Pump, Condenser, And Heat Rejection Design For Immersion Loops

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Immersion Cooling Technology Background and Objectives

Immersion cooling technology has evolved significantly over the past decades, transitioning from niche applications to a mainstream thermal management solution. Originally developed for high-performance computing in the 1980s, immersion cooling involves submerging electronic components directly in dielectric fluids that conduct heat but not electricity. This approach eliminates the thermal boundary layer limitations inherent in air cooling systems, allowing for more efficient heat transfer and thermal management.

The evolution of immersion cooling has been accelerated by the exponential growth in data center power densities, which have increased from approximately 5 kW per rack in the early 2000s to exceeding 100 kW per rack in modern high-performance computing environments. This dramatic increase has pushed traditional air cooling methods beyond their practical and economic limits, creating a compelling need for alternative cooling technologies.

Immersion cooling systems are categorized into two primary types: single-phase and two-phase systems. Single-phase systems maintain the coolant in liquid form throughout the cooling cycle, while two-phase systems utilize the latent heat of vaporization as the fluid changes state from liquid to gas when absorbing heat. Both approaches offer significant advantages over traditional air cooling, including higher heat transfer coefficients, reduced energy consumption, and elimination of fans and heat sinks.

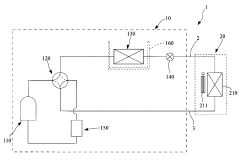

The pump, condenser, and heat rejection components form the critical infrastructure of immersion cooling loops. These elements are responsible for circulating the cooling fluid, transferring heat from the fluid to a secondary cooling medium, and ultimately rejecting that heat to the environment. The design and optimization of these components directly impact the efficiency, reliability, and scalability of immersion cooling systems.

Current technological objectives in this field focus on several key areas: increasing energy efficiency to reduce operational costs and environmental impact; enhancing reliability to minimize downtime in critical applications; improving scalability to accommodate growing computing demands; and developing more environmentally friendly cooling fluids with lower global warming potential.

Additionally, there is significant interest in standardizing immersion cooling technologies to facilitate broader adoption across various industries. This includes developing universal design principles, establishing performance metrics, and creating interoperability standards that allow for seamless integration with existing infrastructure and future technologies.

The advancement of immersion cooling technology aligns with broader industry trends toward sustainable computing and green data centers, positioning it as a key enabler for the next generation of high-performance computing systems, artificial intelligence platforms, and edge computing deployments.

The evolution of immersion cooling has been accelerated by the exponential growth in data center power densities, which have increased from approximately 5 kW per rack in the early 2000s to exceeding 100 kW per rack in modern high-performance computing environments. This dramatic increase has pushed traditional air cooling methods beyond their practical and economic limits, creating a compelling need for alternative cooling technologies.

Immersion cooling systems are categorized into two primary types: single-phase and two-phase systems. Single-phase systems maintain the coolant in liquid form throughout the cooling cycle, while two-phase systems utilize the latent heat of vaporization as the fluid changes state from liquid to gas when absorbing heat. Both approaches offer significant advantages over traditional air cooling, including higher heat transfer coefficients, reduced energy consumption, and elimination of fans and heat sinks.

The pump, condenser, and heat rejection components form the critical infrastructure of immersion cooling loops. These elements are responsible for circulating the cooling fluid, transferring heat from the fluid to a secondary cooling medium, and ultimately rejecting that heat to the environment. The design and optimization of these components directly impact the efficiency, reliability, and scalability of immersion cooling systems.

Current technological objectives in this field focus on several key areas: increasing energy efficiency to reduce operational costs and environmental impact; enhancing reliability to minimize downtime in critical applications; improving scalability to accommodate growing computing demands; and developing more environmentally friendly cooling fluids with lower global warming potential.

Additionally, there is significant interest in standardizing immersion cooling technologies to facilitate broader adoption across various industries. This includes developing universal design principles, establishing performance metrics, and creating interoperability standards that allow for seamless integration with existing infrastructure and future technologies.

The advancement of immersion cooling technology aligns with broader industry trends toward sustainable computing and green data centers, positioning it as a key enabler for the next generation of high-performance computing systems, artificial intelligence platforms, and edge computing deployments.

