Reliability Testing Protocols For Two-Phase Immersion Data Centers

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Two-Phase Immersion Cooling Background and Objectives

Two-phase immersion cooling represents a paradigm shift in data center thermal management, evolving from traditional air cooling methods that have reached their practical limits. This technology utilizes the phase change properties of dielectric fluids to efficiently dissipate heat from electronic components. The evolution began in the 1960s with single-phase immersion cooling in specialized applications, progressing to two-phase solutions in the 2010s as computing densities increased exponentially.

The fundamental principle leverages the latent heat of vaporization, where the dielectric fluid absorbs heat from components, evaporates, condenses at the top of the tank, and returns to the system in a continuous cycle. This passive cooling approach eliminates the need for pumps and reduces energy consumption by 30-50% compared to traditional cooling methods.

Current technological development is driven by several factors: increasing power densities in modern computing systems (now exceeding 100 kW per rack), the limitations of air cooling (practical ceiling of approximately 15-20 kW per rack), and the growing emphasis on energy efficiency in data centers which currently consume 1-2% of global electricity.

The primary objective of reliability testing protocols for two-phase immersion cooling is to establish standardized methodologies that ensure consistent performance, longevity, and safety across various operational conditions. These protocols aim to address the unique challenges posed by the interaction between electronic components and dielectric fluids over extended periods.

Specific technical goals include quantifying the long-term effects of fluid-component interaction, establishing thermal cycling parameters that reflect real-world conditions, developing accelerated aging protocols that accurately predict system lifespan, and creating standardized testing frameworks that enable meaningful comparison between different cooling solutions.

Additionally, these protocols seek to evaluate the impact of fluid degradation on cooling efficiency, assess the reliability of sealed systems under various environmental conditions, and determine the compatibility of different materials and components with immersion cooling fluids. The ultimate aim is to provide data center operators with confidence in the long-term viability of two-phase immersion cooling technologies.

As the industry moves toward higher-density computing applications like AI training clusters, edge computing installations, and high-performance computing facilities, the need for reliable and standardized testing methodologies becomes increasingly critical to widespread adoption and implementation of this promising cooling technology.

The fundamental principle leverages the latent heat of vaporization, where the dielectric fluid absorbs heat from components, evaporates, condenses at the top of the tank, and returns to the system in a continuous cycle. This passive cooling approach eliminates the need for pumps and reduces energy consumption by 30-50% compared to traditional cooling methods.

Current technological development is driven by several factors: increasing power densities in modern computing systems (now exceeding 100 kW per rack), the limitations of air cooling (practical ceiling of approximately 15-20 kW per rack), and the growing emphasis on energy efficiency in data centers which currently consume 1-2% of global electricity.

The primary objective of reliability testing protocols for two-phase immersion cooling is to establish standardized methodologies that ensure consistent performance, longevity, and safety across various operational conditions. These protocols aim to address the unique challenges posed by the interaction between electronic components and dielectric fluids over extended periods.

Specific technical goals include quantifying the long-term effects of fluid-component interaction, establishing thermal cycling parameters that reflect real-world conditions, developing accelerated aging protocols that accurately predict system lifespan, and creating standardized testing frameworks that enable meaningful comparison between different cooling solutions.

Additionally, these protocols seek to evaluate the impact of fluid degradation on cooling efficiency, assess the reliability of sealed systems under various environmental conditions, and determine the compatibility of different materials and components with immersion cooling fluids. The ultimate aim is to provide data center operators with confidence in the long-term viability of two-phase immersion cooling technologies.

As the industry moves toward higher-density computing applications like AI training clusters, edge computing installations, and high-performance computing facilities, the need for reliable and standardized testing methodologies becomes increasingly critical to widespread adoption and implementation of this promising cooling technology.

Market Analysis for Immersion-Cooled Data Centers

The immersion cooling market for data centers is experiencing significant growth, driven by increasing power densities and the limitations of traditional air cooling systems. The global market for liquid immersion cooling was valued at approximately $200 million in 2020 and is projected to reach $700 million by 2026, representing a compound annual growth rate (CAGR) of 22.8%. This growth trajectory is particularly pronounced in regions with high energy costs and stringent environmental regulations.

