Nichrome and Its Future in Smart Heating Technologies

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Smart Heating Goals

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in heating technologies for over a century. Its evolution has been marked by continuous improvements in composition and manufacturing processes, leading to enhanced performance and durability. As we look towards the future of smart heating technologies, nichrome's role is poised for significant transformation and expansion.

The historical development of nichrome began in the early 1900s, with its initial application in electrical resistance heating elements. Over the decades, researchers and engineers have fine-tuned the nickel-chromium ratio and introduced additional elements to optimize its properties for various applications. This ongoing refinement has resulted in nichrome variants with improved heat resistance, longevity, and electrical characteristics.

In the context of smart heating technologies, the evolution of nichrome is closely tied to the broader trends in IoT (Internet of Things) and energy efficiency. The integration of nichrome-based heating elements with advanced sensors, microcontrollers, and wireless connectivity is opening up new possibilities for precise temperature control and energy management. This convergence is driving the development of intelligent heating systems that can adapt to environmental conditions and user preferences in real-time.

The technological goals for nichrome in smart heating applications are multifaceted. One primary objective is to enhance the material's responsiveness to rapid temperature changes, enabling faster heating and cooling cycles. This improvement would allow for more dynamic and efficient heating solutions in various sectors, from consumer appliances to industrial processes.

Another crucial goal is the development of nichrome-based heating elements with built-in sensing capabilities. By incorporating temperature and current sensors directly into the nichrome structure, manufacturers aim to create self-monitoring heating systems that can optimize performance and detect potential failures before they occur. This integration would significantly enhance the reliability and safety of smart heating devices.

Furthermore, researchers are exploring ways to improve nichrome's energy efficiency, a critical factor in the era of sustainability and smart energy management. This includes developing nichrome alloys with lower electrical resistance at operating temperatures, which could reduce power consumption without compromising heating performance.

As we progress towards more advanced smart heating technologies, the evolution of nichrome is expected to focus on its compatibility with emerging manufacturing techniques, such as 3D printing and nanotechnology. These advancements could lead to the creation of complex, customized heating elements that are optimized for specific applications and integrated seamlessly into smart devices and systems.

The historical development of nichrome began in the early 1900s, with its initial application in electrical resistance heating elements. Over the decades, researchers and engineers have fine-tuned the nickel-chromium ratio and introduced additional elements to optimize its properties for various applications. This ongoing refinement has resulted in nichrome variants with improved heat resistance, longevity, and electrical characteristics.

In the context of smart heating technologies, the evolution of nichrome is closely tied to the broader trends in IoT (Internet of Things) and energy efficiency. The integration of nichrome-based heating elements with advanced sensors, microcontrollers, and wireless connectivity is opening up new possibilities for precise temperature control and energy management. This convergence is driving the development of intelligent heating systems that can adapt to environmental conditions and user preferences in real-time.

The technological goals for nichrome in smart heating applications are multifaceted. One primary objective is to enhance the material's responsiveness to rapid temperature changes, enabling faster heating and cooling cycles. This improvement would allow for more dynamic and efficient heating solutions in various sectors, from consumer appliances to industrial processes.

Another crucial goal is the development of nichrome-based heating elements with built-in sensing capabilities. By incorporating temperature and current sensors directly into the nichrome structure, manufacturers aim to create self-monitoring heating systems that can optimize performance and detect potential failures before they occur. This integration would significantly enhance the reliability and safety of smart heating devices.

Furthermore, researchers are exploring ways to improve nichrome's energy efficiency, a critical factor in the era of sustainability and smart energy management. This includes developing nichrome alloys with lower electrical resistance at operating temperatures, which could reduce power consumption without compromising heating performance.

As we progress towards more advanced smart heating technologies, the evolution of nichrome is expected to focus on its compatibility with emerging manufacturing techniques, such as 3D printing and nanotechnology. These advancements could lead to the creation of complex, customized heating elements that are optimized for specific applications and integrated seamlessly into smart devices and systems.

Smart Heating Market Demand Analysis

The smart heating market has experienced significant growth in recent years, driven by increasing consumer demand for energy-efficient and connected home solutions. This trend is expected to continue, with the global smart thermostat market projected to reach $6.8 billion by 2026, growing at a CAGR of 23.1% from 2021 to 2026. The adoption of smart heating technologies is particularly strong in North America and Europe, where consumers are increasingly aware of energy conservation and seek ways to reduce their carbon footprint.

