Nichrome in Biotech: Innovation in Thermal Regulation Devices

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Biotech Evolution

The evolution of Nichrome in biotech thermal regulation devices represents a significant leap in precision temperature control for biological applications. Initially developed in the early 20th century as a resistive heating element, Nichrome's journey into biotechnology began in the 1970s with its incorporation into laboratory incubators and water baths.

The 1980s marked a turning point as researchers recognized Nichrome's potential for more sophisticated biotech applications. Its high resistance and stability at elevated temperatures made it ideal for DNA amplification techniques, leading to its integration into the first commercial PCR thermal cyclers. This innovation dramatically accelerated genetic research and diagnostics.

Throughout the 1990s, Nichrome's role expanded into cell culture technologies. Microplate readers and automated cell culture systems began incorporating Nichrome heating elements, enabling precise temperature control for cell growth and assay conditions. This period also saw the development of Nichrome-based microheaters for lab-on-a-chip devices, paving the way for miniaturized bioassays.

The early 2000s witnessed Nichrome's adaptation to more complex biotech instruments. Its use in advanced bioreactors allowed for tighter control of fermentation processes, enhancing the production of biopharmaceuticals. Simultaneously, Nichrome found applications in proteomics, powering instruments for protein crystallization and structural analysis.

Recent years have seen Nichrome's integration into cutting-edge biotech fields. In tissue engineering, Nichrome-based heating systems are crucial for maintaining optimal conditions in bioprinters and organ-on-a-chip devices. The material has also been instrumental in developing thermal cyclers for CRISPR-Cas9 gene editing protocols, contributing to the precision and efficiency of this revolutionary technique.

Looking forward, Nichrome continues to evolve in biotech thermal regulation. Current research focuses on developing nanostructured Nichrome films for ultra-precise temperature control in microfluidic devices. Additionally, efforts are underway to create smart, responsive Nichrome heating elements that can adapt to dynamic biological processes in real-time, potentially revolutionizing fields such as personalized medicine and synthetic biology.

The 1980s marked a turning point as researchers recognized Nichrome's potential for more sophisticated biotech applications. Its high resistance and stability at elevated temperatures made it ideal for DNA amplification techniques, leading to its integration into the first commercial PCR thermal cyclers. This innovation dramatically accelerated genetic research and diagnostics.

Throughout the 1990s, Nichrome's role expanded into cell culture technologies. Microplate readers and automated cell culture systems began incorporating Nichrome heating elements, enabling precise temperature control for cell growth and assay conditions. This period also saw the development of Nichrome-based microheaters for lab-on-a-chip devices, paving the way for miniaturized bioassays.

The early 2000s witnessed Nichrome's adaptation to more complex biotech instruments. Its use in advanced bioreactors allowed for tighter control of fermentation processes, enhancing the production of biopharmaceuticals. Simultaneously, Nichrome found applications in proteomics, powering instruments for protein crystallization and structural analysis.

Recent years have seen Nichrome's integration into cutting-edge biotech fields. In tissue engineering, Nichrome-based heating systems are crucial for maintaining optimal conditions in bioprinters and organ-on-a-chip devices. The material has also been instrumental in developing thermal cyclers for CRISPR-Cas9 gene editing protocols, contributing to the precision and efficiency of this revolutionary technique.

Looking forward, Nichrome continues to evolve in biotech thermal regulation. Current research focuses on developing nanostructured Nichrome films for ultra-precise temperature control in microfluidic devices. Additionally, efforts are underway to create smart, responsive Nichrome heating elements that can adapt to dynamic biological processes in real-time, potentially revolutionizing fields such as personalized medicine and synthetic biology.

Thermal Regulation Market

The thermal regulation market has experienced significant growth in recent years, driven by advancements in biotechnology and increasing demand for precise temperature control in various applications. This market encompasses a wide range of devices and systems designed to maintain, adjust, and monitor temperature in biological and medical processes.

The global thermal regulation market for biotech applications is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other sectors in the biotechnology industry. This growth is primarily fueled by the expanding pharmaceutical and biotechnology research sectors, as well as the increasing adoption of thermal regulation devices in clinical diagnostics and personalized medicine.

One of the key drivers of market demand is the growing need for temperature-sensitive biological sample handling and storage. As research in genomics, proteomics, and cell biology advances, the requirement for precise thermal control in laboratory processes has become paramount. This has led to a surge in demand for sophisticated thermal cyclers, incubators, and cryogenic storage systems.

