Nichrome in Modern Transportation: Key Heating Applications

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Heating Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in the evolution of heating applications within the transportation sector. The journey of nichrome in this field can be traced back to the early 20th century when it was first developed as a resistance heating element. Its unique properties, including high electrical resistance and excellent heat resistance, quickly made it a preferred material for various heating applications.

In the automotive industry, nichrome's evolution began with its use in simple car cigarette lighters. As vehicle technology advanced, so did the applications of nichrome. It found its way into more critical systems, such as engine block heaters, which became essential for cold weather starts. The material's reliability and efficiency in converting electrical energy to heat made it an ideal choice for these applications.

The aviation sector saw nichrome's potential early on, incorporating it into aircraft de-icing systems. As air travel became more prevalent and aircraft flew at higher altitudes, the need for effective de-icing mechanisms grew. Nichrome-based heating elements proved crucial in preventing ice formation on wings and other critical surfaces, significantly enhancing flight safety.

In the rail industry, nichrome's evolution took a different path. It became integral to passenger comfort systems, powering seat warmers and cabin heating units in trains. The material's ability to provide consistent and controllable heat output made it ideal for maintaining comfortable temperatures in varying climate conditions.

The marine sector also benefited from nichrome's heating capabilities. Its corrosion-resistant properties made it suitable for use in saltwater environments. Nichrome heating elements found applications in anti-condensation systems for ship electronics and in maintaining optimal temperatures for sensitive equipment.

As environmental concerns grew, nichrome's role evolved to meet new challenges. In electric and hybrid vehicles, it became a key component in battery thermal management systems. These systems ensure optimal battery performance and longevity by maintaining ideal operating temperatures, crucial for the efficiency and range of electric vehicles.

The most recent evolution of nichrome in transportation heating applications involves its integration with smart control systems. Advanced sensors and microprocessors now work in tandem with nichrome heating elements to provide precise temperature control and energy efficiency. This development has led to more sophisticated climate control systems in vehicles and aircraft, enhancing both comfort and fuel efficiency.

Looking ahead, the evolution of nichrome in transportation heating continues. Research is ongoing into nanoscale modifications of the alloy to further improve its performance characteristics. Additionally, its potential in emerging transportation technologies, such as hyperloop systems and autonomous vehicles, is being explored, promising new and innovative applications for this versatile material.

In the automotive industry, nichrome's evolution began with its use in simple car cigarette lighters. As vehicle technology advanced, so did the applications of nichrome. It found its way into more critical systems, such as engine block heaters, which became essential for cold weather starts. The material's reliability and efficiency in converting electrical energy to heat made it an ideal choice for these applications.

The aviation sector saw nichrome's potential early on, incorporating it into aircraft de-icing systems. As air travel became more prevalent and aircraft flew at higher altitudes, the need for effective de-icing mechanisms grew. Nichrome-based heating elements proved crucial in preventing ice formation on wings and other critical surfaces, significantly enhancing flight safety.

In the rail industry, nichrome's evolution took a different path. It became integral to passenger comfort systems, powering seat warmers and cabin heating units in trains. The material's ability to provide consistent and controllable heat output made it ideal for maintaining comfortable temperatures in varying climate conditions.

The marine sector also benefited from nichrome's heating capabilities. Its corrosion-resistant properties made it suitable for use in saltwater environments. Nichrome heating elements found applications in anti-condensation systems for ship electronics and in maintaining optimal temperatures for sensitive equipment.

As environmental concerns grew, nichrome's role evolved to meet new challenges. In electric and hybrid vehicles, it became a key component in battery thermal management systems. These systems ensure optimal battery performance and longevity by maintaining ideal operating temperatures, crucial for the efficiency and range of electric vehicles.

The most recent evolution of nichrome in transportation heating applications involves its integration with smart control systems. Advanced sensors and microprocessors now work in tandem with nichrome heating elements to provide precise temperature control and energy efficiency. This development has led to more sophisticated climate control systems in vehicles and aircraft, enhancing both comfort and fuel efficiency.

Looking ahead, the evolution of nichrome in transportation heating continues. Research is ongoing into nanoscale modifications of the alloy to further improve its performance characteristics. Additionally, its potential in emerging transportation technologies, such as hyperloop systems and autonomous vehicles, is being explored, promising new and innovative applications for this versatile material.

Transportation Market Demand

The transportation sector has witnessed a significant surge in demand for nichrome-based heating applications, driven by the increasing need for efficient and reliable heating solutions in various modes of transport. This demand is particularly pronounced in automotive, aerospace, and railway industries, where nichrome's unique properties make it an ideal material for heating elements.

