics, particularly in regions with stringent environmental regulations.

The semiconductor industry's continuous pursuit of Moore's Law has created substantial market opportunities for SAM technologies. As device dimensions shrink below 5nm, traditional surface modification techniques face limitations, creating a growing demand for molecular-level interface engineering solutions that SAMs can provide. This trend is particularly evident in advanced logic and memory chip manufacturing, where precise control of semiconductor interfaces is critical.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for approximately 65% of the global SAM semiconductor applications. This dominance is attributed to the high concentration of semiconductor fabrication facilities in countries like Taiwan, South Korea, and China. North America follows with about 20% market share, driven by research activities and specialized semiconductor manufacturing.

Market segmentation by application shows that logic devices represent the largest segment (45%), followed by memory devices (30%), and sensors and MEMS devices (15%). The remaining 10% is distributed among various niche applications. The high adoption rate in logic devices is primarily due to the critical role of interface properties in transistor performance and reliability.

From a customer perspective, the market is characterized by high concentration, with the top five semiconductor manufacturers accounting for over 60% of SAM consumption. This concentration presents both opportunities and challenges for SAM technology providers, as securing contracts with major players can significantly impact market position.

Key market drivers include the growing adoption of 3D integration technologies, increasing focus on reducing power consumption in electronic devices, and the emergence of new semiconductor materials requiring specialized interface engineering. Additionally, the expansion of applications in emerging fields such as quantum computing and neuromorphic chips is creating new market opportunities for SAM technologies.

Market barriers include the high cost of implementation, technical challenges in achieving uniform monolayer coverage at industrial scales, and competition from alternative interface engineering technologies. Regulatory considerations related to the use of certain chemical compounds in SAM formulations also impact market dynamics, particularly in regions with stringent environmental regulations.

Current SAM Technology Challenges at Interfaces

Despite significant advancements in Self-Assembled Monolayer (SAM) technology, several critical challenges persist at semiconductor interfaces that impede their widespread industrial adoption. The primary challenge remains achieving uniform and defect-free SAM coverage across large-area semiconductor substrates. Even minor imperfections in monolayer formation can create electron trapping sites or leakage paths, significantly compromising device performance and reliability.

Stability issues present another major hurdle, particularly in harsh processing environments. SAMs must withstand subsequent fabrication steps including high temperatures, plasma exposure, and chemical treatments. Current SAM structures often degrade under these conditions, limiting their integration into standard semiconductor manufacturing processes. The thermal stability threshold of most SAMs (typically below 200°C) falls short of many semiconductor processing requirements.

Interface engineering challenges are equally problematic. Controlling the electronic properties at the SAM-semiconductor junction with precision remains difficult, especially when attempting to manipulate band alignment, work function, and charge transfer characteristics. The molecular-level interactions that determine these properties are highly complex and sensitive to subtle variations in processing conditions.

Characterization limitations further complicate SAM development for semiconductor applications. Current analytical techniques struggle to provide real-time, non-destructive assessment of SAM quality, coverage, and electronic properties at buried interfaces. This hampers both fundamental research and quality control in manufacturing settings.

Reproducibility and scalability represent significant barriers to commercialization. Laboratory-scale successes often fail to translate to industrial-scale production due to sensitivity to environmental conditions, substrate variations, and processing parameters. The lack of standardized deposition methods compatible with existing semiconductor fabrication lines creates additional implementation challenges.

Material compatibility issues arise when integrating SAMs with diverse semiconductor materials beyond traditional silicon. Emerging technologies utilizing compound semiconductors, 2D materials, or organic semiconductors each present unique surface chemistry challenges that require tailored SAM solutions.

Long-term reliability remains inadequately addressed, with limited data on SAM performance degradation over device lifetimes. Environmental factors such as humidity, temperature cycling, and electrical stress can potentially compromise SAM integrity over time, raising concerns about device longevity in commercial applications.

Addressing these interconnected challenges requires interdisciplinary approaches combining surface chemistry, materials science, electrical engineering, and advanced manufacturing techniques to realize the full potential of SAMs in next-generation semiconductor devices.

Stability issues present another major hurdle, particularly in harsh processing environments. SAMs must withstand subsequent fabrication steps including high temperatures, plasma exposure, and chemical treatments. Current SAM structures often degrade under these conditions, limiting their integration into standard semiconductor manufacturing processes. The thermal stability threshold of most SAMs (typically below 200°C) falls short of many semiconductor processing requirements.

