Nichrome Applications in Sustainable Energy Development

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Technology Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has played a significant role in the evolution of sustainable energy technologies. Its unique properties, including high electrical resistance and excellent heat resistance, have made it a crucial material in various energy-related applications. The journey of nichrome in sustainable energy development can be traced back to the early 20th century when it was first used in electrical heating elements.

The initial applications of nichrome in energy-related fields were primarily focused on heating elements for industrial and domestic use. As the demand for more efficient and sustainable energy solutions grew, researchers and engineers began exploring new ways to leverage nichrome's properties. This led to its incorporation in solar thermal systems, where nichrome-based absorber coatings improved the efficiency of solar collectors.

In recent decades, the evolution of nichrome technology has accelerated, driven by the urgent need for sustainable energy solutions to combat climate change. One of the most notable advancements has been the development of nichrome-based thermoelectric materials. These materials can convert waste heat into electricity, offering a promising avenue for improving energy efficiency in various industrial processes and automotive applications.

The objectives of nichrome technology in sustainable energy development are multifaceted. Firstly, there is a strong focus on enhancing the efficiency of existing energy systems. This includes improving the performance of solar thermal collectors, developing more efficient heating elements for industrial processes, and optimizing thermoelectric generators for waste heat recovery.

Secondly, researchers are exploring novel applications of nichrome in emerging sustainable energy technologies. For instance, nichrome-based materials are being investigated for use in high-temperature fuel cells, which could play a crucial role in future clean energy systems. Additionally, there is ongoing research into the potential of nichrome alloys in advanced energy storage systems, particularly in high-temperature batteries and thermal energy storage devices.

Another key objective is to improve the durability and longevity of nichrome-based components in sustainable energy applications. This is particularly important in harsh environments, such as concentrated solar power plants, where materials are subjected to extreme temperatures and corrosive conditions. Enhancing the resilience of nichrome alloys could significantly extend the lifespan of these energy systems, improving their overall sustainability and cost-effectiveness.

Looking ahead, the evolution of nichrome technology is expected to continue, with a focus on developing more advanced alloys and composites. These new materials aim to push the boundaries of performance in sustainable energy applications, potentially enabling breakthroughs in energy efficiency and renewable energy generation. As global efforts to transition to clean energy intensify, nichrome's role in sustainable energy development is likely to become even more crucial, driving innovation and contributing to a more sustainable future.

The initial applications of nichrome in energy-related fields were primarily focused on heating elements for industrial and domestic use. As the demand for more efficient and sustainable energy solutions grew, researchers and engineers began exploring new ways to leverage nichrome's properties. This led to its incorporation in solar thermal systems, where nichrome-based absorber coatings improved the efficiency of solar collectors.

In recent decades, the evolution of nichrome technology has accelerated, driven by the urgent need for sustainable energy solutions to combat climate change. One of the most notable advancements has been the development of nichrome-based thermoelectric materials. These materials can convert waste heat into electricity, offering a promising avenue for improving energy efficiency in various industrial processes and automotive applications.

The objectives of nichrome technology in sustainable energy development are multifaceted. Firstly, there is a strong focus on enhancing the efficiency of existing energy systems. This includes improving the performance of solar thermal collectors, developing more efficient heating elements for industrial processes, and optimizing thermoelectric generators for waste heat recovery.

Secondly, researchers are exploring novel applications of nichrome in emerging sustainable energy technologies. For instance, nichrome-based materials are being investigated for use in high-temperature fuel cells, which could play a crucial role in future clean energy systems. Additionally, there is ongoing research into the potential of nichrome alloys in advanced energy storage systems, particularly in high-temperature batteries and thermal energy storage devices.

Another key objective is to improve the durability and longevity of nichrome-based components in sustainable energy applications. This is particularly important in harsh environments, such as concentrated solar power plants, where materials are subjected to extreme temperatures and corrosive conditions. Enhancing the resilience of nichrome alloys could significantly extend the lifespan of these energy systems, improving their overall sustainability and cost-effectiveness.

Looking ahead, the evolution of nichrome technology is expected to continue, with a focus on developing more advanced alloys and composites. These new materials aim to push the boundaries of performance in sustainable energy applications, potentially enabling breakthroughs in energy efficiency and renewable energy generation. As global efforts to transition to clean energy intensify, nichrome's role in sustainable energy development is likely to become even more crucial, driving innovation and contributing to a more sustainable future.