In the automotive industry, the market for nichrome heating applications has been expanding rapidly. The growing adoption of electric vehicles (EVs) has created a substantial demand for battery thermal management systems, where nichrome plays a crucial role in maintaining optimal battery temperature. Additionally, the increasing consumer preference for comfort features in vehicles has led to a rise in the use of nichrome-based seat heaters, steering wheel heaters, and defrosting systems.

The aerospace sector represents another significant market for nichrome heating applications. Aircraft de-icing systems, which are critical for flight safety, extensively utilize nichrome heating elements. The increasing air traffic and the need for all-weather operations have further boosted the demand for these systems. Moreover, nichrome is widely used in aircraft cabin heating systems, contributing to passenger comfort during flights.

In the railway industry, nichrome heating applications are essential for ensuring passenger comfort and operational efficiency. Train heating systems, including underfloor heating and seat warmers, often incorporate nichrome elements. The expansion of high-speed rail networks globally has further amplified the demand for these heating solutions, as they need to operate reliably under various climatic conditions.

The marine transportation sector, although smaller in market size compared to automotive and aerospace, also presents a growing demand for nichrome heating applications. These are primarily used in anti-icing systems for ships operating in cold regions and in various onboard heating systems for passenger comfort.

The overall market trend indicates a steady growth in the demand for nichrome heating applications across all transportation sectors. This growth is fueled by factors such as increasing electrification of vehicles, advancements in transportation technology, and the rising emphasis on passenger comfort and safety. The versatility of nichrome in withstanding high temperatures and its excellent electrical resistance properties continue to make it a preferred material for heating applications in modern transportation.

As environmental regulations become more stringent, there is also a growing focus on energy-efficient heating solutions in transportation. This trend is likely to drive further innovations in nichrome-based heating technologies, potentially expanding its applications and market demand in the coming years.

In the automotive industry, the market for nichrome heating applications has been expanding rapidly. The growing adoption of electric vehicles (EVs) has created a substantial demand for battery thermal management systems, where nichrome plays a crucial role in maintaining optimal battery temperature. Additionally, the increasing consumer preference for comfort features in vehicles has led to a rise in the use of nichrome-based seat heaters, steering wheel heaters, and defrosting systems.

The aerospace sector represents another significant market for nichrome heating applications. Aircraft de-icing systems, which are critical for flight safety, extensively utilize nichrome heating elements. The increasing air traffic and the need for all-weather operations have further boosted the demand for these systems. Moreover, nichrome is widely used in aircraft cabin heating systems, contributing to passenger comfort during flights.

In the railway industry, nichrome heating applications are essential for ensuring passenger comfort and operational efficiency. Train heating systems, including underfloor heating and seat warmers, often incorporate nichrome elements. The expansion of high-speed rail networks globally has further amplified the demand for these heating solutions, as they need to operate reliably under various climatic conditions.

The marine transportation sector, although smaller in market size compared to automotive and aerospace, also presents a growing demand for nichrome heating applications. These are primarily used in anti-icing systems for ships operating in cold regions and in various onboard heating systems for passenger comfort.

The overall market trend indicates a steady growth in the demand for nichrome heating applications across all transportation sectors. This growth is fueled by factors such as increasing electrification of vehicles, advancements in transportation technology, and the rising emphasis on passenger comfort and safety. The versatility of nichrome in withstanding high temperatures and its excellent electrical resistance properties continue to make it a preferred material for heating applications in modern transportation.

As environmental regulations become more stringent, there is also a growing focus on energy-efficient heating solutions in transportation. This trend is likely to drive further innovations in nichrome-based heating technologies, potentially expanding its applications and market demand in the coming years.

Current Nichrome Challenges

Despite its widespread use in modern transportation, nichrome faces several significant challenges that limit its potential and efficiency in heating applications. One of the primary issues is the material's susceptibility to oxidation at high temperatures. When exposed to air at elevated temperatures, nichrome forms a chromium oxide layer on its surface. While this layer initially provides some protection, it can lead to reduced conductivity and heat transfer efficiency over time, potentially compromising the performance of heating systems in vehicles.

Another challenge is the relatively high cost of nichrome compared to some alternative materials. The increasing demand for nickel and chromium in various industries has led to price volatility, making it difficult for manufacturers to maintain consistent production costs. This economic factor can impact the affordability and widespread adoption of nichrome-based heating solutions in transportation applications.

The weight of nichrome components is also a concern, particularly in aerospace and electric vehicle applications where every gram matters. As the transportation industry moves towards lighter, more fuel-efficient vehicles, the relatively high density of nichrome can be a drawback. Engineers must balance the excellent heating properties of nichrome against the need for weight reduction in modern vehicle design.