The healthcare sector represents a significant portion of the thermal regulation market, with applications ranging from patient temperature management to vaccine storage and transport. The COVID-19 pandemic has further highlighted the importance of reliable thermal regulation in vaccine distribution, contributing to increased market growth and innovation in portable cooling solutions.

Another emerging trend in the thermal regulation market is the integration of smart technologies and IoT capabilities. These advancements allow for remote monitoring, data logging, and automated temperature adjustments, enhancing the efficiency and reliability of thermal regulation devices. This trend is particularly relevant in large-scale biobanking and pharmaceutical manufacturing processes.

The market is also witnessing a shift towards more energy-efficient and environmentally friendly thermal regulation solutions. This includes the development of new materials and designs that optimize heat transfer while reducing power consumption. Such innovations are crucial in addressing the growing concerns about energy usage and environmental impact in laboratory and industrial settings.

Geographically, North America and Europe currently dominate the thermal regulation market for biotech applications, owing to their well-established biotechnology and pharmaceutical industries. However, the Asia-Pacific region is expected to show the fastest growth in the coming years, driven by increasing investment in life sciences research and healthcare infrastructure.

As the field of biotechnology continues to evolve, the thermal regulation market is poised for further expansion and innovation. The development of more precise, efficient, and versatile thermal regulation devices will be crucial in supporting advancements in areas such as regenerative medicine, synthetic biology, and personalized therapeutics.

The global thermal regulation market for biotech applications is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many other sectors in the biotechnology industry. This growth is primarily fueled by the expanding pharmaceutical and biotechnology research sectors, as well as the increasing adoption of thermal regulation devices in clinical diagnostics and personalized medicine.

One of the key drivers of market demand is the growing need for temperature-sensitive biological sample handling and storage. As research in genomics, proteomics, and cell biology advances, the requirement for precise thermal control in laboratory processes has become paramount. This has led to a surge in demand for sophisticated thermal cyclers, incubators, and cryogenic storage systems.

The healthcare sector represents a significant portion of the thermal regulation market, with applications ranging from patient temperature management to vaccine storage and transport. The COVID-19 pandemic has further highlighted the importance of reliable thermal regulation in vaccine distribution, contributing to increased market growth and innovation in portable cooling solutions.

Another emerging trend in the thermal regulation market is the integration of smart technologies and IoT capabilities. These advancements allow for remote monitoring, data logging, and automated temperature adjustments, enhancing the efficiency and reliability of thermal regulation devices. This trend is particularly relevant in large-scale biobanking and pharmaceutical manufacturing processes.

The market is also witnessing a shift towards more energy-efficient and environmentally friendly thermal regulation solutions. This includes the development of new materials and designs that optimize heat transfer while reducing power consumption. Such innovations are crucial in addressing the growing concerns about energy usage and environmental impact in laboratory and industrial settings.

Geographically, North America and Europe currently dominate the thermal regulation market for biotech applications, owing to their well-established biotechnology and pharmaceutical industries. However, the Asia-Pacific region is expected to show the fastest growth in the coming years, driven by increasing investment in life sciences research and healthcare infrastructure.

As the field of biotechnology continues to evolve, the thermal regulation market is poised for further expansion and innovation. The development of more precise, efficient, and versatile thermal regulation devices will be crucial in supporting advancements in areas such as regenerative medicine, synthetic biology, and personalized therapeutics.

Nichrome Challenges

Despite the widespread use of nichrome in thermal regulation devices for biotech applications, several challenges persist in its implementation and optimization. One of the primary concerns is the precise control of temperature in sensitive biological processes. Nichrome's thermal properties, while generally reliable, can sometimes lead to temperature fluctuations that may affect the accuracy of experimental results or the efficacy of biotech processes.

The durability of nichrome in biotech environments presents another significant challenge. Exposure to various biological substances, chemicals, and sterilization processes can potentially degrade the nichrome elements over time, affecting their performance and longevity. This necessitates frequent maintenance and replacement, which can be both costly and time-consuming for biotech facilities.

Heat distribution uniformity is a critical factor in many biotech applications, and achieving this with nichrome-based devices can be challenging. Uneven heating can lead to inconsistent results in processes such as PCR, cell culture incubation, or protein crystallization. Engineers must carefully design heating elements and incorporate advanced control systems to mitigate these issues.

The power consumption of nichrome-based thermal regulation devices is another area of concern, particularly in large-scale biotech operations. As energy efficiency becomes increasingly important, there is a growing need to develop more power-efficient nichrome implementations or explore alternative materials that can provide similar thermal properties with lower energy requirements.