Market Analysis for Immersion Cooling Solutions

The immersion cooling market is experiencing unprecedented growth, driven by the increasing power density of computing systems and the need for more efficient cooling solutions. The global market for immersion cooling was valued at approximately $250 million in 2021 and is projected to reach $700 million by 2026, representing a compound annual growth rate (CAGR) of 22.8%. This growth trajectory is primarily fueled by the expansion of data centers, cryptocurrency mining operations, and high-performance computing facilities.

Data centers represent the largest market segment for immersion cooling solutions, accounting for nearly 45% of the total market share. The rising adoption of artificial intelligence and machine learning technologies has significantly increased computational demands, pushing traditional air cooling systems to their limits. Immersion cooling offers a compelling alternative, reducing cooling energy consumption by up to 95% and enabling higher density deployments.

Geographically, North America currently leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid digital infrastructure development and favorable government initiatives promoting energy-efficient technologies.

The market landscape features both established players and innovative startups. Major cooling system manufacturers like Asperitas, Green Revolution Cooling, and Submer Technologies have developed proprietary immersion cooling solutions. Meanwhile, technology giants including Microsoft, Google, and Intel are actively investing in immersion cooling research and deployment for their data centers.

Customer segmentation reveals distinct market needs across different sectors. Enterprise data centers prioritize reliability and total cost of ownership, while cloud service providers focus on scalability and energy efficiency. The cryptocurrency mining segment values cost-effectiveness and deployment speed, creating diverse market opportunities for specialized immersion cooling solutions.

Key market drivers include the push for greater energy efficiency, with immersion cooling offering potential PUE (Power Usage Effectiveness) values as low as 1.03 compared to 1.5-2.0 for traditional air cooling. Environmental regulations and sustainability goals are also accelerating adoption, as immersion cooling can significantly reduce carbon footprints through decreased energy consumption and elimination of water usage in cooling towers.

Market challenges include high initial investment costs, concerns about liquid maintenance, and compatibility issues with existing infrastructure. However, the long-term operational savings and performance benefits are increasingly outweighing these barriers, particularly for new facility deployments.

Data centers represent the largest market segment for immersion cooling solutions, accounting for nearly 45% of the total market share. The rising adoption of artificial intelligence and machine learning technologies has significantly increased computational demands, pushing traditional air cooling systems to their limits. Immersion cooling offers a compelling alternative, reducing cooling energy consumption by up to 95% and enabling higher density deployments.

Geographically, North America currently leads the market with approximately 40% share, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to witness the highest growth rate over the next five years due to rapid digital infrastructure development and favorable government initiatives promoting energy-efficient technologies.

The market landscape features both established players and innovative startups. Major cooling system manufacturers like Asperitas, Green Revolution Cooling, and Submer Technologies have developed proprietary immersion cooling solutions. Meanwhile, technology giants including Microsoft, Google, and Intel are actively investing in immersion cooling research and deployment for their data centers.

Customer segmentation reveals distinct market needs across different sectors. Enterprise data centers prioritize reliability and total cost of ownership, while cloud service providers focus on scalability and energy efficiency. The cryptocurrency mining segment values cost-effectiveness and deployment speed, creating diverse market opportunities for specialized immersion cooling solutions.

Key market drivers include the push for greater energy efficiency, with immersion cooling offering potential PUE (Power Usage Effectiveness) values as low as 1.03 compared to 1.5-2.0 for traditional air cooling. Environmental regulations and sustainability goals are also accelerating adoption, as immersion cooling can significantly reduce carbon footprints through decreased energy consumption and elimination of water usage in cooling towers.

Market challenges include high initial investment costs, concerns about liquid maintenance, and compatibility issues with existing infrastructure. However, the long-term operational savings and performance benefits are increasingly outweighing these barriers, particularly for new facility deployments.

Current Challenges in Immersion Loop Systems

Immersion cooling systems face several significant technical challenges that impede their widespread adoption and optimal performance. The primary issue revolves around pump reliability in immersion environments. Traditional pumps often experience accelerated wear when operating continuously in dielectric fluids, leading to premature failure and system downtime. The seals and bearings in these pumps are particularly vulnerable to degradation when exposed to the chemical properties of immersion coolants, creating maintenance challenges and increasing operational costs.

