Materials Compatibility And Sealants In Immersion-Cooled Racks

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Immersion Cooling Technology Background and Objectives

Immersion cooling technology has evolved significantly over the past two decades, transitioning from niche applications in supercomputing to a mainstream cooling solution for data centers facing increasing power density challenges. Initially developed in the 1960s for cooling high-performance military electronics, immersion cooling has experienced renewed interest due to the exponential growth in computing power and the associated thermal management challenges.

The technology involves submerging computing hardware directly in dielectric fluids that conduct heat but not electricity, eliminating the need for traditional air cooling infrastructure. This approach has demonstrated superior thermal efficiency, with the potential to handle heat loads exceeding 100 kW per rack, far surpassing the capabilities of conventional air cooling systems limited to approximately 15-20 kW per rack.

Two primary immersion cooling methodologies have emerged: single-phase, where the coolant remains in liquid form throughout the cooling cycle, and two-phase, where the coolant undergoes phase change from liquid to vapor during heat absorption. Each approach offers distinct advantages depending on specific application requirements and environmental considerations.

The materials compatibility aspect represents a critical technical challenge in immersion cooling implementation. Various components within server racks—including printed circuit boards, connectors, capacitors, and structural elements—must maintain their integrity and functionality when continuously exposed to dielectric fluids. Historical implementations have revealed compatibility issues such as material degradation, swelling of polymers, and chemical reactions that compromise system reliability.

Sealants play a particularly crucial role in immersion-cooled environments, as they must prevent fluid leakage while withstanding prolonged exposure to potentially aggressive coolants. The development of specialized sealants that maintain their mechanical properties and adhesion characteristics under these conditions represents a significant technical objective in advancing immersion cooling technology.

Current technological objectives focus on developing comprehensive material compatibility standards, identifying optimal sealant formulations for different coolant types, and establishing accelerated testing methodologies to predict long-term material performance. Additionally, the industry aims to create environmentally sustainable solutions that minimize the use of potentially harmful chemicals while maintaining thermal performance.

The evolution of immersion cooling technology aligns with broader industry trends toward greater energy efficiency, reduced carbon footprint, and increased computing density. As data centers continue to expand and processing demands intensify, immersion cooling presents a promising pathway to sustainable growth, with material compatibility and sealant technology serving as key enablers for widespread adoption.

The technology involves submerging computing hardware directly in dielectric fluids that conduct heat but not electricity, eliminating the need for traditional air cooling infrastructure. This approach has demonstrated superior thermal efficiency, with the potential to handle heat loads exceeding 100 kW per rack, far surpassing the capabilities of conventional air cooling systems limited to approximately 15-20 kW per rack.

Two primary immersion cooling methodologies have emerged: single-phase, where the coolant remains in liquid form throughout the cooling cycle, and two-phase, where the coolant undergoes phase change from liquid to vapor during heat absorption. Each approach offers distinct advantages depending on specific application requirements and environmental considerations.

The materials compatibility aspect represents a critical technical challenge in immersion cooling implementation. Various components within server racks—including printed circuit boards, connectors, capacitors, and structural elements—must maintain their integrity and functionality when continuously exposed to dielectric fluids. Historical implementations have revealed compatibility issues such as material degradation, swelling of polymers, and chemical reactions that compromise system reliability.

Sealants play a particularly crucial role in immersion-cooled environments, as they must prevent fluid leakage while withstanding prolonged exposure to potentially aggressive coolants. The development of specialized sealants that maintain their mechanical properties and adhesion characteristics under these conditions represents a significant technical objective in advancing immersion cooling technology.

Current technological objectives focus on developing comprehensive material compatibility standards, identifying optimal sealant formulations for different coolant types, and establishing accelerated testing methodologies to predict long-term material performance. Additionally, the industry aims to create environmentally sustainable solutions that minimize the use of potentially harmful chemicals while maintaining thermal performance.

The evolution of immersion cooling technology aligns with broader industry trends toward greater energy efficiency, reduced carbon footprint, and increased computing density. As data centers continue to expand and processing demands intensify, immersion cooling presents a promising pathway to sustainable growth, with material compatibility and sealant technology serving as key enablers for widespread adoption.