Miniaturization of biotech devices presents unique challenges for nichrome integration. As devices become smaller and more compact, incorporating nichrome heating elements while maintaining thermal efficiency and uniform heat distribution becomes more complex. This is particularly relevant in the development of lab-on-a-chip devices and portable diagnostic tools.

Safety considerations also pose challenges in nichrome applications for biotech. The high temperatures generated by nichrome elements can potentially pose risks in environments with flammable or sensitive biological materials. Implementing adequate safety measures and fail-safe mechanisms is crucial to prevent accidents and ensure the integrity of biotech processes.

Lastly, the environmental impact of nichrome production and disposal is an emerging concern in the biotech industry's push towards sustainability. Developing more eco-friendly manufacturing processes for nichrome and exploring recyclable or biodegradable alternatives are becoming important areas of research to address these environmental challenges.

The durability of nichrome in biotech environments presents another significant challenge. Exposure to various biological substances, chemicals, and sterilization processes can potentially degrade the nichrome elements over time, affecting their performance and longevity. This necessitates frequent maintenance and replacement, which can be both costly and time-consuming for biotech facilities.

Heat distribution uniformity is a critical factor in many biotech applications, and achieving this with nichrome-based devices can be challenging. Uneven heating can lead to inconsistent results in processes such as PCR, cell culture incubation, or protein crystallization. Engineers must carefully design heating elements and incorporate advanced control systems to mitigate these issues.

The power consumption of nichrome-based thermal regulation devices is another area of concern, particularly in large-scale biotech operations. As energy efficiency becomes increasingly important, there is a growing need to develop more power-efficient nichrome implementations or explore alternative materials that can provide similar thermal properties with lower energy requirements.

Miniaturization of biotech devices presents unique challenges for nichrome integration. As devices become smaller and more compact, incorporating nichrome heating elements while maintaining thermal efficiency and uniform heat distribution becomes more complex. This is particularly relevant in the development of lab-on-a-chip devices and portable diagnostic tools.

Safety considerations also pose challenges in nichrome applications for biotech. The high temperatures generated by nichrome elements can potentially pose risks in environments with flammable or sensitive biological materials. Implementing adequate safety measures and fail-safe mechanisms is crucial to prevent accidents and ensure the integrity of biotech processes.

Lastly, the environmental impact of nichrome production and disposal is an emerging concern in the biotech industry's push towards sustainability. Developing more eco-friendly manufacturing processes for nichrome and exploring recyclable or biodegradable alternatives are becoming important areas of research to address these environmental challenges.

Nichrome Solutions

01 Nichrome heating elements for thermal regulation

Nichrome wire is commonly used as a heating element in thermal regulation systems due to its high electrical resistance and heat-generating properties. These elements can be precisely controlled to maintain specific temperatures in various applications, including industrial processes, consumer appliances, and scientific instruments.- Nichrome heating elements for thermal regulation: Nichrome wire is commonly used as a heating element in thermal regulation systems due to its high electrical resistance and heat-generating properties. These elements can be precisely controlled to maintain specific temperatures in various applications, including industrial processes, consumer appliances, and scientific instruments.

- Temperature control in medical devices: Nichrome-based thermal regulation is utilized in medical devices for maintaining precise temperatures. This is particularly important in applications such as patient warming systems, therapeutic devices, and diagnostic equipment where accurate temperature control is crucial for patient safety and treatment efficacy.

- Thermal management in electronic systems: Nichrome elements are employed in electronic systems for thermal management purposes. They can be used to regulate temperatures in components such as processors, power supplies, and other heat-sensitive parts, ensuring optimal performance and preventing overheating.

- Aerospace and automotive thermal regulation: In aerospace and automotive industries, nichrome-based thermal regulation systems are used for de-icing, cabin temperature control, and engine management. These applications require reliable and efficient temperature control in challenging environments.

- Advanced control systems for nichrome heating: Modern thermal regulation systems incorporating nichrome elements often feature advanced control mechanisms. These may include microprocessor-based controllers, feedback loops, and adaptive algorithms to optimize heating efficiency and precision across various operating conditions.