One of the key drivers of market demand is the potential for energy savings. Smart heating systems, which often incorporate nichrome heating elements, can reduce energy consumption by up to 31% compared to traditional heating methods. This not only translates to cost savings for consumers but also aligns with growing environmental concerns and government regulations aimed at reducing energy consumption in buildings.

The integration of smart heating technologies with home automation systems and IoT devices is another factor fueling market growth. Consumers are increasingly looking for seamless connectivity and control over their home environment, with 57% of smart home device owners citing convenience as a primary reason for adoption. This trend has led to the development of more sophisticated heating systems that can be controlled remotely via smartphones or voice assistants, offering personalized comfort and improved energy management.

In the commercial sector, there is a growing demand for smart heating solutions in office buildings, hotels, and other public spaces. Facility managers are recognizing the benefits of intelligent heating systems in optimizing energy use and improving occupant comfort. The commercial smart HVAC market is expected to grow at a CAGR of 12.5% from 2021 to 2026, with nichrome-based heating elements playing a crucial role in these systems.

The COVID-19 pandemic has also influenced market demand, with increased focus on indoor air quality and the need for touchless control systems. This has led to the development of smart heating solutions that incorporate air purification features and can be controlled through mobile apps or voice commands, minimizing physical contact with devices.

As the market for smart heating technologies continues to expand, there is a growing need for advanced materials like nichrome that can meet the demands of these innovative systems. The ability of nichrome to provide precise temperature control, rapid heating, and energy efficiency positions it as a key component in the future of smart heating technologies.

One of the key drivers of market demand is the potential for energy savings. Smart heating systems, which often incorporate nichrome heating elements, can reduce energy consumption by up to 31% compared to traditional heating methods. This not only translates to cost savings for consumers but also aligns with growing environmental concerns and government regulations aimed at reducing energy consumption in buildings.

The integration of smart heating technologies with home automation systems and IoT devices is another factor fueling market growth. Consumers are increasingly looking for seamless connectivity and control over their home environment, with 57% of smart home device owners citing convenience as a primary reason for adoption. This trend has led to the development of more sophisticated heating systems that can be controlled remotely via smartphones or voice assistants, offering personalized comfort and improved energy management.

In the commercial sector, there is a growing demand for smart heating solutions in office buildings, hotels, and other public spaces. Facility managers are recognizing the benefits of intelligent heating systems in optimizing energy use and improving occupant comfort. The commercial smart HVAC market is expected to grow at a CAGR of 12.5% from 2021 to 2026, with nichrome-based heating elements playing a crucial role in these systems.

The COVID-19 pandemic has also influenced market demand, with increased focus on indoor air quality and the need for touchless control systems. This has led to the development of smart heating solutions that incorporate air purification features and can be controlled through mobile apps or voice commands, minimizing physical contact with devices.

As the market for smart heating technologies continues to expand, there is a growing need for advanced materials like nichrome that can meet the demands of these innovative systems. The ability of nichrome to provide precise temperature control, rapid heating, and energy efficiency positions it as a key component in the future of smart heating technologies.

Nichrome Technology Status and Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in heating technologies for decades. However, its current status and future challenges in smart heating technologies are complex and multifaceted.

The global market for smart heating systems is experiencing rapid growth, with nichrome playing a crucial role in many applications. Its high resistance to oxidation and corrosion, coupled with excellent electrical resistivity, makes it ideal for heating elements in smart devices. However, the increasing demand for more efficient and responsive heating solutions is pushing the boundaries of nichrome's capabilities.

One of the main challenges facing nichrome in smart heating technologies is its relatively slow response time compared to newer materials. As smart heating systems require rapid temperature changes and precise control, this limitation is becoming more apparent. Researchers and engineers are exploring ways to enhance nichrome's thermal responsiveness through various methods, including altering its composition and developing new manufacturing techniques.

Another significant challenge is the energy efficiency of nichrome-based heating elements. While nichrome is reliable and cost-effective, it may not meet the stringent energy efficiency standards that are becoming increasingly important in smart home and industrial applications. This has led to a surge in research focused on improving nichrome's energy conversion efficiency or finding alternative materials that can outperform it.

