Nichrome's Contribution to Energy-Efficient Appliances

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome Evolution

Nichrome, an alloy primarily composed of nickel and chromium, has played a pivotal role in the evolution of energy-efficient appliances. Its journey began in the early 20th century when Albert Marsh discovered the alloy's exceptional properties, particularly its high electrical resistance and ability to withstand high temperatures without oxidizing.

In the 1920s and 1930s, nichrome found its first widespread application in electrical heating elements for household appliances. This marked a significant improvement over earlier materials, as nichrome's durability and consistent performance allowed for more reliable and longer-lasting heating devices. The 1940s and 1950s saw further refinement in nichrome production techniques, leading to more uniform and higher-quality heating elements.

The energy crisis of the 1970s sparked a renewed interest in energy efficiency, propelling nichrome to the forefront of appliance design. Manufacturers began to focus on creating more efficient heating elements, and nichrome's properties made it an ideal candidate for this purpose. Its ability to quickly reach and maintain high temperatures with relatively low power input contributed significantly to the development of more energy-efficient toasters, ovens, and hair dryers.

The 1980s and 1990s witnessed the integration of nichrome into more sophisticated appliance designs. Microprocessor-controlled heating systems began to utilize nichrome's predictable resistance properties to achieve precise temperature control. This era also saw the development of thinner nichrome wires and more complex coil designs, further enhancing energy efficiency and heat distribution in appliances.

As environmental concerns grew in the 21st century, nichrome continued to evolve to meet stricter energy efficiency standards. Advanced manufacturing techniques allowed for the production of nichrome elements with even more precise specifications, optimizing power consumption in modern appliances. Additionally, research into nichrome alloy compositions led to variants with improved performance characteristics, such as faster heating times and greater durability.

Recent years have seen the integration of nichrome elements with smart technology. IoT-enabled appliances now utilize nichrome's properties in conjunction with advanced sensors and control systems to provide unprecedented levels of energy efficiency. This combination allows for dynamic power adjustment based on real-time usage patterns and environmental conditions, further reducing energy consumption.

Looking ahead, ongoing research into nanoscale modifications of nichrome promises to yield even more efficient heating elements. These developments aim to enhance the alloy's already impressive properties, potentially leading to a new generation of ultra-efficient appliances that could significantly reduce global energy consumption in household and industrial settings.

In the 1920s and 1930s, nichrome found its first widespread application in electrical heating elements for household appliances. This marked a significant improvement over earlier materials, as nichrome's durability and consistent performance allowed for more reliable and longer-lasting heating devices. The 1940s and 1950s saw further refinement in nichrome production techniques, leading to more uniform and higher-quality heating elements.

The energy crisis of the 1970s sparked a renewed interest in energy efficiency, propelling nichrome to the forefront of appliance design. Manufacturers began to focus on creating more efficient heating elements, and nichrome's properties made it an ideal candidate for this purpose. Its ability to quickly reach and maintain high temperatures with relatively low power input contributed significantly to the development of more energy-efficient toasters, ovens, and hair dryers.

The 1980s and 1990s witnessed the integration of nichrome into more sophisticated appliance designs. Microprocessor-controlled heating systems began to utilize nichrome's predictable resistance properties to achieve precise temperature control. This era also saw the development of thinner nichrome wires and more complex coil designs, further enhancing energy efficiency and heat distribution in appliances.

As environmental concerns grew in the 21st century, nichrome continued to evolve to meet stricter energy efficiency standards. Advanced manufacturing techniques allowed for the production of nichrome elements with even more precise specifications, optimizing power consumption in modern appliances. Additionally, research into nichrome alloy compositions led to variants with improved performance characteristics, such as faster heating times and greater durability.

Recent years have seen the integration of nichrome elements with smart technology. IoT-enabled appliances now utilize nichrome's properties in conjunction with advanced sensors and control systems to provide unprecedented levels of energy efficiency. This combination allows for dynamic power adjustment based on real-time usage patterns and environmental conditions, further reducing energy consumption.