Interface engineering challenges are equally problematic. Controlling the electronic properties at the SAM-semiconductor junction with precision remains difficult, especially when attempting to manipulate band alignment, work function, and charge transfer characteristics. The molecular-level interactions that determine these properties are highly complex and sensitive to subtle variations in processing conditions.

Characterization limitations further complicate SAM development for semiconductor applications. Current analytical techniques struggle to provide real-time, non-destructive assessment of SAM quality, coverage, and electronic properties at buried interfaces. This hampers both fundamental research and quality control in manufacturing settings.

Reproducibility and scalability represent significant barriers to commercialization. Laboratory-scale successes often fail to translate to industrial-scale production due to sensitivity to environmental conditions, substrate variations, and processing parameters. The lack of standardized deposition methods compatible with existing semiconductor fabrication lines creates additional implementation challenges.

Material compatibility issues arise when integrating SAMs with diverse semiconductor materials beyond traditional silicon. Emerging technologies utilizing compound semiconductors, 2D materials, or organic semiconductors each present unique surface chemistry challenges that require tailored SAM solutions.

Long-term reliability remains inadequately addressed, with limited data on SAM performance degradation over device lifetimes. Environmental factors such as humidity, temperature cycling, and electrical stress can potentially compromise SAM integrity over time, raising concerns about device longevity in commercial applications.

Addressing these interconnected challenges requires interdisciplinary approaches combining surface chemistry, materials science, electrical engineering, and advanced manufacturing techniques to realize the full potential of SAMs in next-generation semiconductor devices.

Current Interface Modification Solutions

01 Formation and modification of SAMs on semiconductor surfaces

Self-assembled monolayers (SAMs) can be formed on semiconductor surfaces through various methods, including solution deposition and vapor phase techniques. These SAMs can be modified through chemical reactions to introduce specific functional groups, enabling tailored surface properties. The formation process typically involves organic molecules with specific binding groups that have high affinity for semiconductor surfaces, creating well-ordered molecular structures that modify the electronic and chemical properties of the interface.- Formation and modification of SAMs on semiconductor surfaces: Self-assembled monolayers (SAMs) can be formed on semiconductor surfaces through various chemical processes. These monolayers can be modified to achieve specific properties at the semiconductor interface. The formation typically involves organic molecules with functional groups that have high affinity for the semiconductor surface, creating well-ordered molecular structures. Modification techniques include chemical functionalization, thermal treatment, and photochemical reactions to tailor the electronic and physical properties of the interface.

- Electronic properties and charge transfer at SAM-semiconductor interfaces: Self-assembled monolayers significantly influence the electronic properties of semiconductor interfaces by modifying charge transfer characteristics, energy levels, and band alignment. These molecular layers can create dipole moments that shift the work function of the semiconductor, control electron injection/extraction barriers, and modify surface states. The electronic properties can be tuned by selecting appropriate molecular structures with specific functional groups, enabling optimization of semiconductor devices for various applications including transistors, sensors, and photovoltaic cells.

- SAMs for passivation and protection of semiconductor surfaces: Self-assembled monolayers serve as effective passivation layers for semiconductor surfaces, protecting them from oxidation, contamination, and degradation. These molecular films can neutralize dangling bonds, reduce surface states, and prevent unwanted chemical reactions at the semiconductor interface. The passivation properties of SAMs help maintain the electrical performance and stability of semiconductor devices over time, particularly important for sensitive materials like III-V semiconductors, silicon, and emerging 2D materials.

- Functionalized SAMs for biosensing and biointerfaces on semiconductors: Functionalized self-assembled monolayers on semiconductor surfaces enable the development of biosensors and bioelectronic interfaces. These SAMs can be modified with biomolecules such as proteins, DNA, or antibodies to create specific recognition sites. The molecular architecture of the SAM provides control over the orientation and density of the biomolecules while maintaining their biological activity. This approach allows for the integration of biological components with semiconductor devices for applications in medical diagnostics, environmental monitoring, and bioelectronics.