The miniaturization trend in smart devices also poses a challenge for nichrome. As devices become smaller and more compact, there is a growing need for heating elements that can deliver high performance in confined spaces. This has spurred innovation in nichrome thin-film technology and the exploration of novel nichrome-based nanostructures.

Geographically, the development and application of nichrome in smart heating technologies are not evenly distributed. Countries with advanced manufacturing capabilities, such as Japan, Germany, and the United States, are at the forefront of nichrome innovation. However, emerging economies like China and India are rapidly catching up, investing heavily in research and development to close the technological gap.

Despite these challenges, nichrome continues to evolve. Recent advancements include the development of nichrome alloys with improved thermal properties and the integration of nichrome into smart composite materials. These innovations aim to address the current limitations while leveraging nichrome's proven reliability and cost-effectiveness.

In conclusion, while nichrome faces several technological hurdles in the context of smart heating technologies, ongoing research and development efforts are focused on overcoming these challenges. The future of nichrome in this field will likely depend on the success of these initiatives and the emergence of competing materials and technologies.

The global market for smart heating systems is experiencing rapid growth, with nichrome playing a crucial role in many applications. Its high resistance to oxidation and corrosion, coupled with excellent electrical resistivity, makes it ideal for heating elements in smart devices. However, the increasing demand for more efficient and responsive heating solutions is pushing the boundaries of nichrome's capabilities.

One of the main challenges facing nichrome in smart heating technologies is its relatively slow response time compared to newer materials. As smart heating systems require rapid temperature changes and precise control, this limitation is becoming more apparent. Researchers and engineers are exploring ways to enhance nichrome's thermal responsiveness through various methods, including altering its composition and developing new manufacturing techniques.

Another significant challenge is the energy efficiency of nichrome-based heating elements. While nichrome is reliable and cost-effective, it may not meet the stringent energy efficiency standards that are becoming increasingly important in smart home and industrial applications. This has led to a surge in research focused on improving nichrome's energy conversion efficiency or finding alternative materials that can outperform it.

The miniaturization trend in smart devices also poses a challenge for nichrome. As devices become smaller and more compact, there is a growing need for heating elements that can deliver high performance in confined spaces. This has spurred innovation in nichrome thin-film technology and the exploration of novel nichrome-based nanostructures.

Geographically, the development and application of nichrome in smart heating technologies are not evenly distributed. Countries with advanced manufacturing capabilities, such as Japan, Germany, and the United States, are at the forefront of nichrome innovation. However, emerging economies like China and India are rapidly catching up, investing heavily in research and development to close the technological gap.

Despite these challenges, nichrome continues to evolve. Recent advancements include the development of nichrome alloys with improved thermal properties and the integration of nichrome into smart composite materials. These innovations aim to address the current limitations while leveraging nichrome's proven reliability and cost-effectiveness.

In conclusion, while nichrome faces several technological hurdles in the context of smart heating technologies, ongoing research and development efforts are focused on overcoming these challenges. The future of nichrome in this field will likely depend on the success of these initiatives and the emergence of competing materials and technologies.

Current Smart Heating Solutions

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Nichrome in heating elements and electrical devices: Nichrome is widely used in heating elements for various electrical devices due to its high resistance and ability to withstand high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's properties allow for efficient and controlled heat generation in these applications.

- Nichrome in thin film resistors and electronic components: Nichrome is utilized in the production of thin film resistors and other electronic components. Its stable electrical properties and ability to be deposited in thin layers make it suitable for miniaturized electronic devices and integrated circuits. The alloy's resistance to oxidation contributes to the longevity of these components.

- Manufacturing processes for nichrome products: Various manufacturing processes are employed to produce nichrome products, including wire drawing, thin film deposition, and powder metallurgy. These processes are optimized to achieve desired properties such as specific resistivity, tensile strength, and surface finish. Heat treatment and surface coating techniques may also be applied to enhance performance characteristics.

