Nichrome and Its Applications in Precise Temperature Sensors

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has undergone significant evolution since its discovery in the early 20th century. Initially developed as a heating element material, its unique properties quickly led to its adoption in various applications, including precise temperature sensors.

The evolution of nichrome in temperature sensing can be traced through several key stages. In the 1920s, the basic composition of nichrome was established, typically consisting of 80% nickel and 20% chromium. This composition provided a good balance of electrical resistance, temperature stability, and oxidation resistance, making it suitable for use in resistive temperature devices (RTDs).

During the 1940s and 1950s, researchers focused on refining the nichrome composition to enhance its stability and accuracy for temperature measurement. This period saw the introduction of additional elements such as silicon and aluminum in small quantities to improve the alloy's performance. These modifications resulted in nichrome variants with improved temperature coefficients of resistance, allowing for more precise temperature measurements.

The 1960s and 1970s marked a significant leap in nichrome's application in temperature sensors. With the advent of thin-film deposition techniques, it became possible to create nichrome-based sensors with extremely fine geometries. This advancement led to the development of miniaturized temperature sensors with faster response times and higher sensitivity.

In the 1980s and 1990s, the focus shifted towards improving the long-term stability of nichrome-based sensors. Researchers developed new heat treatment and passivation techniques to minimize drift and enhance the sensors' reliability over extended periods. This era also saw the integration of nichrome sensors with advanced electronic circuits, enabling digital temperature measurement and improved signal processing.

The turn of the millennium brought about further refinements in nichrome sensor technology. Nanotechnology advancements allowed for the creation of nanostructured nichrome films, offering unprecedented levels of sensitivity and response time. Additionally, the development of multi-layer sensor designs incorporating nichrome elements led to sensors capable of measuring temperature across wider ranges with improved accuracy.

In recent years, the evolution of nichrome in temperature sensing has focused on enhancing its compatibility with emerging technologies. This includes the development of flexible and stretchable nichrome-based sensors for wearable devices and the integration of nichrome sensors with Internet of Things (IoT) platforms for remote temperature monitoring and control.

Throughout its evolution, nichrome has consistently demonstrated its versatility and reliability in precise temperature measurement applications. From its humble beginnings as a simple heating element to its current status as a key material in advanced temperature sensing technologies, nichrome continues to play a crucial role in the ongoing development of accurate and responsive temperature measurement solutions.

The evolution of nichrome in temperature sensing can be traced through several key stages. In the 1920s, the basic composition of nichrome was established, typically consisting of 80% nickel and 20% chromium. This composition provided a good balance of electrical resistance, temperature stability, and oxidation resistance, making it suitable for use in resistive temperature devices (RTDs).

During the 1940s and 1950s, researchers focused on refining the nichrome composition to enhance its stability and accuracy for temperature measurement. This period saw the introduction of additional elements such as silicon and aluminum in small quantities to improve the alloy's performance. These modifications resulted in nichrome variants with improved temperature coefficients of resistance, allowing for more precise temperature measurements.

The 1960s and 1970s marked a significant leap in nichrome's application in temperature sensors. With the advent of thin-film deposition techniques, it became possible to create nichrome-based sensors with extremely fine geometries. This advancement led to the development of miniaturized temperature sensors with faster response times and higher sensitivity.

In the 1980s and 1990s, the focus shifted towards improving the long-term stability of nichrome-based sensors. Researchers developed new heat treatment and passivation techniques to minimize drift and enhance the sensors' reliability over extended periods. This era also saw the integration of nichrome sensors with advanced electronic circuits, enabling digital temperature measurement and improved signal processing.

The turn of the millennium brought about further refinements in nichrome sensor technology. Nanotechnology advancements allowed for the creation of nanostructured nichrome films, offering unprecedented levels of sensitivity and response time. Additionally, the development of multi-layer sensor designs incorporating nichrome elements led to sensors capable of measuring temperature across wider ranges with improved accuracy.

In recent years, the evolution of nichrome in temperature sensing has focused on enhancing its compatibility with emerging technologies. This includes the development of flexible and stretchable nichrome-based sensors for wearable devices and the integration of nichrome sensors with Internet of Things (IoT) platforms for remote temperature monitoring and control.

Throughout its evolution, nichrome has consistently demonstrated its versatility and reliability in precise temperature measurement applications. From its humble beginnings as a simple heating element to its current status as a key material in advanced temperature sensing technologies, nichrome continues to play a crucial role in the ongoing development of accurate and responsive temperature measurement solutions.