- SAMs for controlling growth and integration of semiconductor materials: Self-assembled monolayers can direct the nucleation, growth, and integration of semiconductor materials and nanostructures. By patterning SAMs on surfaces, selective deposition of semiconductor materials can be achieved, enabling precise spatial control over material growth. These molecular templates influence crystallization processes, orientation, and morphology of deposited materials. This approach facilitates the fabrication of complex semiconductor heterostructures, quantum dots, nanowires, and thin films with enhanced properties for electronic and optoelectronic applications.

02 Electronic device applications of SAMs at semiconductor interfaces

Self-assembled monolayers at semiconductor interfaces are utilized in various electronic devices including field-effect transistors, sensors, and photovoltaic cells. These SAMs can modify charge transport properties, create electronic barriers or channels, and tune the work function of electrodes. By precisely controlling the molecular structure of the SAM, the electronic properties of semiconductor interfaces can be engineered to enhance device performance, stability, and functionality, enabling advancements in organic electronics, flexible displays, and molecular electronics.Expand Specific Solutions03 Biomolecular and sensing applications of SAMs on semiconductors

Self-assembled monolayers on semiconductor surfaces provide platforms for biomolecular attachment and sensing applications. These SAMs can be functionalized with specific recognition elements such as antibodies, DNA, or enzymes to create highly sensitive biosensors. The controlled surface chemistry of SAMs allows for reduced non-specific binding while maintaining high sensitivity for target analytes. These interfaces enable label-free detection methods based on changes in electrical, optical, or mechanical properties when target molecules bind to the functionalized surface.Expand Specific Solutions04 Novel materials and methods for SAM formation on semiconductors

Advanced materials and methods are being developed for creating self-assembled monolayers on semiconductor interfaces with enhanced properties. These include novel thiol compounds, silanes, phosphonic acids, and other organic molecules specifically designed for semiconductor surface attachment. Innovative deposition techniques such as microcontact printing, photolithographic patterning, and selective area deposition allow for spatial control of SAM formation. These approaches enable the creation of complex patterns and gradients of surface properties for specialized applications in nanotechnology and semiconductor processing.Expand Specific Solutions05 Interface engineering using SAMs for improved semiconductor device performance

Self-assembled monolayers are employed for interface engineering in semiconductor devices to improve performance characteristics. By inserting SAMs between different materials in a device structure, interfacial properties such as charge injection barriers, recombination rates, and contact resistance can be optimized. These molecular interfaces can passivate surface defects, reduce trap states, and modify band alignment between materials. The controlled thickness and composition of SAMs allow for precise tuning of interface properties, resulting in enhanced efficiency, stability, and lifetime of semiconductor devices.Expand Specific Solutions

Key Industry Players in SAM Development

The self-assembled monolayers (SAMs) technology for semiconductor interfaces is currently in a growth phase, with increasing market adoption as the semiconductor industry seeks enhanced surface modification solutions. The global market is expanding rapidly, driven by demands for miniaturization and improved device performance. From a technical maturity perspective, industry leaders like Taiwan Semiconductor Manufacturing Co., Intel, Samsung Electronics, and Applied Materials are advancing commercial applications, while research institutions such as MIT, Harvard, and Hanyang University are developing next-generation SAM technologies. GLOBALFOUNDRIES and SK hynix are integrating SAMs into manufacturing processes, while specialized materials companies like Merck Patent GmbH and BASF are developing tailored molecular solutions. The competitive landscape shows a collaborative ecosystem between semiconductor manufacturers, equipment providers, and materials specialists.

International Business Machines Corp.

Technical Solution: IBM has developed advanced self-assembled monolayer (SAM) technology for semiconductor interfaces that focuses on molecular engineering at the nanoscale. Their approach utilizes precisely designed organic molecules with specific functional groups that form well-ordered monolayers on semiconductor surfaces. IBM's SAM technology employs thiol-based and silane-based chemistries to create uniform molecular coatings that modify surface properties and electronic characteristics at semiconductor interfaces. The company has pioneered the use of SAMs as ultrathin dielectrics in field-effect transistors, achieving gate dielectric thicknesses below 2nm while maintaining excellent insulating properties[1]. IBM researchers have demonstrated that properly engineered SAMs can significantly reduce interface trap densities and improve carrier mobility in semiconductor devices. Their work extends to using SAMs as adhesion promoters, surface passivation layers, and as templates for subsequent material deposition in advanced node semiconductor manufacturing[3].