Two-phase immersion cooling technology, specifically, is gaining traction due to its superior thermal efficiency compared to single-phase solutions. Market research indicates that while single-phase immersion cooling currently dominates with about 65% market share, two-phase solutions are expected to grow at a faster rate of 25% annually through 2025, gradually increasing their market presence.

The primary market segments adopting immersion cooling include hyperscale data centers, high-performance computing facilities, cryptocurrency mining operations, and edge computing installations. Hyperscale providers account for approximately 40% of current implementations, with high-performance computing representing another 30%. The cryptocurrency mining segment, while volatile, has been an early adopter and continues to represent about 15% of the market.

Geographically, North America leads adoption with 45% market share, followed by Europe at 30% and Asia-Pacific at 20%. The Middle East and Africa, though currently representing only 5% of the market, are expected to see accelerated growth rates due to climate conditions that favor immersion cooling solutions.

Key market drivers include the rising power density of computing equipment, with modern servers often exceeding 15-20 kW per rack, far beyond the practical limits of air cooling. Energy efficiency concerns also propel market growth, as immersion cooling can reduce cooling energy consumption by up to 95% compared to traditional methods, translating to potential PUE (Power Usage Effectiveness) values as low as 1.03.

Market barriers include high initial capital expenditure, with immersion cooling installations typically costing 30-50% more than traditional cooling systems initially. Concerns about fluid maintenance, compatibility with IT equipment, and the lack of standardized reliability testing protocols also impede faster market adoption.

Customer demand increasingly focuses on total cost of ownership (TCO) benefits, with the market showing willingness to accept higher upfront costs when 3-5 year TCO advantages can be demonstrated. This has created opportunities for cooling-as-a-service business models, which are growing at 35% annually within this segment.

Two-phase immersion cooling technology, specifically, is gaining traction due to its superior thermal efficiency compared to single-phase solutions. Market research indicates that while single-phase immersion cooling currently dominates with about 65% market share, two-phase solutions are expected to grow at a faster rate of 25% annually through 2025, gradually increasing their market presence.

The primary market segments adopting immersion cooling include hyperscale data centers, high-performance computing facilities, cryptocurrency mining operations, and edge computing installations. Hyperscale providers account for approximately 40% of current implementations, with high-performance computing representing another 30%. The cryptocurrency mining segment, while volatile, has been an early adopter and continues to represent about 15% of the market.

Geographically, North America leads adoption with 45% market share, followed by Europe at 30% and Asia-Pacific at 20%. The Middle East and Africa, though currently representing only 5% of the market, are expected to see accelerated growth rates due to climate conditions that favor immersion cooling solutions.

Key market drivers include the rising power density of computing equipment, with modern servers often exceeding 15-20 kW per rack, far beyond the practical limits of air cooling. Energy efficiency concerns also propel market growth, as immersion cooling can reduce cooling energy consumption by up to 95% compared to traditional methods, translating to potential PUE (Power Usage Effectiveness) values as low as 1.03.

Market barriers include high initial capital expenditure, with immersion cooling installations typically costing 30-50% more than traditional cooling systems initially. Concerns about fluid maintenance, compatibility with IT equipment, and the lack of standardized reliability testing protocols also impede faster market adoption.

Customer demand increasingly focuses on total cost of ownership (TCO) benefits, with the market showing willingness to accept higher upfront costs when 3-5 year TCO advantages can be demonstrated. This has created opportunities for cooling-as-a-service business models, which are growing at 35% annually within this segment.

Current Reliability Testing Challenges

The reliability testing landscape for two-phase immersion cooling systems in data centers faces significant challenges due to the nascent nature of this technology. Traditional air-cooled and single-phase liquid cooling reliability standards prove inadequate when applied to two-phase immersion environments, creating a standardization gap that hampers industry-wide adoption and confidence.

Material compatibility testing represents a primary challenge, as the dielectric fluids used in two-phase immersion cooling interact differently with server components compared to air or water-based cooling solutions. Current testing protocols fail to adequately assess long-term effects of continuous component exposure to these specialized fluids, particularly regarding potential degradation of polymers, solder joints, and surface treatments over extended operational periods.