Market Demand Analysis

The market demand for precise temperature sensors utilizing Nichrome has been steadily increasing across various industries. This growth is primarily driven by the expanding applications in sectors such as automotive, aerospace, industrial manufacturing, and healthcare. The automotive industry, in particular, has shown a significant uptake in the use of Nichrome-based temperature sensors for engine management systems, exhaust gas recirculation, and battery thermal management in electric vehicles.

In the aerospace sector, the demand for high-precision temperature sensors is fueled by the need for accurate temperature monitoring in aircraft engines, hydraulic systems, and environmental control systems. The ability of Nichrome-based sensors to withstand extreme temperatures and provide reliable measurements in harsh environments makes them particularly attractive for aerospace applications.

Industrial manufacturing processes, including metal processing, chemical production, and food processing, require precise temperature control to ensure product quality and process efficiency. This has led to an increased adoption of Nichrome-based temperature sensors in these sectors. The sensors' ability to provide accurate readings over a wide temperature range and their durability in corrosive environments contribute to their growing popularity.

The healthcare industry has also emerged as a significant market for precise temperature sensors. Applications range from medical equipment such as incubators and sterilizers to patient monitoring devices. The demand for non-invasive and highly accurate temperature measurement in medical settings has further boosted the market for Nichrome-based sensors.

The global market for temperature sensors, including those utilizing Nichrome, is projected to experience substantial growth in the coming years. This growth is attributed to the increasing automation in various industries, the rise of Internet of Things (IoT) applications, and the growing emphasis on energy efficiency and environmental monitoring.

Emerging technologies such as smart homes, wearable devices, and autonomous vehicles are expected to create new opportunities for precise temperature sensors. These applications require miniaturized, energy-efficient sensors capable of providing accurate and real-time temperature data, further driving the demand for advanced Nichrome-based solutions.

Geographically, North America and Europe currently dominate the market for precise temperature sensors due to their advanced industrial sectors and stringent regulatory requirements. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing investments in healthcare infrastructure.

In the aerospace sector, the demand for high-precision temperature sensors is fueled by the need for accurate temperature monitoring in aircraft engines, hydraulic systems, and environmental control systems. The ability of Nichrome-based sensors to withstand extreme temperatures and provide reliable measurements in harsh environments makes them particularly attractive for aerospace applications.

Industrial manufacturing processes, including metal processing, chemical production, and food processing, require precise temperature control to ensure product quality and process efficiency. This has led to an increased adoption of Nichrome-based temperature sensors in these sectors. The sensors' ability to provide accurate readings over a wide temperature range and their durability in corrosive environments contribute to their growing popularity.

The healthcare industry has also emerged as a significant market for precise temperature sensors. Applications range from medical equipment such as incubators and sterilizers to patient monitoring devices. The demand for non-invasive and highly accurate temperature measurement in medical settings has further boosted the market for Nichrome-based sensors.

The global market for temperature sensors, including those utilizing Nichrome, is projected to experience substantial growth in the coming years. This growth is attributed to the increasing automation in various industries, the rise of Internet of Things (IoT) applications, and the growing emphasis on energy efficiency and environmental monitoring.

Emerging technologies such as smart homes, wearable devices, and autonomous vehicles are expected to create new opportunities for precise temperature sensors. These applications require miniaturized, energy-efficient sensors capable of providing accurate and real-time temperature data, further driving the demand for advanced Nichrome-based solutions.

Geographically, North America and Europe currently dominate the market for precise temperature sensors due to their advanced industrial sectors and stringent regulatory requirements. However, the Asia-Pacific region is anticipated to witness the fastest growth, driven by rapid industrialization, increasing automotive production, and growing investments in healthcare infrastructure.

Technical Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has been widely used in precise temperature sensors due to its unique properties. However, the application of nichrome in this field faces several technical challenges that require careful consideration and innovative solutions.

One of the primary challenges is achieving and maintaining high accuracy in temperature measurements. While nichrome exhibits a relatively stable resistance-temperature relationship, factors such as thermal drift and self-heating can introduce errors in readings. These issues become particularly pronounced in applications requiring extreme precision, such as in scientific research or industrial process control.

The long-term stability of nichrome sensors presents another significant challenge. Over time, the alloy may undergo subtle changes in its microstructure or chemical composition, potentially altering its electrical properties. This can lead to calibration drift, necessitating frequent recalibration or replacement of sensors, which can be costly and time-consuming in critical applications.