Durability under extreme conditions poses another challenge. While nichrome is known for its resistance to corrosion and high-temperature stability, it can still degrade over time when subjected to repeated thermal cycling and mechanical stress. This is particularly relevant in transportation applications where heating elements may need to withstand vibrations, shocks, and frequent temperature changes.

Furthermore, the limited malleability of nichrome can complicate its integration into complex or compact heating system designs. As vehicles become more sophisticated and space-constrained, there is a growing need for heating elements that can be easily shaped and miniaturized without compromising performance. Nichrome's relative rigidity compared to some newer alloys can restrict design flexibility and innovation in heating system layouts.

Lastly, the environmental impact of nichrome production and disposal is an emerging concern. The mining and processing of nickel and chromium have significant environmental footprints, and the increasing focus on sustainability in the transportation sector is driving the search for more eco-friendly alternatives. Additionally, the recycling of nichrome components at the end of their lifecycle presents challenges due to the need to separate the alloying elements effectively.

Another challenge is the relatively high cost of nichrome compared to some alternative materials. The increasing demand for nickel and chromium in various industries has led to price volatility, making it difficult for manufacturers to maintain consistent production costs. This economic factor can impact the affordability and widespread adoption of nichrome-based heating solutions in transportation applications.

The weight of nichrome components is also a concern, particularly in aerospace and electric vehicle applications where every gram matters. As the transportation industry moves towards lighter, more fuel-efficient vehicles, the relatively high density of nichrome can be a drawback. Engineers must balance the excellent heating properties of nichrome against the need for weight reduction in modern vehicle design.

Durability under extreme conditions poses another challenge. While nichrome is known for its resistance to corrosion and high-temperature stability, it can still degrade over time when subjected to repeated thermal cycling and mechanical stress. This is particularly relevant in transportation applications where heating elements may need to withstand vibrations, shocks, and frequent temperature changes.

Furthermore, the limited malleability of nichrome can complicate its integration into complex or compact heating system designs. As vehicles become more sophisticated and space-constrained, there is a growing need for heating elements that can be easily shaped and miniaturized without compromising performance. Nichrome's relative rigidity compared to some newer alloys can restrict design flexibility and innovation in heating system layouts.

Lastly, the environmental impact of nichrome production and disposal is an emerging concern. The mining and processing of nickel and chromium have significant environmental footprints, and the increasing focus on sustainability in the transportation sector is driving the search for more eco-friendly alternatives. Additionally, the recycling of nichrome components at the end of their lifecycle presents challenges due to the need to separate the alloying elements effectively.

Nichrome Heating Solutions

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying proportions depending on the specific application. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Manufacturing processes for nichrome components: Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy techniques. These processes allow for the creation of nichrome elements in different forms such as wires, films, and powders, tailored for specific applications in electronics and heating systems.

- Applications in heating elements and resistors: Nichrome is widely used in the production of heating elements and resistors due to its high electrical resistance and heat-resistant properties. It is commonly found in household appliances, industrial heaters, and electronic devices where precise temperature control or electrical resistance is required.

- Use in thin film technology and sensors: Nichrome is utilized in thin film technology for the fabrication of sensors, microelectronic devices, and precision instruments. Its stability and consistent electrical properties make it suitable for creating thin film resistors and temperature sensors in various electronic applications.

- Innovations in nichrome-based materials and coatings: Recent innovations involve the development of new nichrome-based materials and coatings with enhanced properties. These include improved oxidation resistance, better adhesion to substrates, and optimized electrical characteristics. Such advancements expand the potential applications of nichrome in aerospace, automotive, and advanced manufacturing sectors.

02 Nichrome in heating elements and electrical resistors

Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and heat-generating properties. It is commonly found in appliances such as toasters, hair dryers, and electric heaters. The alloy's stability at high temperatures makes it ideal for these applications.Expand Specific Solutions03 Nichrome in thin film technology

Nichrome is utilized in thin film technology for various electronic applications. It can be deposited as a thin film on substrates to create resistive elements, sensors, or other electronic components. The process of depositing nichrome thin films often involves techniques such as sputtering or vapor deposition.Expand Specific Solutions04 Nichrome in aerospace and antenna applications

Nichrome finds applications in aerospace and antenna technologies due to its unique properties. It can be used in the construction of certain antenna components or in specialized aerospace materials. The alloy's resistance to high temperatures and corrosion makes it suitable for these demanding environments.Expand Specific Solutions05 Innovations in nichrome-based materials and coatings

Ongoing research and development efforts are focused on improving nichrome-based materials and coatings. This includes creating new alloy compositions, developing advanced coating techniques, and exploring novel applications for nichrome in various industries. These innovations aim to enhance the performance and expand the use of nichrome in different technological fields.Expand Specific Solutions

Key Nichrome Manufacturers

The market for nichrome applications in modern transportation is in a growth phase, driven by increasing demand for efficient heating solutions in various vehicle systems. The global market size for automotive heating elements, including nichrome-based components, is expanding steadily. Technologically, nichrome applications are mature but continue to evolve, with companies like Air Liquide SA, Resonac Holdings Corp., and Siemens Energy Global GmbH & Co. KG leading innovations in high-performance alloys and heating systems. These industry leaders, along with specialized manufacturers such as Yancheng Xinyang Electric Heating Material Co., Ltd., are focusing on developing more efficient, durable, and lightweight nichrome-based solutions to meet the growing needs of the transportation sector.