Market Analysis for Immersion-Cooled Data Centers

The immersion cooling data center market is experiencing unprecedented growth, driven by the increasing power density of modern computing systems and the need for more efficient cooling solutions. Current market valuations place the immersion cooling sector at approximately 500 million USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 25-30% over the next five years, potentially reaching 1.8 billion USD by 2028.

This growth trajectory is primarily fueled by hyperscale data center operators seeking to accommodate high-performance computing workloads, particularly those related to artificial intelligence and machine learning applications. These applications require specialized hardware such as GPUs and TPUs that generate significant heat, making traditional air cooling increasingly inadequate and economically unfeasible.

Geographically, North America currently dominates the market with approximately 40% share, followed by Asia-Pacific at 30% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid digital transformation initiatives and increasing data center investments in countries like China, Singapore, and Japan.

From a customer segmentation perspective, cloud service providers represent the largest market segment (45%), followed by enterprise data centers (30%) and colocation providers (20%). The remaining market share is distributed among edge computing facilities and specialized high-performance computing centers.

The demand for materials compatibility solutions and advanced sealants in immersion-cooled environments presents a significant market opportunity. Current estimates suggest that specialized materials and sealants account for approximately 15% of the total immersion cooling system costs, representing a market segment valued at 75 million USD in 2023, with projected growth to 270 million USD by 2028.

Key market drivers include the increasing adoption of two-phase immersion cooling technology, which requires more specialized materials and sealants capable of withstanding the phase-change process. Additionally, the industry's shift toward more environmentally friendly dielectric fluids is creating demand for compatible sealing solutions that maintain their integrity when exposed to these newer coolants.

Market barriers include the relatively high initial investment costs for immersion cooling infrastructure, concerns about long-term reliability, and the limited standardization across the industry. However, the total cost of ownership (TCO) advantages, including reduced energy consumption (typically 25-40% lower than traditional cooling) and higher compute density capabilities, continue to drive market expansion despite these challenges.

This growth trajectory is primarily fueled by hyperscale data center operators seeking to accommodate high-performance computing workloads, particularly those related to artificial intelligence and machine learning applications. These applications require specialized hardware such as GPUs and TPUs that generate significant heat, making traditional air cooling increasingly inadequate and economically unfeasible.

Geographically, North America currently dominates the market with approximately 40% share, followed by Asia-Pacific at 30% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid digital transformation initiatives and increasing data center investments in countries like China, Singapore, and Japan.

From a customer segmentation perspective, cloud service providers represent the largest market segment (45%), followed by enterprise data centers (30%) and colocation providers (20%). The remaining market share is distributed among edge computing facilities and specialized high-performance computing centers.

The demand for materials compatibility solutions and advanced sealants in immersion-cooled environments presents a significant market opportunity. Current estimates suggest that specialized materials and sealants account for approximately 15% of the total immersion cooling system costs, representing a market segment valued at 75 million USD in 2023, with projected growth to 270 million USD by 2028.

Key market drivers include the increasing adoption of two-phase immersion cooling technology, which requires more specialized materials and sealants capable of withstanding the phase-change process. Additionally, the industry's shift toward more environmentally friendly dielectric fluids is creating demand for compatible sealing solutions that maintain their integrity when exposed to these newer coolants.

Market barriers include the relatively high initial investment costs for immersion cooling infrastructure, concerns about long-term reliability, and the limited standardization across the industry. However, the total cost of ownership (TCO) advantages, including reduced energy consumption (typically 25-40% lower than traditional cooling) and higher compute density capabilities, continue to drive market expansion despite these challenges.

Current Materials Compatibility Challenges in Immersion Cooling

Immersion cooling technology faces significant materials compatibility challenges that must be addressed for widespread adoption. The primary concern is the interaction between cooling fluids and various rack components. Dielectric fluids, while non-conductive, can still cause degradation of certain materials over time. Polymers commonly used in traditional data center equipment often experience swelling, embrittlement, or complete dissolution when exposed to these specialized coolants for extended periods.

Electronic components present particular compatibility issues. Capacitor casings, connector housings, and PCB substrates may deteriorate when submerged, leading to premature system failures. Additionally, thermal interface materials designed for air cooling environments frequently prove inadequate in immersion systems, as they can leach compounds into the coolant or lose their thermal transfer properties.