- Innovations and applications of nichrome in emerging technologies: Ongoing research and development efforts are focused on expanding the applications of nichrome in emerging technologies. This includes its use in advanced sensors, MEMS devices, and energy harvesting systems. Modifications to the alloy composition and structure are being explored to enhance its performance in specific applications and extreme environments.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes are optimized to achieve desired physical and electrical properties for specific applications, such as heating elements or sensors.Expand Specific Solutions03 Applications in electronic devices and sensors

Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is employed in the fabrication of thin-film resistors, temperature sensors, and other electronic components that require precise resistance values and temperature stability.Expand Specific Solutions04 Heating element applications

Nichrome is extensively used in heating elements for various applications, including household appliances, industrial heaters, and laboratory equipment. Its high resistance to oxidation at elevated temperatures and uniform heating properties make it an ideal material for these applications.Expand Specific Solutions05 Surface treatment and coating techniques

Various surface treatment and coating techniques are applied to nichrome components to enhance their performance and durability. These include oxidation-resistant coatings, insulation layers, and surface modifications to improve adhesion or electrical properties for specific applications.Expand Specific Solutions

Key Players in Nichrome and Smart Heating

The market for nichrome in smart heating technologies is in a growth phase, driven by increasing demand for energy-efficient and precise temperature control solutions. The global smart heating market is expanding rapidly, with projections indicating significant growth in the coming years. While nichrome technology is mature, its application in smart heating is evolving, with companies like Sunamp Ltd. and Akurate Dynamics LLC innovating in heat battery storage and spray foam technologies respectively. Established players such as Panasonic Holdings Corp. and Samsung Electronics Co., Ltd. are leveraging their expertise to integrate nichrome into advanced heating systems. Specialized manufacturers like Yancheng Xinyang Electric Heating Material Co., Ltd. and Watlow Electric Manufacturing Co. are focusing on high-performance nichrome alloys for specific industrial applications.

Sunamp Ltd.

Technical Solution: Sunamp has developed innovative thermal storage technologies that incorporate nichrome-based heating elements. Their Phase Change Material (PCM) heat batteries use nichrome heating elements to charge the PCM, storing thermal energy for later use[10]. This technology allows for efficient heat storage and release, reducing energy consumption in heating applications. Sunamp has also integrated their PCM heat batteries with smart control systems, enabling demand-response heating solutions for residential and commercial buildings[11]. The company's UniQ heat batteries, which utilize nichrome heating elements, can be connected to various heat sources and provide hot water and space heating on demand[12].

Strengths: Efficient thermal energy storage, integration with renewable energy sources, scalable for various applications. Weaknesses: Higher initial cost compared to traditional heating systems, potential for thermal degradation of PCM over time.

Arkema France SA

Technical Solution: Arkema has contributed to the advancement of nichrome-based smart heating technologies through materials innovation. They have developed high-performance polymers and coatings that enhance the durability and efficiency of nichrome heating elements[13]. Arkema's Kynar® fluoropolymer coatings are used to protect nichrome wires in extreme temperature and corrosive environments, extending the lifespan of heating elements in industrial applications[14]. The company has also developed conductive polymer composites that can be used in conjunction with nichrome elements to create flexible and uniform heating surfaces for automotive and aerospace applications[15]. Arkema's materials enable the miniaturization of heating elements, facilitating their integration into smart, compact devices.

Strengths: Enhanced durability of nichrome elements, enabling new form factors and applications, improved chemical resistance. Weaknesses: Potentially higher material costs, limited to specific applications requiring advanced materials.

Nichrome Innovations for Smart Heating

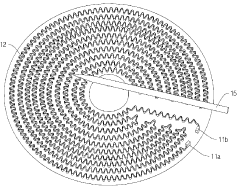

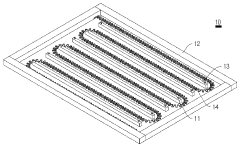

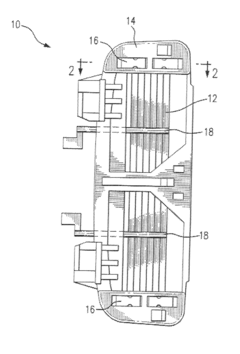

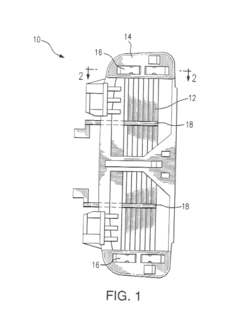

Heating apparatus having structure of nichrome strip

PatentInactiveKR1020150058831A

Innovation

- A heater device with a nichrome strip structure that extends in a screw or zigzag form, varying in thickness and length to optimize resistance and heat generation, incorporating a detection sensor and control unit for voltage regulation to enhance efficiency.