Siemens Energy Global GmbH & Co. KG

Technical Solution: Siemens Energy has developed advanced nichrome-based heating solutions for modern transportation applications. Their technology utilizes precision-engineered nichrome alloys to create efficient and reliable heating elements for various transportation systems. These elements are designed to operate at high temperatures while maintaining structural integrity, making them ideal for use in aircraft de-icing systems, train braking systems, and electric vehicle battery thermal management[1]. Siemens' nichrome heating solutions incorporate advanced control systems that allow for precise temperature regulation and energy optimization, resulting in improved fuel efficiency and reduced emissions in transportation vehicles[2].

Strengths: High temperature resistance, precise temperature control, and energy efficiency. Weaknesses: Higher initial cost compared to traditional heating methods and potential for electromagnetic interference in sensitive electronic systems.

Robert Bosch GmbH

Technical Solution: Bosch has innovated in the field of nichrome heating applications for modern transportation, particularly focusing on automotive systems. Their technology integrates nichrome heating elements into various vehicle components, such as side mirrors, windshields, and sensor systems, to enhance safety and performance in adverse weather conditions[3]. Bosch's nichrome-based heating solutions are designed for rapid heat-up times and uniform heat distribution, crucial for maintaining clear visibility and sensor functionality in autonomous vehicles. The company has also developed smart control algorithms that adjust heating power based on ambient conditions and vehicle speed, optimizing energy consumption[4].

Strengths: Rapid heating capability, integration with vehicle systems, and energy-efficient operation. Weaknesses: Complexity in implementation and potential for increased vehicle weight due to additional components.