Metallic components introduce another dimension of complexity. Certain metal alloys may experience accelerated corrosion or galvanic reactions when immersed in dielectric fluids, especially in the presence of contaminants or at elevated operating temperatures. This necessitates careful material selection and sometimes protective coatings for susceptible components.

Sealant compatibility represents a critical challenge that directly impacts system integrity. Traditional sealants used in air-cooled environments often fail in immersion cooling applications. They may harden, crack, or lose adhesion properties when exposed to dielectric fluids. This compromises the fluid containment system and can lead to leaks, fluid contamination, or electrical failures.

The diversity of available cooling fluids compounds these challenges. Mineral oil-based coolants, engineered synthetic fluids, and fluorocarbon-based solutions each present unique compatibility profiles. A material that performs excellently with one coolant type may rapidly degrade when exposed to another, creating significant standardization difficulties across the industry.

Temperature cycling effects further complicate material selection. As systems power up and down, the resulting thermal expansion and contraction create mechanical stresses at material interfaces. Components that maintain integrity at steady-state conditions may still fail prematurely due to these cyclical stresses, particularly at sealing points and material transitions.

Lastly, long-term aging effects remain poorly understood for many material-coolant combinations. While accelerated testing provides some insights, the actual performance of materials over the 5-10 year expected lifespan of data center equipment requires more comprehensive research. This knowledge gap creates uncertainty in total cost of ownership calculations and reliability projections for immersion cooling implementations.

Electronic components present particular compatibility issues. Capacitor casings, connector housings, and PCB substrates may deteriorate when submerged, leading to premature system failures. Additionally, thermal interface materials designed for air cooling environments frequently prove inadequate in immersion systems, as they can leach compounds into the coolant or lose their thermal transfer properties.

Metallic components introduce another dimension of complexity. Certain metal alloys may experience accelerated corrosion or galvanic reactions when immersed in dielectric fluids, especially in the presence of contaminants or at elevated operating temperatures. This necessitates careful material selection and sometimes protective coatings for susceptible components.

Sealant compatibility represents a critical challenge that directly impacts system integrity. Traditional sealants used in air-cooled environments often fail in immersion cooling applications. They may harden, crack, or lose adhesion properties when exposed to dielectric fluids. This compromises the fluid containment system and can lead to leaks, fluid contamination, or electrical failures.

The diversity of available cooling fluids compounds these challenges. Mineral oil-based coolants, engineered synthetic fluids, and fluorocarbon-based solutions each present unique compatibility profiles. A material that performs excellently with one coolant type may rapidly degrade when exposed to another, creating significant standardization difficulties across the industry.

Temperature cycling effects further complicate material selection. As systems power up and down, the resulting thermal expansion and contraction create mechanical stresses at material interfaces. Components that maintain integrity at steady-state conditions may still fail prematurely due to these cyclical stresses, particularly at sealing points and material transitions.

Lastly, long-term aging effects remain poorly understood for many material-coolant combinations. While accelerated testing provides some insights, the actual performance of materials over the 5-10 year expected lifespan of data center equipment requires more comprehensive research. This knowledge gap creates uncertainty in total cost of ownership calculations and reliability projections for immersion cooling implementations.

Existing Material and Sealant Solutions for Immersion Environments

01 Compatibility of sealants with electronic components

Sealants used in electronic applications must be compatible with sensitive components to prevent damage or interference. These materials need to provide proper insulation while maintaining electrical properties. The compatibility between sealants and electronic components is crucial for ensuring long-term reliability and performance, particularly in environments with temperature fluctuations or exposure to moisture.- Compatibility of sealants with electronic components: Sealants used in electronic applications must be compatible with sensitive components to prevent damage or interference. These materials need to provide proper insulation while maintaining electrical properties. The formulations often include specific compounds that ensure compatibility with circuit boards, sensors, and other electronic parts while providing effective sealing against environmental factors such as moisture and dust.

- Chemical resistance of sealant materials: Sealant materials must demonstrate resistance to various chemicals they may encounter during use. This includes resistance to oils, fuels, solvents, and other aggressive substances. Formulations are designed to maintain integrity and sealing properties even when exposed to harsh chemical environments, preventing degradation that could compromise the seal and lead to system failures.