02 Temperature control in wearable devices

Nichrome-based heating elements are integrated into wearable devices for personalized thermal regulation. These systems can provide localized heating or cooling, enhancing comfort in various environmental conditions. The technology is particularly useful in medical devices, sports equipment, and protective gear.Expand Specific Solutions03 Thermal management in electronic components

Nichrome alloys are utilized in the thermal management of electronic components and systems. They can be incorporated into heat sinks, thermal interfaces, or as part of active cooling systems to regulate temperature and prevent overheating in high-performance electronics and telecommunications equipment.Expand Specific Solutions04 Precision temperature control in scientific instruments

Nichrome-based heating systems are employed in scientific instruments for precise temperature control. These systems are crucial in laboratory equipment, analytical devices, and research apparatus where maintaining exact temperatures is essential for accurate measurements and experimental conditions.Expand Specific Solutions05 Automotive thermal management applications

Nichrome elements are used in automotive thermal management systems for applications such as heated seats, defrosting systems, and engine temperature regulation. These systems improve vehicle comfort, safety, and performance by providing controlled heating in various parts of the vehicle.Expand Specific Solutions

Biotech Thermal Players

The biotech thermal regulation devices market is in a growth phase, driven by increasing demand for precise temperature control in various biomedical applications. The market size is expanding rapidly, with significant potential for further growth. Technological maturity varies across different segments, with established players like Koninklijke Philips NV and Intel Corp. leading in innovation. Emerging companies such as Domus Diagnostics and Cepheid are introducing novel solutions, particularly in point-of-care diagnostics. Academic institutions like California Institute of Technology and Shanghai Jiao Tong University contribute to advancing the field through research collaborations. The competitive landscape is diverse, with both large corporations and specialized biotech firms vying for market share in this promising sector.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced thermal regulation devices using nichrome for biotech applications. Their innovative approach involves precision-controlled nichrome heating elements integrated into microfluidic platforms for DNA amplification and analysis[1]. The company's technology utilizes thin-film nichrome resistors deposited on glass or silicon substrates, allowing for rapid and uniform heating of biological samples[3]. This system enables accurate temperature control within ±0.1°C, crucial for sensitive biotech processes like PCR (Polymerase Chain Reaction)[5]. Philips has also incorporated smart power management algorithms to optimize energy consumption and reduce thermal gradients across the heating surface[2].

Strengths: Precise temperature control, rapid heating/cooling cycles, and integration with existing biotech workflows. Weaknesses: Higher cost compared to traditional heating methods and potential for electromagnetic interference in sensitive assays.

CEPHEID

Technical Solution: CEPHEID has pioneered the use of nichrome-based thermal regulation in their GeneXpert system for rapid molecular diagnostics. Their technology employs a unique cartridge design with embedded nichrome heating elements for precise temperature cycling in nucleic acid amplification tests[4]. The system achieves heating rates of up to 10°C/second and can maintain temperatures within ±0.5°C accuracy[6]. CEPHEID's innovation lies in the miniaturization of the thermal regulation components, allowing for portable and point-of-care diagnostic devices. The company has also developed specialized coatings for the nichrome elements to enhance biocompatibility and reduce potential interference with biological samples[8].

Strengths: Rapid thermal cycling, compact design suitable for point-of-care diagnostics, and high reliability. Weaknesses: Limited to specific cartridge formats and potentially higher per-test costs.

Nichrome Innovations

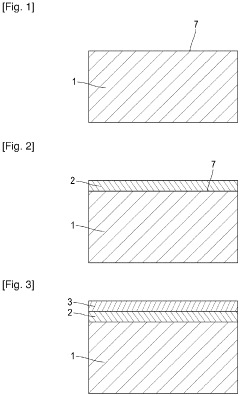

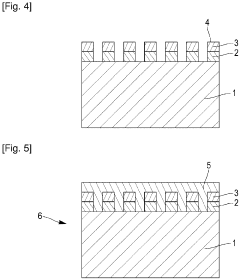

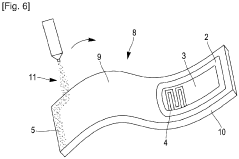

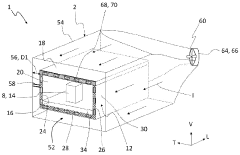

Method for manufacturing an assembly comprising a body and a device for thermal regulation of said body and assembly obtained

PatentPendingEP4228376A1

Innovation

- A method involving the application of an electrically insulating polymer, a resistive alloy, and etching to create a thin, shape-matched thermal regulation device directly integrated onto the body, using techniques like laser etching, vapor phase deposition, and thermal spraying, allowing for flexible design and miniaturization.