Sustainable Energy Market Demand Analysis

The sustainable energy market has witnessed significant growth in recent years, driven by increasing environmental concerns, government initiatives, and technological advancements. The demand for nichrome applications in this sector is closely tied to the overall expansion of renewable energy sources and energy-efficient technologies.

In the solar energy sector, nichrome finds applications in the production of photovoltaic cells and solar thermal systems. The global solar energy market is projected to grow at a compound annual growth rate (CAGR) of 20.5% from 2021 to 2026, reaching a market value of $223.3 billion by the end of the forecast period. This growth is expected to drive the demand for nichrome in solar panel manufacturing processes and thermal energy storage systems.

Wind energy, another key player in the sustainable energy landscape, also presents opportunities for nichrome applications. The global wind energy market is forecasted to grow at a CAGR of 14.2% from 2021 to 2026, with an estimated market value of $127.2 billion by 2026. Nichrome is used in the production of wind turbine components, particularly in heating elements for de-icing systems, contributing to the overall market demand.

The energy storage sector, crucial for the integration of renewable energy sources into the grid, is experiencing rapid growth. The global energy storage market is expected to reach $26.1 billion by 2026, growing at a CAGR of 34.2% from 2021. Nichrome's properties make it suitable for various energy storage applications, including advanced battery technologies and thermal energy storage systems.

In the realm of energy efficiency, nichrome plays a vital role in the development of smart grid technologies and energy-efficient appliances. The global smart grid market is projected to grow at a CAGR of 20.9% from 2021 to 2026, reaching a market value of $92.2 billion by the end of the forecast period. This growth is driven by the need for improved energy management and distribution systems, where nichrome-based components can contribute to enhanced efficiency and reliability.

The hydrogen energy sector, although still in its early stages, shows promising growth potential. The global hydrogen energy market is expected to grow at a CAGR of 9.2% from 2021 to 2026, reaching a market value of $12.7 billion by the end of the forecast period. Nichrome's high-temperature resistance properties make it suitable for various applications in hydrogen production and fuel cell technologies.

As governments worldwide implement stricter environmental regulations and set ambitious renewable energy targets, the demand for sustainable energy solutions is expected to continue its upward trajectory. This trend will likely drive further innovation in nichrome applications, particularly in areas such as improved energy conversion efficiency, enhanced durability of renewable energy components, and advanced energy storage technologies.

In the solar energy sector, nichrome finds applications in the production of photovoltaic cells and solar thermal systems. The global solar energy market is projected to grow at a compound annual growth rate (CAGR) of 20.5% from 2021 to 2026, reaching a market value of $223.3 billion by the end of the forecast period. This growth is expected to drive the demand for nichrome in solar panel manufacturing processes and thermal energy storage systems.

Wind energy, another key player in the sustainable energy landscape, also presents opportunities for nichrome applications. The global wind energy market is forecasted to grow at a CAGR of 14.2% from 2021 to 2026, with an estimated market value of $127.2 billion by 2026. Nichrome is used in the production of wind turbine components, particularly in heating elements for de-icing systems, contributing to the overall market demand.

The energy storage sector, crucial for the integration of renewable energy sources into the grid, is experiencing rapid growth. The global energy storage market is expected to reach $26.1 billion by 2026, growing at a CAGR of 34.2% from 2021. Nichrome's properties make it suitable for various energy storage applications, including advanced battery technologies and thermal energy storage systems.

In the realm of energy efficiency, nichrome plays a vital role in the development of smart grid technologies and energy-efficient appliances. The global smart grid market is projected to grow at a CAGR of 20.9% from 2021 to 2026, reaching a market value of $92.2 billion by the end of the forecast period. This growth is driven by the need for improved energy management and distribution systems, where nichrome-based components can contribute to enhanced efficiency and reliability.

The hydrogen energy sector, although still in its early stages, shows promising growth potential. The global hydrogen energy market is expected to grow at a CAGR of 9.2% from 2021 to 2026, reaching a market value of $12.7 billion by the end of the forecast period. Nichrome's high-temperature resistance properties make it suitable for various applications in hydrogen production and fuel cell technologies.

As governments worldwide implement stricter environmental regulations and set ambitious renewable energy targets, the demand for sustainable energy solutions is expected to continue its upward trajectory. This trend will likely drive further innovation in nichrome applications, particularly in areas such as improved energy conversion efficiency, enhanced durability of renewable energy components, and advanced energy storage technologies.

Nichrome in Energy: Current Status and Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has gained significant attention in the field of sustainable energy development. The current status of nichrome applications in energy systems is characterized by both promising advancements and notable challenges.

