Nichrome Optimization Techniques for Consumer Electronics

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has been a cornerstone in consumer electronics for decades. Its evolution can be traced back to the early 20th century when it was first developed for use in electrical resistance heating elements. Since then, nichrome has undergone significant advancements, driven by the ever-increasing demands of the consumer electronics industry.

The journey of nichrome in consumer electronics began with its application in simple heating devices, such as toasters and hair dryers. As technology progressed, the need for more precise and efficient heating elements grew, pushing researchers and engineers to optimize nichrome's properties. This led to the development of various nichrome compositions, each tailored to specific applications within the consumer electronics sector.

One of the key milestones in nichrome's evolution was the introduction of thin-film deposition techniques in the 1960s and 1970s. This breakthrough allowed for the creation of extremely thin and uniform nichrome layers, opening up new possibilities for miniaturization and improved performance in electronic devices. The ability to precisely control the thickness and composition of nichrome films became crucial in the manufacturing of advanced sensors, microelectronics, and display technologies.

In recent years, the focus of nichrome optimization has shifted towards enhancing its durability, thermal stability, and electrical properties. Researchers have been exploring ways to improve nichrome's resistance to oxidation and corrosion, which are critical factors in extending the lifespan of electronic components. Additionally, efforts have been made to fine-tune the alloy's composition to achieve better temperature coefficients of resistance, enabling more accurate and reliable temperature sensing and control in various devices.

The objectives of current nichrome optimization techniques in consumer electronics are multifaceted. Firstly, there is a strong emphasis on improving energy efficiency, as consumer devices face increasing pressure to reduce power consumption. This involves developing nichrome-based heating elements and sensors that can operate at lower voltages while maintaining optimal performance. Secondly, researchers are working on enhancing the material's compatibility with emerging manufacturing processes, such as 3D printing and flexible electronics, to enable new form factors and applications.

Another crucial objective is to address the environmental concerns associated with nichrome production and disposal. This includes exploring more sustainable manufacturing methods and investigating potential recycling techniques for nichrome-containing devices. Furthermore, there is ongoing research into alternative alloys that could potentially replace nichrome in certain applications, offering improved performance or reduced environmental impact.

As consumer electronics continue to evolve, the optimization of nichrome remains a critical area of focus. The industry aims to push the boundaries of what is possible with this versatile alloy, striving for higher performance, greater reliability, and increased sustainability in the next generation of electronic devices.

The journey of nichrome in consumer electronics began with its application in simple heating devices, such as toasters and hair dryers. As technology progressed, the need for more precise and efficient heating elements grew, pushing researchers and engineers to optimize nichrome's properties. This led to the development of various nichrome compositions, each tailored to specific applications within the consumer electronics sector.

One of the key milestones in nichrome's evolution was the introduction of thin-film deposition techniques in the 1960s and 1970s. This breakthrough allowed for the creation of extremely thin and uniform nichrome layers, opening up new possibilities for miniaturization and improved performance in electronic devices. The ability to precisely control the thickness and composition of nichrome films became crucial in the manufacturing of advanced sensors, microelectronics, and display technologies.

In recent years, the focus of nichrome optimization has shifted towards enhancing its durability, thermal stability, and electrical properties. Researchers have been exploring ways to improve nichrome's resistance to oxidation and corrosion, which are critical factors in extending the lifespan of electronic components. Additionally, efforts have been made to fine-tune the alloy's composition to achieve better temperature coefficients of resistance, enabling more accurate and reliable temperature sensing and control in various devices.

The objectives of current nichrome optimization techniques in consumer electronics are multifaceted. Firstly, there is a strong emphasis on improving energy efficiency, as consumer devices face increasing pressure to reduce power consumption. This involves developing nichrome-based heating elements and sensors that can operate at lower voltages while maintaining optimal performance. Secondly, researchers are working on enhancing the material's compatibility with emerging manufacturing processes, such as 3D printing and flexible electronics, to enable new form factors and applications.

Another crucial objective is to address the environmental concerns associated with nichrome production and disposal. This includes exploring more sustainable manufacturing methods and investigating potential recycling techniques for nichrome-containing devices. Furthermore, there is ongoing research into alternative alloys that could potentially replace nichrome in certain applications, offering improved performance or reduced environmental impact.

As consumer electronics continue to evolve, the optimization of nichrome remains a critical area of focus. The industry aims to push the boundaries of what is possible with this versatile alloy, striving for higher performance, greater reliability, and increased sustainability in the next generation of electronic devices.