Strengths: IBM's SAM technology enables precise molecular-level control over interface properties, allowing for tunable work functions and reduced leakage currents. Their approach integrates well with existing semiconductor fabrication processes. Weaknesses: The stability of some SAM structures under high-temperature processing conditions remains challenging, potentially limiting integration into certain manufacturing steps.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive SAM-based solutions for semiconductor interface engineering that address multiple aspects of advanced device fabrication. Their technology platform includes specialized deposition equipment and process recipes for creating highly uniform self-assembled monolayers across 300mm wafers with precise thickness control down to the angstrom level. Applied Materials' approach utilizes vapor-phase and solution-based deposition methods optimized for different SAM chemistries, including phosphonic acids, silanes, and thiol-based compounds. Their SAM technology serves multiple functions in semiconductor manufacturing, including surface energy modification for improved subsequent layer deposition, work function engineering for threshold voltage control, and interface defect passivation for enhanced carrier transport[4]. The company has demonstrated SAM integration into high-k metal gate processes, enabling improved equivalent oxide thickness scaling while maintaining reliability metrics. Applied Materials has also developed in-line metrology solutions specifically designed to characterize SAM quality, uniformity, and thickness during the manufacturing process[7].

Strengths: Applied Materials offers end-to-end solutions for SAM integration, from deposition equipment to process optimization and metrology. Their technology enables precise interface engineering across full wafers with excellent uniformity and repeatability. Weaknesses: Some SAM deposition processes may require longer processing times compared to conventional deposition methods, potentially impacting manufacturing throughput in high-volume production environments.

