Monitoring Arrhenius Acid Levels in Industrial Emissions

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Industrial Emission Monitoring Background and Objectives

The monitoring of Arrhenius acid levels in industrial emissions has become increasingly critical in modern industrial operations as environmental regulations tighten globally. Historically, acid emissions monitoring evolved from basic pH measurements in the early 20th century to sophisticated real-time analytical systems in the 21st century. This technological progression has been driven by growing awareness of the environmental impact of acidic compounds such as sulfuric acid, hydrochloric acid, and nitric acid released during manufacturing, power generation, and chemical processing.

The industrial revolution marked the beginning of significant acid emissions, but systematic monitoring only gained traction in the 1970s with the establishment of environmental protection agencies worldwide. Early detection methods relied on wet chemistry techniques and manual sampling, which provided limited temporal resolution and delayed response capabilities. The technological landscape transformed dramatically with the introduction of continuous emission monitoring systems (CEMS) in the 1980s and 1990s, enabling more accurate tracking of emission patterns.

Current technological trends point toward integration of IoT capabilities, artificial intelligence for predictive analytics, and miniaturization of sensing equipment. These advancements allow for more comprehensive monitoring networks that can detect subtle variations in acid concentrations across industrial facilities. The evolution of spectroscopic techniques, particularly Fourier-transform infrared spectroscopy (FTIR) and tunable diode laser absorption spectroscopy (TDLAS), has significantly improved the specificity and sensitivity of acid detection systems.

The primary objectives of modern Arrhenius acid monitoring technologies include achieving sub-ppm detection limits for various acidic compounds, developing corrosion-resistant sensors capable of withstanding harsh industrial environments, and creating systems that provide real-time data with minimal maintenance requirements. Additionally, there is a growing emphasis on developing cost-effective solutions that can be deployed across industries of varying scales and technical capabilities.

Another crucial goal is the standardization of monitoring protocols to ensure consistency in measurement methodologies and reporting frameworks across different regions and industrial sectors. This standardization facilitates regulatory compliance and enables meaningful comparison of emission data between facilities. Furthermore, the integration of acid monitoring systems with broader environmental management platforms represents an important technological objective, allowing for holistic assessment of industrial environmental impact.

The technological trajectory suggests that future acid monitoring systems will increasingly focus on predictive capabilities, enabling industries to anticipate potential emission events before they occur and implement preventive measures accordingly. This proactive approach aligns with the broader industrial shift toward sustainable manufacturing practices and circular economy principles.

The industrial revolution marked the beginning of significant acid emissions, but systematic monitoring only gained traction in the 1970s with the establishment of environmental protection agencies worldwide. Early detection methods relied on wet chemistry techniques and manual sampling, which provided limited temporal resolution and delayed response capabilities. The technological landscape transformed dramatically with the introduction of continuous emission monitoring systems (CEMS) in the 1980s and 1990s, enabling more accurate tracking of emission patterns.

Current technological trends point toward integration of IoT capabilities, artificial intelligence for predictive analytics, and miniaturization of sensing equipment. These advancements allow for more comprehensive monitoring networks that can detect subtle variations in acid concentrations across industrial facilities. The evolution of spectroscopic techniques, particularly Fourier-transform infrared spectroscopy (FTIR) and tunable diode laser absorption spectroscopy (TDLAS), has significantly improved the specificity and sensitivity of acid detection systems.

The primary objectives of modern Arrhenius acid monitoring technologies include achieving sub-ppm detection limits for various acidic compounds, developing corrosion-resistant sensors capable of withstanding harsh industrial environments, and creating systems that provide real-time data with minimal maintenance requirements. Additionally, there is a growing emphasis on developing cost-effective solutions that can be deployed across industries of varying scales and technical capabilities.

Another crucial goal is the standardization of monitoring protocols to ensure consistency in measurement methodologies and reporting frameworks across different regions and industrial sectors. This standardization facilitates regulatory compliance and enables meaningful comparison of emission data between facilities. Furthermore, the integration of acid monitoring systems with broader environmental management platforms represents an important technological objective, allowing for holistic assessment of industrial environmental impact.