Nichrome Alloy Innovations

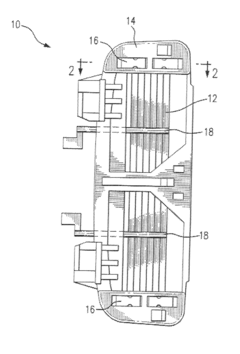

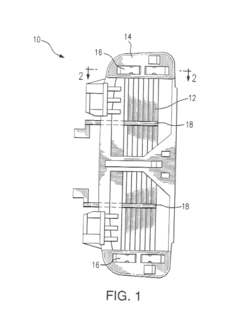

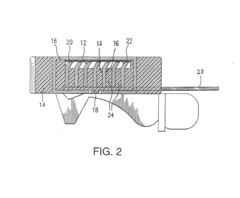

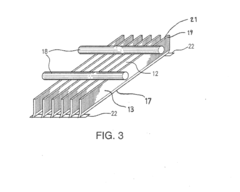

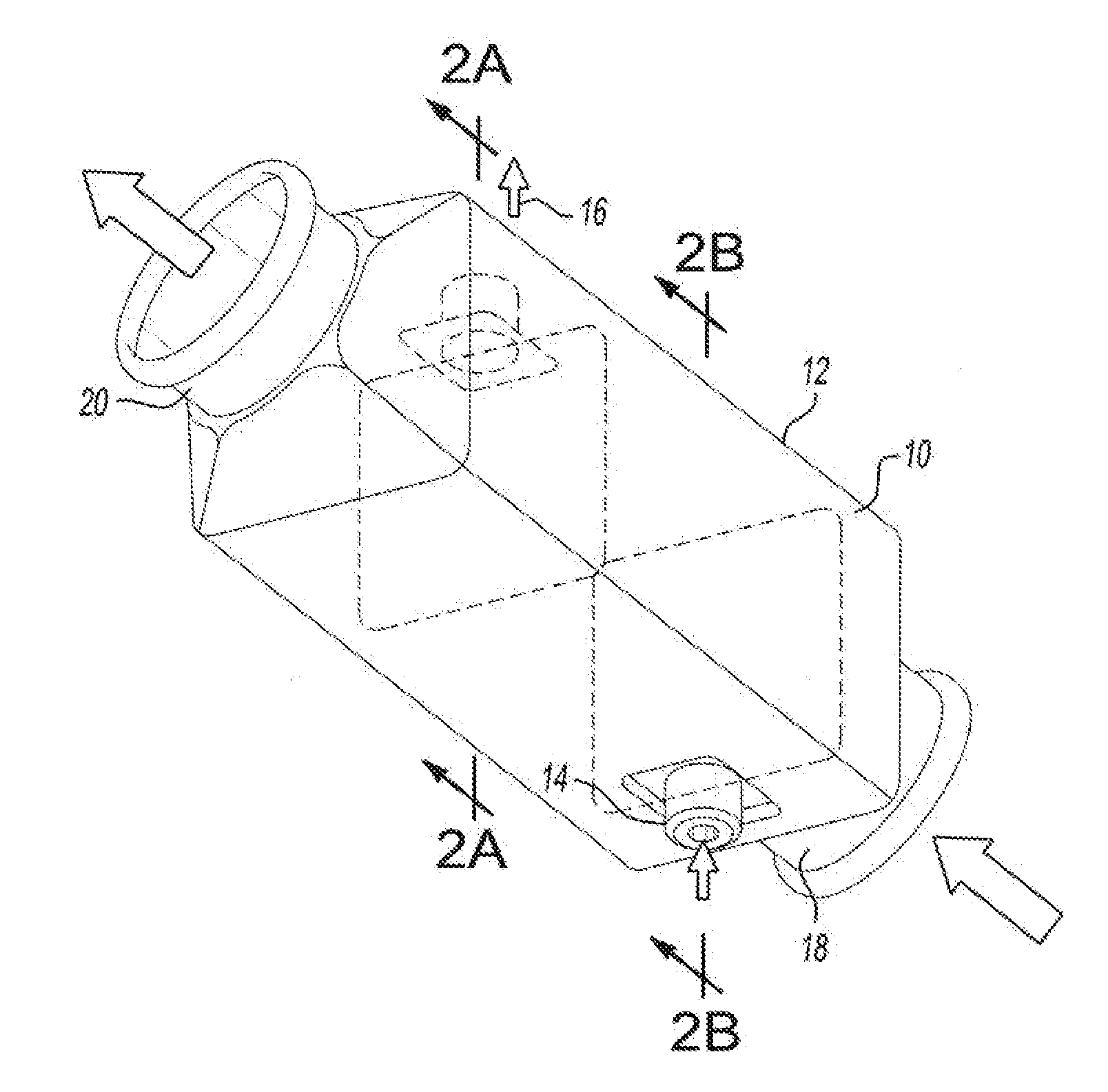

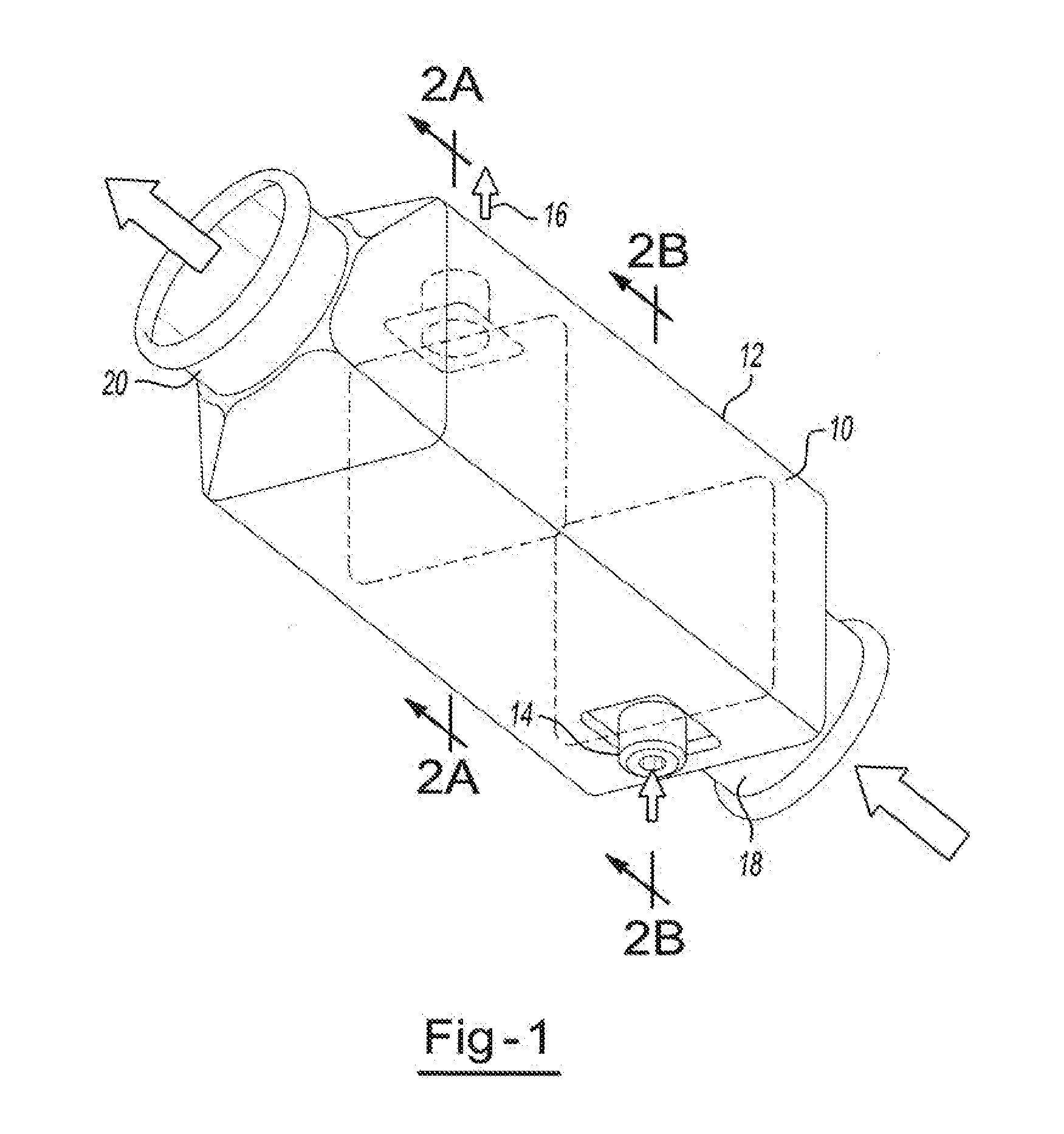

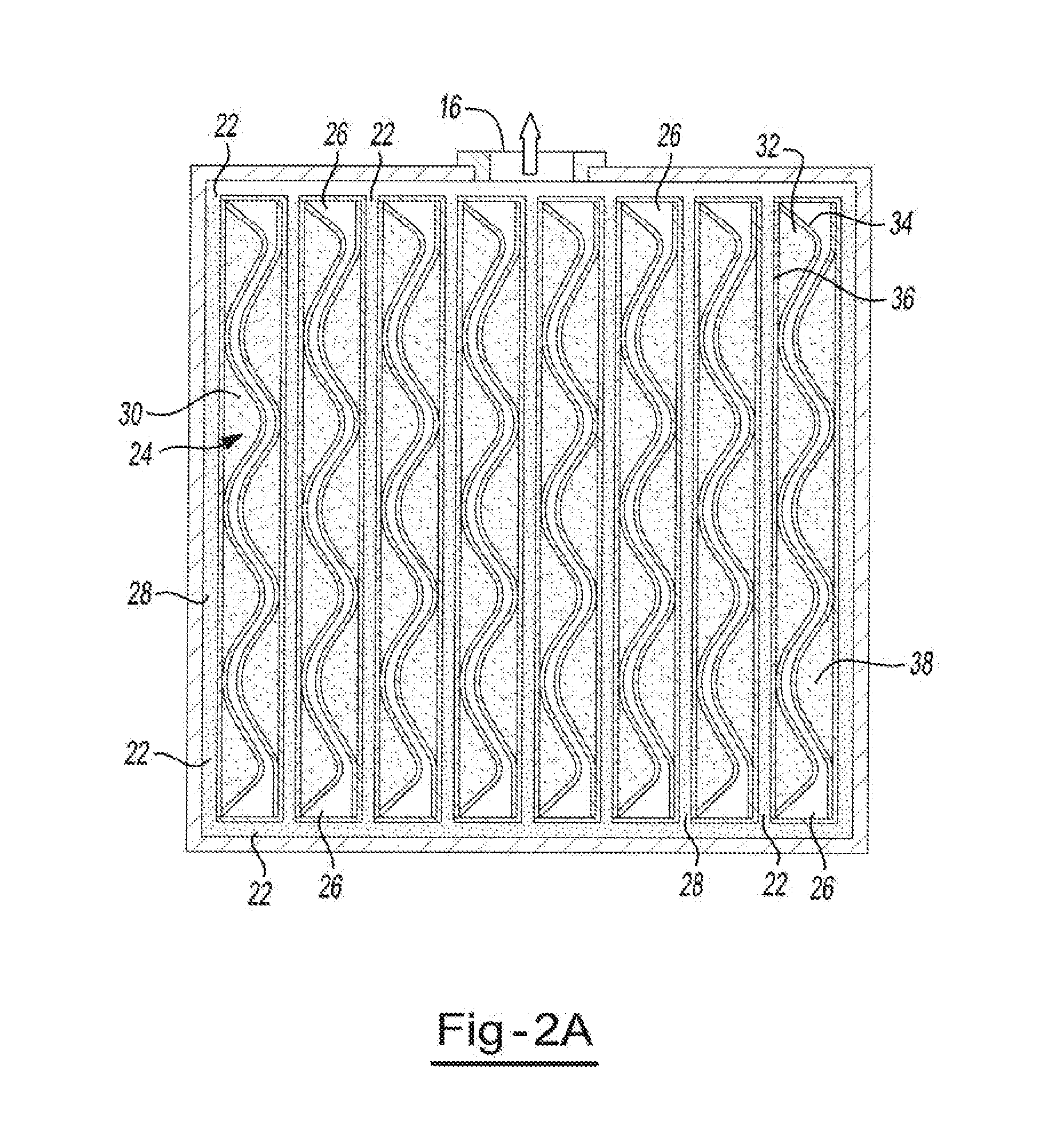

Razor with blade heating system

PatentActiveUS20140245611A1

Innovation

- The use of high resistance electrically conductive contact segments, such as Nichrome, connected to the back edges of razor blades with standard conductive wires, forming an electric circuit that generates heat through electric current flow, combined with a radiator effect to distribute heat uniformly across the blades, allowing for dual heat control with minimal voltage and efficient battery power usage.

Heat transfer system utilizing thermal energy storage materials

PatentInactiveUS20120168111A1

Innovation

- A capillary pumped loop system with a heat storage device containing a thermal energy storage material that undergoes a solid to liquid phase transition above 50°C, utilizing a capillary structure to efficiently store and discharge heat, including a working fluid compartment and a heat transfer fluid compartment, allowing for high power density and long heat retention.

Nichrome Safety Standards

Safety standards for nichrome in modern transportation applications are crucial to ensure the reliable and secure operation of heating systems. These standards encompass various aspects, including material composition, electrical properties, thermal performance, and durability requirements. The American Society for Testing and Materials (ASTM) has established specific guidelines for nichrome alloys used in heating elements, such as ASTM B344, which outlines the standard specifications for drawn or rolled nickel-chromium and nickel-chromium-iron alloys for electrical heating elements.