Critical SAM Patents and Technical Literature

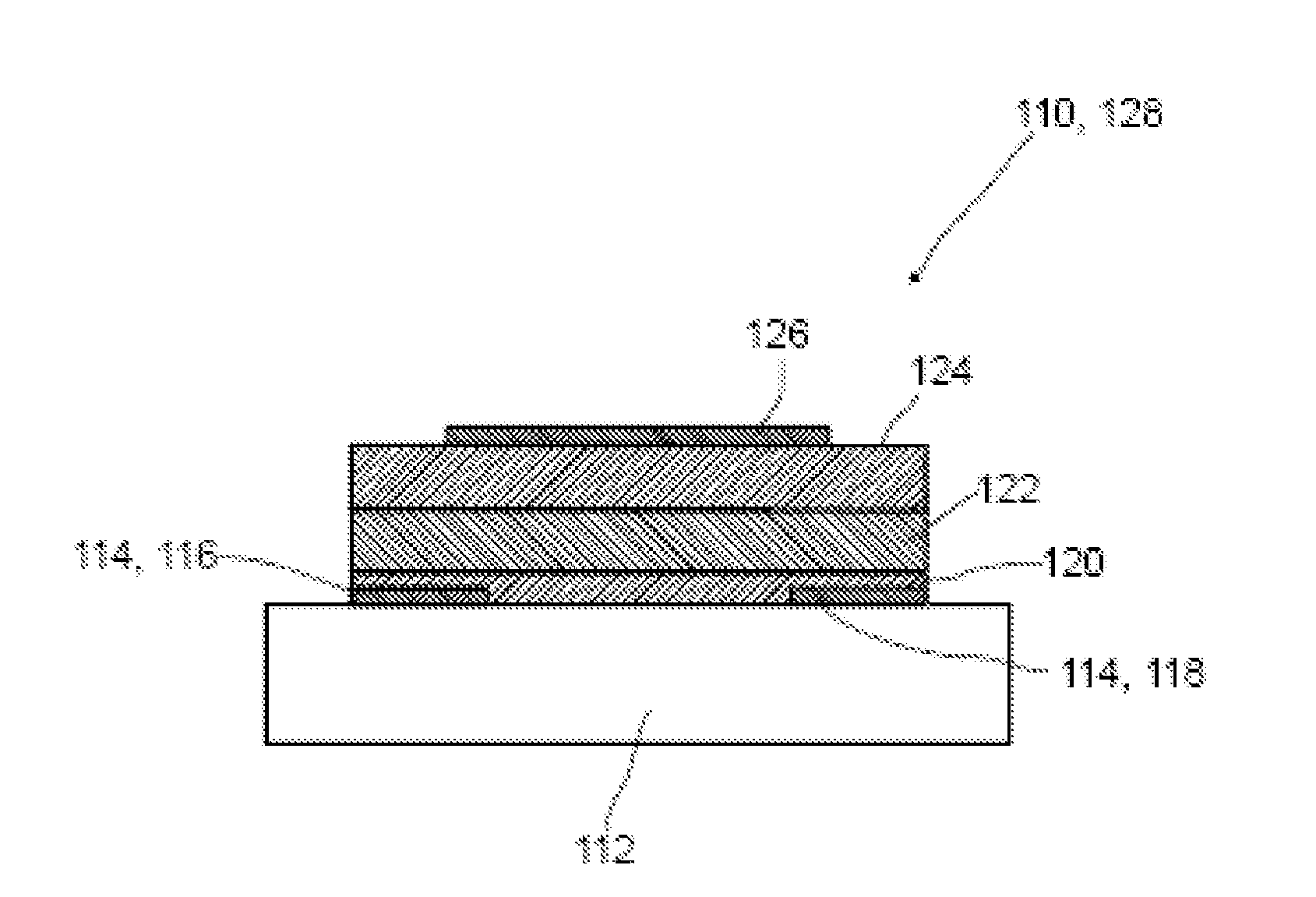

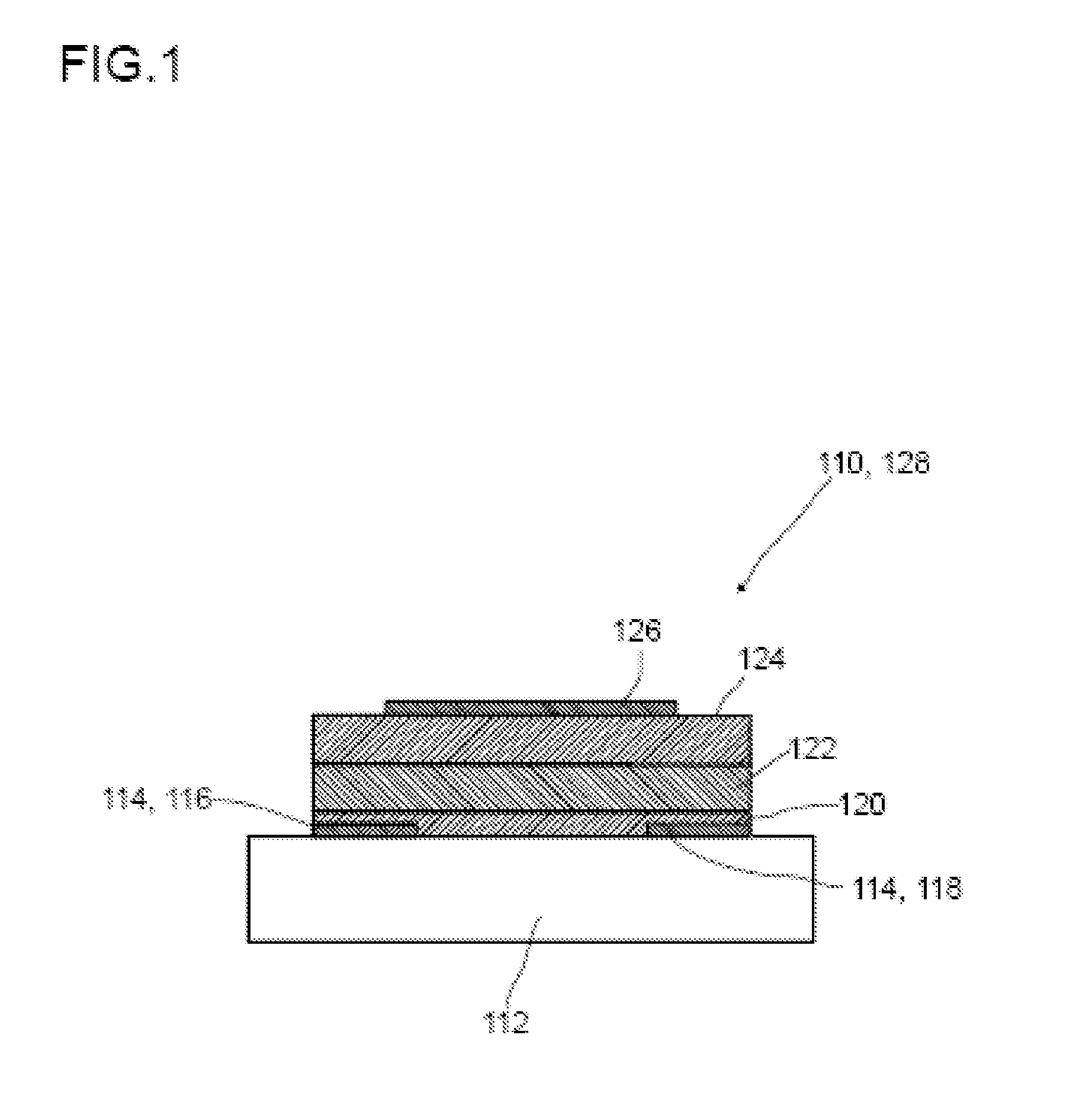

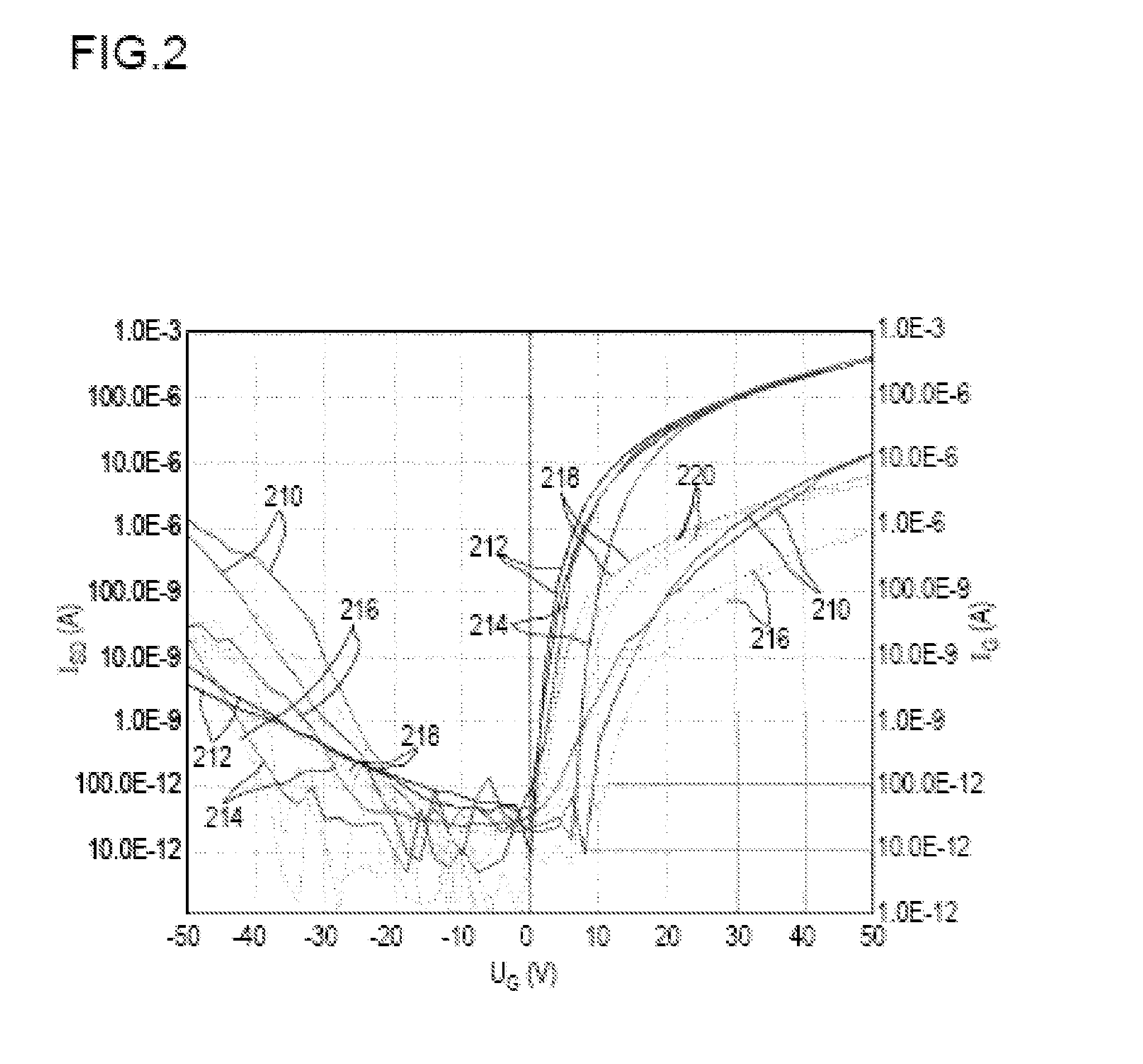

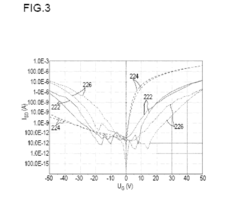

Method for producing an organic semiconductor device

PatentActiveUS20130200336A1

Innovation

- The introduction of a thin intermediate layer comprising thiol compounds with specific dipole moments between the organic semiconducting material and electrodes to suppress ambipolar charge carrier transport, favoring unipolar transport by adjusting the energy levels and reducing contact resistance.

Environmental Impact of SAM Processing

The environmental impact of Self-Assembled Monolayer (SAM) processing represents a critical consideration in semiconductor manufacturing. Traditional semiconductor processing often involves harsh chemicals, high energy consumption, and significant waste generation. In contrast, SAM technology offers several environmentally advantageous attributes that align with sustainable manufacturing principles.

SAM processing typically employs significantly lower volumes of organic solvents compared to conventional semiconductor surface treatments. Most SAM formation protocols utilize dilute solutions of molecules in common solvents like ethanol, toluene, or hexane, with concentrations typically in the millimolar range. This represents a substantial reduction in chemical usage compared to traditional wet chemical processes that may require concentrated acids, bases, or specialized etchants.