Condenser design presents another critical challenge, as current configurations struggle to achieve optimal heat transfer efficiency. The interface between the dielectric fluid and the condenser surface often develops thermal resistance layers that reduce overall system performance. Additionally, condensers must be precisely sized to handle peak thermal loads while maintaining compact dimensions, a balance that remains difficult to achieve in practical applications.

Heat rejection mechanisms in immersion loops face limitations in dissipating the increasingly high heat densities generated by modern computing and power electronics. The thermal gradient between the coolant and ambient environment significantly impacts system efficiency, with diminishing returns as ambient temperatures rise. This challenge becomes particularly acute in data center environments where multiple immersion systems operate in proximity, creating localized hot spots that further stress cooling infrastructure.

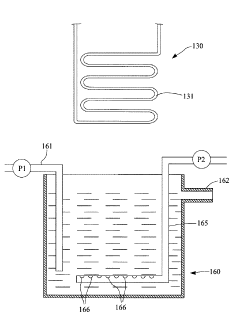

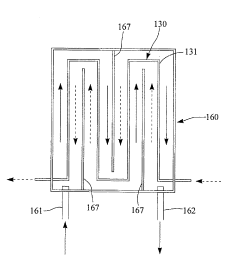

Fluid dynamics within immersion loops present complex engineering challenges, as the movement of dielectric fluids through the system must be carefully controlled to prevent dead zones where heat can accumulate. Current pump designs often struggle to maintain optimal flow rates without introducing turbulence that can reduce cooling efficiency or damage sensitive components.

Energy consumption remains a significant concern, with pumping systems typically accounting for 15-20% of the total power draw in immersion cooling setups. This parasitic energy loss directly impacts the overall efficiency advantage that immersion cooling promises over traditional air cooling methods. The industry has yet to develop pumping solutions that can deliver the required flow rates with substantially lower energy inputs.

Material compatibility issues continue to plague immersion systems, as certain components may degrade when continuously exposed to dielectric fluids. This necessitates careful material selection and often requires specialized, more expensive components that can withstand long-term immersion, increasing system costs and limiting design flexibility.

Standardization remains elusive in the immersion cooling industry, with various proprietary designs and fluid formulations creating interoperability challenges. This fragmentation hampers the development of universal design principles for pumps, condensers, and heat rejection systems that could accelerate industry-wide adoption and innovation.

Condenser design presents another critical challenge, as current configurations struggle to achieve optimal heat transfer efficiency. The interface between the dielectric fluid and the condenser surface often develops thermal resistance layers that reduce overall system performance. Additionally, condensers must be precisely sized to handle peak thermal loads while maintaining compact dimensions, a balance that remains difficult to achieve in practical applications.

Heat rejection mechanisms in immersion loops face limitations in dissipating the increasingly high heat densities generated by modern computing and power electronics. The thermal gradient between the coolant and ambient environment significantly impacts system efficiency, with diminishing returns as ambient temperatures rise. This challenge becomes particularly acute in data center environments where multiple immersion systems operate in proximity, creating localized hot spots that further stress cooling infrastructure.

Fluid dynamics within immersion loops present complex engineering challenges, as the movement of dielectric fluids through the system must be carefully controlled to prevent dead zones where heat can accumulate. Current pump designs often struggle to maintain optimal flow rates without introducing turbulence that can reduce cooling efficiency or damage sensitive components.

Energy consumption remains a significant concern, with pumping systems typically accounting for 15-20% of the total power draw in immersion cooling setups. This parasitic energy loss directly impacts the overall efficiency advantage that immersion cooling promises over traditional air cooling methods. The industry has yet to develop pumping solutions that can deliver the required flow rates with substantially lower energy inputs.

Material compatibility issues continue to plague immersion systems, as certain components may degrade when continuously exposed to dielectric fluids. This necessitates careful material selection and often requires specialized, more expensive components that can withstand long-term immersion, increasing system costs and limiting design flexibility.

Standardization remains elusive in the immersion cooling industry, with various proprietary designs and fluid formulations creating interoperability challenges. This fragmentation hampers the development of universal design principles for pumps, condensers, and heat rejection systems that could accelerate industry-wide adoption and innovation.