Looking ahead, ongoing research into nanoscale modifications of nichrome promises to yield even more efficient heating elements. These developments aim to enhance the alloy's already impressive properties, potentially leading to a new generation of ultra-efficient appliances that could significantly reduce global energy consumption in household and industrial settings.

Energy Efficiency Demand

The global demand for energy-efficient appliances has been steadily increasing over the past decade, driven by a combination of environmental concerns, rising energy costs, and regulatory pressures. Consumers are becoming increasingly aware of the long-term financial benefits of energy-efficient products, as well as their positive impact on reducing carbon footprints. This shift in consumer behavior has created a significant market opportunity for manufacturers who can deliver appliances that offer superior energy performance without compromising functionality.

In the residential sector, energy-efficient appliances such as refrigerators, washing machines, and HVAC systems have seen substantial growth in demand. The commercial sector has also shown a strong interest in energy-efficient equipment, particularly in areas like commercial kitchens, office equipment, and industrial heating systems. This trend is expected to continue, with projections indicating that the global energy-efficient appliances market could reach a value of several hundred billion dollars by 2030.

Government initiatives and regulations have played a crucial role in driving this demand. Many countries have implemented energy labeling programs and minimum energy performance standards (MEPS) for appliances. These policies have not only educated consumers but also pushed manufacturers to innovate and improve their products' energy efficiency. For instance, the European Union's Ecodesign Directive and Energy Labelling Regulation have significantly influenced product design and consumer choices across the continent.

The demand for energy-efficient appliances is not uniform across all regions. Developed economies, particularly in North America and Europe, have been early adopters, with high penetration rates for energy-efficient products. However, emerging markets in Asia-Pacific and Latin America are now showing rapid growth in demand, driven by urbanization, rising disposable incomes, and increasing awareness of environmental issues.

Nichrome, as a key component in many heating elements, plays a significant role in meeting this growing demand for energy-efficient appliances. Its unique properties allow for the development of heating elements that can achieve high temperatures quickly and maintain them efficiently. This translates to appliances that consume less energy while delivering the same or better performance, aligning perfectly with consumer and regulatory demands for energy efficiency.

The market trend indicates a growing preference for smart, connected appliances that can optimize energy use based on real-time data and user behavior. This presents an opportunity for nichrome-based heating elements to be integrated with smart control systems, further enhancing their energy efficiency capabilities and meeting the evolving demands of the market.

In the residential sector, energy-efficient appliances such as refrigerators, washing machines, and HVAC systems have seen substantial growth in demand. The commercial sector has also shown a strong interest in energy-efficient equipment, particularly in areas like commercial kitchens, office equipment, and industrial heating systems. This trend is expected to continue, with projections indicating that the global energy-efficient appliances market could reach a value of several hundred billion dollars by 2030.

Government initiatives and regulations have played a crucial role in driving this demand. Many countries have implemented energy labeling programs and minimum energy performance standards (MEPS) for appliances. These policies have not only educated consumers but also pushed manufacturers to innovate and improve their products' energy efficiency. For instance, the European Union's Ecodesign Directive and Energy Labelling Regulation have significantly influenced product design and consumer choices across the continent.

The demand for energy-efficient appliances is not uniform across all regions. Developed economies, particularly in North America and Europe, have been early adopters, with high penetration rates for energy-efficient products. However, emerging markets in Asia-Pacific and Latin America are now showing rapid growth in demand, driven by urbanization, rising disposable incomes, and increasing awareness of environmental issues.

Nichrome, as a key component in many heating elements, plays a significant role in meeting this growing demand for energy-efficient appliances. Its unique properties allow for the development of heating elements that can achieve high temperatures quickly and maintain them efficiently. This translates to appliances that consume less energy while delivering the same or better performance, aligning perfectly with consumer and regulatory demands for energy efficiency.