Thermal cycling reliability presents another major obstacle. The rapid phase-change processes inherent to two-phase immersion cooling create unique thermal expansion and contraction patterns that differ substantially from those in conventional cooling systems. Existing testing methodologies cannot accurately simulate these conditions, leading to uncertainty about component lifespan and system durability under real-world operational conditions.

Fluid degradation monitoring poses additional complications. The chemical stability of dielectric fluids under continuous operation, their potential contamination pathways, and the effects of fluid aging on cooling performance lack standardized assessment protocols. This absence creates significant uncertainty regarding maintenance schedules and operational economics for data center operators considering this technology.

Electrical safety verification under immersion conditions remains problematic. Current electrical safety standards were developed primarily for air-cooled environments and require substantial adaptation for immersion scenarios. The interaction between electrical components and dielectric fluids during fault conditions or power surges demands specialized testing approaches not yet formalized in industry standards.

Scalability of testing protocols presents a systemic challenge. Laboratory-scale reliability tests often fail to capture the complex fluid dynamics and thermal behaviors present in full-scale data center deployments. This disconnect between testing environments and production implementations creates uncertainty regarding the predictive value of current reliability assessments.

Interoperability testing between different hardware vendors and cooling solution providers lacks standardization. The proprietary nature of many two-phase immersion cooling implementations has resulted in fragmented testing approaches that impede the development of universal reliability benchmarks and complicate multi-vendor deployments.

Material compatibility testing represents a primary challenge, as the dielectric fluids used in two-phase immersion cooling interact differently with server components compared to air or water-based cooling solutions. Current testing protocols fail to adequately assess long-term effects of continuous component exposure to these specialized fluids, particularly regarding potential degradation of polymers, solder joints, and surface treatments over extended operational periods.

Thermal cycling reliability presents another major obstacle. The rapid phase-change processes inherent to two-phase immersion cooling create unique thermal expansion and contraction patterns that differ substantially from those in conventional cooling systems. Existing testing methodologies cannot accurately simulate these conditions, leading to uncertainty about component lifespan and system durability under real-world operational conditions.

Fluid degradation monitoring poses additional complications. The chemical stability of dielectric fluids under continuous operation, their potential contamination pathways, and the effects of fluid aging on cooling performance lack standardized assessment protocols. This absence creates significant uncertainty regarding maintenance schedules and operational economics for data center operators considering this technology.

Electrical safety verification under immersion conditions remains problematic. Current electrical safety standards were developed primarily for air-cooled environments and require substantial adaptation for immersion scenarios. The interaction between electrical components and dielectric fluids during fault conditions or power surges demands specialized testing approaches not yet formalized in industry standards.

Scalability of testing protocols presents a systemic challenge. Laboratory-scale reliability tests often fail to capture the complex fluid dynamics and thermal behaviors present in full-scale data center deployments. This disconnect between testing environments and production implementations creates uncertainty regarding the predictive value of current reliability assessments.

Interoperability testing between different hardware vendors and cooling solution providers lacks standardization. The proprietary nature of many two-phase immersion cooling implementations has resulted in fragmented testing approaches that impede the development of universal reliability benchmarks and complicate multi-vendor deployments.

Existing Reliability Testing Methodologies

01 Reliability enhancement through fluid composition optimization

The reliability of two-phase immersion cooling systems can be significantly improved by optimizing the cooling fluid composition. This includes selecting dielectric fluids with appropriate boiling points, thermal conductivity, and chemical stability. Engineered fluids with reduced degradation rates and enhanced heat transfer properties help maintain consistent cooling performance over extended operational periods. Additionally, incorporating additives that prevent fluid breakdown and minimize the formation of deposits on electronic components ensures long-term system reliability.- Reliability enhancement through fluid composition and management: Two-phase immersion cooling systems can achieve improved reliability through careful selection and management of cooling fluids. This includes using dielectric fluids with specific properties, implementing fluid filtration systems to remove contaminants, and monitoring fluid degradation over time. Proper fluid management prevents issues like thermal breakdown, contamination, and ensures consistent heat transfer performance, which directly impacts the overall reliability of the cooling system.