In the automotive industry, nichrome heating elements must comply with stringent safety regulations set by organizations like the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards address issues such as electrical insulation, temperature control, and fire resistance. For instance, SAE J1772 provides guidelines for electric vehicle supply equipment, including heating systems that may utilize nichrome elements.

The aerospace sector imposes even more rigorous safety standards on nichrome applications. The Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established comprehensive regulations for aircraft heating systems. These standards cover aspects such as electromagnetic compatibility, vibration resistance, and performance under extreme environmental conditions. Nichrome components used in aircraft de-icing systems, for example, must meet the requirements outlined in SAE AS8037 for electrical de-icing systems.

Safety standards also address the potential health and environmental impacts of nichrome usage. The Occupational Safety and Health Administration (OSHA) has set exposure limits for nickel and chromium compounds, which are relevant to the manufacturing and maintenance of nichrome heating elements. Additionally, the European Union's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous substances in electrical and electronic equipment, including nichrome-based components.

To ensure compliance with these safety standards, manufacturers of nichrome heating elements for transportation applications must implement rigorous quality control processes. This includes regular testing of material properties, performance validation under various operating conditions, and documentation of compliance with relevant standards. Third-party certification bodies, such as Underwriters Laboratories (UL) and TÜV, often play a crucial role in verifying adherence to safety standards and issuing certifications for nichrome-based heating products.

As transportation technologies continue to evolve, safety standards for nichrome applications are also subject to ongoing review and updates. Emerging trends, such as the increased adoption of electric vehicles and the development of more energy-efficient heating systems, may lead to the establishment of new or revised safety standards in the future. Manufacturers and engineers working with nichrome in transportation applications must stay informed about these evolving standards to ensure continued compliance and safety in their products.

In the automotive industry, nichrome heating elements must comply with stringent safety regulations set by organizations like the Society of Automotive Engineers (SAE) and the International Organization for Standardization (ISO). These standards address issues such as electrical insulation, temperature control, and fire resistance. For instance, SAE J1772 provides guidelines for electric vehicle supply equipment, including heating systems that may utilize nichrome elements.

The aerospace sector imposes even more rigorous safety standards on nichrome applications. The Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established comprehensive regulations for aircraft heating systems. These standards cover aspects such as electromagnetic compatibility, vibration resistance, and performance under extreme environmental conditions. Nichrome components used in aircraft de-icing systems, for example, must meet the requirements outlined in SAE AS8037 for electrical de-icing systems.

