Magnesium Nitrate’s Effect on Cold Storage of Horticultural Produce

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg(NO3)2 in Horticulture

Magnesium nitrate has emerged as a significant compound in the field of horticulture, particularly in the cold storage of produce. This inorganic salt, with its unique properties, has shown promising effects on extending the shelf life and maintaining the quality of various fruits and vegetables during storage. The use of Mg(NO3)2 in horticulture represents a convergence of agricultural science and chemical engineering, aiming to address the critical challenge of post-harvest losses in the global food supply chain.

The application of magnesium nitrate in cold storage solutions stems from its ability to influence cellular processes within plant tissues. When applied as a pre-harvest spray or post-harvest treatment, Mg(NO3)2 can enhance the fruit's natural defense mechanisms against chilling injury and physiological disorders. This is particularly crucial for climacteric fruits, which continue to ripen after harvest and are more susceptible to quality degradation during storage.

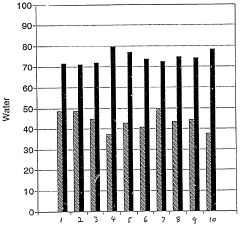

Research has demonstrated that magnesium nitrate treatments can significantly reduce respiration rates and ethylene production in stored produce. By slowing down these metabolic processes, the compound effectively delays senescence and maintains fruit firmness for extended periods. This is especially beneficial for delicate fruits like peaches, nectarines, and plums, which are prone to rapid softening and loss of texture during cold storage.

Moreover, Mg(NO3)2 has shown potential in preserving the nutritional value of horticultural produce. Studies have indicated that fruits treated with magnesium nitrate retain higher levels of vitamins, antioxidants, and other bioactive compounds throughout the storage period. This aspect is particularly important in the context of increasing consumer demand for high-quality, nutrient-rich fresh produce.

The mechanism by which magnesium nitrate exerts its beneficial effects is multifaceted. It is believed to enhance the stability of cell membranes, thereby reducing electrolyte leakage and maintaining cellular integrity under cold stress conditions. Additionally, the magnesium component plays a role in chlorophyll preservation, which is crucial for maintaining the visual appeal of leafy greens and other chlorophyll-rich produce during storage.

In the broader context of sustainable agriculture, the use of Mg(NO3)2 in cold storage aligns with efforts to reduce food waste and improve food security. By extending the storage life of perishable horticultural products, this technology can help mitigate post-harvest losses, which account for a significant portion of global food waste. This is particularly relevant for developing countries, where inadequate storage infrastructure often leads to substantial losses of fresh produce.

The application of magnesium nitrate in cold storage solutions stems from its ability to influence cellular processes within plant tissues. When applied as a pre-harvest spray or post-harvest treatment, Mg(NO3)2 can enhance the fruit's natural defense mechanisms against chilling injury and physiological disorders. This is particularly crucial for climacteric fruits, which continue to ripen after harvest and are more susceptible to quality degradation during storage.

Research has demonstrated that magnesium nitrate treatments can significantly reduce respiration rates and ethylene production in stored produce. By slowing down these metabolic processes, the compound effectively delays senescence and maintains fruit firmness for extended periods. This is especially beneficial for delicate fruits like peaches, nectarines, and plums, which are prone to rapid softening and loss of texture during cold storage.

Moreover, Mg(NO3)2 has shown potential in preserving the nutritional value of horticultural produce. Studies have indicated that fruits treated with magnesium nitrate retain higher levels of vitamins, antioxidants, and other bioactive compounds throughout the storage period. This aspect is particularly important in the context of increasing consumer demand for high-quality, nutrient-rich fresh produce.

The mechanism by which magnesium nitrate exerts its beneficial effects is multifaceted. It is believed to enhance the stability of cell membranes, thereby reducing electrolyte leakage and maintaining cellular integrity under cold stress conditions. Additionally, the magnesium component plays a role in chlorophyll preservation, which is crucial for maintaining the visual appeal of leafy greens and other chlorophyll-rich produce during storage.

In the broader context of sustainable agriculture, the use of Mg(NO3)2 in cold storage aligns with efforts to reduce food waste and improve food security. By extending the storage life of perishable horticultural products, this technology can help mitigate post-harvest losses, which account for a significant portion of global food waste. This is particularly relevant for developing countries, where inadequate storage infrastructure often leads to substantial losses of fresh produce.