In terms of progress, nichrome has found widespread use in various energy-related applications due to its excellent electrical resistance and high-temperature stability. It is commonly employed in heating elements for industrial processes, electric furnaces, and domestic appliances. The material's ability to withstand high temperatures while maintaining consistent electrical properties has made it invaluable in these contexts.

Moreover, nichrome has shown potential in emerging sustainable energy technologies. For instance, it has been explored as a catalyst support in fuel cells, particularly in solid oxide fuel cells (SOFCs). The alloy's resistance to oxidation and corrosion at elevated temperatures makes it an attractive option for such applications.

However, the integration of nichrome in sustainable energy systems faces several challenges. One significant hurdle is the high cost of nickel, a primary component of the alloy. As global demand for nickel increases, driven partly by the electric vehicle battery market, the economic viability of nichrome-based solutions in energy applications may be affected.

Another challenge lies in the limited thermal efficiency of nichrome in certain applications. While it performs well in many high-temperature scenarios, there is ongoing research to enhance its heat transfer properties and overall energy efficiency, particularly in heating elements and thermal management systems.

Environmental concerns also pose challenges to the widespread adoption of nichrome in sustainable energy development. The mining and processing of nickel and chromium have significant environmental impacts, including habitat destruction and greenhouse gas emissions. This has led to increased scrutiny and the need for more sustainable production methods.

Furthermore, the recyclability and end-of-life management of nichrome-containing devices present additional challenges. Developing efficient recycling processes for nichrome alloys is crucial to minimize waste and reduce the environmental footprint of energy technologies utilizing this material.

In the context of renewable energy systems, nichrome faces competition from alternative materials and technologies. For instance, in solar thermal applications, other alloys and advanced ceramics are being explored as potential replacements, offering improved performance or cost-effectiveness.

Despite these challenges, ongoing research and development efforts are focused on addressing these issues and expanding the potential of nichrome in sustainable energy applications. Innovations in alloy composition, manufacturing processes, and application techniques continue to drive progress in this field.

In terms of progress, nichrome has found widespread use in various energy-related applications due to its excellent electrical resistance and high-temperature stability. It is commonly employed in heating elements for industrial processes, electric furnaces, and domestic appliances. The material's ability to withstand high temperatures while maintaining consistent electrical properties has made it invaluable in these contexts.

Moreover, nichrome has shown potential in emerging sustainable energy technologies. For instance, it has been explored as a catalyst support in fuel cells, particularly in solid oxide fuel cells (SOFCs). The alloy's resistance to oxidation and corrosion at elevated temperatures makes it an attractive option for such applications.

However, the integration of nichrome in sustainable energy systems faces several challenges. One significant hurdle is the high cost of nickel, a primary component of the alloy. As global demand for nickel increases, driven partly by the electric vehicle battery market, the economic viability of nichrome-based solutions in energy applications may be affected.

Another challenge lies in the limited thermal efficiency of nichrome in certain applications. While it performs well in many high-temperature scenarios, there is ongoing research to enhance its heat transfer properties and overall energy efficiency, particularly in heating elements and thermal management systems.

Environmental concerns also pose challenges to the widespread adoption of nichrome in sustainable energy development. The mining and processing of nickel and chromium have significant environmental impacts, including habitat destruction and greenhouse gas emissions. This has led to increased scrutiny and the need for more sustainable production methods.

Furthermore, the recyclability and end-of-life management of nichrome-containing devices present additional challenges. Developing efficient recycling processes for nichrome alloys is crucial to minimize waste and reduce the environmental footprint of energy technologies utilizing this material.

In the context of renewable energy systems, nichrome faces competition from alternative materials and technologies. For instance, in solar thermal applications, other alloys and advanced ceramics are being explored as potential replacements, offering improved performance or cost-effectiveness.

Despite these challenges, ongoing research and development efforts are focused on addressing these issues and expanding the potential of nichrome in sustainable energy applications. Innovations in alloy composition, manufacturing processes, and application techniques continue to drive progress in this field.

Current Nichrome Solutions in Energy Development

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Manufacturing processes for nichrome components: Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes aim to achieve specific dimensions, shapes, and properties required for different applications, such as heating elements or sensors.

- Applications in electronic devices and sensors: Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is employed in the fabrication of resistors, thermocouples, and strain gauges. The alloy's temperature coefficient of resistance makes it suitable for precise temperature measurement and control applications.