Consumer Electronics Market Analysis

The consumer electronics market has experienced significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. This market encompasses a wide range of products, including smartphones, tablets, laptops, smart home devices, wearables, and audio equipment. The global consumer electronics market size was valued at $689.45 billion in 2020 and is projected to reach $989.37 billion by 2027, growing at a CAGR of 5.3% during the forecast period.

Smartphones continue to dominate the consumer electronics landscape, accounting for a substantial portion of market revenue. The smartphone market is characterized by intense competition among major players such as Apple, Samsung, and Huawei, with emerging brands like Xiaomi and Oppo gaining market share in developing regions. The increasing adoption of 5G technology is expected to drive smartphone sales further in the coming years.

The smart home devices segment has shown remarkable growth, fueled by the increasing popularity of voice-controlled assistants and the Internet of Things (IoT) ecosystem. Products such as smart speakers, thermostats, security cameras, and lighting systems are gaining traction among consumers seeking enhanced convenience and energy efficiency in their homes.

Wearable technology, including smartwatches and fitness trackers, has emerged as a rapidly growing segment within the consumer electronics market. The integration of health monitoring features and improved battery life has contributed to the increased adoption of these devices. Major players in this space include Apple, Fitbit, and Garmin.

The COVID-19 pandemic has significantly impacted consumer electronics market dynamics. The shift towards remote work and online education has boosted demand for laptops, tablets, and webcams. Additionally, there has been an increased focus on health and wellness products, driving sales of air purifiers and UV sterilizers.

Regionally, Asia-Pacific dominates the consumer electronics market, with China and India being key growth drivers. North America and Europe follow closely, with mature markets characterized by high smartphone penetration rates and early adoption of emerging technologies.

Sustainability and environmental concerns are increasingly influencing consumer purchasing decisions in the electronics market. Manufacturers are responding by incorporating recycled materials, improving energy efficiency, and implementing take-back programs for electronic waste.

In conclusion, the consumer electronics market continues to evolve rapidly, driven by technological innovation and changing consumer needs. The integration of AI, IoT, and 5G technologies is expected to shape the future of this market, presenting both opportunities and challenges for manufacturers and retailers alike.

Smartphones continue to dominate the consumer electronics landscape, accounting for a substantial portion of market revenue. The smartphone market is characterized by intense competition among major players such as Apple, Samsung, and Huawei, with emerging brands like Xiaomi and Oppo gaining market share in developing regions. The increasing adoption of 5G technology is expected to drive smartphone sales further in the coming years.

The smart home devices segment has shown remarkable growth, fueled by the increasing popularity of voice-controlled assistants and the Internet of Things (IoT) ecosystem. Products such as smart speakers, thermostats, security cameras, and lighting systems are gaining traction among consumers seeking enhanced convenience and energy efficiency in their homes.

Wearable technology, including smartwatches and fitness trackers, has emerged as a rapidly growing segment within the consumer electronics market. The integration of health monitoring features and improved battery life has contributed to the increased adoption of these devices. Major players in this space include Apple, Fitbit, and Garmin.

The COVID-19 pandemic has significantly impacted consumer electronics market dynamics. The shift towards remote work and online education has boosted demand for laptops, tablets, and webcams. Additionally, there has been an increased focus on health and wellness products, driving sales of air purifiers and UV sterilizers.

Regionally, Asia-Pacific dominates the consumer electronics market, with China and India being key growth drivers. North America and Europe follow closely, with mature markets characterized by high smartphone penetration rates and early adoption of emerging technologies.

Sustainability and environmental concerns are increasingly influencing consumer purchasing decisions in the electronics market. Manufacturers are responding by incorporating recycled materials, improving energy efficiency, and implementing take-back programs for electronic waste.

In conclusion, the consumer electronics market continues to evolve rapidly, driven by technological innovation and changing consumer needs. The integration of AI, IoT, and 5G technologies is expected to shape the future of this market, presenting both opportunities and challenges for manufacturers and retailers alike.

Nichrome Challenges in Electronics

Nichrome, a widely used alloy in consumer electronics, faces several significant challenges in its application and optimization. The primary issue lies in balancing the material's resistivity and temperature coefficient of resistance (TCR) to achieve optimal performance across various electronic devices. As consumer electronics continue to shrink in size while demanding higher power efficiency, the limitations of nichrome become more pronounced.