Market for Cold Storage

The cold storage market for horticultural produce has experienced significant growth in recent years, driven by increasing demand for fresh fruits and vegetables year-round. This market segment is crucial for maintaining the quality and extending the shelf life of perishable produce, thereby reducing food waste and ensuring a stable supply chain for the agricultural sector.

Global market trends indicate a steady expansion of cold storage facilities, particularly in developing countries where rapid urbanization and changing dietary habits are fueling demand for fresh produce. The Asia-Pacific region, led by countries like China and India, has emerged as a key growth area for cold storage infrastructure. In more mature markets such as North America and Europe, the focus has shifted towards upgrading existing facilities with advanced technologies to improve energy efficiency and storage conditions.

The market for cold storage in horticulture is closely tied to technological advancements in refrigeration systems, temperature control, and preservation methods. Innovations in these areas have led to improved storage conditions, longer shelf life, and better quality retention of fruits and vegetables. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) technologies in cold storage management has further enhanced the precision and efficiency of storage operations.

Consumer preferences for fresh, high-quality produce and the growing popularity of organic and locally sourced foods have also contributed to the expansion of the cold storage market. Retailers and distributors are investing in cold chain logistics to meet these demands and maintain competitive advantage in the market.

The COVID-19 pandemic has highlighted the critical importance of robust cold storage infrastructure in ensuring food security and reducing supply chain disruptions. This has led to increased investment in cold storage facilities and technologies, with governments and private sector players recognizing the need for resilient food supply chains.

Environmental concerns and regulatory pressures are driving the adoption of more sustainable cold storage solutions. This includes the use of natural refrigerants, energy-efficient cooling systems, and renewable energy sources to power cold storage facilities. The market is seeing a shift towards eco-friendly refrigerants and technologies that minimize the carbon footprint of cold storage operations.

As the cold storage market continues to evolve, there is growing interest in innovative preservation techniques that can complement or enhance traditional cold storage methods. This is where technologies like the use of magnesium nitrate in cold storage of horticultural produce come into play, offering potential improvements in storage efficiency and produce quality retention.

Global market trends indicate a steady expansion of cold storage facilities, particularly in developing countries where rapid urbanization and changing dietary habits are fueling demand for fresh produce. The Asia-Pacific region, led by countries like China and India, has emerged as a key growth area for cold storage infrastructure. In more mature markets such as North America and Europe, the focus has shifted towards upgrading existing facilities with advanced technologies to improve energy efficiency and storage conditions.

The market for cold storage in horticulture is closely tied to technological advancements in refrigeration systems, temperature control, and preservation methods. Innovations in these areas have led to improved storage conditions, longer shelf life, and better quality retention of fruits and vegetables. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) technologies in cold storage management has further enhanced the precision and efficiency of storage operations.

Consumer preferences for fresh, high-quality produce and the growing popularity of organic and locally sourced foods have also contributed to the expansion of the cold storage market. Retailers and distributors are investing in cold chain logistics to meet these demands and maintain competitive advantage in the market.

The COVID-19 pandemic has highlighted the critical importance of robust cold storage infrastructure in ensuring food security and reducing supply chain disruptions. This has led to increased investment in cold storage facilities and technologies, with governments and private sector players recognizing the need for resilient food supply chains.

Environmental concerns and regulatory pressures are driving the adoption of more sustainable cold storage solutions. This includes the use of natural refrigerants, energy-efficient cooling systems, and renewable energy sources to power cold storage facilities. The market is seeing a shift towards eco-friendly refrigerants and technologies that minimize the carbon footprint of cold storage operations.

As the cold storage market continues to evolve, there is growing interest in innovative preservation techniques that can complement or enhance traditional cold storage methods. This is where technologies like the use of magnesium nitrate in cold storage of horticultural produce come into play, offering potential improvements in storage efficiency and produce quality retention.

Challenges in Produce

The cold storage of horticultural produce presents several significant challenges that impact the quality, shelf life, and marketability of fruits and vegetables. One of the primary issues is the management of temperature fluctuations. Even minor deviations from optimal storage temperatures can accelerate ripening, increase respiration rates, and promote microbial growth, leading to rapid deterioration of produce quality.