Energy consumption during SAM processing presents another environmental advantage. The self-assembly process occurs spontaneously at room temperature or with mild heating (typically below 100°C), contrasting sharply with conventional semiconductor processing steps that often require high-temperature annealing or plasma treatments exceeding several hundred degrees Celsius. This temperature differential translates to meaningful energy savings and reduced carbon footprint across manufacturing operations.

Waste stream management also benefits from SAM implementation. The molecular precision of SAMs means that nearly all introduced molecules participate in the intended surface modification, resulting in minimal waste generation. Additionally, the organic solvents used can often be recovered and recycled through standard distillation processes, further reducing environmental impact.

However, certain environmental challenges remain. Some SAM precursor molecules contain fluorinated components or heavy metals that pose potential ecological risks if improperly handled or disposed of. The synthesis of specialized SAM molecules may also involve multi-step organic chemistry procedures with their own environmental considerations. Manufacturers must implement proper containment and waste management protocols to mitigate these risks.

Looking forward, green chemistry approaches are emerging to address these concerns. Bio-inspired SAMs derived from natural compounds, solvent-free deposition methods, and water-based SAM systems represent promising directions for further reducing environmental impact. Additionally, the extended lifetime and improved performance of semiconductor devices enabled by SAM technology indirectly contributes to sustainability by reducing electronic waste generation and resource consumption for replacement components.