One of the key challenges is the trade-off between resistivity and TCR. While higher resistivity is desirable for creating compact resistive elements, it often comes at the cost of increased TCR, which can lead to instability in device performance across different operating temperatures. This balance is particularly crucial in portable devices that may be subjected to a wide range of environmental conditions.

Another significant challenge is the thermal management of nichrome components. As devices become more compact, the heat generated by nichrome elements becomes increasingly difficult to dissipate effectively. This can lead to localized hot spots, potentially causing device failure or reduced lifespan. The need for efficient heat dissipation solutions without compromising device size or performance presents a complex engineering challenge.

The durability and longevity of nichrome elements in consumer electronics also pose challenges. Repeated thermal cycling and exposure to various environmental factors can lead to degradation of the nichrome film, affecting its electrical properties over time. This is particularly problematic in devices expected to have a long operational life, such as smart home appliances or automotive electronics.

Furthermore, the manufacturing process for integrating nichrome elements into modern electronic devices presents its own set of challenges. Achieving consistent thin-film deposition with precise control over thickness and composition is critical for maintaining uniform electrical properties across production batches. The need for high-precision manufacturing techniques adds complexity and cost to the production process.

Lastly, as the electronics industry moves towards more sustainable and environmentally friendly practices, the recyclability and end-of-life management of nichrome components become increasingly important considerations. Developing methods for efficient recovery and recycling of nichrome from discarded electronic devices, while maintaining economic viability, remains a challenge that requires innovative solutions.

Addressing these challenges requires a multidisciplinary approach, combining materials science, electrical engineering, thermal management, and manufacturing technology. As consumer electronics continue to evolve, overcoming these nichrome-related challenges will be crucial for advancing the performance, reliability, and sustainability of future devices.

One of the key challenges is the trade-off between resistivity and TCR. While higher resistivity is desirable for creating compact resistive elements, it often comes at the cost of increased TCR, which can lead to instability in device performance across different operating temperatures. This balance is particularly crucial in portable devices that may be subjected to a wide range of environmental conditions.

Another significant challenge is the thermal management of nichrome components. As devices become more compact, the heat generated by nichrome elements becomes increasingly difficult to dissipate effectively. This can lead to localized hot spots, potentially causing device failure or reduced lifespan. The need for efficient heat dissipation solutions without compromising device size or performance presents a complex engineering challenge.

The durability and longevity of nichrome elements in consumer electronics also pose challenges. Repeated thermal cycling and exposure to various environmental factors can lead to degradation of the nichrome film, affecting its electrical properties over time. This is particularly problematic in devices expected to have a long operational life, such as smart home appliances or automotive electronics.

Furthermore, the manufacturing process for integrating nichrome elements into modern electronic devices presents its own set of challenges. Achieving consistent thin-film deposition with precise control over thickness and composition is critical for maintaining uniform electrical properties across production batches. The need for high-precision manufacturing techniques adds complexity and cost to the production process.

Lastly, as the electronics industry moves towards more sustainable and environmentally friendly practices, the recyclability and end-of-life management of nichrome components become increasingly important considerations. Developing methods for efficient recovery and recycling of nichrome from discarded electronic devices, while maintaining economic viability, remains a challenge that requires innovative solutions.

Addressing these challenges requires a multidisciplinary approach, combining materials science, electrical engineering, thermal management, and manufacturing technology. As consumer electronics continue to evolve, overcoming these nichrome-related challenges will be crucial for advancing the performance, reliability, and sustainability of future devices.

Current Nichrome Optimization Methods

01 Composition optimization of nichrome alloys

Optimizing the composition of nichrome alloys by adjusting the ratio of nickel and chromium, as well as adding other elements like iron, manganese, or silicon to enhance specific properties such as electrical resistance, oxidation resistance, and mechanical strength.- Composition optimization of nichrome alloys: Optimizing the composition of nichrome alloys by adjusting the ratio of nickel and chromium, as well as adding other elements like iron, aluminum, or silicon. This can improve the alloy's electrical resistance, temperature coefficient, and overall performance for specific applications.

- Heat treatment and manufacturing processes: Developing improved heat treatment and manufacturing processes for nichrome wires and components. This includes optimizing annealing temperatures, cooling rates, and drawing techniques to enhance the material's mechanical properties and electrical characteristics.

- Surface treatment and coating techniques: Applying various surface treatments and coating techniques to nichrome elements to improve their corrosion resistance, oxidation resistance, and overall lifespan. This may involve the use of protective layers or surface modifications to enhance performance in harsh environments.