The market trend indicates a growing preference for smart, connected appliances that can optimize energy use based on real-time data and user behavior. This presents an opportunity for nichrome-based heating elements to be integrated with smart control systems, further enhancing their energy efficiency capabilities and meeting the evolving demands of the market.

Nichrome Challenges

Despite its widespread use in energy-efficient appliances, nichrome faces several challenges that limit its potential and necessitate ongoing research and development efforts. One of the primary challenges is the material's susceptibility to oxidation at high temperatures. When exposed to air at elevated temperatures, nichrome forms a protective oxide layer, which can affect its electrical properties and reduce its overall efficiency over time.

Another significant challenge is the trade-off between resistance and durability. While higher resistance can lead to more efficient heating, it also increases the risk of mechanical failure due to thermal stress. This necessitates careful balancing in the design of nichrome heating elements to ensure both performance and longevity.

The cost of nichrome is also a concern for manufacturers. As a nickel-chromium alloy, the price of nichrome is subject to fluctuations in the global metals market, which can impact the overall cost of appliance production. This volatility can make it challenging for manufacturers to maintain consistent pricing and profit margins.

Environmental concerns present another challenge for nichrome usage. The mining and processing of nickel and chromium have significant environmental impacts, including greenhouse gas emissions and potential soil and water contamination. As consumers and regulators become more environmentally conscious, there is increasing pressure to find more sustainable alternatives or improve the production processes of nichrome.

The limited temperature range of nichrome is another area of concern. While it performs well in many household appliances, certain industrial applications require materials that can withstand even higher temperatures. This limitation restricts nichrome's use in some high-temperature industrial processes and creates a need for alternative materials in these scenarios.

Thermal cycling, the repeated heating and cooling of nichrome elements, can lead to fatigue and eventual failure of the material. This is particularly problematic in appliances that are frequently turned on and off, such as toasters or hair dryers. Improving nichrome's resistance to thermal fatigue is an ongoing challenge for materials scientists and engineers.

Lastly, the increasing demand for smart and connected appliances presents new challenges for nichrome integration. As appliances become more sophisticated, there is a need to develop nichrome elements that can be more precisely controlled and integrated with digital systems. This requires advancements in both material science and electronic control systems to fully leverage nichrome's potential in the next generation of energy-efficient appliances.

Another significant challenge is the trade-off between resistance and durability. While higher resistance can lead to more efficient heating, it also increases the risk of mechanical failure due to thermal stress. This necessitates careful balancing in the design of nichrome heating elements to ensure both performance and longevity.

The cost of nichrome is also a concern for manufacturers. As a nickel-chromium alloy, the price of nichrome is subject to fluctuations in the global metals market, which can impact the overall cost of appliance production. This volatility can make it challenging for manufacturers to maintain consistent pricing and profit margins.

Environmental concerns present another challenge for nichrome usage. The mining and processing of nickel and chromium have significant environmental impacts, including greenhouse gas emissions and potential soil and water contamination. As consumers and regulators become more environmentally conscious, there is increasing pressure to find more sustainable alternatives or improve the production processes of nichrome.

The limited temperature range of nichrome is another area of concern. While it performs well in many household appliances, certain industrial applications require materials that can withstand even higher temperatures. This limitation restricts nichrome's use in some high-temperature industrial processes and creates a need for alternative materials in these scenarios.

Thermal cycling, the repeated heating and cooling of nichrome elements, can lead to fatigue and eventual failure of the material. This is particularly problematic in appliances that are frequently turned on and off, such as toasters or hair dryers. Improving nichrome's resistance to thermal fatigue is an ongoing challenge for materials scientists and engineers.

Lastly, the increasing demand for smart and connected appliances presents new challenges for nichrome integration. As appliances become more sophisticated, there is a need to develop nichrome elements that can be more precisely controlled and integrated with digital systems. This requires advancements in both material science and electronic control systems to fully leverage nichrome's potential in the next generation of energy-efficient appliances.