The technological trajectory suggests that future acid monitoring systems will increasingly focus on predictive capabilities, enabling industries to anticipate potential emission events before they occur and implement preventive measures accordingly. This proactive approach aligns with the broader industrial shift toward sustainable manufacturing practices and circular economy principles.

Market Demand for Arrhenius Acid Detection Systems

The global market for Arrhenius acid detection systems has experienced significant growth in recent years, primarily driven by increasingly stringent environmental regulations across industrialized nations. The Environmental Protection Agency (EPA) in the United States, the European Environment Agency (EEA), and similar regulatory bodies in Asia-Pacific regions have established progressively lower permissible emission thresholds, creating substantial demand for advanced monitoring solutions.

Industrial sectors including chemical manufacturing, petroleum refining, power generation, and metallurgy represent the largest market segments for these detection systems. These industries face mounting pressure to monitor and control acidic emissions to avoid regulatory penalties, which can reach millions of dollars for serious violations. This regulatory landscape has transformed acid monitoring from a discretionary practice to an essential operational requirement.

Market research indicates that the global industrial emission monitoring systems market reached approximately $4.5 billion in 2022, with acid detection systems constituting a significant portion of this value. Analysts project a compound annual growth rate of 7.8% through 2028, potentially expanding the market to $7.1 billion, with Arrhenius acid detection systems expected to outpace the broader market growth.

The demand pattern shows notable regional variations. North America and Europe currently represent mature markets with steady growth, primarily driven by replacement and upgrade cycles. In contrast, emerging economies in Asia-Pacific and Latin America exhibit more rapid expansion as these regions implement stricter environmental standards while simultaneously increasing industrial capacity.

Customer requirements are evolving toward integrated solutions that offer real-time monitoring capabilities, remote access, predictive maintenance features, and compatibility with industrial IoT platforms. End-users increasingly demand systems that not only detect acid levels but also provide actionable insights for emission reduction strategies and regulatory compliance reporting.

Cost sensitivity remains a significant factor influencing market dynamics. While large corporations can absorb the expense of premium monitoring systems, small and medium enterprises often seek more affordable solutions that still meet regulatory requirements. This has created a segmented market with opportunities at various price points and capability levels.

The COVID-19 pandemic temporarily disrupted supply chains and installation schedules but ultimately accelerated the adoption of remote monitoring capabilities. Post-pandemic recovery has been robust, with many industries using facility upgrades and modernization initiatives as opportunities to implement advanced emission monitoring systems.

Industrial sectors including chemical manufacturing, petroleum refining, power generation, and metallurgy represent the largest market segments for these detection systems. These industries face mounting pressure to monitor and control acidic emissions to avoid regulatory penalties, which can reach millions of dollars for serious violations. This regulatory landscape has transformed acid monitoring from a discretionary practice to an essential operational requirement.

Market research indicates that the global industrial emission monitoring systems market reached approximately $4.5 billion in 2022, with acid detection systems constituting a significant portion of this value. Analysts project a compound annual growth rate of 7.8% through 2028, potentially expanding the market to $7.1 billion, with Arrhenius acid detection systems expected to outpace the broader market growth.

The demand pattern shows notable regional variations. North America and Europe currently represent mature markets with steady growth, primarily driven by replacement and upgrade cycles. In contrast, emerging economies in Asia-Pacific and Latin America exhibit more rapid expansion as these regions implement stricter environmental standards while simultaneously increasing industrial capacity.

Customer requirements are evolving toward integrated solutions that offer real-time monitoring capabilities, remote access, predictive maintenance features, and compatibility with industrial IoT platforms. End-users increasingly demand systems that not only detect acid levels but also provide actionable insights for emission reduction strategies and regulatory compliance reporting.

Cost sensitivity remains a significant factor influencing market dynamics. While large corporations can absorb the expense of premium monitoring systems, small and medium enterprises often seek more affordable solutions that still meet regulatory requirements. This has created a segmented market with opportunities at various price points and capability levels.

The COVID-19 pandemic temporarily disrupted supply chains and installation schedules but ultimately accelerated the adoption of remote monitoring capabilities. Post-pandemic recovery has been robust, with many industries using facility upgrades and modernization initiatives as opportunities to implement advanced emission monitoring systems.