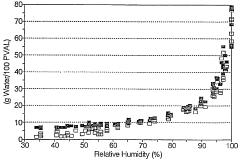

Moisture control is another critical challenge in cold storage facilities. Excessive humidity can encourage mold growth and bacterial proliferation, while insufficient moisture can cause wilting and shriveling of produce. Striking the right balance is essential but often difficult to maintain consistently across different types of produce with varying moisture requirements.

Ethylene management poses a substantial hurdle in cold storage. This naturally occurring plant hormone, produced by many fruits and some vegetables, can accelerate ripening and senescence in ethylene-sensitive produce. Controlling ethylene levels in mixed storage environments is complex and requires sophisticated ventilation and filtration systems.

Chilling injury is a significant concern for many tropical and subtropical fruits and vegetables when stored at low temperatures. This physiological disorder can cause discoloration, pitting, and off-flavors, rendering the produce unmarketable. Determining the optimal storage temperature for each type of produce to prevent chilling injury while maintaining quality is a delicate balancing act.

Pest and disease control in cold storage facilities presents ongoing challenges. Despite low temperatures, some pathogens can still thrive, and insects may enter dormancy only to become active again when produce is removed from storage. Implementing effective sanitation protocols and monitoring systems is crucial but can be resource-intensive.

The energy consumption of cold storage facilities is a growing concern, both from an economic and environmental perspective. Maintaining consistent low temperatures requires significant energy input, and improving energy efficiency without compromising storage conditions is an ongoing challenge for the industry.

Lastly, the diversity of horticultural produce, each with its unique storage requirements, complicates the design and management of cold storage facilities. Creating versatile storage solutions that can accommodate a wide range of produce while maintaining optimal conditions for each type is a complex logistical and technological challenge that continues to drive innovation in the field.

Moisture control is another critical challenge in cold storage facilities. Excessive humidity can encourage mold growth and bacterial proliferation, while insufficient moisture can cause wilting and shriveling of produce. Striking the right balance is essential but often difficult to maintain consistently across different types of produce with varying moisture requirements.

Ethylene management poses a substantial hurdle in cold storage. This naturally occurring plant hormone, produced by many fruits and some vegetables, can accelerate ripening and senescence in ethylene-sensitive produce. Controlling ethylene levels in mixed storage environments is complex and requires sophisticated ventilation and filtration systems.

Chilling injury is a significant concern for many tropical and subtropical fruits and vegetables when stored at low temperatures. This physiological disorder can cause discoloration, pitting, and off-flavors, rendering the produce unmarketable. Determining the optimal storage temperature for each type of produce to prevent chilling injury while maintaining quality is a delicate balancing act.

Pest and disease control in cold storage facilities presents ongoing challenges. Despite low temperatures, some pathogens can still thrive, and insects may enter dormancy only to become active again when produce is removed from storage. Implementing effective sanitation protocols and monitoring systems is crucial but can be resource-intensive.

The energy consumption of cold storage facilities is a growing concern, both from an economic and environmental perspective. Maintaining consistent low temperatures requires significant energy input, and improving energy efficiency without compromising storage conditions is an ongoing challenge for the industry.

Lastly, the diversity of horticultural produce, each with its unique storage requirements, complicates the design and management of cold storage facilities. Creating versatile storage solutions that can accommodate a wide range of produce while maintaining optimal conditions for each type is a complex logistical and technological challenge that continues to drive innovation in the field.

Current Mg(NO3)2 Usage

01 Use of magnesium nitrate in cold storage systems

Magnesium nitrate is utilized in cold storage systems due to its ability to absorb and release heat during phase changes. This property makes it an effective material for thermal energy storage in refrigeration and air conditioning applications, helping to maintain stable temperatures and improve energy efficiency.- Use of magnesium nitrate in cold storage systems: Magnesium nitrate is utilized in cold storage systems to enhance cooling efficiency and maintain low temperatures. It can be incorporated into phase change materials or cooling solutions to improve thermal energy storage and heat transfer properties in refrigeration applications.

- Magnesium nitrate as a component in cold packs: Magnesium nitrate is used as an active ingredient in cold packs for medical and therapeutic purposes. When combined with other compounds, it creates an endothermic reaction that produces a cooling effect, making it effective for treating injuries or reducing inflammation.