- Structural design optimization: Optimizing the structural design of nichrome heating elements and components to improve heat distribution, energy efficiency, and mechanical stability. This includes developing novel shapes, patterns, and configurations for specific applications.

- Integration with advanced materials and technologies: Combining nichrome with advanced materials or integrating it into new technologies to enhance its performance and expand its applications. This may include incorporating nichrome into composite materials, nanotechnology, or advanced electronic systems.

02 Heat treatment and manufacturing processes

Developing improved heat treatment and manufacturing processes for nichrome, including annealing, cold working, and precision control of temperature and time during production to achieve desired microstructure and properties.Expand Specific Solutions03 Surface modification and coating techniques

Applying surface modification and coating techniques to nichrome materials to enhance their performance, such as improving corrosion resistance, reducing electrical contact resistance, or increasing durability in high-temperature applications.Expand Specific Solutions04 Nichrome wire optimization for heating elements

Optimizing nichrome wire design and configuration for use in heating elements, including adjusting wire diameter, coil spacing, and overall geometry to improve heat distribution, energy efficiency, and longevity in various applications.Expand Specific Solutions05 Advanced nichrome-based composite materials

Developing advanced nichrome-based composite materials by combining nichrome with other materials such as ceramics, polymers, or other metals to create hybrid structures with enhanced properties for specific applications in electronics, aerospace, or energy sectors.Expand Specific Solutions

Key Nichrome Manufacturers

The nichrome optimization techniques for consumer electronics market is in a mature stage, with a substantial global market size driven by the increasing demand for efficient heating elements in various appliances. The technology's maturity is evident from the involvement of established players like Lam Research Corp. and LG Chem Ltd., who are leveraging their expertise in semiconductor and materials science to enhance nichrome performance. Emerging companies such as Yancheng Xinyang Electric Heating Material Co., Ltd. are focusing on specialized applications, while research institutions like Huazhong University of Science & Technology are contributing to further advancements. The competitive landscape is characterized by a mix of large corporations and niche players, with ongoing research aimed at improving efficiency and durability of nichrome-based components in consumer electronics.

Lam Research Corp.

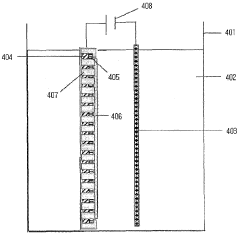

Technical Solution: Lam Research Corp. has developed cutting-edge nichrome optimization techniques for consumer electronics, focusing on enhancing the deposition and etching processes used in manufacturing nichrome-based components. Their approach involves the use of advanced plasma-enhanced chemical vapor deposition (PECVD) techniques to create highly uniform and precisely controlled nichrome thin films[6]. Lam Research has also developed specialized etching processes that allow for the creation of complex nichrome patterns with nanoscale precision, enabling the fabrication of high-performance resistive elements for various consumer electronic devices[7]. Furthermore, the company has implemented in-situ metrology systems to monitor and control the nichrome deposition and etching processes in real-time, ensuring consistent quality and performance across large-scale production runs[8].

Strengths: Precise control over nichrome deposition and etching, nanoscale patterning capabilities, and real-time process monitoring. Weaknesses: Potentially higher equipment costs and complexity compared to traditional manufacturing methods.

Rohm and Haas Electronic Materials, Inc.

Technical Solution: Rohm and Haas Electronic Materials, Inc. has developed advanced nichrome optimization techniques for consumer electronics, focusing on the formulation of specialized nichrome alloys and the development of novel deposition methods. Their approach involves the use of proprietary additives and dopants to enhance the electrical and thermal properties of nichrome thin films[9]. The company has also implemented advanced sputtering techniques that allow for the creation of highly uniform and dense nichrome layers with improved adhesion to various substrate materials[10]. Additionally, Rohm and Haas has developed post-deposition treatment processes, such as controlled annealing and surface passivation, to further optimize the performance and reliability of nichrome components in consumer electronic devices[11].

Strengths: Specialized alloy formulations, improved film quality, and enhanced adhesion properties. Weaknesses: Potential limitations in compatibility with certain substrate materials or manufacturing processes.