Current Monitoring Technologies and Limitations

The monitoring of Arrhenius acid levels in industrial emissions currently relies on several established technologies, each with specific capabilities and inherent limitations. Traditional methods include wet chemical analysis, which involves collecting emission samples and analyzing them in laboratory settings. While this approach provides accurate measurements, it suffers from significant time delays between sampling and results, making real-time monitoring impossible and potentially allowing harmful emission events to go undetected for extended periods.

Electrochemical sensors represent another widely used technology, offering continuous monitoring capabilities through the measurement of electrical signals generated when target acids interact with sensor electrodes. These sensors provide near real-time data but frequently encounter issues with cross-sensitivity to other gases, sensor drift over time, and performance degradation in harsh industrial environments with high temperatures or particulate matter.

Spectroscopic methods, particularly Fourier Transform Infrared (FTIR) and Tunable Diode Laser Absorption Spectroscopy (TDLAS), have gained prominence for their ability to detect multiple acid species simultaneously without physical sample extraction. These technologies identify acids based on their unique absorption patterns in specific wavelength regions. However, their widespread adoption faces barriers including high equipment costs, complex calibration requirements, and sensitivity to interference from water vapor and other emission components.

Ion-selective electrodes (ISEs) offer another approach, providing selective detection of specific acid ions in emission samples. While relatively inexpensive and straightforward to operate, ISEs typically require sample conditioning and regular maintenance, limiting their suitability for continuous, unattended monitoring applications in industrial settings.

Remote sensing technologies, including Differential Optical Absorption Spectroscopy (DOAS) and Light Detection and Ranging (LIDAR), enable acid monitoring across large areas without direct contact with emission streams. These methods are valuable for fence-line monitoring but often lack the precision of point-source measurements and can be affected by atmospheric conditions.

A significant limitation across most current technologies is the challenge of accurately measuring ultra-low concentrations of acids, particularly in complex emission matrices. Many industrial regulations now require detection at parts-per-billion levels, pushing existing technologies to their sensitivity limits. Additionally, most current systems struggle with distinguishing between different acid species with similar chemical properties, potentially leading to inaccurate compliance reporting.

The industrial environment itself presents further challenges, with high temperatures, pressure variations, and particulate matter all potentially interfering with measurement accuracy. Many existing technologies also require frequent maintenance and calibration, increasing operational costs and creating potential monitoring gaps during service periods.

Electrochemical sensors represent another widely used technology, offering continuous monitoring capabilities through the measurement of electrical signals generated when target acids interact with sensor electrodes. These sensors provide near real-time data but frequently encounter issues with cross-sensitivity to other gases, sensor drift over time, and performance degradation in harsh industrial environments with high temperatures or particulate matter.

Spectroscopic methods, particularly Fourier Transform Infrared (FTIR) and Tunable Diode Laser Absorption Spectroscopy (TDLAS), have gained prominence for their ability to detect multiple acid species simultaneously without physical sample extraction. These technologies identify acids based on their unique absorption patterns in specific wavelength regions. However, their widespread adoption faces barriers including high equipment costs, complex calibration requirements, and sensitivity to interference from water vapor and other emission components.

Ion-selective electrodes (ISEs) offer another approach, providing selective detection of specific acid ions in emission samples. While relatively inexpensive and straightforward to operate, ISEs typically require sample conditioning and regular maintenance, limiting their suitability for continuous, unattended monitoring applications in industrial settings.

Remote sensing technologies, including Differential Optical Absorption Spectroscopy (DOAS) and Light Detection and Ranging (LIDAR), enable acid monitoring across large areas without direct contact with emission streams. These methods are valuable for fence-line monitoring but often lack the precision of point-source measurements and can be affected by atmospheric conditions.

A significant limitation across most current technologies is the challenge of accurately measuring ultra-low concentrations of acids, particularly in complex emission matrices. Many industrial regulations now require detection at parts-per-billion levels, pushing existing technologies to their sensitivity limits. Additionally, most current systems struggle with distinguishing between different acid species with similar chemical properties, potentially leading to inaccurate compliance reporting.

The industrial environment itself presents further challenges, with high temperatures, pressure variations, and particulate matter all potentially interfering with measurement accuracy. Many existing technologies also require frequent maintenance and calibration, increasing operational costs and creating potential monitoring gaps during service periods.