- Temperature and environmental stability of sealants: Sealants must maintain their properties across a wide range of temperatures and environmental conditions. This includes resistance to thermal cycling, UV exposure, and humidity. Advanced formulations incorporate additives that enhance stability under extreme conditions, preventing cracking, shrinking, or other forms of degradation that could compromise the sealing function.

- Material interface and adhesion properties: The compatibility between sealants and substrate materials is crucial for effective sealing. This involves understanding the surface energy, chemical interactions, and mechanical bonding at the interface. Proper adhesion to various materials such as metals, plastics, ceramics, and composites ensures long-term seal integrity and prevents leakage or bond failure under mechanical stress or environmental exposure.

- Testing and validation methods for sealant compatibility: Specialized testing protocols are essential to verify the compatibility of sealants with various materials. These include accelerated aging tests, chemical exposure tests, and mechanical stress evaluations. Advanced analytical techniques help identify potential incompatibilities before field deployment, ensuring that sealants will perform as expected throughout the intended service life of the application.

02 Chemical resistance of materials and sealants

Materials and sealants must demonstrate resistance to various chemicals they may encounter during use. This includes resistance to oils, fuels, cleaning agents, and environmental contaminants. The chemical compatibility between sealants and the materials they protect is essential for maintaining structural integrity and preventing degradation over time, especially in industrial applications where exposure to harsh chemicals is common.Expand Specific Solutions03 Temperature and environmental compatibility

Sealants must maintain their properties across a wide range of temperatures and environmental conditions. This includes resistance to thermal cycling, UV exposure, and humidity. The compatibility between materials and sealants under varying environmental conditions affects the longevity and effectiveness of the seal, particularly in outdoor applications or in systems that experience significant temperature variations.Expand Specific Solutions04 Material interface and adhesion properties

The interface between different materials and sealants is critical for creating effective seals. Proper adhesion depends on surface preparation, material compatibility, and application techniques. Compatibility issues at material interfaces can lead to seal failure, leakage, or structural weaknesses, making it essential to select sealants that bond well with the specific materials being joined.Expand Specific Solutions05 Long-term aging and degradation compatibility

Materials and sealants must remain compatible throughout their service life, resisting degradation from aging, stress, and environmental factors. This includes maintaining flexibility, adhesion, and sealing properties over time. The long-term compatibility between materials affects maintenance requirements and overall system reliability, particularly in applications where replacement or maintenance is difficult or costly.Expand Specific Solutions

Leading Manufacturers in Immersion Cooling Industry

The immersion cooling rack materials compatibility and sealants market is currently in a growth phase, driven by increasing data center densities and energy efficiency demands. The market is expected to reach $2.5-3 billion by 2027, with a CAGR of approximately 25%. Technical maturity varies significantly across players, with established chemical companies like BASF, Henkel, and Robert Bosch demonstrating advanced solutions through extensive R&D investments. Specialized players such as Zhejiang Juhua and Suzhou Inspur are rapidly developing region-specific innovations. Material compatibility challenges remain, particularly in sealant longevity and chemical stability with various coolants. Leading manufacturers like DENSO and MANN+HUMMEL are advancing thermal interface materials specifically designed for immersion environments, while companies like Caterpillar bring industrial-grade sealing expertise to this emerging application.

BASF Corp.

Technical Solution: BASF has pioneered advanced polymer solutions specifically engineered for immersion cooling environments. Their technology focuses on chemically resistant elastomers and thermoplastics that maintain structural integrity and sealing properties when continuously exposed to dielectric cooling fluids. BASF's approach includes fluoropolymer-based compounds with enhanced resistance to both hydrolysis and chemical degradation, ensuring long-term performance in immersion cooling applications. Their materials feature specialized cross-linking technologies that prevent extraction of plasticizers and additives into the cooling medium, maintaining both fluid purity and material properties over time. BASF has developed gradient material structures that provide both excellent adhesion to various substrates and compatibility with cooling fluids at the fluid interface. Their solutions incorporate nanotechnology-enhanced fillers that improve thermal conductivity while maintaining electrical insulation properties critical for immersion cooling environments. BASF's materials undergo comprehensive compatibility testing with common dielectric fluids including engineered hydrocarbons, fluorocarbons, and synthetic esters to ensure long-term reliability across different cooling technologies. The company also provides computational modeling tools to predict material behavior under various operating conditions.