Miniaturization of nichrome-based temperature sensors poses additional technical hurdles. As devices become smaller, the challenge lies in maintaining the sensor's performance while reducing its size. This includes issues related to heat dissipation, electrical connections, and ensuring uniform temperature distribution across the sensing element.

The response time of nichrome sensors is another area of concern, particularly in applications requiring rapid temperature measurements. The thermal mass of the sensor and its housing can introduce lag in temperature readings, which may be problematic in dynamic environments or when monitoring fast-changing temperatures.

Environmental factors also present challenges for nichrome sensors. Exposure to harsh chemicals, high humidity, or extreme temperatures can affect the sensor's performance and longevity. Developing protective coatings or encapsulation techniques that do not compromise the sensor's sensitivity is an ongoing area of research.

Interference from electromagnetic fields is a significant issue, especially in industrial settings or near electronic equipment. Shielding nichrome sensors effectively without impacting their performance or increasing their size substantially remains a technical challenge.

Lastly, the manufacturing process of nichrome sensors presents its own set of challenges. Achieving consistent quality and uniformity in the alloy composition, as well as precise control over the sensor's geometry and electrical properties during production, is crucial for ensuring reliable and repeatable performance across different batches of sensors.

Addressing these technical challenges requires ongoing research and development efforts, including exploring new alloy compositions, innovative sensor designs, and advanced manufacturing techniques. Overcoming these hurdles will be key to further enhancing the capabilities and expanding the applications of nichrome-based precise temperature sensors.

One of the primary challenges is achieving and maintaining high accuracy in temperature measurements. While nichrome exhibits a relatively stable resistance-temperature relationship, factors such as thermal drift and self-heating can introduce errors in readings. These issues become particularly pronounced in applications requiring extreme precision, such as in scientific research or industrial process control.

The long-term stability of nichrome sensors presents another significant challenge. Over time, the alloy may undergo subtle changes in its microstructure or chemical composition, potentially altering its electrical properties. This can lead to calibration drift, necessitating frequent recalibration or replacement of sensors, which can be costly and time-consuming in critical applications.

Miniaturization of nichrome-based temperature sensors poses additional technical hurdles. As devices become smaller, the challenge lies in maintaining the sensor's performance while reducing its size. This includes issues related to heat dissipation, electrical connections, and ensuring uniform temperature distribution across the sensing element.

The response time of nichrome sensors is another area of concern, particularly in applications requiring rapid temperature measurements. The thermal mass of the sensor and its housing can introduce lag in temperature readings, which may be problematic in dynamic environments or when monitoring fast-changing temperatures.

Environmental factors also present challenges for nichrome sensors. Exposure to harsh chemicals, high humidity, or extreme temperatures can affect the sensor's performance and longevity. Developing protective coatings or encapsulation techniques that do not compromise the sensor's sensitivity is an ongoing area of research.

Interference from electromagnetic fields is a significant issue, especially in industrial settings or near electronic equipment. Shielding nichrome sensors effectively without impacting their performance or increasing their size substantially remains a technical challenge.

Lastly, the manufacturing process of nichrome sensors presents its own set of challenges. Achieving consistent quality and uniformity in the alloy composition, as well as precise control over the sensor's geometry and electrical properties during production, is crucial for ensuring reliable and repeatable performance across different batches of sensors.

Addressing these technical challenges requires ongoing research and development efforts, including exploring new alloy compositions, innovative sensor designs, and advanced manufacturing techniques. Overcoming these hurdles will be key to further enhancing the capabilities and expanding the applications of nichrome-based precise temperature sensors.

Current Sensor Design

01 Nichrome heating elements in electronic devices

Nichrome is widely used as a heating element in various electronic devices due to its high resistance and ability to withstand high temperatures. It is commonly employed in applications such as electric heaters, ovens, and other heating appliances where precise temperature control is required.- Nichrome heating elements in electronic devices: Nichrome is commonly used as a heating element in various electronic devices due to its high resistance and ability to withstand high temperatures. It is utilized in applications such as electric heaters, thermostats, and temperature sensors. The temperature of nichrome elements can be precisely controlled to achieve desired heating effects in these devices.

- Temperature measurement and control using nichrome: Nichrome is employed in temperature measurement and control systems. Its temperature-dependent resistance properties make it suitable for use in thermocouples and resistance temperature detectors (RTDs). These devices can accurately measure and monitor temperatures in various industrial and scientific applications.