Current Nichrome Apps

01 Nichrome heating element design

Optimizing the design of nichrome heating elements can improve energy efficiency. This includes considerations such as wire thickness, coil spacing, and overall geometry to maximize heat transfer while minimizing energy consumption. Advanced designs may incorporate multiple layers or innovative shapes to enhance performance.- Nichrome heating element design: Optimizing the design of nichrome heating elements can improve energy efficiency. This includes considerations such as the wire diameter, coil spacing, and overall geometry of the heating element. Proper design can maximize heat transfer while minimizing energy loss, leading to improved efficiency in various heating applications.

- Energy-efficient control systems: Implementing advanced control systems for nichrome heating elements can significantly enhance energy efficiency. These systems may include precise temperature regulation, adaptive power management, and intelligent heating cycles. By optimizing the power input and heating duration, these control systems can reduce energy consumption while maintaining desired performance.

- Insulation and heat retention techniques: Improving insulation and heat retention around nichrome heating elements can boost energy efficiency. This may involve using advanced insulating materials, optimizing the placement of heating elements, and designing enclosures that minimize heat loss. Effective insulation ensures that more of the generated heat is utilized for the intended purpose, reducing overall energy consumption.

- Nichrome alloy composition optimization: Refining the composition of nichrome alloys can lead to improved energy efficiency. By adjusting the ratio of nickel and chromium, as well as incorporating other elements, the electrical and thermal properties of the alloy can be optimized. This can result in better heat generation and distribution, ultimately improving the energy efficiency of heating systems using nichrome elements.

- Integration with renewable energy sources: Combining nichrome heating systems with renewable energy sources can enhance overall energy efficiency. This may involve integrating solar power, wind energy, or other sustainable sources to power nichrome heating elements. Such integration can reduce reliance on conventional energy sources and improve the environmental impact of heating systems using nichrome technology.

02 Energy management systems for nichrome-based devices

Implementing sophisticated energy management systems can significantly improve the efficiency of nichrome-based heating devices. These systems may include intelligent controllers, power modulation techniques, and adaptive algorithms to optimize energy usage based on real-time requirements and environmental conditions.Expand Specific Solutions03 Nichrome alloy composition optimization

Refining the composition of nichrome alloys can lead to improved energy efficiency. This may involve adjusting the ratio of nickel to chromium or incorporating additional elements to enhance electrical resistance properties and thermal stability, resulting in more efficient heat generation with less energy input.Expand Specific Solutions04 Insulation and heat retention techniques

Enhancing insulation and heat retention in nichrome-based systems can significantly improve overall energy efficiency. This may include using advanced insulating materials, designing efficient heat reflectors, or implementing thermal management strategies to minimize heat loss and maximize the utilization of generated heat.Expand Specific Solutions05 Integration with renewable energy sources

Combining nichrome heating systems with renewable energy sources can enhance overall energy efficiency. This may involve integrating solar panels, wind turbines, or other sustainable energy technologies to power nichrome-based devices, reducing reliance on conventional energy sources and improving the system's environmental impact.Expand Specific Solutions

Key Nichrome Players

The market for energy-efficient appliances utilizing Nichrome technology is in a mature growth phase, with a global market size expected to reach billions of dollars by 2025. Major players like Panasonic, Arçelik, and BSH Hausgeräte are driving innovation in this space, leveraging Nichrome's properties to enhance appliance performance and energy efficiency. Technological advancements are focused on improving heat distribution, durability, and power consumption. Emerging companies such as Yancheng Xinyang Electric Heating Material and Baowu Special Metallurgy are also contributing to the competitive landscape by developing specialized Nichrome alloys for specific appliance applications.

Panasonic Holdings Corp.

Technical Solution: Panasonic has developed advanced nichrome heating elements for energy-efficient appliances. Their technology incorporates a proprietary alloy composition that optimizes electrical resistance and heat distribution. The company's nichrome elements feature a unique coil design that maximizes surface area for improved heat transfer[1]. Panasonic has also implemented a precision control system that allows for rapid temperature adjustments, reducing energy waste during appliance operation[3]. Their nichrome elements are coated with a specialized ceramic material that enhances durability and prevents oxidation, extending the lifespan of heating components in household appliances[5].