Current Pump and Heat Rejection Design Approaches

01 Advanced pump designs for immersion cooling systems

Specialized pump designs are critical for efficient fluid circulation in immersion cooling systems. These pumps are engineered to handle the unique properties of dielectric coolants while maintaining optimal flow rates. Advanced features include variable speed control, low-noise operation, and integration with system monitoring to adjust flow based on heat load. These pumps often incorporate redundancy features to ensure continuous operation in critical applications, and are designed to minimize energy consumption while maximizing heat transfer efficiency.- Advanced pump designs for immersion cooling systems: Specialized pump designs are critical for efficient fluid circulation in immersion cooling systems. These pumps are engineered to handle the unique properties of dielectric coolants while maintaining optimal flow rates. Advanced features include variable speed control, low-noise operation, and integration with system monitoring. These pumps help maintain consistent coolant temperature throughout the system, which directly impacts the overall heat rejection efficiency of immersion cooling solutions.

- Condenser optimization techniques for heat rejection: Condenser design plays a crucial role in the heat rejection efficiency of immersion cooling systems. Innovations include enhanced surface area designs, multi-phase condensers, and specialized materials that improve thermal conductivity. Advanced condensers incorporate micro-channel technology and optimized fin structures to maximize heat transfer from the coolant to the ambient environment. These improvements allow for more efficient phase change processes and ultimately higher cooling capacity with reduced energy consumption.

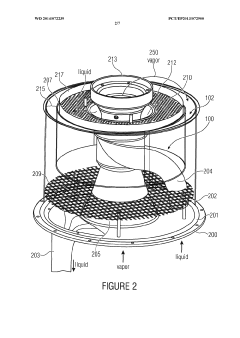

- Two-phase immersion cooling technologies: Two-phase immersion cooling systems utilize the latent heat of vaporization to achieve superior heat rejection efficiency. In these systems, the coolant absorbs heat from electronic components, vaporizes, rises to condensers where it releases heat, and then returns to the liquid state. This natural circulation reduces or eliminates the need for pumping power while providing highly efficient cooling. The technology enables higher heat flux handling capabilities compared to single-phase systems and offers improved temperature uniformity across components.

- Integrated heat rejection components for compact systems: Integrated heat rejection components combine multiple cooling functions into unified, space-efficient designs. These systems feature compact arrangements of pumps, heat exchangers, and condensers that minimize the overall footprint while maintaining high cooling efficiency. Advanced integration techniques include modular designs that allow for scalability and easier maintenance. These integrated solutions optimize fluid paths to reduce pressure drops and improve overall system performance while enabling deployment in space-constrained environments.

- Energy-efficient heat rejection methods: Energy-efficient heat rejection methods focus on minimizing power consumption while maximizing cooling performance. These approaches include passive cooling elements, waste heat recovery systems, and intelligent control algorithms that optimize system operation based on real-time thermal loads. Advanced designs incorporate free cooling techniques that leverage environmental conditions when possible and variable-speed components that adjust to changing demands. These methods significantly reduce the energy footprint of immersion cooling systems while maintaining or improving their heat rejection capabilities.

02 Condenser optimization for heat rejection

Condenser design plays a crucial role in the overall efficiency of immersion cooling systems. Advanced condensers feature enhanced surface areas, specialized fin designs, and optimized tube configurations to maximize heat transfer. Some innovations include multi-pass condensers, micro-channel technology, and phase-change materials that improve thermal conductivity. These designs focus on reducing thermal resistance between the coolant and ambient environment, resulting in more efficient heat rejection and lower operating temperatures for the entire cooling system.Expand Specific Solutions03 Two-phase immersion cooling technologies

Two-phase immersion cooling leverages the latent heat of vaporization to achieve superior thermal performance. In these systems, the dielectric coolant absorbs heat from components, vaporizes, rises to condensers where it releases heat, and returns to liquid form. This natural circulation reduces or eliminates the need for pumps in some designs. Innovations in this area include specialized fluid formulations with optimized boiling points, enhanced nucleation site designs on heat-generating surfaces, and vapor flow management systems that improve overall heat rejection efficiency.Expand Specific Solutions04 Integrated cooling system architectures