- High-temperature applications of nichrome alloys: Nichrome alloys are utilized in high-temperature applications due to their excellent heat resistance and oxidation resistance. They are used in furnaces, kilns, and other industrial equipment where materials need to withstand extreme temperatures. The composition of nichrome alloys can be adjusted to optimize their performance at different temperature ranges.

- Nichrome wire in electrical resistance heating: Nichrome wire is widely used in electrical resistance heating applications. Its high electrical resistivity and ability to maintain stability at elevated temperatures make it ideal for use in heating elements for appliances, industrial processes, and laboratory equipment. The temperature of nichrome wire can be controlled by adjusting the electrical current passing through it.

- Temperature-dependent properties of nichrome for sensors: The temperature-dependent electrical and mechanical properties of nichrome are exploited in the development of various sensors. These include strain gauges, pressure sensors, and flow meters. The change in resistance of nichrome with temperature allows for accurate measurements and monitoring of different physical parameters in industrial and scientific applications.

02 Temperature sensing and control using nichrome

Nichrome can be utilized in temperature sensing and control systems. Its temperature-dependent resistance properties make it suitable for creating temperature sensors or thermocouples. These sensors can be integrated into various devices to monitor and regulate temperature accurately.Expand Specific Solutions03 Nichrome in thin film technology

Nichrome is used in thin film technology for creating resistive elements and conductive layers. Its properties allow for the fabrication of precise and stable thin film resistors, which are crucial in microelectronics and semiconductor manufacturing processes.Expand Specific Solutions04 High-temperature applications of nichrome

Nichrome's ability to withstand high temperatures makes it suitable for use in extreme thermal environments. It is employed in furnaces, kilns, and other high-temperature industrial applications where materials need to maintain their properties under intense heat.Expand Specific Solutions05 Nichrome in aerospace and aviation

The aerospace and aviation industries utilize nichrome in various applications due to its temperature resistance and stability. It is used in aircraft engine components, de-icing systems, and other high-temperature environments encountered in flight.Expand Specific Solutions

Key Industry Players

The market for nichrome and its applications in precise temperature sensors is in a mature growth stage, with a steady global market size driven by increasing demand for accurate temperature measurement across various industries. The technology has reached a high level of maturity, with established players like Robert Bosch GmbH and Seiko Epson Corp. leading in sensor development. Emerging companies such as Gaona Aero Material Co., Ltd. and Baowu Special Metallurgy Co., Ltd. are focusing on advanced alloy materials, potentially driving innovation in nichrome-based sensors. Research institutions like the Electronics & Telecommunications Research Institute and universities are contributing to further advancements, indicating ongoing refinement and potential for new applications in this well-established field.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed a cutting-edge nichrome-based temperature sensing technology for automotive and industrial applications. Their approach combines thin-film nichrome sensing elements with advanced MEMS fabrication techniques to create highly miniaturized and robust sensors. Bosch's sensors feature a unique suspended membrane structure that provides excellent thermal isolation, resulting in faster response times and reduced power consumption[5]. The company has also implemented proprietary laser trimming processes to achieve high accuracy and interchangeability between sensors. Bosch's nichrome sensors incorporate on-chip diagnostics and self-calibration capabilities, ensuring long-term reliability in demanding automotive environments[6].

Strengths: Excellent miniaturization, fast response times, low power consumption, and advanced self-diagnostic features. Weaknesses: Higher complexity and cost compared to traditional sensing technologies, and potential for mechanical stress-induced errors in some applications.

National Institute for Materials Science IAI

Technical Solution: The National Institute for Materials Science (NIMS) in Japan has conducted extensive research on nichrome alloys for precise temperature sensing applications. Their work focuses on optimizing the composition and microstructure of nichrome films to achieve superior stability and sensitivity. NIMS researchers have developed a novel nanostructured nichrome alloy with enhanced strain resistance and improved TCR linearity[7]. This material shows promise for ultra-high precision temperature measurements in scientific and metrological applications. The institute has also explored the use of advanced deposition techniques, such as atomic layer deposition (ALD), to create ultra-thin nichrome films with exceptional uniformity and control over composition[8].

Strengths: Cutting-edge materials research, potential for ultra-high precision measurements, and advanced fabrication techniques. Weaknesses: Technologies still in research phase, not yet commercially available, and potentially high cost for initial implementation.

Core Nichrome Patents

Surface temperature-measuring device

PatentInactiveEP0289793A3

Innovation

- A self-supporting thermocouple design using two spring-hard nichrome and nickel strips connected at a crossing point, embedded in a high electrical and thermal resistance insulating piece, eliminating the need for additional supporting or pressure parts and minimizing heat dissipation.