Strengths: Extensive chemical expertise allowing for molecular-level material design; comprehensive testing capabilities for long-term performance validation; ability to customize formulations for specific cooling fluids and operating conditions. Weaknesses: Higher material costs compared to standard industrial sealants; some specialized formulations may have limited availability; implementation may require redesign of existing sealing systems.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed specialized sealant solutions specifically designed for immersion cooling environments in data centers. Their technology focuses on thermally conductive adhesives and sealants that maintain integrity when exposed to dielectric fluids. Henkel's approach includes silicone-based compounds with enhanced chemical resistance properties that prevent degradation when in constant contact with cooling fluids. Their materials feature dual-cure mechanisms (both UV and moisture curing) to ensure complete sealing in complex rack geometries. The company has engineered these sealants to maintain flexibility across wide temperature ranges (-40°C to +200°C) while preventing fluid ingress into sensitive electronic components. Henkel's solutions also incorporate corrosion inhibitors to protect metal surfaces within the immersion cooling system from long-term degradation. Their materials undergo rigorous compatibility testing with various dielectric fluids including synthetic esters, mineral oils, and engineered fluids to ensure long-term reliability in immersion cooling applications.

Strengths: Extensive polymer chemistry expertise allowing for customized formulations specific to different cooling fluids; global manufacturing capabilities ensuring consistent supply chain; comprehensive testing protocols for long-term reliability verification. Weaknesses: Higher initial cost compared to standard industrial sealants; some formulations may require specific application equipment; curing times can be longer than conventional alternatives.

Key Innovations in Immersion-Compatible Materials and Compounds

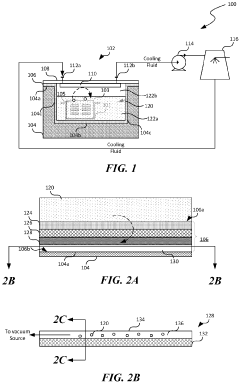

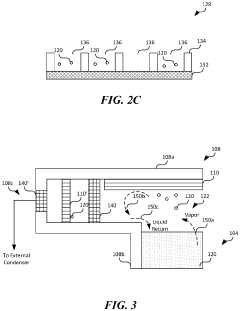

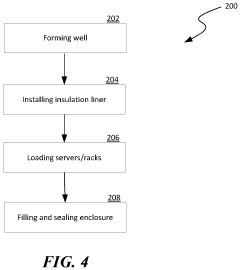

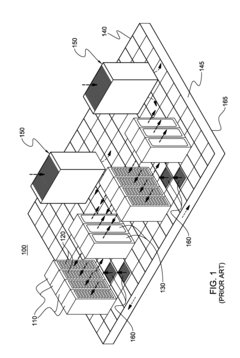

Immersion cooling enclosures with insulating liners

PatentPendingEP4362621A2

Innovation

- An insulated-well design for immersion cooling enclosures is implemented, where a well is formed in concrete or earth and lined with a non-permeable insulating liner, such as high-density polypropylene, to prevent dielectric coolant leakage and reduce construction complexity, using a lid with a condenser and filter layers to manage vapor and coolant circulation.

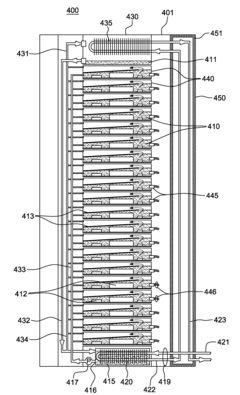

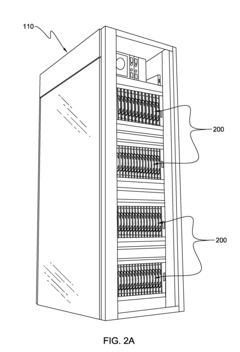

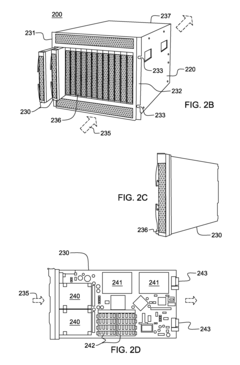

Liquid-cooled electronics rack with immersion-cooled electronic subsystems

PatentInactiveUS8184436B2

Innovation

- A liquid-cooled electronics rack system with immersion-cooled electronic subsystems using a dielectric fluid, where electronic components are partially immersed in a dielectric fluid within sealed compartments, and a vapor-condensing heat exchanger is used to facilitate condensation of vaporized fluid, with a sub-cooling heat exchanger and pump to maintain fluid flow and cooling efficiency.