Innovative Nichrome Alloy Patents

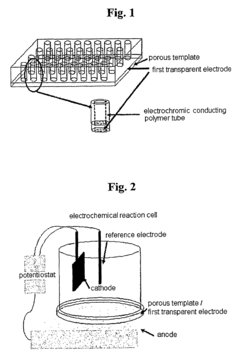

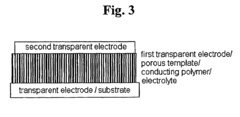

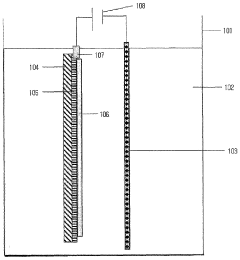

Electropolymerization method for preparing nano-tube type conducting polymer using porous template, method for preparing electrochromic device, and electrochromic device prepared therefrom

PatentInactiveUS7623284B2

Innovation

- An electropolymerization method is developed to create a nanotube-type conducting polymer using a porous template, increasing the surface area of the polymer, which involves forming an electrochemical reaction cell with a transparent working electrode and a porous template, and electropolymerizing the polymer in an electrolyte solution to produce a tubular shape with enhanced electrochromic properties.

Electrode comprising lithium nickel oxide layer, method for preparing the same, and electrochromic device comprising the same

PatentWO2008091099A1

Innovation

- Applying a voltage in all directions along the circumference of the electrode during the formatting process, ensuring uniform electrochemical treatment, and using a method to achieve a single oxidation number for nickel ions in the lithium nickel oxide layer by alternating oxidation and reduction voltages, which are applied uniformly across the electrode's outer circumference.

Thermal Management Strategies

Thermal management is a critical aspect of consumer electronics design, particularly when utilizing nichrome elements. Effective strategies are essential to maintain optimal device performance, ensure user safety, and extend product lifespan. One primary approach involves heat dissipation through conduction, where thermal energy is transferred from the nichrome element to a heat sink or chassis. This method often employs materials with high thermal conductivity, such as copper or aluminum, to efficiently draw heat away from critical components.

Convection-based cooling techniques are also widely implemented, utilizing air or liquid circulation to remove excess heat. Forced-air cooling systems, incorporating fans or blowers, are common in larger devices, while passive convection relies on natural air circulation in more compact designs. Liquid cooling solutions, though less prevalent in consumer electronics, offer superior heat dissipation capabilities for high-performance applications.

Radiation-based thermal management strategies leverage the principle of heat transfer through electromagnetic waves. This approach is particularly effective in devices with limited space for traditional cooling mechanisms. Surface treatments and coatings can be applied to enhance radiative heat transfer, improving overall thermal efficiency.

Thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between components. These materials, ranging from thermal pastes to phase-change compounds, fill microscopic air gaps between surfaces, significantly improving thermal conductivity. The selection of appropriate TIMs is vital for maximizing the effectiveness of heat sinks and other cooling elements.

Advanced thermal management techniques include the use of heat pipes and vapor chambers. These passive systems utilize the phase change of a working fluid to transport heat rapidly from source to sink. Heat pipes are particularly effective in thin devices, while vapor chambers offer superior performance in applications requiring uniform heat distribution across larger surface areas.

Thermal simulation and modeling tools have become indispensable in the design process, allowing engineers to predict and optimize thermal behavior before physical prototyping. These tools enable the evaluation of various cooling strategies and material choices, significantly reducing development time and costs.

Emerging technologies in thermal management include thermoelectric cooling, which uses the Peltier effect to create a temperature differential, and microfluidic cooling systems that circulate coolant through microscale channels. While these technologies are not yet widespread in consumer electronics, they show promise for future applications, particularly in high-performance and miniaturized devices.

Convection-based cooling techniques are also widely implemented, utilizing air or liquid circulation to remove excess heat. Forced-air cooling systems, incorporating fans or blowers, are common in larger devices, while passive convection relies on natural air circulation in more compact designs. Liquid cooling solutions, though less prevalent in consumer electronics, offer superior heat dissipation capabilities for high-performance applications.

Radiation-based thermal management strategies leverage the principle of heat transfer through electromagnetic waves. This approach is particularly effective in devices with limited space for traditional cooling mechanisms. Surface treatments and coatings can be applied to enhance radiative heat transfer, improving overall thermal efficiency.

Thermal interface materials (TIMs) play a crucial role in optimizing heat transfer between components. These materials, ranging from thermal pastes to phase-change compounds, fill microscopic air gaps between surfaces, significantly improving thermal conductivity. The selection of appropriate TIMs is vital for maximizing the effectiveness of heat sinks and other cooling elements.