- Nichrome in heating elements and industrial equipment: Nichrome is extensively used in heating elements for various industrial and household applications. Its high melting point and resistance to oxidation at elevated temperatures make it ideal for use in electric heaters, furnaces, and other high-temperature equipment. The alloy's durability contributes to the longevity of these heating devices.

- Surface treatments and coatings for nichrome: Various surface treatments and coatings are applied to nichrome components to enhance their performance or protect them from environmental factors. These treatments may include oxidation-resistant coatings, insulation layers, or surface modifications to improve adhesion or electrical properties in specific applications.

02 Nichrome in heating elements and electrical resistors

Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and ability to withstand high temperatures. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's stability at high temperatures ensures consistent performance and longevity of these devices.Expand Specific Solutions03 Nichrome in thin film technology

Nichrome is utilized in thin film technology for various applications, including the production of resistive elements in microelectronics and sensors. Its ability to be deposited as a thin film with precise thickness control makes it valuable in the fabrication of integrated circuits and other miniaturized electronic components.Expand Specific Solutions04 Nichrome in aerospace and high-temperature applications

The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that need to withstand extreme heat, such as rocket nozzles, furnace elements, and high-temperature sensors. The alloy's ability to maintain its properties under harsh conditions contributes to the reliability of these critical systems.Expand Specific Solutions05 Surface treatment and coating of nichrome

Various surface treatment and coating techniques are applied to nichrome to enhance its properties or protect it from specific environmental conditions. These treatments can improve corrosion resistance, reduce oxidation at high temperatures, or modify the surface characteristics for better adhesion in composite materials. Such modifications extend the range of applications for nichrome in different industries.Expand Specific Solutions

Key Players in Nichrome and Sustainable Energy

The nichrome applications in sustainable energy development sector is currently in a growth phase, with increasing market size driven by the global push for clean energy solutions. The technology's maturity varies across different applications, ranging from established uses in heating elements to emerging roles in renewable energy systems. Key players like Jingmen Gem Co., Ltd. and Hunan Bangpu Recycling Technology Co., Ltd. are advancing nichrome's potential in battery technologies, while companies such as EnPower, Inc. and Samsung SDI Co., Ltd. are exploring its use in energy storage solutions. The market is characterized by a mix of established industrial giants and innovative startups, indicating a dynamic and competitive landscape with significant potential for technological advancements and market expansion.

De Luca Oven Technologies LLC

Technical Solution: De Luca Oven Technologies LLC has pioneered the use of nichrome in advanced thermal processing systems for sustainable energy applications. Their innovative oven designs incorporate nichrome heating elements optimized for rapid heating and precise temperature control [9]. These ovens are used in the production of various sustainable energy components, including solar cells, fuel cell membranes, and advanced battery materials. The company's nichrome-based heating systems offer superior energy efficiency and temperature uniformity, crucial for the manufacturing of high-quality sustainable energy products [10].

Strengths: Rapid heating capabilities, precise temperature control, and energy efficiency in manufacturing processes. Weaknesses: Initial high cost of implementation and potential for element degradation in certain processing environments.

NuScale Power LLC

Technical Solution: NuScale Power LLC has developed innovative small modular reactor (SMR) technology that incorporates nichrome elements in its design. Their SMR uses nichrome wire heating elements in the pressurizer to maintain system pressure and temperature [1]. The nichrome elements provide precise and reliable heating, crucial for the reactor's operation. NuScale's SMR design also utilizes nichrome in sensor sheaths and other components where high-temperature resistance and stability are required [2]. This application of nichrome contributes to the overall efficiency and safety of their sustainable nuclear energy solution, aligning with the growing demand for clean, scalable power generation.

Strengths: Reliable and precise temperature control, high-temperature resistance, and compatibility with nuclear applications. Weaknesses: Potential for material degradation over long-term exposure to radiation and high temperatures.