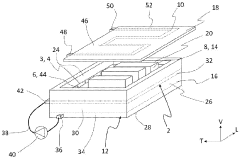

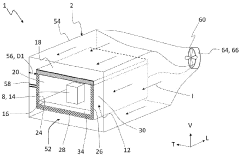

thermal control device

PatentInactiveFR3105715A1

Innovation

- A thermal regulation device with a fluid circulation pipe surrounding the casing, incorporating a dielectric fluid circuit for uniform cooling, a condensation wall for phase change, and a phase change material to enhance thermal inertia, ensuring efficient temperature regulation.

Biocompatibility Issues

Biocompatibility is a critical concern when integrating nichrome into biotech applications, particularly in thermal regulation devices. The primary challenge lies in ensuring that nichrome, an alloy primarily composed of nickel and chromium, does not elicit adverse biological responses when in contact with living tissues or fluids.

One of the main biocompatibility issues with nichrome is the potential for nickel ion leaching. Nickel is known to cause allergic reactions in some individuals, and prolonged exposure can lead to more severe health complications. In thermal regulation devices, where nichrome may be in close proximity to or in direct contact with biological systems, this risk is particularly pronounced.

Chromium, the other primary component of nichrome, also presents biocompatibility challenges. While chromium is an essential trace element in the human body, excessive exposure can lead to toxicity. The oxidation state of chromium is crucial, with hexavalent chromium being particularly harmful. The potential for chromium oxidation in nichrome-based devices must be carefully evaluated and mitigated.

The surface properties of nichrome can significantly impact its biocompatibility. Rough or porous surfaces may promote protein adsorption and subsequent cellular adhesion, potentially leading to undesired biological responses or device fouling. Conversely, excessively smooth surfaces might not provide adequate integration with surrounding tissues in certain applications.

Thermal cycling, inherent in many thermal regulation devices, can exacerbate biocompatibility issues. Repeated heating and cooling cycles may accelerate corrosion or degradation of the nichrome, potentially releasing harmful byproducts or altering the device's surface properties over time.

To address these biocompatibility concerns, several strategies are being explored. Surface modification techniques, such as coating nichrome with biocompatible materials like titanium nitride or diamond-like carbon, show promise in reducing ion leaching and improving overall biocompatibility. Another approach involves alloying nichrome with additional elements to enhance its corrosion resistance and reduce the release of potentially harmful ions.

Rigorous testing protocols are essential to evaluate the biocompatibility of nichrome-based thermal regulation devices. These typically include in vitro cytotoxicity assays, sensitization tests, and long-term implantation studies in animal models. Advanced analytical techniques, such as inductively coupled plasma mass spectrometry (ICP-MS), are employed to monitor ion release and degradation products over extended periods.

As the field of biotech continues to advance, there is a growing need for innovative materials that can meet both the thermal regulation requirements and stringent biocompatibility standards. While nichrome offers excellent thermal properties, addressing its biocompatibility issues remains a key focus for researchers and engineers developing next-generation biomedical devices.

One of the main biocompatibility issues with nichrome is the potential for nickel ion leaching. Nickel is known to cause allergic reactions in some individuals, and prolonged exposure can lead to more severe health complications. In thermal regulation devices, where nichrome may be in close proximity to or in direct contact with biological systems, this risk is particularly pronounced.

Chromium, the other primary component of nichrome, also presents biocompatibility challenges. While chromium is an essential trace element in the human body, excessive exposure can lead to toxicity. The oxidation state of chromium is crucial, with hexavalent chromium being particularly harmful. The potential for chromium oxidation in nichrome-based devices must be carefully evaluated and mitigated.

The surface properties of nichrome can significantly impact its biocompatibility. Rough or porous surfaces may promote protein adsorption and subsequent cellular adhesion, potentially leading to undesired biological responses or device fouling. Conversely, excessively smooth surfaces might not provide adequate integration with surrounding tissues in certain applications.

Thermal cycling, inherent in many thermal regulation devices, can exacerbate biocompatibility issues. Repeated heating and cooling cycles may accelerate corrosion or degradation of the nichrome, potentially releasing harmful byproducts or altering the device's surface properties over time.

To address these biocompatibility concerns, several strategies are being explored. Surface modification techniques, such as coating nichrome with biocompatible materials like titanium nitride or diamond-like carbon, show promise in reducing ion leaching and improving overall biocompatibility. Another approach involves alloying nichrome with additional elements to enhance its corrosion resistance and reduce the release of potentially harmful ions.