Advanced thermal management techniques include the use of heat pipes and vapor chambers. These passive systems utilize the phase change of a working fluid to transport heat rapidly from source to sink. Heat pipes are particularly effective in thin devices, while vapor chambers offer superior performance in applications requiring uniform heat distribution across larger surface areas.

Thermal simulation and modeling tools have become indispensable in the design process, allowing engineers to predict and optimize thermal behavior before physical prototyping. These tools enable the evaluation of various cooling strategies and material choices, significantly reducing development time and costs.

Emerging technologies in thermal management include thermoelectric cooling, which uses the Peltier effect to create a temperature differential, and microfluidic cooling systems that circulate coolant through microscale channels. While these technologies are not yet widespread in consumer electronics, they show promise for future applications, particularly in high-performance and miniaturized devices.

Nichrome Sustainability Aspects

Nichrome, a widely used alloy in consumer electronics, presents both opportunities and challenges in terms of sustainability. The increasing demand for electronic devices has raised concerns about the environmental impact of nichrome production and disposal.

One of the primary sustainability aspects of nichrome is its recyclability. The alloy can be recovered and reprocessed from discarded electronic devices, reducing the need for new raw materials. However, the recycling process itself requires energy and may produce emissions, necessitating the development of more efficient recycling technologies.

The production of nichrome also has environmental implications. Mining and processing nickel and chromium, the primary components of nichrome, can lead to habitat destruction and water pollution if not managed properly. Sustainable mining practices and stricter environmental regulations are essential to mitigate these impacts.

Energy consumption during nichrome production is another critical sustainability factor. The high melting point of the alloy requires significant energy input, contributing to carbon emissions. Optimizing production processes and exploring alternative energy sources can help reduce the carbon footprint of nichrome manufacturing.

Durability is a key sustainability advantage of nichrome. Its resistance to corrosion and high temperatures extends the lifespan of electronic components, potentially reducing electronic waste. However, this durability can also pose challenges for end-of-life management, as nichrome-containing devices may persist in landfills for extended periods.

The toxicity of nichrome components, particularly chromium, raises concerns about potential health and environmental risks. While nichrome is generally stable in its alloyed form, improper disposal or recycling can lead to the release of harmful substances. Developing safer alternatives or improving containment methods is crucial for addressing these concerns.

In the context of consumer electronics, nichrome's efficiency in heat generation can contribute to energy savings during device operation. However, this benefit must be balanced against the energy required for production and the potential for increased power consumption in poorly designed applications.

As the electronics industry moves towards more sustainable practices, innovations in nichrome optimization techniques are focusing on reducing material usage, improving energy efficiency, and enhancing recyclability. These efforts aim to align nichrome utilization with broader sustainability goals in consumer electronics manufacturing.

One of the primary sustainability aspects of nichrome is its recyclability. The alloy can be recovered and reprocessed from discarded electronic devices, reducing the need for new raw materials. However, the recycling process itself requires energy and may produce emissions, necessitating the development of more efficient recycling technologies.

The production of nichrome also has environmental implications. Mining and processing nickel and chromium, the primary components of nichrome, can lead to habitat destruction and water pollution if not managed properly. Sustainable mining practices and stricter environmental regulations are essential to mitigate these impacts.

Energy consumption during nichrome production is another critical sustainability factor. The high melting point of the alloy requires significant energy input, contributing to carbon emissions. Optimizing production processes and exploring alternative energy sources can help reduce the carbon footprint of nichrome manufacturing.

Durability is a key sustainability advantage of nichrome. Its resistance to corrosion and high temperatures extends the lifespan of electronic components, potentially reducing electronic waste. However, this durability can also pose challenges for end-of-life management, as nichrome-containing devices may persist in landfills for extended periods.

The toxicity of nichrome components, particularly chromium, raises concerns about potential health and environmental risks. While nichrome is generally stable in its alloyed form, improper disposal or recycling can lead to the release of harmful substances. Developing safer alternatives or improving containment methods is crucial for addressing these concerns.

In the context of consumer electronics, nichrome's efficiency in heat generation can contribute to energy savings during device operation. However, this benefit must be balanced against the energy required for production and the potential for increased power consumption in poorly designed applications.

As the electronics industry moves towards more sustainable practices, innovations in nichrome optimization techniques are focusing on reducing material usage, improving energy efficiency, and enhancing recyclability. These efforts aim to align nichrome utilization with broader sustainability goals in consumer electronics manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!