Integrated cooling architectures combine multiple components into cohesive systems that optimize overall heat rejection efficiency. These designs feature careful placement of pumps, condensers, and heat exchangers to minimize fluid resistance and thermal gradients. Advanced systems incorporate secondary cooling loops, heat recovery mechanisms, and intelligent control systems that adjust operating parameters based on thermal load and ambient conditions. Some innovations include modular designs for scalability, redundant pathways for fault tolerance, and compact arrangements that reduce the system footprint while maintaining high cooling capacity.Expand Specific Solutions05 Heat rejection efficiency monitoring and control systems

Sophisticated monitoring and control systems are essential for optimizing heat rejection efficiency in immersion cooling setups. These systems employ temperature sensors, flow meters, and pressure transducers to collect real-time data on system performance. Advanced controllers use predictive algorithms to anticipate thermal loads and adjust cooling parameters proactively. Some innovations include machine learning capabilities that continuously optimize system operation, remote monitoring interfaces for facility management, and automated maintenance alerts that identify potential efficiency degradations before they impact system performance.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The immersion cooling technology market for "Pump, Condenser, and Heat Rejection Design for Immersion Loops" is currently in a growth phase, with increasing adoption driven by data center efficiency demands. The market is projected to expand significantly as liquid cooling becomes essential for high-density computing applications. Companies like JETCOOL Technologies and LiquidStack are pioneering specialized microjet cooling solutions, while established players such as Vertiv, Wiwynn, and Fujitsu are integrating immersion cooling into their broader thermal management portfolios. Traditional manufacturers including Grundfos and Efficient Energy are adapting their expertise in pumps and heat exchange systems to serve this emerging market. The technology is approaching mainstream adoption in high-performance computing environments, with varying levels of maturity across single-phase and two-phase immersion cooling solutions.

Vertiv Srl

Technical Solution: Vertiv has developed comprehensive immersion cooling solutions with particular emphasis on reliability and serviceability in mission-critical environments. Their pump systems feature N+1 redundancy configurations with hot-swappable components to eliminate single points of failure in the cooling loop. The pumps utilize advanced variable frequency drives that optimize energy consumption based on real-time cooling demands. For condensers, Vertiv employs brazed plate heat exchangers with specialized materials selected for long-term compatibility with dielectric fluids and resistance to fouling. Their heat rejection systems integrate with existing building management systems and can utilize various heat sinks including cooling towers, dry coolers, or chilled water loops depending on facility infrastructure. Vertiv's immersion solutions include sophisticated monitoring systems that track fluid quality parameters, temperature gradients, and system performance metrics to enable predictive maintenance and optimize operational efficiency.

Strengths: Extensive experience in critical infrastructure cooling translates to highly reliable immersion systems; global service network provides comprehensive support; solutions designed with serviceability and maintenance in mind. Weaknesses: Traditional focus on air cooling means immersion technology is a newer addition to their portfolio; systems may have higher initial costs due to redundancy features; solutions may be more conservative in design compared to newer market entrants.

JETCOOL Technologies, Inc.

Technical Solution: JETCOOL has developed microconvective cooling technology specifically for immersion cooling loops that targets hotspots directly. Their innovative approach uses microjet arrays integrated into heat sinks that create high-velocity fluid impingement directly on heat-generating components. For immersion loops, JETCOOL has engineered specialized pump systems that maintain precise pressure differentials required for optimal microjet performance while minimizing energy consumption. Their condenser designs incorporate advanced surface geometries that enhance phase-change efficiency and reduce thermal resistance. The heat rejection systems employ modular designs that can scale with computing demands while maintaining thermal efficiency. JETCOOL's technology enables more targeted cooling compared to traditional immersion approaches, allowing for higher power densities and more efficient use of cooling fluid circulation.

Strengths: Microjet technology provides superior cooling efficiency with lower pumping power requirements; targeted cooling approach addresses hotspots directly; compatible with both single and two-phase immersion systems. Weaknesses: More complex implementation requiring precise manufacturing tolerances; higher component-level integration complexity; may require more specialized maintenance expertise.

Key Technical Innovations in Immersion Cooling

Heat pump device

PatentActiveJP2020051714A

Innovation

- An open-loop direct-expansion heat pump system with a water-refrigerant heat exchanger immersed in a water tank, utilizing groundwater for enhanced heat exchange, where the refrigerant and water flows in opposite directions for counterflow heat transfer, and an inverter-controlled compressor adjusts speed based on heat exchange needs.