- Redundant cooling system architectures: Implementing redundancy in two-phase immersion cooling systems significantly enhances reliability. This includes redundant cooling loops, backup pumps, multiple heat exchangers, and failover mechanisms that activate automatically when primary components fail. These redundant architectures ensure continuous operation even during component failures, reducing system downtime and extending the overall lifespan of electronic equipment being cooled.

- Monitoring and predictive maintenance systems: Advanced monitoring systems play a crucial role in maintaining the reliability of two-phase immersion cooling systems. These include sensors for temperature, pressure, flow rates, and fluid quality that continuously track system performance. Integrated with predictive maintenance algorithms, these systems can detect early signs of potential failures, allowing for preventive maintenance before critical issues occur. This approach significantly reduces unexpected failures and extends system lifespan.

- Thermal interface optimization: The reliability of two-phase immersion cooling systems depends significantly on the thermal interface between electronic components and the cooling fluid. Optimized designs include specialized surface treatments, enhanced component packaging, and engineered flow patterns that maximize heat transfer efficiency. These optimizations prevent hotspots, reduce thermal cycling stress, and ensure uniform cooling across all components, which directly improves system reliability and extends component lifespan.

- Environmental control and contamination prevention: Environmental factors significantly impact the reliability of two-phase immersion cooling systems. Advanced designs incorporate sealed enclosures, pressure management systems, humidity control, and contamination barriers to protect the cooling environment. These measures prevent external contaminants from entering the system, control condensation issues, and maintain optimal operating conditions, ensuring consistent cooling performance and enhanced system reliability over extended periods.

02 Redundant cooling system architectures

Implementing redundant components and failsafe mechanisms in two-phase immersion cooling systems significantly enhances reliability. These architectures include backup cooling loops, redundant pumps, multiple condensers, and fault-tolerant control systems. By designing systems with N+1 or 2N redundancy, continuous operation can be maintained even when individual components fail. Advanced monitoring systems that detect potential failures before they occur allow for preventive maintenance, further improving system reliability and reducing downtime risks.Expand Specific Solutions03 Contamination prevention and filtration systems

Maintaining the purity of cooling fluids is crucial for the reliability of two-phase immersion cooling systems. Advanced filtration systems remove particulates, moisture, and other contaminants that could degrade cooling performance or damage electronic components. Hermetically sealed enclosures prevent environmental contamination, while specialized filters target specific contaminants that might enter the system. Regular fluid analysis and replacement schedules based on actual contamination levels rather than fixed time intervals help maintain optimal cooling performance and extend system lifespan.Expand Specific Solutions04 Thermal management control systems

Sophisticated control systems that dynamically adjust cooling parameters based on real-time monitoring significantly improve the reliability of two-phase immersion cooling systems. These systems employ sensors to monitor temperature, pressure, fluid level, and flow rates throughout the cooling circuit. Advanced algorithms optimize cooling efficiency under varying load conditions while preventing thermal stress on components. Predictive analytics capabilities identify potential issues before they affect system performance, allowing for proactive maintenance and ensuring consistent cooling performance even during peak load conditions.Expand Specific Solutions05 Material compatibility and corrosion prevention

The selection of materials compatible with cooling fluids is essential for long-term reliability of two-phase immersion cooling systems. Specialized coatings protect sensitive electronic components from potential chemical interactions with the cooling medium. Corrosion-resistant materials for tanks, piping, and heat exchangers prevent system degradation over time. Regular monitoring of material integrity and implementing galvanic isolation where necessary helps prevent premature component failure. Additionally, maintaining appropriate fluid chemistry through pH control and corrosion inhibitors extends the operational life of the entire cooling system.Expand Specific Solutions

Leading Companies in Two-Phase Immersion Cooling

The reliability testing landscape for two-phase immersion data centers is evolving rapidly, currently in an early growth phase with increasing market adoption. The global market size is expanding as organizations seek energy-efficient cooling solutions for high-density computing. From a technological maturity perspective, key players demonstrate varying levels of advancement: Huawei and VMware lead with comprehensive testing protocols, while State Grid and ICBC contribute significant infrastructure validation methodologies. Inspur and Ping An Technology are developing specialized immersion cooling reliability frameworks, with academic institutions like Beihang University and Zhejiang University providing research foundations. Chinese telecom providers (China Telecom) are actively implementing standardized testing approaches, while international players like Siemens bring cross-industry reliability expertise to this emerging field.