- Magnesium nitrate in agriculture and food preservation: In agricultural applications, magnesium nitrate is used in cold storage facilities to preserve fruits, vegetables, and other perishable goods. It helps maintain optimal humidity levels and prevents spoilage, extending the shelf life of produce during storage and transportation.

- Magnesium nitrate in industrial cooling processes: Magnesium nitrate is employed in industrial cooling processes, particularly in large-scale refrigeration systems. It can be used as a component in cooling solutions or as part of heat exchange systems to improve energy efficiency and maintain consistent low temperatures in manufacturing and processing facilities.

- Magnesium nitrate in energy storage applications: Magnesium nitrate is utilized in thermal energy storage systems for cold storage applications. It can be incorporated into phase change materials or used in conjunction with other compounds to store and release thermal energy efficiently, supporting renewable energy integration and improving overall energy management in cooling systems.

02 Magnesium nitrate in phase change materials (PCMs)

Magnesium nitrate is incorporated into phase change materials for cold storage applications. These PCMs can store and release large amounts of latent heat during the phase transition process, allowing for efficient temperature control and energy management in various cooling systems.Expand Specific Solutions03 Combination with other salts for enhanced cold storage properties

Magnesium nitrate is often combined with other salts to create eutectic mixtures with improved cold storage properties. These combinations can result in lower melting points, higher energy storage capacities, and better overall performance in cold storage applications.Expand Specific Solutions04 Application in refrigeration and air conditioning systems

Magnesium nitrate-based cold storage solutions are integrated into refrigeration and air conditioning systems to enhance their efficiency and performance. These systems can utilize the thermal energy storage capabilities of magnesium nitrate to reduce energy consumption and maintain stable temperatures.Expand Specific Solutions05 Encapsulation techniques for magnesium nitrate in cold storage

Various encapsulation methods are employed to improve the stability and handling of magnesium nitrate in cold storage applications. These techniques can prevent leakage, enhance thermal conductivity, and increase the overall effectiveness of magnesium nitrate-based cold storage systems.Expand Specific Solutions

Key Industry Players

The market for magnesium nitrate's effect on cold storage of horticultural produce is in an early development stage, with growing interest due to increasing demand for extended shelf life of fresh produce. The global market size is relatively small but expanding, driven by the need for improved post-harvest technologies. Technical maturity is moderate, with ongoing research to optimize application methods and efficacy. Key players like Yara International ASA and Tessenderlo Kerley, Inc. are leading in fertilizer and chemical production, while research institutions such as Nanjing Agricultural University and Punjab Agricultural University are contributing to scientific advancements. Companies like Sunamp Ltd. are exploring innovative thermal storage solutions that could potentially integrate with cold storage technologies.

Yara International ASA

Technical Solution: Yara International ASA has developed a proprietary technology utilizing magnesium nitrate for cold storage of horticultural produce. Their approach involves the application of a magnesium nitrate-based solution as a pre-harvest spray or post-harvest dip treatment. This method has shown to enhance the cold storage tolerance of various fruits and vegetables by stabilizing cell membranes and reducing chilling injury[1]. The company's research indicates that magnesium nitrate treatment can extend the shelf life of produce by up to 30% in cold storage conditions, while maintaining quality attributes such as firmness, color, and nutritional value[2]. Yara has also integrated this technology into their precision farming solutions, allowing for optimized application based on crop type and environmental conditions[3].

Strengths: Comprehensive research on various crop types, integration with existing precision farming solutions, and proven efficacy in extending shelf life. Weaknesses: May require additional equipment for application, and effectiveness can vary depending on crop variety and storage conditions.

Syngenta Participations AG

Technical Solution: Syngenta has developed an innovative approach to using magnesium nitrate in cold storage of horticultural produce. Their technology involves a controlled release formulation of magnesium nitrate that is applied as a coating to fruits and vegetables before cold storage. This formulation gradually releases magnesium ions during storage, which helps maintain cellular integrity and reduces oxidative stress in the produce[4]. Syngenta's research has shown that this method can reduce cold-induced physiological disorders by up to 40% in sensitive crops like tomatoes and peppers[5]. Additionally, they have developed a complementary sensor technology that monitors magnesium levels in storage facilities, allowing for real-time adjustments to optimize storage conditions[6].

