Nichrome Applications in Cutting-Edge Metallurgy

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has undergone significant evolution since its inception in the early 20th century. Initially developed as a resistance heating element, nichrome has found its way into cutting-edge metallurgical applications due to its unique properties and versatility.

The evolution of nichrome in metallurgy can be traced through several key stages. In its early days, nichrome was primarily used in electrical heating elements due to its high resistivity and excellent oxidation resistance. As metallurgical processes advanced, the potential of nichrome in high-temperature applications became apparent, leading to its adoption in furnace components and thermal processing equipment.

The 1960s and 1970s saw a surge in nichrome's use in aerospace and industrial applications, where its ability to maintain strength and resist corrosion at elevated temperatures proved invaluable. This period marked a significant shift in nichrome's role from a purely electrical material to a critical component in advanced metallurgical processes.

In recent decades, the focus has shifted towards optimizing nichrome's composition and manufacturing techniques to enhance its performance in cutting-edge metallurgical applications. Research has been directed towards improving its microstructure, thermal stability, and mechanical properties at extreme temperatures.

The current objectives in nichrome research and development for metallurgical applications are multifaceted. One primary goal is to extend the temperature range at which nichrome can operate effectively, pushing the boundaries of high-temperature metallurgical processes. This involves exploring new alloying elements and heat treatment techniques to enhance nichrome's already impressive heat resistance.

Another objective is to improve nichrome's resistance to corrosion and oxidation in aggressive environments, particularly in molten metal handling and processing. This aim is crucial for expanding nichrome's applications in advanced smelting and refining processes.

Researchers are also focusing on developing nichrome-based composites and coatings to combine its thermal properties with other desirable characteristics such as improved wear resistance or electrical conductivity. These developments could open up new avenues for nichrome in specialized metallurgical applications.

The miniaturization trend in various industries has led to a new objective: adapting nichrome for use in micro-scale metallurgical processes. This includes its potential application in additive manufacturing techniques for producing complex, high-temperature resistant components.

Lastly, there is a growing emphasis on making nichrome more sustainable and cost-effective. This involves optimizing production processes to reduce energy consumption and exploring recycling methods to recover and reuse nichrome from end-of-life products, aligning with the broader goals of sustainable metallurgy.

The evolution of nichrome in metallurgy can be traced through several key stages. In its early days, nichrome was primarily used in electrical heating elements due to its high resistivity and excellent oxidation resistance. As metallurgical processes advanced, the potential of nichrome in high-temperature applications became apparent, leading to its adoption in furnace components and thermal processing equipment.

The 1960s and 1970s saw a surge in nichrome's use in aerospace and industrial applications, where its ability to maintain strength and resist corrosion at elevated temperatures proved invaluable. This period marked a significant shift in nichrome's role from a purely electrical material to a critical component in advanced metallurgical processes.

In recent decades, the focus has shifted towards optimizing nichrome's composition and manufacturing techniques to enhance its performance in cutting-edge metallurgical applications. Research has been directed towards improving its microstructure, thermal stability, and mechanical properties at extreme temperatures.

The current objectives in nichrome research and development for metallurgical applications are multifaceted. One primary goal is to extend the temperature range at which nichrome can operate effectively, pushing the boundaries of high-temperature metallurgical processes. This involves exploring new alloying elements and heat treatment techniques to enhance nichrome's already impressive heat resistance.

Another objective is to improve nichrome's resistance to corrosion and oxidation in aggressive environments, particularly in molten metal handling and processing. This aim is crucial for expanding nichrome's applications in advanced smelting and refining processes.

Researchers are also focusing on developing nichrome-based composites and coatings to combine its thermal properties with other desirable characteristics such as improved wear resistance or electrical conductivity. These developments could open up new avenues for nichrome in specialized metallurgical applications.

The miniaturization trend in various industries has led to a new objective: adapting nichrome for use in micro-scale metallurgical processes. This includes its potential application in additive manufacturing techniques for producing complex, high-temperature resistant components.

Lastly, there is a growing emphasis on making nichrome more sustainable and cost-effective. This involves optimizing production processes to reduce energy consumption and exploring recycling methods to recover and reuse nichrome from end-of-life products, aligning with the broader goals of sustainable metallurgy.