Innovative Nichrome Technologies for Energy

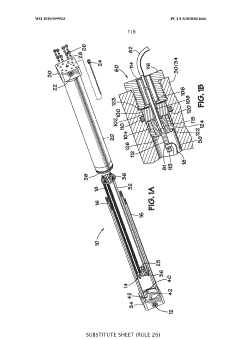

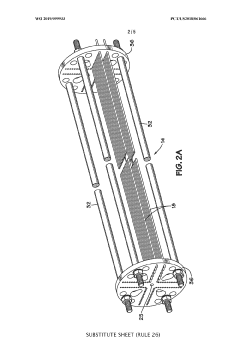

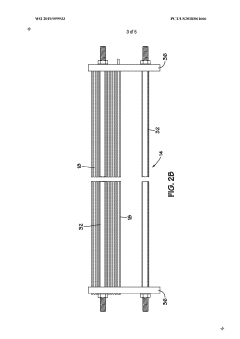

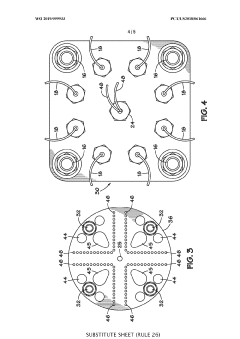

In-line electric heater for plural component materials

PatentWO2019099933A1

Innovation

- An in-line electric heater design featuring a housing with multiple electric resistance heating elements along the fluid flow path, supported by a wire loom assembly and temperature sensors, using INCONEL wires coated with Teflon for improved durability and insulation, and a power feedthrough system for secure electrical connections, enhancing heat transfer and temperature control.

Support of a sustainable energy supply having a carbon cycle using regeneratively generated hydrogen

PatentInactiveEP2181491A2

Innovation

- Regenerative energy is used to produce hydrogen through electrolysis, which is then hydrogenated with CO2 to form combustible hydrocarbons, allowing for intermediate storage and stable energy supply, decoupling renewable energy generation from demand and enabling predictable electricity generation in base-load power plants.

Environmental Impact of Nichrome Energy Applications

The environmental impact of nichrome applications in sustainable energy development is a critical consideration as the world moves towards cleaner energy solutions. Nichrome, an alloy of nickel and chromium, has gained attention for its potential in various energy-related applications due to its unique properties.

One of the primary environmental benefits of nichrome in sustainable energy development is its role in improving energy efficiency. When used in heating elements, nichrome's high electrical resistance and ability to withstand high temperatures contribute to more efficient energy conversion processes. This increased efficiency translates to reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation.

However, the production and disposal of nichrome-based components present environmental challenges. The mining and processing of nickel and chromium ores can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. Additionally, the energy-intensive manufacturing process of nichrome alloys contributes to carbon emissions, potentially offsetting some of the environmental gains achieved through its applications.

The durability and corrosion resistance of nichrome offer environmental advantages in terms of product longevity. Nichrome-based components in energy systems tend to have extended lifespans, reducing the frequency of replacements and associated waste generation. This characteristic aligns well with sustainable development goals by minimizing resource consumption and waste production over time.

In the context of renewable energy technologies, nichrome plays a role in enhancing the performance and reliability of certain systems. For instance, in solar thermal applications, nichrome heating elements can improve heat transfer efficiency, potentially increasing the overall effectiveness of solar energy conversion. This indirect contribution to renewable energy adoption supports the transition away from fossil fuel-based energy sources.

The recyclability of nichrome is another important environmental consideration. While the alloy can be recycled, the process requires specialized facilities and significant energy input. Improving recycling technologies and infrastructure for nichrome and similar alloys is crucial for minimizing the environmental footprint of their use in sustainable energy applications.

As with many materials used in energy technologies, the environmental impact of nichrome applications must be assessed through a lifecycle analysis approach. This holistic evaluation considers the environmental costs and benefits from raw material extraction through manufacturing, use, and end-of-life management. Such analyses can guide the optimization of nichrome use in sustainable energy development, ensuring that its applications truly contribute to environmental sustainability goals.

One of the primary environmental benefits of nichrome in sustainable energy development is its role in improving energy efficiency. When used in heating elements, nichrome's high electrical resistance and ability to withstand high temperatures contribute to more efficient energy conversion processes. This increased efficiency translates to reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation.

However, the production and disposal of nichrome-based components present environmental challenges. The mining and processing of nickel and chromium ores can lead to habitat destruction, soil erosion, and water pollution if not managed responsibly. Additionally, the energy-intensive manufacturing process of nichrome alloys contributes to carbon emissions, potentially offsetting some of the environmental gains achieved through its applications.

The durability and corrosion resistance of nichrome offer environmental advantages in terms of product longevity. Nichrome-based components in energy systems tend to have extended lifespans, reducing the frequency of replacements and associated waste generation. This characteristic aligns well with sustainable development goals by minimizing resource consumption and waste production over time.

In the context of renewable energy technologies, nichrome plays a role in enhancing the performance and reliability of certain systems. For instance, in solar thermal applications, nichrome heating elements can improve heat transfer efficiency, potentially increasing the overall effectiveness of solar energy conversion. This indirect contribution to renewable energy adoption supports the transition away from fossil fuel-based energy sources.