SAM processing typically employs significantly lower volumes of organic solvents compared to conventional semiconductor surface treatments. Most SAM formation protocols utilize dilute solutions of molecules in common solvents like ethanol, toluene, or hexane, with concentrations typically in the millimolar range. This represents a substantial reduction in chemical usage compared to traditional wet chemical processes that may require concentrated acids, bases, or specialized etchants.

Energy consumption during SAM processing presents another environmental advantage. The self-assembly process occurs spontaneously at room temperature or with mild heating (typically below 100°C), contrasting sharply with conventional semiconductor processing steps that often require high-temperature annealing or plasma treatments exceeding several hundred degrees Celsius. This temperature differential translates to meaningful energy savings and reduced carbon footprint across manufacturing operations.

Waste stream management also benefits from SAM implementation. The molecular precision of SAMs means that nearly all introduced molecules participate in the intended surface modification, resulting in minimal waste generation. Additionally, the organic solvents used can often be recovered and recycled through standard distillation processes, further reducing environmental impact.

However, certain environmental challenges remain. Some SAM precursor molecules contain fluorinated components or heavy metals that pose potential ecological risks if improperly handled or disposed of. The synthesis of specialized SAM molecules may also involve multi-step organic chemistry procedures with their own environmental considerations. Manufacturers must implement proper containment and waste management protocols to mitigate these risks.