Metallurgical Market Analysis

The global metallurgical market has been experiencing significant growth, driven by the increasing demand for advanced materials in various industries. Nichrome, an alloy composed primarily of nickel and chromium, has emerged as a crucial material in cutting-edge metallurgical applications. The market for nichrome and its related products has shown a steady upward trend, with a compound annual growth rate (CAGR) exceeding the average for the broader metallurgical sector.

In recent years, the automotive and aerospace industries have been major contributors to the growth of the nichrome market. The push for lightweight, high-performance materials in these sectors has led to increased adoption of nichrome-based alloys. Additionally, the electronics industry has shown a growing interest in nichrome for its unique electrical properties, particularly in the production of resistive elements and heating components.

The energy sector, including both traditional and renewable energy industries, has also become a significant consumer of nichrome-based products. The material's excellent corrosion resistance and high-temperature stability make it ideal for applications in power generation equipment, such as gas turbines and solar thermal systems. This diversification of end-use industries has contributed to the overall market stability and growth potential for nichrome.

Geographically, Asia-Pacific has emerged as the largest market for nichrome, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe follow closely, with their advanced manufacturing sectors and focus on high-tech industries contributing to steady demand. Emerging economies in South America and Africa are also showing increased interest in nichrome applications, albeit at a slower pace.

The market dynamics for nichrome are closely tied to the prices of its constituent metals, particularly nickel. Fluctuations in raw material costs can significantly impact the overall market value and profitability for manufacturers. However, the unique properties of nichrome and its critical role in various applications have helped maintain a relatively stable demand despite price variations.

Looking ahead, the nichrome market is expected to continue its growth trajectory, supported by ongoing technological advancements and the expansion of its application areas. The increasing focus on sustainable and energy-efficient technologies is likely to create new opportunities for nichrome in emerging fields such as fuel cell technology and advanced energy storage systems. As industries continue to push the boundaries of material performance, the demand for specialized nichrome alloys tailored to specific applications is anticipated to rise, potentially opening new market segments and driving innovation in the metallurgical sector.

In recent years, the automotive and aerospace industries have been major contributors to the growth of the nichrome market. The push for lightweight, high-performance materials in these sectors has led to increased adoption of nichrome-based alloys. Additionally, the electronics industry has shown a growing interest in nichrome for its unique electrical properties, particularly in the production of resistive elements and heating components.

The energy sector, including both traditional and renewable energy industries, has also become a significant consumer of nichrome-based products. The material's excellent corrosion resistance and high-temperature stability make it ideal for applications in power generation equipment, such as gas turbines and solar thermal systems. This diversification of end-use industries has contributed to the overall market stability and growth potential for nichrome.

Geographically, Asia-Pacific has emerged as the largest market for nichrome, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe follow closely, with their advanced manufacturing sectors and focus on high-tech industries contributing to steady demand. Emerging economies in South America and Africa are also showing increased interest in nichrome applications, albeit at a slower pace.

The market dynamics for nichrome are closely tied to the prices of its constituent metals, particularly nickel. Fluctuations in raw material costs can significantly impact the overall market value and profitability for manufacturers. However, the unique properties of nichrome and its critical role in various applications have helped maintain a relatively stable demand despite price variations.

Looking ahead, the nichrome market is expected to continue its growth trajectory, supported by ongoing technological advancements and the expansion of its application areas. The increasing focus on sustainable and energy-efficient technologies is likely to create new opportunities for nichrome in emerging fields such as fuel cell technology and advanced energy storage systems. As industries continue to push the boundaries of material performance, the demand for specialized nichrome alloys tailored to specific applications is anticipated to rise, potentially opening new market segments and driving innovation in the metallurgical sector.

Nichrome Challenges in Metallurgy

Nichrome, an alloy primarily composed of nickel and chromium, faces several significant challenges in cutting-edge metallurgy applications. One of the primary issues is its limited high-temperature strength compared to more advanced superalloys. While nichrome exhibits excellent oxidation resistance, its mechanical properties degrade rapidly at temperatures above 1000°C, restricting its use in extreme environments such as advanced gas turbines or rocket engines.

Another challenge lies in the material's relatively low creep resistance. In applications requiring long-term exposure to high temperatures under stress, nichrome may experience gradual deformation, potentially leading to component failure. This limitation necessitates frequent inspections and replacements in critical systems, increasing maintenance costs and downtime.

The thermal expansion characteristics of nichrome also present difficulties in certain applications. Its coefficient of thermal expansion is higher than some other high-temperature alloys, which can lead to thermal stress and potential misalignment in precision components or in applications where tight tolerances are required.