Suzhou Inspur Intelligent Technology Co., Ltd.

Technical Solution: Inspur has developed a multi-tiered reliability testing protocol specifically for their two-phase immersion cooling solutions that addresses both immediate performance and long-term durability concerns. Their methodology includes component qualification testing that subjects server components to extended immersion periods (1000+ hours) while under varying computational loads. Inspur's approach incorporates thermal cycle testing that simulates years of operational conditions in compressed timeframes, with particular attention to the effects of repeated phase changes on system components. Their protocols feature contamination resistance testing that evaluates how particulate matter and other contaminants affect cooling efficiency and component longevity over time. Inspur has implemented automated monitoring systems that continuously evaluate key parameters including fluid level fluctuations, temperature gradients across components, and phase change efficiency metrics. Their testing regimen also includes specific protocols for evaluating server performance during maintenance events, ensuring that partial system access doesn't compromise overall cooling integrity.

Strengths: Comprehensive component-level testing methodology; strong focus on practical maintenance scenarios that affect real-world reliability. Weaknesses: Testing protocols primarily optimized for Inspur's own hardware configurations; limited published data on cross-vendor compatibility testing.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed comprehensive reliability testing protocols for their two-phase immersion cooling data centers that focus on both component and system-level validation. Their approach includes accelerated life testing under various thermal loads, simulating power fluctuations, and monitoring dielectric fluid degradation over time. Huawei's testing methodology incorporates thermal shock tests (cycling between temperature extremes of -40°C to +85°C) to validate component resilience and uses computational fluid dynamics (CFD) modeling to predict long-term performance. Their protocols specifically address the unique challenges of two-phase cooling, including vapor quality monitoring, condensation efficiency testing, and evaluation of the cooling system's response to varying workloads. Huawei implements continuous monitoring systems that track key parameters including fluid level, contamination, temperature uniformity, and phase change efficiency to ensure optimal operation.

Strengths: Comprehensive end-to-end testing methodology that addresses both hardware reliability and cooling efficiency; extensive global data center experience providing real-world validation data. Weaknesses: Proprietary testing protocols may limit industry-wide standardization; testing primarily optimized for Huawei's own hardware configurations rather than heterogeneous environments.

Critical Patents in Immersion Cooling Reliability

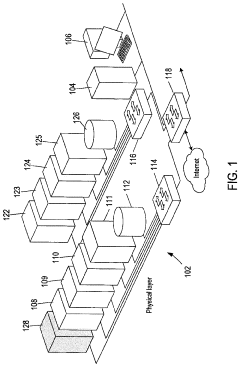

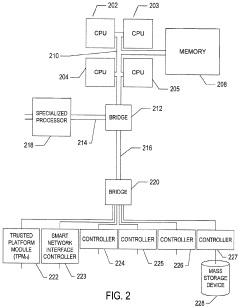

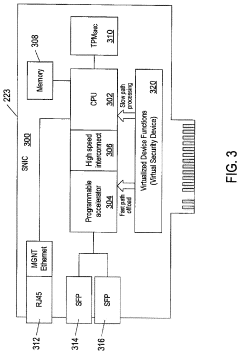

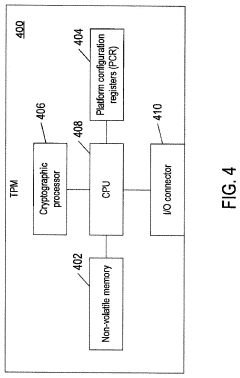

Automated methods and systems for performing host attestation using a smart network interface controller

PatentActiveUS20230188362A1

Innovation

- Implementing a two-phase attestation process using a trust platform module (TPM) and smart network interface controller (SNIC) that isolates the host from the data center network during attestation, preventing vulnerable communication channels and ensuring trustworthiness before granting access.