Strengths: Controlled release technology for sustained effect, complementary monitoring system, and significant reduction in cold-induced disorders. Weaknesses: May require specialized application equipment and training for proper implementation.

Mg(NO3)2 Mechanisms

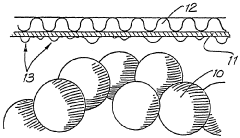

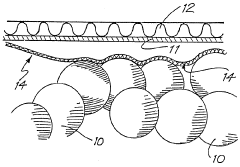

A package allowing cooling and preservation of horticultural produce without condensation or desiccation

PatentInactiveAU688266B

Innovation

- A packaging material comprising a water-vapour and liquid-water impermeable sheet with a water-absorbing film, such as polyvinyl alcohol or fibrous hydrophilic materials, positioned between the produce and a permeable sheet to control condensation and moisture loss, allowing for efficient cooling and storage while preventing damage.

Closed receptable containing liquid garden fertilizer and process for obtaining and bottling this fertilizer

PatentInactiveEP0291652A3

Innovation

- A heat-treated aqueous extract of manure is used, with pre-decomposition and aeration before bottling, and sterilization to kill microorganisms, along with air-tight and light-blocking containers, to maintain nutrient concentration and prevent microbial revival during storage.

Food Safety Regulations

The use of magnesium nitrate in cold storage of horticultural produce is subject to various food safety regulations that must be carefully considered. These regulations are designed to ensure the safety and quality of food products throughout the supply chain, including during storage and transportation.

In the United States, the Food and Drug Administration (FDA) oversees food safety regulations. The FDA's Food Safety Modernization Act (FSMA) includes provisions for the safe transportation of food, which encompasses cold storage practices. Under these regulations, companies must implement preventive controls to minimize food safety risks, including those associated with chemical treatments like magnesium nitrate.

The European Union has established similar regulations through the European Food Safety Authority (EFSA). The EU's General Food Law Regulation (EC) No 178/2002 sets out the general principles and requirements of food law, including the need for scientific risk assessment of food additives and treatments. The use of magnesium nitrate in cold storage would need to comply with these regulations and undergo safety evaluations.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards, guidelines, and codes of practice. These standards often serve as a reference for national food safety regulations and may influence the permissible use of magnesium nitrate in cold storage applications.

Specific regulations may apply to the maximum residue levels (MRLs) of magnesium nitrate allowed on horticultural produce. These levels are typically set based on toxicological assessments and are designed to ensure that any residues present do not pose a risk to consumer health. Producers and distributors must adhere to these MRLs and may be required to conduct regular testing to demonstrate compliance.

Food safety regulations also mandate proper labeling and documentation of any treatments applied to produce during storage. This includes the use of magnesium nitrate, which must be disclosed to ensure transparency throughout the supply chain and to inform consumers of any potential allergens or sensitivities.

Additionally, regulations often require the implementation of Good Agricultural Practices (GAP) and Good Manufacturing Practices (GMP) in the handling and storage of horticultural produce. These practices encompass the proper use and application of treatments like magnesium nitrate, as well as the maintenance of appropriate cold storage conditions to prevent contamination and ensure food safety.

In the United States, the Food and Drug Administration (FDA) oversees food safety regulations. The FDA's Food Safety Modernization Act (FSMA) includes provisions for the safe transportation of food, which encompasses cold storage practices. Under these regulations, companies must implement preventive controls to minimize food safety risks, including those associated with chemical treatments like magnesium nitrate.

The European Union has established similar regulations through the European Food Safety Authority (EFSA). The EU's General Food Law Regulation (EC) No 178/2002 sets out the general principles and requirements of food law, including the need for scientific risk assessment of food additives and treatments. The use of magnesium nitrate in cold storage would need to comply with these regulations and undergo safety evaluations.

Internationally, the Codex Alimentarius Commission, established by the Food and Agriculture Organization (FAO) and the World Health Organization (WHO), provides global food standards, guidelines, and codes of practice. These standards often serve as a reference for national food safety regulations and may influence the permissible use of magnesium nitrate in cold storage applications.

Specific regulations may apply to the maximum residue levels (MRLs) of magnesium nitrate allowed on horticultural produce. These levels are typically set based on toxicological assessments and are designed to ensure that any residues present do not pose a risk to consumer health. Producers and distributors must adhere to these MRLs and may be required to conduct regular testing to demonstrate compliance.