Nichrome's electrical properties, while beneficial in many heating applications, can be a drawback in some cutting-edge metallurgical uses. Its relatively high electrical resistivity, which remains stable at elevated temperatures, may limit its effectiveness in applications requiring high electrical conductivity at extreme temperatures.

The alloy's susceptibility to embrittlement under certain conditions is another concern. Prolonged exposure to specific environments, such as those containing sulfur or carbon, can lead to the formation of brittle phases, compromising the material's ductility and overall structural integrity.

In terms of processing and fabrication, nichrome presents challenges in achieving consistent properties across different production batches. The precise control of alloying elements and heat treatment processes is crucial to maintain the desired microstructure and performance characteristics, which can be difficult to achieve consistently at industrial scales.

Lastly, the cost and availability of nickel, a primary constituent of nichrome, can impact its widespread adoption in new metallurgical applications. Fluctuations in nickel prices and potential supply chain disruptions may affect the economic viability of nichrome-based solutions in emerging technologies.

These challenges collectively highlight the need for ongoing research and development in nichrome metallurgy. Efforts to address these limitations through alloying modifications, novel processing techniques, and innovative design approaches are essential to expand the utility of nichrome in cutting-edge metallurgical applications.

Another challenge lies in the material's relatively low creep resistance. In applications requiring long-term exposure to high temperatures under stress, nichrome may experience gradual deformation, potentially leading to component failure. This limitation necessitates frequent inspections and replacements in critical systems, increasing maintenance costs and downtime.

The thermal expansion characteristics of nichrome also present difficulties in certain applications. Its coefficient of thermal expansion is higher than some other high-temperature alloys, which can lead to thermal stress and potential misalignment in precision components or in applications where tight tolerances are required.

Nichrome's electrical properties, while beneficial in many heating applications, can be a drawback in some cutting-edge metallurgical uses. Its relatively high electrical resistivity, which remains stable at elevated temperatures, may limit its effectiveness in applications requiring high electrical conductivity at extreme temperatures.

The alloy's susceptibility to embrittlement under certain conditions is another concern. Prolonged exposure to specific environments, such as those containing sulfur or carbon, can lead to the formation of brittle phases, compromising the material's ductility and overall structural integrity.

In terms of processing and fabrication, nichrome presents challenges in achieving consistent properties across different production batches. The precise control of alloying elements and heat treatment processes is crucial to maintain the desired microstructure and performance characteristics, which can be difficult to achieve consistently at industrial scales.

Lastly, the cost and availability of nickel, a primary constituent of nichrome, can impact its widespread adoption in new metallurgical applications. Fluctuations in nickel prices and potential supply chain disruptions may affect the economic viability of nichrome-based solutions in emerging technologies.

These challenges collectively highlight the need for ongoing research and development in nichrome metallurgy. Efforts to address these limitations through alloying modifications, novel processing techniques, and innovative design approaches are essential to expand the utility of nichrome in cutting-edge metallurgical applications.

Current Nichrome Applications

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Applications in heating elements: Nichrome is widely used in the manufacturing of heating elements for various devices, including electric heaters, toasters, and industrial furnaces. Its high resistance to oxidation at elevated temperatures and stable electrical properties make it an ideal material for these applications.

- Use in electronic components: Nichrome finds applications in electronic components such as resistors, thermocouples, and strain gauges. Its stable electrical properties and temperature coefficient of resistance make it suitable for precision electronic devices and sensors.

- Thin film deposition techniques: Various methods are employed for depositing nichrome thin films, including sputtering, evaporation, and chemical vapor deposition. These techniques are used to create precise and uniform nichrome layers for applications in microelectronics, sensors, and optical coatings.

- Surface treatment and coating applications: Nichrome is used in surface treatment processes and as a coating material. Its corrosion resistance and adherence properties make it suitable for protective coatings on various substrates, improving their durability and performance in harsh environments.