Looking forward, green chemistry approaches are emerging to address these concerns. Bio-inspired SAMs derived from natural compounds, solvent-free deposition methods, and water-based SAM systems represent promising directions for further reducing environmental impact. Additionally, the extended lifetime and improved performance of semiconductor devices enabled by SAM technology indirectly contributes to sustainability by reducing electronic waste generation and resource consumption for replacement components.

Integration Challenges with Existing Fabrication

The integration of Self-Assembled Monolayers (SAMs) into existing semiconductor fabrication processes presents significant challenges that must be addressed for successful industrial adoption. Traditional semiconductor manufacturing relies on well-established processes optimized for specific materials and conditions, making the introduction of SAM technology particularly complex. One primary challenge involves temperature compatibility, as many conventional semiconductor processes operate at elevated temperatures (>400°C) that can degrade organic SAM structures, which typically begin to decompose at temperatures above 200°C.

Process contamination represents another critical concern. SAM precursors often contain organic components that may introduce unwanted contaminants into ultra-clean fabrication environments. These contaminants can potentially migrate during subsequent processing steps, compromising device performance and reliability. Establishing appropriate containment protocols and developing specialized equipment for SAM deposition becomes necessary to prevent cross-contamination.

Scalability issues further complicate integration efforts. While SAM formation works effectively in laboratory settings with small substrates, scaling to industry-standard 300mm wafers introduces uniformity challenges. Ensuring consistent monolayer coverage across large surface areas requires precise control of deposition parameters, including solution concentration, immersion time, and environmental conditions. The development of specialized equipment capable of maintaining these parameters at industrial scales remains an ongoing challenge.

Compatibility with existing lithography processes presents additional hurdles. Photoresists and developers used in conventional lithography may interact unfavorably with SAMs, potentially causing delamination or chemical modification of the monolayer. This necessitates either the development of SAM-compatible lithography materials or the implementation of protective strategies to preserve SAM integrity during patterning steps.

Metrology and quality control represent significant integration challenges as well. Current semiconductor inspection tools are not optimized for characterizing molecular monolayers, making it difficult to verify SAM quality in production environments. The development of in-line monitoring techniques capable of rapidly assessing monolayer coverage, thickness, and chemical composition is essential for quality assurance in manufacturing settings.

Time constraints in high-volume manufacturing environments pose another obstacle. SAM formation typically requires extended immersion times (often hours), which conflicts with the rapid throughput demands of semiconductor fabrication. Accelerating the self-assembly process without compromising monolayer quality represents a key research priority for industrial implementation.

Process contamination represents another critical concern. SAM precursors often contain organic components that may introduce unwanted contaminants into ultra-clean fabrication environments. These contaminants can potentially migrate during subsequent processing steps, compromising device performance and reliability. Establishing appropriate containment protocols and developing specialized equipment for SAM deposition becomes necessary to prevent cross-contamination.

Scalability issues further complicate integration efforts. While SAM formation works effectively in laboratory settings with small substrates, scaling to industry-standard 300mm wafers introduces uniformity challenges. Ensuring consistent monolayer coverage across large surface areas requires precise control of deposition parameters, including solution concentration, immersion time, and environmental conditions. The development of specialized equipment capable of maintaining these parameters at industrial scales remains an ongoing challenge.

Compatibility with existing lithography processes presents additional hurdles. Photoresists and developers used in conventional lithography may interact unfavorably with SAMs, potentially causing delamination or chemical modification of the monolayer. This necessitates either the development of SAM-compatible lithography materials or the implementation of protective strategies to preserve SAM integrity during patterning steps.

Metrology and quality control represent significant integration challenges as well. Current semiconductor inspection tools are not optimized for characterizing molecular monolayers, making it difficult to verify SAM quality in production environments. The development of in-line monitoring techniques capable of rapidly assessing monolayer coverage, thickness, and chemical composition is essential for quality assurance in manufacturing settings.

Time constraints in high-volume manufacturing environments pose another obstacle. SAM formation typically requires extended immersion times (often hours), which conflicts with the rapid throughput demands of semiconductor fabrication. Accelerating the self-assembly process without compromising monolayer quality represents a key research priority for industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!