The recyclability of nichrome is another important environmental consideration. While the alloy can be recycled, the process requires specialized facilities and significant energy input. Improving recycling technologies and infrastructure for nichrome and similar alloys is crucial for minimizing the environmental footprint of their use in sustainable energy applications.

As with many materials used in energy technologies, the environmental impact of nichrome applications must be assessed through a lifecycle analysis approach. This holistic evaluation considers the environmental costs and benefits from raw material extraction through manufacturing, use, and end-of-life management. Such analyses can guide the optimization of nichrome use in sustainable energy development, ensuring that its applications truly contribute to environmental sustainability goals.

Nichrome Supply Chain and Resource Sustainability

The sustainability of the nichrome supply chain is a critical factor in the long-term viability of its applications in sustainable energy development. Nichrome, an alloy primarily composed of nickel and chromium, relies on the availability and responsible sourcing of these key elements.

Nickel, a crucial component of nichrome, is mined in various countries, with Indonesia, the Philippines, and Russia being major producers. The extraction and processing of nickel have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. To address these concerns, innovative mining techniques and stricter environmental regulations are being implemented in many regions.

Chromium, the other primary constituent of nichrome, is predominantly sourced from South Africa, Kazakhstan, and India. The mining and refining of chromium also pose environmental challenges, particularly in terms of water usage and potential contamination. Sustainable practices in chromium extraction are increasingly being adopted, focusing on water recycling and waste management.

The global supply chain for nichrome involves multiple stages, from raw material extraction to alloy production and distribution. This complex network is vulnerable to geopolitical tensions, trade disputes, and natural disasters, which can disrupt supply and impact prices. To mitigate these risks, diversification of supply sources and the development of strategic reserves are being pursued by many countries and industries.

Recycling plays a crucial role in enhancing the sustainability of the nichrome supply chain. As nichrome is widely used in heating elements and electrical resistors, there is significant potential for recovering and reprocessing end-of-life products. Advanced recycling technologies are being developed to efficiently separate and reclaim nickel and chromium from nichrome alloys, reducing the demand for primary raw materials.

The concept of circular economy is gaining traction in the nichrome industry, with manufacturers increasingly focusing on product design that facilitates easier disassembly and recycling. This approach not only conserves resources but also reduces the environmental footprint associated with nichrome production.

As the demand for nichrome in sustainable energy applications grows, ensuring a stable and environmentally responsible supply chain becomes paramount. Research into alternative materials and more efficient production processes is ongoing, aiming to reduce reliance on critical raw materials and minimize environmental impacts. Additionally, the development of international standards and certifications for responsibly sourced nichrome is being explored to promote transparency and sustainability throughout the supply chain.

Nickel, a crucial component of nichrome, is mined in various countries, with Indonesia, the Philippines, and Russia being major producers. The extraction and processing of nickel have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. To address these concerns, innovative mining techniques and stricter environmental regulations are being implemented in many regions.

Chromium, the other primary constituent of nichrome, is predominantly sourced from South Africa, Kazakhstan, and India. The mining and refining of chromium also pose environmental challenges, particularly in terms of water usage and potential contamination. Sustainable practices in chromium extraction are increasingly being adopted, focusing on water recycling and waste management.

The global supply chain for nichrome involves multiple stages, from raw material extraction to alloy production and distribution. This complex network is vulnerable to geopolitical tensions, trade disputes, and natural disasters, which can disrupt supply and impact prices. To mitigate these risks, diversification of supply sources and the development of strategic reserves are being pursued by many countries and industries.

Recycling plays a crucial role in enhancing the sustainability of the nichrome supply chain. As nichrome is widely used in heating elements and electrical resistors, there is significant potential for recovering and reprocessing end-of-life products. Advanced recycling technologies are being developed to efficiently separate and reclaim nickel and chromium from nichrome alloys, reducing the demand for primary raw materials.

The concept of circular economy is gaining traction in the nichrome industry, with manufacturers increasingly focusing on product design that facilitates easier disassembly and recycling. This approach not only conserves resources but also reduces the environmental footprint associated with nichrome production.

As the demand for nichrome in sustainable energy applications grows, ensuring a stable and environmentally responsible supply chain becomes paramount. Research into alternative materials and more efficient production processes is ongoing, aiming to reduce reliance on critical raw materials and minimize environmental impacts. Additionally, the development of international standards and certifications for responsibly sourced nichrome is being explored to promote transparency and sustainability throughout the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!