02 Nichrome in heating elements and electrical resistors

Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and ability to withstand high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's stability at high temperatures ensures consistent performance and longevity of these devices.Expand Specific Solutions03 Nichrome in thin film technology

Nichrome is utilized in thin film technology for various applications, including the production of resistive elements in microelectronics and sensors. Its ability to be deposited as a thin film with precise thickness control makes it valuable in the fabrication of integrated circuits and other miniaturized electronic components.Expand Specific Solutions04 Nichrome in aerospace and high-temperature applications

The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that require reliable performance under extreme conditions, such as in aircraft engines, rocket nozzles, and industrial furnaces.Expand Specific Solutions05 Surface treatment and coating of nichrome

Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from specific environmental conditions. These treatments can improve corrosion resistance, reduce oxidation at high temperatures, or modify the surface characteristics for specific applications.Expand Specific Solutions

Key Nichrome Industry Players

The nichrome applications market in cutting-edge metallurgy is in a growth phase, driven by increasing demand in aerospace, electronics, and advanced manufacturing sectors. The market size is expanding, with projections indicating significant growth over the next 5-10 years. Technologically, nichrome applications are advancing rapidly, with companies like Sandvik Intellectual Property AB, Kennametal, Inc., and VDM Metals International GmbH leading innovation in high-performance alloys and coatings. These firms are developing novel nichrome-based materials with enhanced properties for extreme environments. The competitive landscape is characterized by a mix of established players and emerging specialists, with ongoing R&D efforts focused on improving material performance, durability, and cost-effectiveness.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed advanced nichrome alloys for cutting-edge metallurgical applications. Their proprietary nichrome compositions offer enhanced thermal stability and corrosion resistance, making them ideal for high-temperature industrial processes. Sandvik's nichrome alloys incorporate precise amounts of chromium (typically 80%) and nickel (20%) with trace elements to optimize performance[1]. These alloys are used in heating elements, thermocouples, and resistance wire applications where consistent electrical properties at elevated temperatures are crucial. Sandvik's nichrome materials also demonstrate improved oxidation resistance, extending the lifespan of components in aggressive environments[2].

Strengths: Superior thermal stability, excellent corrosion resistance, and consistent electrical properties at high temperatures. Weaknesses: Higher cost compared to standard nichrome alloys, limited ductility in certain compositions.

Konfoong Materials International Co., Ltd.

Technical Solution: Konfoong Materials has innovated in nichrome applications for advanced metallurgy by developing nanostructured nichrome coatings. Their process involves plasma spraying of nichrome powders with controlled particle sizes, resulting in coatings with enhanced wear resistance and thermal barrier properties[3]. These nanostructured coatings exhibit improved adhesion to substrates and can withstand thermal cycling better than conventional nichrome coatings. Konfoong's technology allows for the deposition of nichrome layers as thin as 10-50 micrometers while maintaining excellent uniformity and density[4]. This advancement enables the use of nichrome in more precise and demanding applications in aerospace and power generation industries.

Strengths: Enhanced wear resistance, superior thermal barrier properties, and improved adhesion to substrates. Weaknesses: Complex deposition process, potentially higher production costs, and limited thickness range for optimal performance.

Nichrome Innovations Analysis

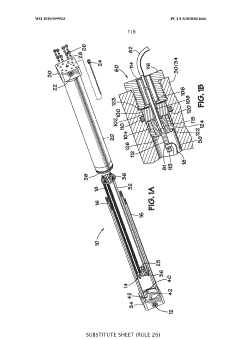

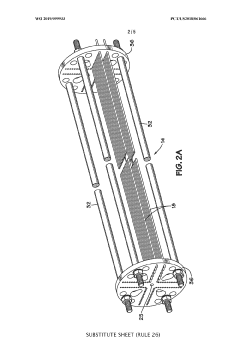

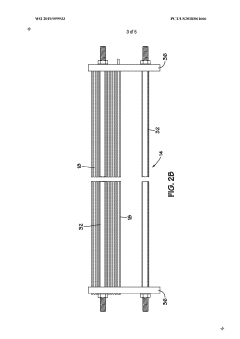

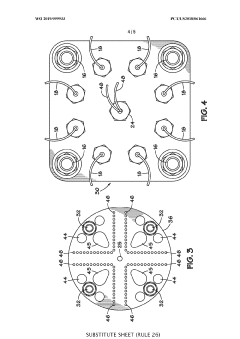

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

Use of a nickel-chromium-iron alloy

PatentWO2021204326A1

Innovation

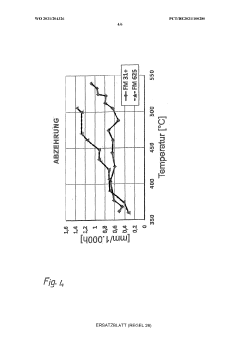

- A nitrogen-alloyed nickel-chromium-iron alloy with specific composition is used as a welding cladding material, forming a sigma phase and chromium carbides to enhance hardness and resistance to erosion and corrosion, suitable for thermal recycling plants, and demonstrating excellent weldability and corrosion resistance.