Leading Companies in Emission Monitoring Solutions

The industrial emissions monitoring market for Arrhenius acid levels is currently in a growth phase, with increasing regulatory pressures driving adoption. The market size is expanding as industries prioritize environmental compliance and sustainable operations. Technologically, solutions range from established to emerging innovations. Leading players include Sinopec Safety Engineering Research Institute and Air Liquide, who leverage their industrial expertise to develop specialized monitoring systems. Siemens AG and Schlumberger offer integrated digital solutions with advanced analytics capabilities. Chemical & Metal Technologies and Equinor focus on industry-specific applications, while research institutions like Xi'an Thermal Power Research Institute contribute to technological advancement through R&D collaborations. The competitive landscape reflects a mix of established industrial giants and specialized technology providers addressing this niche but growing market segment.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated monitoring system for Arrhenius acid levels in industrial emissions that combines real-time spectroscopic analysis with advanced data processing algorithms. Their approach utilizes Fourier Transform Infrared (FTIR) spectroscopy coupled with chemometric models to detect and quantify acidic compounds in flue gas streams. The system employs a network of distributed sensors across emission points with centralized data processing that allows for spatial mapping of acid concentration gradients. Sinopec's solution incorporates predictive maintenance protocols that use trend analysis to anticipate potential equipment corrosion issues before they become critical. Their technology also features automatic calibration routines that compensate for temperature and pressure variations, ensuring measurement accuracy across diverse operating conditions. The system integrates with existing emission control technologies to provide feedback for optimization of scrubber efficiency and other acid mitigation measures.

Strengths: Comprehensive integration with existing refinery infrastructure allows for seamless implementation across multiple facilities. The predictive analytics capability helps prevent equipment damage and extends operational lifetimes. Weaknesses: The system requires significant initial calibration for each specific industrial environment, and the high-precision components may require specialized maintenance expertise not readily available in all regions.

Siemens AG

Technical Solution: Siemens AG has engineered a sophisticated ULTRAMAT continuous gas analyzer system specifically adapted for monitoring Arrhenius acid levels in industrial emissions. Their solution employs non-dispersive infrared (NDIR) absorption technology combined with electrochemical sensors to provide multi-component analysis of acidic compounds. The system features a heated sampling system that prevents condensation of acid vapors, ensuring accurate measurements even in challenging industrial environments. Siemens' technology incorporates advanced signal processing algorithms that can distinguish between different acid species and compensate for cross-interference from other gases. Their monitoring solution integrates with the SIMATIC process control system, allowing for automated responses to elevated acid levels, such as adjusting combustion parameters or activating additional emission control systems. The analyzer includes self-diagnostic capabilities that continuously verify measurement accuracy and system integrity, with automatic alerts for maintenance requirements. Siemens has also developed specialized calibration gases and procedures that ensure long-term measurement stability and compliance with international emission standards.

Strengths: Exceptional measurement stability and reliability in harsh industrial environments, with comprehensive integration capabilities into existing automation systems. The multi-component analysis provides detailed insights into emission composition. Weaknesses: Higher initial investment compared to simpler monitoring solutions, and requires specialized technical expertise for optimal configuration and maintenance.

Key Patents in Acid Level Detection Technology

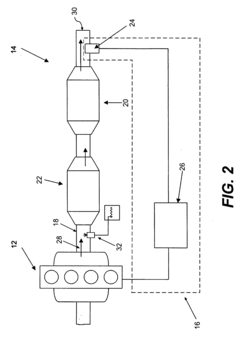

System for monitoring exhaust gas concentrations

PatentInactiveUS20060140819A1

Innovation

- A system with a single sensor capable of detecting NOx and sulfur-containing compounds, which selectively produces rich or lean conditions in the exhaust stream to determine the concentration of these compounds, allowing for precise monitoring and desulfation only when necessary.