Strengths: Superior heat distribution, rapid temperature control, and extended lifespan. Weaknesses: Potentially higher production costs due to specialized materials and manufacturing processes.

Arçelik AS

Technical Solution: Arçelik has contributed to energy-efficient appliances through innovative nichrome applications. The company has developed a proprietary nichrome alloy composition that offers improved electrical resistance stability over a wide temperature range[8]. This allows for more consistent heating performance and better energy efficiency in appliances like ovens and cooktops. Arçelik has also implemented a unique coiling technique for their nichrome elements that maximizes surface area while minimizing material usage[10]. Additionally, the company has integrated smart sensors with their nichrome heating systems to provide real-time temperature feedback and optimize energy consumption based on cooking or heating requirements[12].

Strengths: Stable heating performance, material efficiency, and smart temperature control. Weaknesses: Potential limitations in extreme temperature applications due to specialized alloy composition.

Nichrome Innovations

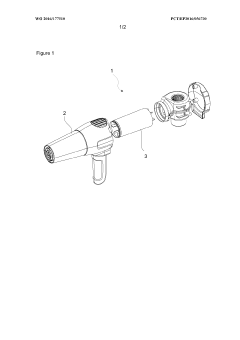

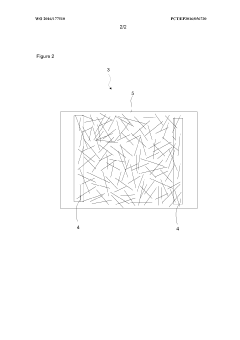

A household appliance provided with a heating element comprising metallic nanowire material

PatentWO2016177510A1

Innovation

- The use of metallic nanowire heating elements with low surface resistance, formed into a mesh structure and coated with metal oxide thin films, reduces energy requirements and provides antibacterial properties, enabling operation under low voltage and direct current, and potential wireless operation with a battery.

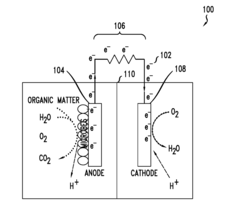

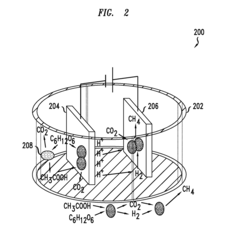

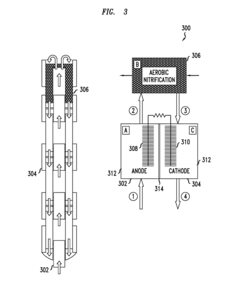

Systems and devices for treating and monitoring water, wastewater and other biodegradable matter

PatentActiveUS20180044210A1

Innovation

- A bio-electrochemical system comprising a reactor with an anode and cathode in close proximity, facilitated by a power source to enhance methane production and control parameters like pH and chemical oxygen demand, using methanogenic microbes to oxidize organic materials and generate methane, and a system for denitrification through separate chambers with a filter to reduce chemical oxygen demand and nitrogenous waste.

Environmental Impact

The environmental impact of Nichrome's contribution to energy-efficient appliances is significant and multifaceted. As a key component in heating elements, Nichrome has played a crucial role in improving the energy efficiency of various household and industrial appliances, leading to reduced energy consumption and lower greenhouse gas emissions.

One of the primary environmental benefits of Nichrome-based heating elements is their ability to rapidly reach and maintain desired temperatures. This quick heating capability reduces the overall energy required for appliance operation, particularly in devices such as toasters, ovens, and hair dryers. The reduced energy consumption translates directly into lower carbon emissions from power generation, contributing to global efforts to mitigate climate change.