Safety standards also address the potential health and environmental impacts of nichrome usage. The Occupational Safety and Health Administration (OSHA) has set exposure limits for nickel and chromium compounds, which are relevant to the manufacturing and maintenance of nichrome heating elements. Additionally, the European Union's Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous substances in electrical and electronic equipment, including nichrome-based components.

To ensure compliance with these safety standards, manufacturers of nichrome heating elements for transportation applications must implement rigorous quality control processes. This includes regular testing of material properties, performance validation under various operating conditions, and documentation of compliance with relevant standards. Third-party certification bodies, such as Underwriters Laboratories (UL) and TÜV, often play a crucial role in verifying adherence to safety standards and issuing certifications for nichrome-based heating products.

As transportation technologies continue to evolve, safety standards for nichrome applications are also subject to ongoing review and updates. Emerging trends, such as the increased adoption of electric vehicles and the development of more energy-efficient heating systems, may lead to the establishment of new or revised safety standards in the future. Manufacturers and engineers working with nichrome in transportation applications must stay informed about these evolving standards to ensure continued compliance and safety in their products.

Environmental Impact

The environmental impact of nichrome in modern transportation heating applications is a critical consideration in the context of sustainability and ecological responsibility. Nichrome, an alloy primarily composed of nickel and chromium, plays a significant role in various heating systems within the transportation sector. However, its production, use, and disposal have notable environmental implications that warrant careful examination.

The manufacturing process of nichrome involves the extraction and processing of nickel and chromium, both of which can have substantial environmental consequences. Mining operations for these metals often lead to habitat destruction, soil erosion, and water pollution. The energy-intensive nature of metal extraction and alloy production contributes to increased carbon emissions, exacerbating climate change concerns.

In the context of transportation applications, nichrome's durability and resistance to corrosion contribute to extended product lifecycles, potentially reducing the frequency of replacement and associated environmental impacts. However, the high operating temperatures of nichrome heating elements in vehicles and aircraft can lead to increased energy consumption, indirectly contributing to higher fuel usage and greenhouse gas emissions.

The disposal of nichrome-containing components at the end of their lifecycle presents another environmental challenge. While the alloy itself is recyclable, the complex nature of many transportation heating systems can make separation and recovery of nichrome difficult. Improper disposal may result in the release of heavy metals into the environment, posing risks to ecosystems and human health.

On the positive side, the efficiency of nichrome in heating applications can lead to improved overall energy efficiency in transportation systems. This can translate to reduced fuel consumption and lower emissions, particularly in electric and hybrid vehicles where efficient heating is crucial for battery performance and passenger comfort.

Efforts to mitigate the environmental impact of nichrome in transportation are ongoing. Research into more sustainable production methods, such as using recycled materials and cleaner energy sources in manufacturing, shows promise. Additionally, advancements in design are focusing on optimizing nichrome usage to minimize material requirements while maintaining performance.

As the transportation industry continues to evolve towards more sustainable practices, the role of nichrome in heating applications is likely to be scrutinized further. Balancing its beneficial properties with environmental concerns will be crucial in developing future transportation technologies that are both efficient and ecologically responsible.

The manufacturing process of nichrome involves the extraction and processing of nickel and chromium, both of which can have substantial environmental consequences. Mining operations for these metals often lead to habitat destruction, soil erosion, and water pollution. The energy-intensive nature of metal extraction and alloy production contributes to increased carbon emissions, exacerbating climate change concerns.

In the context of transportation applications, nichrome's durability and resistance to corrosion contribute to extended product lifecycles, potentially reducing the frequency of replacement and associated environmental impacts. However, the high operating temperatures of nichrome heating elements in vehicles and aircraft can lead to increased energy consumption, indirectly contributing to higher fuel usage and greenhouse gas emissions.

The disposal of nichrome-containing components at the end of their lifecycle presents another environmental challenge. While the alloy itself is recyclable, the complex nature of many transportation heating systems can make separation and recovery of nichrome difficult. Improper disposal may result in the release of heavy metals into the environment, posing risks to ecosystems and human health.

On the positive side, the efficiency of nichrome in heating applications can lead to improved overall energy efficiency in transportation systems. This can translate to reduced fuel consumption and lower emissions, particularly in electric and hybrid vehicles where efficient heating is crucial for battery performance and passenger comfort.

Efforts to mitigate the environmental impact of nichrome in transportation are ongoing. Research into more sustainable production methods, such as using recycled materials and cleaner energy sources in manufacturing, shows promise. Additionally, advancements in design are focusing on optimizing nichrome usage to minimize material requirements while maintaining performance.

As the transportation industry continues to evolve towards more sustainable practices, the role of nichrome in heating applications is likely to be scrutinized further. Balancing its beneficial properties with environmental concerns will be crucial in developing future transportation technologies that are both efficient and ecologically responsible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!