Food safety regulations also mandate proper labeling and documentation of any treatments applied to produce during storage. This includes the use of magnesium nitrate, which must be disclosed to ensure transparency throughout the supply chain and to inform consumers of any potential allergens or sensitivities.

Additionally, regulations often require the implementation of Good Agricultural Practices (GAP) and Good Manufacturing Practices (GMP) in the handling and storage of horticultural produce. These practices encompass the proper use and application of treatments like magnesium nitrate, as well as the maintenance of appropriate cold storage conditions to prevent contamination and ensure food safety.

Environmental Impact

The use of magnesium nitrate in cold storage of horticultural produce has significant environmental implications that warrant careful consideration. One of the primary concerns is the potential for nutrient leaching into soil and water systems. When magnesium nitrate is applied to produce or used in storage facilities, excess amounts may find their way into the environment through runoff or disposal processes. This can lead to increased nitrogen levels in surrounding ecosystems, potentially causing eutrophication in water bodies and altering soil chemistry.

Furthermore, the production of magnesium nitrate involves energy-intensive processes, contributing to greenhouse gas emissions and overall carbon footprint. As the demand for cold storage solutions in horticulture grows, the environmental impact of manufacturing and transporting magnesium nitrate becomes increasingly relevant. This raises questions about the sustainability of its widespread use in the long term.

However, it is important to note that the use of magnesium nitrate in cold storage can also have positive environmental effects. By extending the shelf life of horticultural produce, it reduces food waste, which is a significant contributor to greenhouse gas emissions when decomposing in landfills. This preservation effect can lead to more efficient use of agricultural resources and potentially decrease the need for excessive production to compensate for spoilage.

The application of magnesium nitrate in cold storage facilities may also reduce the energy requirements for maintaining low temperatures. This could result in lower electricity consumption and, consequently, reduced carbon emissions associated with cold storage operations. However, this benefit must be weighed against the environmental costs of producing and using magnesium nitrate.

Another environmental consideration is the potential impact on biodiversity. While direct effects on flora and fauna are limited due to the controlled use in storage facilities, indirect impacts through soil and water contamination could affect local ecosystems. This is particularly relevant if magnesium nitrate-treated produce or waste from storage facilities is not properly managed.

As environmental regulations become more stringent, the use of chemical compounds in food storage is likely to face increased scrutiny. Future research and development in this area may need to focus on finding more environmentally friendly alternatives or optimizing the use of magnesium nitrate to minimize its ecological footprint. This could include developing closed-loop systems for magnesium nitrate application, improving recycling methods, or exploring natural compounds with similar preservative properties.

Furthermore, the production of magnesium nitrate involves energy-intensive processes, contributing to greenhouse gas emissions and overall carbon footprint. As the demand for cold storage solutions in horticulture grows, the environmental impact of manufacturing and transporting magnesium nitrate becomes increasingly relevant. This raises questions about the sustainability of its widespread use in the long term.

However, it is important to note that the use of magnesium nitrate in cold storage can also have positive environmental effects. By extending the shelf life of horticultural produce, it reduces food waste, which is a significant contributor to greenhouse gas emissions when decomposing in landfills. This preservation effect can lead to more efficient use of agricultural resources and potentially decrease the need for excessive production to compensate for spoilage.

The application of magnesium nitrate in cold storage facilities may also reduce the energy requirements for maintaining low temperatures. This could result in lower electricity consumption and, consequently, reduced carbon emissions associated with cold storage operations. However, this benefit must be weighed against the environmental costs of producing and using magnesium nitrate.

Another environmental consideration is the potential impact on biodiversity. While direct effects on flora and fauna are limited due to the controlled use in storage facilities, indirect impacts through soil and water contamination could affect local ecosystems. This is particularly relevant if magnesium nitrate-treated produce or waste from storage facilities is not properly managed.

As environmental regulations become more stringent, the use of chemical compounds in food storage is likely to face increased scrutiny. Future research and development in this area may need to focus on finding more environmentally friendly alternatives or optimizing the use of magnesium nitrate to minimize its ecological footprint. This could include developing closed-loop systems for magnesium nitrate application, improving recycling methods, or exploring natural compounds with similar preservative properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!