Furthermore, Nichrome's durability and resistance to oxidation at high temperatures extend the lifespan of appliances. This longevity reduces the frequency of appliance replacement, thereby decreasing the environmental impact associated with manufacturing, transportation, and disposal of these products. The reduction in electronic waste is particularly significant, as it helps to conserve natural resources and minimize the release of harmful substances into the environment.

In industrial applications, Nichrome-based heating elements have enabled more precise temperature control in manufacturing processes. This precision not only improves product quality but also optimizes energy usage, reducing waste and minimizing the carbon footprint of industrial operations. The improved efficiency in industrial heating processes has far-reaching effects on resource conservation and pollution reduction across various sectors.

However, it is important to consider the environmental impact of Nichrome production itself. The mining and processing of nickel and chromium, the primary components of Nichrome, can have significant environmental consequences, including habitat destruction, water pollution, and energy-intensive refining processes. Balancing these impacts against the long-term environmental benefits of energy-efficient appliances is crucial for a comprehensive assessment.

As global focus on sustainability intensifies, the role of Nichrome in energy-efficient appliances continues to evolve. Ongoing research aims to further improve its properties, potentially leading to even greater energy savings and reduced environmental impact. Additionally, efforts to develop more sustainable mining and production methods for Nichrome's raw materials are underway, which could further enhance its overall environmental profile.

In conclusion, while the production of Nichrome has its own environmental considerations, its contribution to energy-efficient appliances has resulted in substantial positive environmental impacts through reduced energy consumption, lower emissions, and extended appliance lifespans. As technology advances, the balance between these factors will likely continue to improve, further solidifying Nichrome's role in sustainable technology development.

One of the primary environmental benefits of Nichrome-based heating elements is their ability to rapidly reach and maintain desired temperatures. This quick heating capability reduces the overall energy required for appliance operation, particularly in devices such as toasters, ovens, and hair dryers. The reduced energy consumption translates directly into lower carbon emissions from power generation, contributing to global efforts to mitigate climate change.

Furthermore, Nichrome's durability and resistance to oxidation at high temperatures extend the lifespan of appliances. This longevity reduces the frequency of appliance replacement, thereby decreasing the environmental impact associated with manufacturing, transportation, and disposal of these products. The reduction in electronic waste is particularly significant, as it helps to conserve natural resources and minimize the release of harmful substances into the environment.

In industrial applications, Nichrome-based heating elements have enabled more precise temperature control in manufacturing processes. This precision not only improves product quality but also optimizes energy usage, reducing waste and minimizing the carbon footprint of industrial operations. The improved efficiency in industrial heating processes has far-reaching effects on resource conservation and pollution reduction across various sectors.

However, it is important to consider the environmental impact of Nichrome production itself. The mining and processing of nickel and chromium, the primary components of Nichrome, can have significant environmental consequences, including habitat destruction, water pollution, and energy-intensive refining processes. Balancing these impacts against the long-term environmental benefits of energy-efficient appliances is crucial for a comprehensive assessment.

As global focus on sustainability intensifies, the role of Nichrome in energy-efficient appliances continues to evolve. Ongoing research aims to further improve its properties, potentially leading to even greater energy savings and reduced environmental impact. Additionally, efforts to develop more sustainable mining and production methods for Nichrome's raw materials are underway, which could further enhance its overall environmental profile.

In conclusion, while the production of Nichrome has its own environmental considerations, its contribution to energy-efficient appliances has resulted in substantial positive environmental impacts through reduced energy consumption, lower emissions, and extended appliance lifespans. As technology advances, the balance between these factors will likely continue to improve, further solidifying Nichrome's role in sustainable technology development.

Nichrome Supply Chain

The Nichrome supply chain plays a crucial role in the production and distribution of energy-efficient appliances. Nichrome, an alloy primarily composed of nickel and chromium, is widely used in heating elements due to its high electrical resistance and excellent heat-resistant properties.