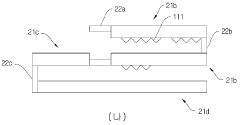

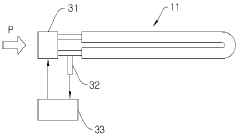

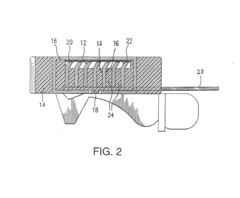

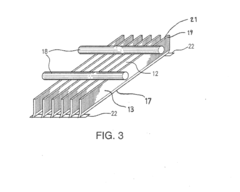

Razor with blade heating system

PatentActiveUS20140245611A1

Innovation

- The use of high resistance electrically conductive contact segments, such as Nichrome, connected to the back edges of razor blades with standard conductive wires, forming an electric circuit that generates heat through electric current flow, combined with a radiator effect to distribute heat uniformly across the blades, allowing for dual heat control with minimal voltage and efficient battery power usage.

Energy Efficiency Regulations

Energy efficiency regulations play a crucial role in shaping the future of smart heating technologies, including those utilizing Nichrome. As governments worldwide strive to reduce energy consumption and carbon emissions, these regulations have become increasingly stringent, driving innovation in the heating industry.

In recent years, many countries have implemented strict energy efficiency standards for heating appliances. The European Union's Ecodesign Directive, for instance, sets minimum energy performance requirements for various products, including electric heating devices. Similarly, the United States Department of Energy has established energy conservation standards for residential furnaces and boilers.

These regulations have spurred manufacturers to develop more efficient heating solutions, with Nichrome-based technologies at the forefront of this innovation. Smart heating systems incorporating Nichrome elements have emerged as a promising solution to meet these stringent requirements. These systems can precisely control temperature and power consumption, optimizing energy use while maintaining comfort levels.

The impact of energy efficiency regulations on Nichrome-based heating technologies is multifaceted. Manufacturers are investing heavily in research and development to improve the thermal properties of Nichrome alloys, enhancing their efficiency and responsiveness. This has led to the development of advanced Nichrome compositions that offer superior heat distribution and faster heating times, reducing overall energy consumption.

Moreover, these regulations have accelerated the integration of smart controls and IoT connectivity in Nichrome-based heating systems. By leveraging data analytics and machine learning algorithms, these smart systems can adapt to user behavior and environmental conditions, further optimizing energy usage. This trend aligns with the broader push towards smart home technologies and energy management systems.

The regulatory landscape is expected to continue evolving, with even more stringent efficiency standards on the horizon. This will likely drive further innovation in Nichrome-based heating technologies, potentially leading to breakthroughs in materials science and control systems. As a result, we can anticipate the development of ultra-efficient heating solutions that not only meet but exceed future energy efficiency requirements.

In conclusion, energy efficiency regulations are a key driver in the advancement of Nichrome-based smart heating technologies. As these regulations become more demanding, they will continue to shape the industry, fostering innovation and pushing the boundaries of what is possible in energy-efficient heating solutions.

In recent years, many countries have implemented strict energy efficiency standards for heating appliances. The European Union's Ecodesign Directive, for instance, sets minimum energy performance requirements for various products, including electric heating devices. Similarly, the United States Department of Energy has established energy conservation standards for residential furnaces and boilers.

These regulations have spurred manufacturers to develop more efficient heating solutions, with Nichrome-based technologies at the forefront of this innovation. Smart heating systems incorporating Nichrome elements have emerged as a promising solution to meet these stringent requirements. These systems can precisely control temperature and power consumption, optimizing energy use while maintaining comfort levels.

The impact of energy efficiency regulations on Nichrome-based heating technologies is multifaceted. Manufacturers are investing heavily in research and development to improve the thermal properties of Nichrome alloys, enhancing their efficiency and responsiveness. This has led to the development of advanced Nichrome compositions that offer superior heat distribution and faster heating times, reducing overall energy consumption.

Moreover, these regulations have accelerated the integration of smart controls and IoT connectivity in Nichrome-based heating systems. By leveraging data analytics and machine learning algorithms, these smart systems can adapt to user behavior and environmental conditions, further optimizing energy usage. This trend aligns with the broader push towards smart home technologies and energy management systems.