Environmental Impact of Nichrome

The environmental impact of nichrome in cutting-edge metallurgy applications is a critical consideration for sustainable industrial practices. Nichrome, an alloy primarily composed of nickel and chromium, offers exceptional heat resistance and electrical conductivity, making it valuable in various high-temperature applications. However, its production and use come with environmental implications that warrant careful examination.

The mining and extraction processes for nickel and chromium, the primary components of nichrome, can lead to significant environmental disturbances. Open-pit mining, often employed for these metals, results in habitat destruction, soil erosion, and potential water pollution. The refining processes for these metals are energy-intensive, contributing to greenhouse gas emissions and climate change concerns.

During the manufacturing of nichrome alloys, the high temperatures required for melting and alloying can result in air emissions, including particulate matter and potentially harmful metal fumes. Proper filtration and emission control systems are essential to mitigate these impacts and ensure compliance with environmental regulations.

In its application within cutting-edge metallurgy, nichrome's durability and resistance to corrosion contribute to extended product lifespans, potentially reducing the frequency of replacement and associated environmental impacts. However, the disposal of nichrome-containing products at the end of their life cycle presents challenges. While the alloy is recyclable, the separation of nickel and chromium can be energy-intensive and may produce hazardous byproducts if not managed properly.

The use of nichrome in high-temperature applications, such as furnaces and heating elements, can indirectly contribute to energy efficiency improvements in various industrial processes. This efficiency can lead to reduced overall energy consumption and associated environmental benefits. However, the potential release of nickel and chromium compounds during high-temperature operations must be carefully monitored and controlled to prevent air and water pollution.

From a lifecycle perspective, the environmental footprint of nichrome extends beyond its production and use. The transportation of raw materials and finished products contributes to carbon emissions, while the energy consumed in the maintenance and repair of nichrome-containing equipment adds to its overall environmental impact.

As industries strive for more sustainable practices, research into alternative materials or improved nichrome formulations with reduced environmental impact is ongoing. Advancements in recycling technologies and closed-loop manufacturing processes offer promising avenues for mitigating the environmental concerns associated with nichrome in cutting-edge metallurgical applications.

The mining and extraction processes for nickel and chromium, the primary components of nichrome, can lead to significant environmental disturbances. Open-pit mining, often employed for these metals, results in habitat destruction, soil erosion, and potential water pollution. The refining processes for these metals are energy-intensive, contributing to greenhouse gas emissions and climate change concerns.

During the manufacturing of nichrome alloys, the high temperatures required for melting and alloying can result in air emissions, including particulate matter and potentially harmful metal fumes. Proper filtration and emission control systems are essential to mitigate these impacts and ensure compliance with environmental regulations.

In its application within cutting-edge metallurgy, nichrome's durability and resistance to corrosion contribute to extended product lifespans, potentially reducing the frequency of replacement and associated environmental impacts. However, the disposal of nichrome-containing products at the end of their life cycle presents challenges. While the alloy is recyclable, the separation of nickel and chromium can be energy-intensive and may produce hazardous byproducts if not managed properly.

The use of nichrome in high-temperature applications, such as furnaces and heating elements, can indirectly contribute to energy efficiency improvements in various industrial processes. This efficiency can lead to reduced overall energy consumption and associated environmental benefits. However, the potential release of nickel and chromium compounds during high-temperature operations must be carefully monitored and controlled to prevent air and water pollution.

From a lifecycle perspective, the environmental footprint of nichrome extends beyond its production and use. The transportation of raw materials and finished products contributes to carbon emissions, while the energy consumed in the maintenance and repair of nichrome-containing equipment adds to its overall environmental impact.

As industries strive for more sustainable practices, research into alternative materials or improved nichrome formulations with reduced environmental impact is ongoing. Advancements in recycling technologies and closed-loop manufacturing processes offer promising avenues for mitigating the environmental concerns associated with nichrome in cutting-edge metallurgical applications.

Nichrome Safety Regulations

Nichrome safety regulations are crucial in the context of cutting-edge metallurgy applications. These regulations encompass a wide range of safety measures and guidelines to ensure the proper handling, use, and disposal of nichrome materials in industrial and research settings.