Thermal Performance Metrics and Testing Methodologies

Evaluating thermal performance in immersion-cooled rack systems requires specialized metrics and methodologies that differ significantly from traditional air-cooled environments. The primary thermal performance indicators for immersion cooling include heat transfer coefficient, thermal resistance, temperature uniformity, and cooling efficiency. These metrics provide quantitative measures of how effectively the immersion coolant removes heat from server components and maintains optimal operating temperatures.

Heat transfer coefficient measurements are particularly critical in immersion cooling, as they determine the rate at which heat can be transferred from electronic components to the dielectric fluid. Standard testing protocols involve controlled heat loads applied to representative server components while monitoring temperature differentials across the fluid boundary layer. These tests must account for the specific properties of the immersion coolant and its interaction with various materials present in the rack system.

Temperature uniformity testing evaluates how consistently the cooling solution maintains temperatures across all components. This is typically measured using thermal imaging and strategically placed temperature sensors throughout the immersion environment. Non-uniform temperature distribution can indicate potential compatibility issues between certain materials and the coolant, or inadequate fluid circulation patterns that may lead to hotspots.

Flow visualization techniques provide valuable insights into coolant movement patterns within the immersion system. These include particle image velocimetry (PIV) and computational fluid dynamics (CFD) simulations that help identify potential stagnation zones where heat transfer might be compromised. Such analyses are essential for optimizing rack design and component placement to ensure maximum thermal performance.

Accelerated aging tests represent another crucial methodology for evaluating long-term thermal performance. These tests subject the immersion-cooled system to elevated temperatures and thermal cycling to simulate years of operation within a compressed timeframe. The resulting data helps predict how material compatibility issues might affect thermal performance over the system's operational lifetime, particularly regarding sealant degradation and its impact on cooling efficiency.

Standardized benchmarking protocols are emerging in the industry to enable meaningful comparisons between different immersion cooling solutions. These typically involve reference workloads that generate predictable heat patterns, allowing for consistent evaluation of thermal management capabilities across various system configurations and coolant formulations. Such standardization is essential for the continued maturation of immersion cooling technology in data center applications.

Heat transfer coefficient measurements are particularly critical in immersion cooling, as they determine the rate at which heat can be transferred from electronic components to the dielectric fluid. Standard testing protocols involve controlled heat loads applied to representative server components while monitoring temperature differentials across the fluid boundary layer. These tests must account for the specific properties of the immersion coolant and its interaction with various materials present in the rack system.

Temperature uniformity testing evaluates how consistently the cooling solution maintains temperatures across all components. This is typically measured using thermal imaging and strategically placed temperature sensors throughout the immersion environment. Non-uniform temperature distribution can indicate potential compatibility issues between certain materials and the coolant, or inadequate fluid circulation patterns that may lead to hotspots.

Flow visualization techniques provide valuable insights into coolant movement patterns within the immersion system. These include particle image velocimetry (PIV) and computational fluid dynamics (CFD) simulations that help identify potential stagnation zones where heat transfer might be compromised. Such analyses are essential for optimizing rack design and component placement to ensure maximum thermal performance.

Accelerated aging tests represent another crucial methodology for evaluating long-term thermal performance. These tests subject the immersion-cooled system to elevated temperatures and thermal cycling to simulate years of operation within a compressed timeframe. The resulting data helps predict how material compatibility issues might affect thermal performance over the system's operational lifetime, particularly regarding sealant degradation and its impact on cooling efficiency.