Condenser, method for condensing and heat pump

PatentWO2014072239A1

Innovation

- The condenser design features a vapor introduction zone where vapor enters laterally into the condensation zone, creating a transverse flow direction relative to the liquid flow, enhancing condensation efficiency without increasing the condenser volume, achieved through geometric design and the use of fillers like Pall rings to induce turbulence and redirect vapor flow.

Energy Efficiency and Sustainability Considerations

Energy efficiency and sustainability have become critical considerations in the design and operation of immersion cooling systems. As data centers and high-performance computing facilities face increasing power demands, immersion cooling loops offer significant advantages over traditional air cooling methods, potentially reducing energy consumption by 30-50%. The pump, condenser, and heat rejection components represent the most energy-intensive elements of these systems, making their optimization essential for sustainable operation.

The pumping systems in immersion loops require careful selection to balance flow requirements with energy consumption. Recent advancements include variable frequency drives (VFDs) that adjust pump speeds according to real-time cooling demands, reducing unnecessary energy expenditure during periods of lower computational load. Studies indicate that implementing smart pumping systems can decrease pumping energy by up to 25% compared to fixed-speed alternatives, with minimal impact on thermal performance.

Condenser design has evolved significantly, with plate heat exchangers and microchannel condensers offering enhanced heat transfer coefficients while requiring less pumping power. These high-efficiency condensers can operate with smaller approach temperatures, improving the overall coefficient of performance (COP) of the cooling system. Materials innovation has also contributed to sustainability, with corrosion-resistant alloys extending operational lifespans and reducing replacement frequency.

Heat rejection systems present opportunities for energy recovery and integration with facility-wide sustainability initiatives. Waste heat from immersion cooling systems can be captured and repurposed for building heating, domestic hot water, or even absorption cooling systems. This waste heat utilization can offset 15-20% of facility energy costs in appropriate climates and configurations. Free cooling opportunities, where ambient conditions permit direct heat rejection without mechanical refrigeration, can further reduce energy consumption during cooler seasons.

Refrigerant selection impacts both energy efficiency and environmental sustainability. The industry is transitioning from high global warming potential (GWP) refrigerants to natural alternatives or synthetic options with lower environmental impact. This transition must balance thermodynamic performance with environmental considerations, as some lower-GWP alternatives may require higher pumping power or larger heat exchange surfaces to achieve equivalent cooling capacity.

Life cycle assessment (LCA) of immersion cooling systems reveals that operational energy consumption typically accounts for over 80% of lifetime environmental impact. Therefore, even modest improvements in pump, condenser, and heat rejection efficiency can yield significant sustainability benefits over the system lifespan. Emerging technologies such as magnetic refrigeration and thermoacoustic cooling may offer future pathways to further enhance sustainability, though these remain in early development stages for immersion cooling applications.

The pumping systems in immersion loops require careful selection to balance flow requirements with energy consumption. Recent advancements include variable frequency drives (VFDs) that adjust pump speeds according to real-time cooling demands, reducing unnecessary energy expenditure during periods of lower computational load. Studies indicate that implementing smart pumping systems can decrease pumping energy by up to 25% compared to fixed-speed alternatives, with minimal impact on thermal performance.

Condenser design has evolved significantly, with plate heat exchangers and microchannel condensers offering enhanced heat transfer coefficients while requiring less pumping power. These high-efficiency condensers can operate with smaller approach temperatures, improving the overall coefficient of performance (COP) of the cooling system. Materials innovation has also contributed to sustainability, with corrosion-resistant alloys extending operational lifespans and reducing replacement frequency.

Heat rejection systems present opportunities for energy recovery and integration with facility-wide sustainability initiatives. Waste heat from immersion cooling systems can be captured and repurposed for building heating, domestic hot water, or even absorption cooling systems. This waste heat utilization can offset 15-20% of facility energy costs in appropriate climates and configurations. Free cooling opportunities, where ambient conditions permit direct heat rejection without mechanical refrigeration, can further reduce energy consumption during cooler seasons.

Refrigerant selection impacts both energy efficiency and environmental sustainability. The industry is transitioning from high global warming potential (GWP) refrigerants to natural alternatives or synthetic options with lower environmental impact. This transition must balance thermodynamic performance with environmental considerations, as some lower-GWP alternatives may require higher pumping power or larger heat exchange surfaces to achieve equivalent cooling capacity.