Rigorous testing protocols are essential to evaluate the biocompatibility of nichrome-based thermal regulation devices. These typically include in vitro cytotoxicity assays, sensitization tests, and long-term implantation studies in animal models. Advanced analytical techniques, such as inductively coupled plasma mass spectrometry (ICP-MS), are employed to monitor ion release and degradation products over extended periods.

As the field of biotech continues to advance, there is a growing need for innovative materials that can meet both the thermal regulation requirements and stringent biocompatibility standards. While nichrome offers excellent thermal properties, addressing its biocompatibility issues remains a key focus for researchers and engineers developing next-generation biomedical devices.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing nichrome-based thermal regulation devices in the biotech industry. The use of nichrome in biomedical applications necessitates adherence to stringent safety and quality standards set by various regulatory bodies. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in overseeing the development and commercialization of medical devices, including those utilizing nichrome for thermal regulation.

Manufacturers must navigate the FDA's premarket approval (PMA) process or 510(k) clearance, depending on the device classification and intended use. This involves demonstrating the safety and efficacy of the nichrome-based thermal regulation device through extensive clinical trials and laboratory testing. The FDA's Quality System Regulation (QSR) also mandates rigorous quality control measures throughout the manufacturing process to ensure consistent product performance and safety.

In the European Union, compliance with the Medical Device Regulation (MDR) is essential for market access. This regulation imposes strict requirements on device manufacturers, including comprehensive technical documentation, risk management procedures, and post-market surveillance. The CE marking process, which indicates conformity with EU health, safety, and environmental protection standards, is a crucial step for nichrome-based devices entering the European market.

International standards such as ISO 13485 for quality management systems in medical devices and IEC 60601 for electrical safety in medical equipment are also pertinent to nichrome-based thermal regulation devices. These standards ensure that the devices meet global benchmarks for safety, reliability, and performance.

Biocompatibility testing, as outlined in ISO 10993, is particularly relevant for nichrome components that may come into contact with biological tissues. Manufacturers must demonstrate that their devices do not elicit adverse biological responses when used as intended. This involves a series of in vitro and in vivo tests to assess cytotoxicity, sensitization, and potential long-term effects.

Environmental regulations also come into play, especially concerning the disposal and recycling of nichrome-containing devices. Compliance with directives such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) is necessary to address the environmental impact of these devices throughout their lifecycle.

As the field of biotech thermal regulation devices evolves, regulatory frameworks are likely to adapt. Manufacturers and researchers must stay abreast of emerging regulations and guidelines, particularly those addressing novel applications of nichrome in biomedical settings. Proactive engagement with regulatory bodies and participation in industry standards development can help shape a favorable regulatory landscape for innovative nichrome-based technologies.

Manufacturers must navigate the FDA's premarket approval (PMA) process or 510(k) clearance, depending on the device classification and intended use. This involves demonstrating the safety and efficacy of the nichrome-based thermal regulation device through extensive clinical trials and laboratory testing. The FDA's Quality System Regulation (QSR) also mandates rigorous quality control measures throughout the manufacturing process to ensure consistent product performance and safety.

In the European Union, compliance with the Medical Device Regulation (MDR) is essential for market access. This regulation imposes strict requirements on device manufacturers, including comprehensive technical documentation, risk management procedures, and post-market surveillance. The CE marking process, which indicates conformity with EU health, safety, and environmental protection standards, is a crucial step for nichrome-based devices entering the European market.

International standards such as ISO 13485 for quality management systems in medical devices and IEC 60601 for electrical safety in medical equipment are also pertinent to nichrome-based thermal regulation devices. These standards ensure that the devices meet global benchmarks for safety, reliability, and performance.

Biocompatibility testing, as outlined in ISO 10993, is particularly relevant for nichrome components that may come into contact with biological tissues. Manufacturers must demonstrate that their devices do not elicit adverse biological responses when used as intended. This involves a series of in vitro and in vivo tests to assess cytotoxicity, sensitization, and potential long-term effects.

Environmental regulations also come into play, especially concerning the disposal and recycling of nichrome-containing devices. Compliance with directives such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) is necessary to address the environmental impact of these devices throughout their lifecycle.

As the field of biotech thermal regulation devices evolves, regulatory frameworks are likely to adapt. Manufacturers and researchers must stay abreast of emerging regulations and guidelines, particularly those addressing novel applications of nichrome in biomedical settings. Proactive engagement with regulatory bodies and participation in industry standards development can help shape a favorable regulatory landscape for innovative nichrome-based technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!