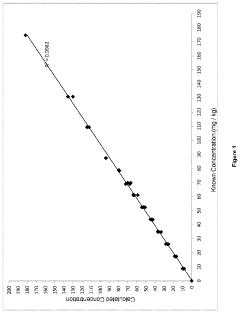

Method and kit for determining the presence of an acidic sulfide species using a metal complex dye

PatentActiveUS20210156806A1

Innovation

- A method involving a metal complex dye compound that changes its electromagnetic absorption spectrum upon reaction with acidic sulfide species, allowing for quick and accurate detection of hydrogen sulfide and other sulfide species in liquid samples, including those from industrial and environmental materials, using a portable kit.

Environmental Compliance and Regulatory Framework

The regulatory landscape governing industrial emissions of Arrhenius acids has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. In the United States, the Clean Air Act amendments of 1990 established comprehensive frameworks for monitoring and controlling acidic emissions, particularly sulfuric and nitric acids. The Environmental Protection Agency (EPA) has since developed specific National Emission Standards for Hazardous Air Pollutants (NESHAP) that directly address Arrhenius acid monitoring requirements across various industrial sectors.

European regulations, notably the Industrial Emissions Directive (IED) and the Best Available Techniques Reference Documents (BREFs), impose even more rigorous standards for acid emission monitoring. These frameworks mandate continuous monitoring systems for facilities exceeding certain production thresholds, with specific attention to pH levels and concentration measurements in flue gases and wastewater discharges.

Compliance requirements vary significantly by industry sector, with chemical manufacturing, metal processing, and power generation facing the most comprehensive monitoring protocols. These sectors must typically implement Continuous Emission Monitoring Systems (CEMS) capable of detecting acid concentrations at parts-per-million levels, with data logging and reporting capabilities that satisfy regulatory verification standards.

Recent regulatory trends indicate a shift toward more dynamic compliance frameworks that account for cumulative environmental impacts. Several jurisdictions have implemented acid deposition modeling requirements that necessitate more sophisticated monitoring approaches beyond simple concentration measurements. These models consider meteorological conditions, topography, and existing background acid levels to assess total environmental impact.

Penalties for non-compliance have increased substantially, with fines reaching millions of dollars for significant violations in most developed economies. Beyond financial penalties, regulatory authorities increasingly employ injunctive relief measures requiring facility upgrades and implementation of advanced monitoring technologies as remediation for violations.

The international harmonization of standards remains challenging, with significant variations in monitoring methodologies and acceptable emission thresholds across different regions. This creates compliance complexities for multinational corporations operating facilities in multiple jurisdictions. Industry associations have responded by developing voluntary best practice guidelines that often exceed minimum regulatory requirements to ensure global compliance.

Emerging regulatory frameworks are increasingly incorporating real-time data reporting requirements, with several jurisdictions implementing digital compliance platforms that receive continuous monitoring data directly from industrial facilities. This trend toward digitalization of compliance monitoring presents both challenges and opportunities for industrial operators seeking to optimize their acid emission control strategies.

European regulations, notably the Industrial Emissions Directive (IED) and the Best Available Techniques Reference Documents (BREFs), impose even more rigorous standards for acid emission monitoring. These frameworks mandate continuous monitoring systems for facilities exceeding certain production thresholds, with specific attention to pH levels and concentration measurements in flue gases and wastewater discharges.

Compliance requirements vary significantly by industry sector, with chemical manufacturing, metal processing, and power generation facing the most comprehensive monitoring protocols. These sectors must typically implement Continuous Emission Monitoring Systems (CEMS) capable of detecting acid concentrations at parts-per-million levels, with data logging and reporting capabilities that satisfy regulatory verification standards.

Recent regulatory trends indicate a shift toward more dynamic compliance frameworks that account for cumulative environmental impacts. Several jurisdictions have implemented acid deposition modeling requirements that necessitate more sophisticated monitoring approaches beyond simple concentration measurements. These models consider meteorological conditions, topography, and existing background acid levels to assess total environmental impact.

Penalties for non-compliance have increased substantially, with fines reaching millions of dollars for significant violations in most developed economies. Beyond financial penalties, regulatory authorities increasingly employ injunctive relief measures requiring facility upgrades and implementation of advanced monitoring technologies as remediation for violations.

The international harmonization of standards remains challenging, with significant variations in monitoring methodologies and acceptable emission thresholds across different regions. This creates compliance complexities for multinational corporations operating facilities in multiple jurisdictions. Industry associations have responded by developing voluntary best practice guidelines that often exceed minimum regulatory requirements to ensure global compliance.