Environmental Impact Assessment

The environmental impact assessment of two-phase immersion cooling technology for data centers reveals significant sustainability advantages compared to traditional cooling methods. Two-phase immersion cooling systems demonstrate up to 95% reduction in cooling energy consumption, substantially decreasing the overall carbon footprint of data center operations. This efficiency stems from the elimination of energy-intensive components such as air handlers, chillers, and cooling towers that conventional air-cooling systems require.

The closed-loop design of two-phase immersion systems minimizes water consumption—a critical environmental consideration as traditional data centers consume millions of gallons annually for cooling purposes. Studies indicate that immersion cooling can reduce water usage by approximately 85-95% compared to air-cooled facilities, addressing growing concerns about water scarcity in many regions hosting large data centers.

Chemical composition and lifecycle management of dielectric fluids present important environmental considerations. Modern engineered fluids used in two-phase immersion cooling typically have zero ozone depletion potential and low global warming potential compared to earlier refrigerants. However, comprehensive testing protocols must evaluate potential environmental risks from fluid leakage, degradation byproducts, and end-of-life disposal procedures to ensure regulatory compliance across different jurisdictions.

Reliability testing protocols should incorporate environmental impact metrics throughout the system lifecycle. This includes assessment of manufacturing processes, operational efficiency, maintenance requirements, and eventual decommissioning. Life Cycle Assessment (LCA) methodologies reveal that the extended hardware lifespan achieved through immersion cooling—often 20-30% longer due to reduced thermal stress and elimination of oxidation—further enhances environmental benefits through reduced electronic waste generation.

Heat recovery capabilities represent another significant environmental advantage. The concentrated heat captured from immersion systems can be more effectively repurposed for district heating or other secondary applications compared to the diffuse waste heat from air-cooled systems. Testing protocols should evaluate the quality and quantity of recoverable heat to accurately assess this environmental benefit.

Noise pollution reduction constitutes an often-overlooked environmental advantage. The elimination of numerous fans and air handling equipment significantly reduces the acoustic footprint of data centers, potentially allowing facilities to operate in more densely populated areas without creating noise disturbances for surrounding communities.

The closed-loop design of two-phase immersion systems minimizes water consumption—a critical environmental consideration as traditional data centers consume millions of gallons annually for cooling purposes. Studies indicate that immersion cooling can reduce water usage by approximately 85-95% compared to air-cooled facilities, addressing growing concerns about water scarcity in many regions hosting large data centers.

Chemical composition and lifecycle management of dielectric fluids present important environmental considerations. Modern engineered fluids used in two-phase immersion cooling typically have zero ozone depletion potential and low global warming potential compared to earlier refrigerants. However, comprehensive testing protocols must evaluate potential environmental risks from fluid leakage, degradation byproducts, and end-of-life disposal procedures to ensure regulatory compliance across different jurisdictions.

Reliability testing protocols should incorporate environmental impact metrics throughout the system lifecycle. This includes assessment of manufacturing processes, operational efficiency, maintenance requirements, and eventual decommissioning. Life Cycle Assessment (LCA) methodologies reveal that the extended hardware lifespan achieved through immersion cooling—often 20-30% longer due to reduced thermal stress and elimination of oxidation—further enhances environmental benefits through reduced electronic waste generation.

Heat recovery capabilities represent another significant environmental advantage. The concentrated heat captured from immersion systems can be more effectively repurposed for district heating or other secondary applications compared to the diffuse waste heat from air-cooled systems. Testing protocols should evaluate the quality and quantity of recoverable heat to accurately assess this environmental benefit.

Noise pollution reduction constitutes an often-overlooked environmental advantage. The elimination of numerous fans and air handling equipment significantly reduces the acoustic footprint of data centers, potentially allowing facilities to operate in more densely populated areas without creating noise disturbances for surrounding communities.