The regulatory landscape is expected to continue evolving, with even more stringent efficiency standards on the horizon. This will likely drive further innovation in Nichrome-based heating technologies, potentially leading to breakthroughs in materials science and control systems. As a result, we can anticipate the development of ultra-efficient heating solutions that not only meet but exceed future energy efficiency requirements.

In conclusion, energy efficiency regulations are a key driver in the advancement of Nichrome-based smart heating technologies. As these regulations become more demanding, they will continue to shape the industry, fostering innovation and pushing the boundaries of what is possible in energy-efficient heating solutions.

Safety Standards for Smart Heating Devices

Safety standards for smart heating devices have become increasingly crucial as the integration of nichrome and other advanced materials in heating technologies continues to evolve. These standards are designed to ensure the safe operation of smart heating devices, protecting consumers from potential hazards while promoting innovation in the industry.

One of the primary safety concerns addressed by these standards is the prevention of overheating and fire risks. Smart heating devices incorporating nichrome elements must undergo rigorous testing to demonstrate their ability to maintain safe operating temperatures under various conditions. This includes stress testing under prolonged use, power fluctuations, and potential malfunction scenarios.

Electrical safety is another critical aspect covered by these standards. As smart heating devices often connect to home networks and power systems, they must comply with stringent electrical safety regulations. This includes proper insulation, grounding, and protection against electrical surges and short circuits. The standards also address the potential for electromagnetic interference, ensuring that these devices do not disrupt other electronic equipment in the home.

The integration of smart features introduces new safety considerations related to cybersecurity and data protection. Standards now require manufacturers to implement robust security measures to prevent unauthorized access to device controls and user data. This includes secure communication protocols, regular software updates, and fail-safe mechanisms in case of connectivity issues.

Energy efficiency is an increasingly important aspect of safety standards for smart heating devices. While not directly related to physical safety, efficient energy use contributes to overall system stability and reduces the risk of electrical overload. Standards now often include requirements for energy consumption ratings and smart energy management features.

As the technology advances, safety standards are evolving to address the unique challenges posed by new materials and designs. For instance, the use of nichrome in flexible heating elements requires specific safety considerations regarding durability and heat distribution. Standards are being developed to ensure these innovative applications maintain the same level of safety as traditional heating systems.

Compliance with these safety standards is typically verified through a combination of laboratory testing, field trials, and documentation review. Certification bodies play a crucial role in assessing and validating the safety of smart heating devices before they can be brought to market. This process helps to ensure that consumers can trust in the safety and reliability of these innovative heating solutions.

One of the primary safety concerns addressed by these standards is the prevention of overheating and fire risks. Smart heating devices incorporating nichrome elements must undergo rigorous testing to demonstrate their ability to maintain safe operating temperatures under various conditions. This includes stress testing under prolonged use, power fluctuations, and potential malfunction scenarios.

Electrical safety is another critical aspect covered by these standards. As smart heating devices often connect to home networks and power systems, they must comply with stringent electrical safety regulations. This includes proper insulation, grounding, and protection against electrical surges and short circuits. The standards also address the potential for electromagnetic interference, ensuring that these devices do not disrupt other electronic equipment in the home.

The integration of smart features introduces new safety considerations related to cybersecurity and data protection. Standards now require manufacturers to implement robust security measures to prevent unauthorized access to device controls and user data. This includes secure communication protocols, regular software updates, and fail-safe mechanisms in case of connectivity issues.

Energy efficiency is an increasingly important aspect of safety standards for smart heating devices. While not directly related to physical safety, efficient energy use contributes to overall system stability and reduces the risk of electrical overload. Standards now often include requirements for energy consumption ratings and smart energy management features.

As the technology advances, safety standards are evolving to address the unique challenges posed by new materials and designs. For instance, the use of nichrome in flexible heating elements requires specific safety considerations regarding durability and heat distribution. Standards are being developed to ensure these innovative applications maintain the same level of safety as traditional heating systems.

Compliance with these safety standards is typically verified through a combination of laboratory testing, field trials, and documentation review. Certification bodies play a crucial role in assessing and validating the safety of smart heating devices before they can be brought to market. This process helps to ensure that consumers can trust in the safety and reliability of these innovative heating solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!