Standardized benchmarking protocols are emerging in the industry to enable meaningful comparisons between different immersion cooling solutions. These typically involve reference workloads that generate predictable heat patterns, allowing for consistent evaluation of thermal management capabilities across various system configurations and coolant formulations. Such standardization is essential for the continued maturation of immersion cooling technology in data center applications.

Environmental Impact and Sustainability Considerations

The environmental impact of immersion cooling technology extends far beyond energy efficiency, encompassing the entire lifecycle of cooling fluids and materials used in these systems. Dielectric fluids, essential for immersion cooling, present significant environmental considerations. Traditional mineral oil-based fluids pose potential contamination risks if leaked, while synthetic alternatives often contain compounds with high global warming potential. The industry is increasingly shifting toward engineered fluids with lower environmental footprints, including biodegradable options that minimize ecological damage in case of accidental release.

Material compatibility issues in immersion-cooled racks directly influence sustainability through system longevity. Incompatible materials that degrade prematurely necessitate more frequent replacement, generating additional electronic waste and increasing resource consumption. Properly selected sealants and materials can extend system lifespan by 30-50%, significantly reducing the environmental burden associated with manufacturing replacement components.

The disposal and recycling challenges of immersion cooling components warrant careful consideration. Dielectric fluids require specialized handling procedures for environmentally responsible disposal or recycling. Some advanced fluids now incorporate design features that facilitate reclamation and reprocessing, reducing waste. Similarly, sealants with lower VOC (Volatile Organic Compound) content minimize air quality impacts during installation and throughout the operational lifecycle.

Carbon footprint analysis reveals that while immersion cooling reduces operational emissions through energy efficiency, the manufacturing and end-of-life phases can offset these gains if not properly managed. Life Cycle Assessment (LCA) studies indicate that environmentally optimized material selection can reduce the overall carbon footprint by up to 25% compared to systems using conventional materials without sustainability considerations.

Regulatory compliance represents another critical dimension, with increasingly stringent environmental regulations affecting material choices for immersion cooling systems. The EU's Restriction of Hazardous Substances (RoHS) directive, REACH regulations, and similar frameworks worldwide are driving manufacturers toward less toxic sealants and more environmentally benign materials. Forward-thinking companies are proactively adopting green chemistry principles in material selection, anticipating future regulatory requirements.

Water conservation benefits of immersion cooling compared to traditional water-cooled systems offer significant sustainability advantages in water-stressed regions. By eliminating evaporative water loss and reducing water treatment chemical usage, immersion cooling can save millions of gallons annually in large data center deployments, contributing to broader water conservation efforts in the technology sector.

Material compatibility issues in immersion-cooled racks directly influence sustainability through system longevity. Incompatible materials that degrade prematurely necessitate more frequent replacement, generating additional electronic waste and increasing resource consumption. Properly selected sealants and materials can extend system lifespan by 30-50%, significantly reducing the environmental burden associated with manufacturing replacement components.

The disposal and recycling challenges of immersion cooling components warrant careful consideration. Dielectric fluids require specialized handling procedures for environmentally responsible disposal or recycling. Some advanced fluids now incorporate design features that facilitate reclamation and reprocessing, reducing waste. Similarly, sealants with lower VOC (Volatile Organic Compound) content minimize air quality impacts during installation and throughout the operational lifecycle.

Carbon footprint analysis reveals that while immersion cooling reduces operational emissions through energy efficiency, the manufacturing and end-of-life phases can offset these gains if not properly managed. Life Cycle Assessment (LCA) studies indicate that environmentally optimized material selection can reduce the overall carbon footprint by up to 25% compared to systems using conventional materials without sustainability considerations.

Regulatory compliance represents another critical dimension, with increasingly stringent environmental regulations affecting material choices for immersion cooling systems. The EU's Restriction of Hazardous Substances (RoHS) directive, REACH regulations, and similar frameworks worldwide are driving manufacturers toward less toxic sealants and more environmentally benign materials. Forward-thinking companies are proactively adopting green chemistry principles in material selection, anticipating future regulatory requirements.

Water conservation benefits of immersion cooling compared to traditional water-cooled systems offer significant sustainability advantages in water-stressed regions. By eliminating evaporative water loss and reducing water treatment chemical usage, immersion cooling can save millions of gallons annually in large data center deployments, contributing to broader water conservation efforts in the technology sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!