One of the primary safety concerns with nichrome is its potential to reach extremely high temperatures when an electric current is passed through it. As such, regulations typically mandate the use of appropriate personal protective equipment (PPE) for workers handling nichrome components. This includes heat-resistant gloves, protective eyewear, and flame-resistant clothing to prevent burns and other heat-related injuries.

Ventilation requirements form another critical aspect of nichrome safety regulations. When heated, nichrome can release potentially harmful fumes, particularly if it contains trace amounts of other metals or contaminants. Adequate ventilation systems must be in place to remove these fumes and maintain air quality in work areas. In some cases, local exhaust ventilation may be required to capture fumes at the source.

Electrical safety is paramount when working with nichrome, given its use in heating elements and electrical resistors. Regulations often specify proper insulation techniques, grounding procedures, and the use of appropriate circuit protection devices to prevent electrical hazards such as short circuits or overheating.

Storage and handling guidelines for nichrome materials are also typically included in safety regulations. These may cover proper storage conditions to prevent contamination or degradation of the material, as well as procedures for safe transportation within facilities.

Waste management and disposal regulations for nichrome-containing materials are essential to prevent environmental contamination. These regulations often require proper segregation of nichrome waste, appropriate labeling, and disposal through authorized channels that can handle potentially hazardous materials.

Emergency response procedures are another critical component of nichrome safety regulations. These outline the steps to be taken in case of accidents, such as fires involving nichrome materials or exposure to nichrome fumes. Training requirements for personnel working with nichrome are typically specified to ensure that all workers are aware of the potential hazards and proper safety protocols.

Regular inspection and maintenance of nichrome-containing equipment are often mandated to prevent accidents due to wear and tear or material degradation. This may include scheduled checks of heating elements, electrical connections, and insulation integrity.

In research and development settings, additional regulations may apply to the use of nichrome in experimental procedures. These could include protocols for risk assessment, documentation of experiments involving nichrome, and specific safety measures for novel applications of the material.

As metallurgy techniques continue to advance, nichrome safety regulations are likely to evolve to address new applications and potential risks. Ongoing research into the long-term effects of nichrome exposure and the development of new safety technologies will inform future regulatory updates, ensuring that safety standards keep pace with technological progress in the field.

One of the primary safety concerns with nichrome is its potential to reach extremely high temperatures when an electric current is passed through it. As such, regulations typically mandate the use of appropriate personal protective equipment (PPE) for workers handling nichrome components. This includes heat-resistant gloves, protective eyewear, and flame-resistant clothing to prevent burns and other heat-related injuries.

Ventilation requirements form another critical aspect of nichrome safety regulations. When heated, nichrome can release potentially harmful fumes, particularly if it contains trace amounts of other metals or contaminants. Adequate ventilation systems must be in place to remove these fumes and maintain air quality in work areas. In some cases, local exhaust ventilation may be required to capture fumes at the source.

Electrical safety is paramount when working with nichrome, given its use in heating elements and electrical resistors. Regulations often specify proper insulation techniques, grounding procedures, and the use of appropriate circuit protection devices to prevent electrical hazards such as short circuits or overheating.

Storage and handling guidelines for nichrome materials are also typically included in safety regulations. These may cover proper storage conditions to prevent contamination or degradation of the material, as well as procedures for safe transportation within facilities.

Waste management and disposal regulations for nichrome-containing materials are essential to prevent environmental contamination. These regulations often require proper segregation of nichrome waste, appropriate labeling, and disposal through authorized channels that can handle potentially hazardous materials.

Emergency response procedures are another critical component of nichrome safety regulations. These outline the steps to be taken in case of accidents, such as fires involving nichrome materials or exposure to nichrome fumes. Training requirements for personnel working with nichrome are typically specified to ensure that all workers are aware of the potential hazards and proper safety protocols.

Regular inspection and maintenance of nichrome-containing equipment are often mandated to prevent accidents due to wear and tear or material degradation. This may include scheduled checks of heating elements, electrical connections, and insulation integrity.

In research and development settings, additional regulations may apply to the use of nichrome in experimental procedures. These could include protocols for risk assessment, documentation of experiments involving nichrome, and specific safety measures for novel applications of the material.

As metallurgy techniques continue to advance, nichrome safety regulations are likely to evolve to address new applications and potential risks. Ongoing research into the long-term effects of nichrome exposure and the development of new safety technologies will inform future regulatory updates, ensuring that safety standards keep pace with technological progress in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!