Life cycle assessment (LCA) of immersion cooling systems reveals that operational energy consumption typically accounts for over 80% of lifetime environmental impact. Therefore, even modest improvements in pump, condenser, and heat rejection efficiency can yield significant sustainability benefits over the system lifespan. Emerging technologies such as magnetic refrigeration and thermoacoustic cooling may offer future pathways to further enhance sustainability, though these remain in early development stages for immersion cooling applications.

Thermal Management Standards and Compliance

Immersion cooling systems must adhere to various thermal management standards and compliance requirements to ensure safety, reliability, and interoperability. The International Organization for Standardization (ISO) has established several standards relevant to liquid cooling systems, including ISO 14903 for refrigeration systems and heat pumps, which outlines requirements for tightness, strength, and performance of components in fluid circuits.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides comprehensive guidelines for liquid cooling systems through standards like ASHRAE 90.1, which addresses energy efficiency requirements for HVAC systems including pumps and condensers. Additionally, ASHRAE Technical Committee 9.9 has published specific guidelines for liquid cooling in data centers, which are increasingly adopting immersion cooling technologies.

For electrical safety considerations, immersion cooling systems must comply with standards such as IEC 60529, which defines Ingress Protection (IP) ratings for electrical enclosures. Systems handling dielectric fluids must meet UL 489 requirements for circuit breakers and UL 1950 for information technology equipment safety.

Environmental regulations also impact immersion cooling system design. The European Union's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electrical and electronic equipment. Similarly, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of chemical substances that might be present in cooling fluids.

Thermal performance standards like JEDEC JESD51-14 provide methodologies for thermal measurements of electronic packages in liquid cooling environments. These standards ensure consistent testing and reporting of thermal performance across different systems and components.

Energy efficiency certifications such as ENERGY STAR and the EU Ecodesign Directive establish minimum efficiency requirements for various components used in cooling systems. The pump and condenser designs for immersion loops must meet these efficiency thresholds to achieve certification and market acceptance.

Industry-specific standards also apply to immersion cooling systems in specialized applications. For instance, NEBS (Network Equipment Building System) requirements govern telecommunications equipment, while medical device cooling systems must comply with IEC 60601 standards for safety and essential performance.

Emerging standards specifically addressing liquid immersion cooling are being developed by organizations like The Green Grid and the Open Compute Project. These collaborative efforts aim to standardize designs, testing methodologies, and performance metrics for immersion cooling technologies, facilitating broader adoption across various industries.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provides comprehensive guidelines for liquid cooling systems through standards like ASHRAE 90.1, which addresses energy efficiency requirements for HVAC systems including pumps and condensers. Additionally, ASHRAE Technical Committee 9.9 has published specific guidelines for liquid cooling in data centers, which are increasingly adopting immersion cooling technologies.

For electrical safety considerations, immersion cooling systems must comply with standards such as IEC 60529, which defines Ingress Protection (IP) ratings for electrical enclosures. Systems handling dielectric fluids must meet UL 489 requirements for circuit breakers and UL 1950 for information technology equipment safety.

Environmental regulations also impact immersion cooling system design. The European Union's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials in electrical and electronic equipment. Similarly, the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation governs the use of chemical substances that might be present in cooling fluids.

Thermal performance standards like JEDEC JESD51-14 provide methodologies for thermal measurements of electronic packages in liquid cooling environments. These standards ensure consistent testing and reporting of thermal performance across different systems and components.

Energy efficiency certifications such as ENERGY STAR and the EU Ecodesign Directive establish minimum efficiency requirements for various components used in cooling systems. The pump and condenser designs for immersion loops must meet these efficiency thresholds to achieve certification and market acceptance.

Industry-specific standards also apply to immersion cooling systems in specialized applications. For instance, NEBS (Network Equipment Building System) requirements govern telecommunications equipment, while medical device cooling systems must comply with IEC 60601 standards for safety and essential performance.

Emerging standards specifically addressing liquid immersion cooling are being developed by organizations like The Green Grid and the Open Compute Project. These collaborative efforts aim to standardize designs, testing methodologies, and performance metrics for immersion cooling technologies, facilitating broader adoption across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!