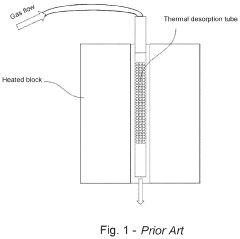

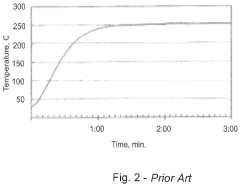

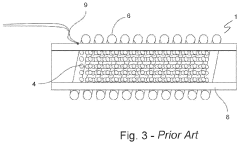

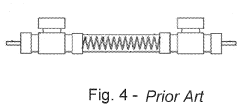

Thermal Desorption Tube for Portable, Battery-Powered Field Analyzer or Line-Powered Analyzer

PatentActiveUS20210088425A1

Innovation

- A thermal desorption tube with an embedded heating element made from a metal with a high Resistance Temperature Coefficient (RTC) value, allowing for precise temperature control by measuring electrical current and voltage drop, ensuring rapid and energy-efficient heating of the sorbent material without overheating.

Material Properties

Nichrome, an alloy primarily composed of nickel and chromium, exhibits unique material properties that make it exceptionally suitable for precise temperature sensing applications. The composition of nichrome typically consists of 80% nickel and 20% chromium, though slight variations exist depending on specific requirements. This alloy's most notable characteristic is its high electrical resistivity, which remains relatively stable across a wide temperature range. This stability is crucial for accurate temperature measurements, as it minimizes errors due to resistance fluctuations.

The thermal expansion coefficient of nichrome is another key property that contributes to its effectiveness in temperature sensors. With a low and predictable thermal expansion rate, nichrome maintains dimensional stability under varying temperatures, ensuring consistent performance in sensing applications. This property is particularly valuable in environments where thermal cycling is frequent or extreme.

Nichrome also boasts excellent oxidation resistance, attributed to the formation of a protective chromium oxide layer on its surface when exposed to high temperatures. This self-passivating behavior enhances the longevity and reliability of nichrome-based temperature sensors, especially in harsh or corrosive environments. The alloy's high melting point, typically around 1400°C, further extends its operational range, allowing for accurate temperature sensing in extreme heat conditions.

The mechanical properties of nichrome complement its electrical and thermal characteristics. It exhibits good tensile strength and ductility, facilitating the manufacturing of thin wires or films commonly used in temperature sensing elements. These properties ensure that nichrome-based sensors can withstand mechanical stresses associated with installation, operation, and maintenance.

Furthermore, nichrome demonstrates remarkable chemical stability, resisting degradation from various chemical agents. This stability is crucial in maintaining sensor accuracy over extended periods, particularly in industrial or laboratory settings where exposure to diverse chemical environments is common. The alloy's low magnetic susceptibility is another advantageous property, minimizing interference in applications where magnetic fields are present or where electromagnetic compatibility is a concern.

In terms of thermal conductivity, nichrome strikes a balance that is beneficial for temperature sensing. Its moderate thermal conductivity allows for quick response to temperature changes while preventing rapid heat dissipation that could affect measurement accuracy. This property, combined with its high specific heat capacity, contributes to the sensor's ability to provide stable and responsive temperature readings.

The thermal expansion coefficient of nichrome is another key property that contributes to its effectiveness in temperature sensors. With a low and predictable thermal expansion rate, nichrome maintains dimensional stability under varying temperatures, ensuring consistent performance in sensing applications. This property is particularly valuable in environments where thermal cycling is frequent or extreme.

Nichrome also boasts excellent oxidation resistance, attributed to the formation of a protective chromium oxide layer on its surface when exposed to high temperatures. This self-passivating behavior enhances the longevity and reliability of nichrome-based temperature sensors, especially in harsh or corrosive environments. The alloy's high melting point, typically around 1400°C, further extends its operational range, allowing for accurate temperature sensing in extreme heat conditions.

The mechanical properties of nichrome complement its electrical and thermal characteristics. It exhibits good tensile strength and ductility, facilitating the manufacturing of thin wires or films commonly used in temperature sensing elements. These properties ensure that nichrome-based sensors can withstand mechanical stresses associated with installation, operation, and maintenance.