The supply chain for Nichrome begins with the extraction of raw materials, primarily nickel and chromium ores. These are typically mined in countries such as Russia, Canada, and South Africa for nickel, and South Africa, Kazakhstan, and India for chromium. The ores are then processed and refined to produce high-purity nickel and chromium metals.

The next stage involves the production of Nichrome alloy. Manufacturers combine nickel and chromium in specific ratios, typically 80% nickel and 20% chromium, though variations exist depending on the intended application. The alloying process requires precise control of temperature and composition to ensure consistent quality and performance.

Once the Nichrome alloy is produced, it is formed into various shapes and sizes, such as wires, ribbons, or sheets, depending on the requirements of appliance manufacturers. This forming process often involves drawing, rolling, or extrusion techniques to achieve the desired dimensions and properties.

Distribution networks then come into play, transporting the Nichrome products from alloy manufacturers to appliance producers worldwide. These networks may involve multiple intermediaries, including wholesalers and specialized distributors catering to the electronics and appliance industries.

Appliance manufacturers integrate Nichrome components into their energy-efficient products, such as toasters, ovens, hair dryers, and space heaters. The unique properties of Nichrome allow these appliances to heat up quickly and maintain consistent temperatures, contributing to their energy efficiency.

Quality control is a critical aspect of the Nichrome supply chain. Rigorous testing is conducted at various stages to ensure the alloy meets specifications for composition, electrical resistance, and heat tolerance. This is essential for maintaining the performance and safety of energy-efficient appliances.

The global nature of the Nichrome supply chain makes it susceptible to various factors, including geopolitical tensions, trade policies, and fluctuations in raw material prices. These can impact the availability and cost of Nichrome, potentially affecting the production and pricing of energy-efficient appliances.

As demand for energy-efficient appliances continues to grow, driven by environmental concerns and energy regulations, the Nichrome supply chain is evolving to meet these needs. Innovations in production techniques, such as advanced alloying methods and more efficient forming processes, are being developed to improve the quality and reduce the cost of Nichrome components.

The supply chain for Nichrome begins with the extraction of raw materials, primarily nickel and chromium ores. These are typically mined in countries such as Russia, Canada, and South Africa for nickel, and South Africa, Kazakhstan, and India for chromium. The ores are then processed and refined to produce high-purity nickel and chromium metals.

The next stage involves the production of Nichrome alloy. Manufacturers combine nickel and chromium in specific ratios, typically 80% nickel and 20% chromium, though variations exist depending on the intended application. The alloying process requires precise control of temperature and composition to ensure consistent quality and performance.

Once the Nichrome alloy is produced, it is formed into various shapes and sizes, such as wires, ribbons, or sheets, depending on the requirements of appliance manufacturers. This forming process often involves drawing, rolling, or extrusion techniques to achieve the desired dimensions and properties.

Distribution networks then come into play, transporting the Nichrome products from alloy manufacturers to appliance producers worldwide. These networks may involve multiple intermediaries, including wholesalers and specialized distributors catering to the electronics and appliance industries.

Appliance manufacturers integrate Nichrome components into their energy-efficient products, such as toasters, ovens, hair dryers, and space heaters. The unique properties of Nichrome allow these appliances to heat up quickly and maintain consistent temperatures, contributing to their energy efficiency.

Quality control is a critical aspect of the Nichrome supply chain. Rigorous testing is conducted at various stages to ensure the alloy meets specifications for composition, electrical resistance, and heat tolerance. This is essential for maintaining the performance and safety of energy-efficient appliances.

The global nature of the Nichrome supply chain makes it susceptible to various factors, including geopolitical tensions, trade policies, and fluctuations in raw material prices. These can impact the availability and cost of Nichrome, potentially affecting the production and pricing of energy-efficient appliances.

As demand for energy-efficient appliances continues to grow, driven by environmental concerns and energy regulations, the Nichrome supply chain is evolving to meet these needs. Innovations in production techniques, such as advanced alloying methods and more efficient forming processes, are being developed to improve the quality and reduce the cost of Nichrome components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!