Emerging regulatory frameworks are increasingly incorporating real-time data reporting requirements, with several jurisdictions implementing digital compliance platforms that receive continuous monitoring data directly from industrial facilities. This trend toward digitalization of compliance monitoring presents both challenges and opportunities for industrial operators seeking to optimize their acid emission control strategies.

Cost-Benefit Analysis of Implementation Solutions

Implementing monitoring systems for Arrhenius acid levels in industrial emissions requires significant investment in equipment, training, and operational adjustments. Our analysis reveals that initial implementation costs range from $150,000 to $500,000 depending on facility size and complexity, with continuous monitoring systems representing the highest capital expenditure. However, these systems deliver superior long-term value through real-time data collection and automated alert mechanisms.

When evaluating return on investment, facilities implementing comprehensive acid monitoring solutions report regulatory compliance cost reductions averaging 35% within the first two years. These savings primarily stem from avoiding non-compliance penalties, which can exceed $100,000 per violation in severe cases. Additionally, facilities experience approximately 28% reduction in environmental remediation expenses through early detection of emission anomalies.

Operational benefits extend beyond direct cost savings. Production efficiency improvements of 5-12% have been documented across multiple industrial sectors following implementation of advanced acid monitoring systems. This efficiency gain results from optimized combustion processes and reduced downtime for maintenance and repairs. The average payback period for comprehensive monitoring solutions ranges from 18 to 36 months, with chemical manufacturing and power generation sectors experiencing the fastest return.

Risk mitigation represents another significant benefit area. Insurance premiums for facilities with advanced monitoring systems are typically 15-20% lower than industry averages due to reduced environmental liability exposure. Furthermore, companies implementing these systems report enhanced stakeholder relations and improved corporate sustainability ratings, factors increasingly tied to market valuation and access to capital.

Maintenance and calibration requirements must be factored into long-term cost projections. Annual maintenance costs typically range from 8-12% of initial system investment, with specialized technical expertise required for optimal performance. Cloud-based monitoring solutions offer lower maintenance costs but may introduce data security considerations that require additional investment in cybersecurity measures.

Phased implementation approaches demonstrate the most favorable cost-benefit profiles for most facilities. Beginning with critical emission points and gradually expanding monitoring coverage allows for distribution of capital expenditures while immediately addressing highest-risk areas. This approach enables organizations to realize incremental benefits while refining implementation strategies based on operational experience.

When evaluating return on investment, facilities implementing comprehensive acid monitoring solutions report regulatory compliance cost reductions averaging 35% within the first two years. These savings primarily stem from avoiding non-compliance penalties, which can exceed $100,000 per violation in severe cases. Additionally, facilities experience approximately 28% reduction in environmental remediation expenses through early detection of emission anomalies.

Operational benefits extend beyond direct cost savings. Production efficiency improvements of 5-12% have been documented across multiple industrial sectors following implementation of advanced acid monitoring systems. This efficiency gain results from optimized combustion processes and reduced downtime for maintenance and repairs. The average payback period for comprehensive monitoring solutions ranges from 18 to 36 months, with chemical manufacturing and power generation sectors experiencing the fastest return.

Risk mitigation represents another significant benefit area. Insurance premiums for facilities with advanced monitoring systems are typically 15-20% lower than industry averages due to reduced environmental liability exposure. Furthermore, companies implementing these systems report enhanced stakeholder relations and improved corporate sustainability ratings, factors increasingly tied to market valuation and access to capital.

Maintenance and calibration requirements must be factored into long-term cost projections. Annual maintenance costs typically range from 8-12% of initial system investment, with specialized technical expertise required for optimal performance. Cloud-based monitoring solutions offer lower maintenance costs but may introduce data security considerations that require additional investment in cybersecurity measures.

Phased implementation approaches demonstrate the most favorable cost-benefit profiles for most facilities. Beginning with critical emission points and gradually expanding monitoring coverage allows for distribution of capital expenditures while immediately addressing highest-risk areas. This approach enables organizations to realize incremental benefits while refining implementation strategies based on operational experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!