Standardization Efforts

The standardization landscape for two-phase immersion cooling reliability testing remains fragmented, with multiple organizations working to establish cohesive frameworks. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has formed Technical Committee 9.9, which is specifically addressing liquid cooling technologies including immersion cooling. Their Technical Committee has published guidelines that are gradually incorporating two-phase immersion cooling considerations, though comprehensive standards specifically for reliability testing protocols remain under development.

The Open Compute Project (OCP) has established working groups focused on immersion cooling standardization, with recent efforts to define testing methodologies for hardware compatibility and long-term reliability in two-phase immersion environments. Their Advanced Cooling Solutions subgroup has published preliminary recommendations for testing procedures that address thermal cycling, dielectric fluid degradation assessment, and component compatibility verification.

ISO/IEC has begun incorporating immersion cooling considerations into their environmental testing standards, with Technical Committee 104 working on adaptations of existing reliability testing frameworks to accommodate the unique challenges of two-phase immersion cooling systems. These efforts aim to standardize testing conditions, measurement methodologies, and reporting formats to enable consistent evaluation across different implementations.

The Green Grid consortium has initiated projects to develop metrics specifically for immersion cooling efficiency and reliability, working to establish standardized performance indicators that can be used to compare different two-phase immersion cooling solutions. Their focus includes developing standardized testing protocols that address both energy efficiency and system reliability under various operational conditions.

Industry alliances like the Liquid Cooling Consortium (LCC) are collaborating with component manufacturers to establish compatibility testing standards that ensure hardware can withstand long-term exposure to two-phase coolants. These efforts include standardized accelerated aging tests, material compatibility verification procedures, and performance degradation assessments.

JEDEC, traditionally focused on semiconductor engineering standardization, has expanded its scope to address reliability testing for electronic components in immersion cooling environments. Their JC-14 committee on Quality and Reliability is developing test methods specifically for evaluating component performance and longevity in two-phase immersion cooling systems.

Despite these initiatives, significant gaps remain in standardization efforts. Current challenges include harmonizing competing approaches, addressing the rapid evolution of two-phase coolant formulations, and establishing consensus on acceptable reliability thresholds across different data center operational profiles. The industry would benefit from greater coordination between these various standardization bodies to develop a unified framework for reliability testing protocols.

The Open Compute Project (OCP) has established working groups focused on immersion cooling standardization, with recent efforts to define testing methodologies for hardware compatibility and long-term reliability in two-phase immersion environments. Their Advanced Cooling Solutions subgroup has published preliminary recommendations for testing procedures that address thermal cycling, dielectric fluid degradation assessment, and component compatibility verification.

ISO/IEC has begun incorporating immersion cooling considerations into their environmental testing standards, with Technical Committee 104 working on adaptations of existing reliability testing frameworks to accommodate the unique challenges of two-phase immersion cooling systems. These efforts aim to standardize testing conditions, measurement methodologies, and reporting formats to enable consistent evaluation across different implementations.

The Green Grid consortium has initiated projects to develop metrics specifically for immersion cooling efficiency and reliability, working to establish standardized performance indicators that can be used to compare different two-phase immersion cooling solutions. Their focus includes developing standardized testing protocols that address both energy efficiency and system reliability under various operational conditions.

Industry alliances like the Liquid Cooling Consortium (LCC) are collaborating with component manufacturers to establish compatibility testing standards that ensure hardware can withstand long-term exposure to two-phase coolants. These efforts include standardized accelerated aging tests, material compatibility verification procedures, and performance degradation assessments.

JEDEC, traditionally focused on semiconductor engineering standardization, has expanded its scope to address reliability testing for electronic components in immersion cooling environments. Their JC-14 committee on Quality and Reliability is developing test methods specifically for evaluating component performance and longevity in two-phase immersion cooling systems.

Despite these initiatives, significant gaps remain in standardization efforts. Current challenges include harmonizing competing approaches, addressing the rapid evolution of two-phase coolant formulations, and establishing consensus on acceptable reliability thresholds across different data center operational profiles. The industry would benefit from greater coordination between these various standardization bodies to develop a unified framework for reliability testing protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!