Furthermore, nichrome demonstrates remarkable chemical stability, resisting degradation from various chemical agents. This stability is crucial in maintaining sensor accuracy over extended periods, particularly in industrial or laboratory settings where exposure to diverse chemical environments is common. The alloy's low magnetic susceptibility is another advantageous property, minimizing interference in applications where magnetic fields are present or where electromagnetic compatibility is a concern.

In terms of thermal conductivity, nichrome strikes a balance that is beneficial for temperature sensing. Its moderate thermal conductivity allows for quick response to temperature changes while preventing rapid heat dissipation that could affect measurement accuracy. This property, combined with its high specific heat capacity, contributes to the sensor's ability to provide stable and responsive temperature readings.

Calibration Techniques

Calibration techniques play a crucial role in ensuring the accuracy and reliability of nichrome-based precise temperature sensors. These techniques involve a series of procedures and methods to adjust and verify the sensor's output against known reference temperatures.

One of the primary calibration methods for nichrome temperature sensors is the comparison calibration technique. This approach involves comparing the sensor's output with a highly accurate reference thermometer at multiple temperature points. The process typically begins with immersing both the sensor and reference thermometer in a temperature-controlled bath or furnace. As the temperature is gradually changed, readings from both devices are recorded and compared. This method allows for the creation of a calibration curve that can be used to correct the sensor's output across its entire operating range.

Another important calibration technique is the fixed-point method. This approach utilizes the known melting or freezing points of pure substances as reference temperatures. For example, the triple point of water (0.01°C) and the freezing point of zinc (419.527°C) are commonly used fixed points. By exposing the nichrome sensor to these precisely defined temperatures, technicians can establish accurate calibration points and adjust the sensor's response accordingly.

In-situ calibration is becoming increasingly popular for nichrome temperature sensors in industrial applications. This method involves calibrating the sensor while it remains installed in its operating environment. By using portable calibration equipment or comparing the sensor's output with a temporarily installed reference sensor, technicians can account for environmental factors that may affect the sensor's performance.

For high-precision applications, multi-point calibration is often employed. This technique involves calibrating the sensor at multiple temperature points across its operating range. By doing so, non-linearities in the sensor's response can be identified and compensated for, resulting in improved accuracy across the entire measurement range.

Digital calibration techniques have also gained prominence with the advent of smart sensors and digital signal processing. These methods involve storing calibration data directly in the sensor's memory or in associated electronics. This allows for real-time correction of sensor output based on complex calibration algorithms, improving overall accuracy and reducing drift over time.

Periodic recalibration is essential to maintain the accuracy of nichrome temperature sensors. The frequency of recalibration depends on factors such as the sensor's application, environmental conditions, and required accuracy. Regular calibration checks and adjustments help compensate for sensor drift and ensure continued measurement reliability.

One of the primary calibration methods for nichrome temperature sensors is the comparison calibration technique. This approach involves comparing the sensor's output with a highly accurate reference thermometer at multiple temperature points. The process typically begins with immersing both the sensor and reference thermometer in a temperature-controlled bath or furnace. As the temperature is gradually changed, readings from both devices are recorded and compared. This method allows for the creation of a calibration curve that can be used to correct the sensor's output across its entire operating range.

Another important calibration technique is the fixed-point method. This approach utilizes the known melting or freezing points of pure substances as reference temperatures. For example, the triple point of water (0.01°C) and the freezing point of zinc (419.527°C) are commonly used fixed points. By exposing the nichrome sensor to these precisely defined temperatures, technicians can establish accurate calibration points and adjust the sensor's response accordingly.

In-situ calibration is becoming increasingly popular for nichrome temperature sensors in industrial applications. This method involves calibrating the sensor while it remains installed in its operating environment. By using portable calibration equipment or comparing the sensor's output with a temporarily installed reference sensor, technicians can account for environmental factors that may affect the sensor's performance.

For high-precision applications, multi-point calibration is often employed. This technique involves calibrating the sensor at multiple temperature points across its operating range. By doing so, non-linearities in the sensor's response can be identified and compensated for, resulting in improved accuracy across the entire measurement range.

Digital calibration techniques have also gained prominence with the advent of smart sensors and digital signal processing. These methods involve storing calibration data directly in the sensor's memory or in associated electronics. This allows for real-time correction of sensor output based on complex calibration algorithms, improving overall accuracy and reducing drift over time.

Periodic recalibration is essential to maintain the accuracy of nichrome temperature sensors. The frequency of recalibration depends on factors such as the sensor's application, environmental conditions, and required accuracy. Regular calibration checks and adjustments help compensate for sensor drift and ensure continued measurement reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!