Nichrome's Growing Importance in Electric Vehicle Technology

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nichrome in EVs: Background and Objectives

Nichrome, an alloy primarily composed of nickel and chromium, has emerged as a critical material in the rapidly evolving electric vehicle (EV) industry. The journey of nichrome in automotive applications began in the early 20th century, primarily used in heating elements due to its high electrical resistance and excellent heat tolerance. However, its role has expanded significantly with the advent of electric vehicles.

The evolution of nichrome's importance in EV technology is closely tied to the broader trend of electrification in the automotive sector. As global efforts to reduce carbon emissions intensify, the demand for efficient and reliable electric vehicles has surged. This shift has brought nichrome to the forefront of EV component design, particularly in battery and powertrain systems.

In the context of electric vehicles, nichrome's unique properties make it invaluable. Its high resistance to corrosion and oxidation, coupled with its stability at high temperatures, addresses several critical challenges in EV design. These characteristics are particularly crucial in battery management systems, where temperature control and electrical resistance play vital roles in ensuring optimal performance and safety.

The technical objectives for nichrome in EV applications are multifaceted. Primarily, researchers and engineers aim to leverage nichrome's properties to enhance the efficiency and longevity of EV components. This includes improving battery thermal management systems, developing more durable electrical connectors, and creating more efficient heating elements for cabin climate control.

Another key objective is to optimize nichrome alloys specifically for EV applications. This involves fine-tuning the composition to achieve an ideal balance between electrical resistance, thermal conductivity, and durability. The goal is to create nichrome variants that can withstand the unique stresses of EV operations while contributing to overall vehicle efficiency.

Furthermore, there is a growing focus on integrating nichrome into next-generation EV technologies. This includes its potential use in solid-state batteries, where its thermal properties could play a crucial role in managing the high operating temperatures. Additionally, researchers are exploring nichrome's applications in advanced power electronics and motor designs, aiming to push the boundaries of EV performance and reliability.

As the EV market continues to expand, the demand for nichrome is expected to grow correspondingly. This presents both opportunities and challenges for the industry. On one hand, it drives innovation in nichrome production and application. On the other, it necessitates the development of sustainable sourcing and recycling methods to ensure a stable supply chain for this critical material.

The evolution of nichrome's importance in EV technology is closely tied to the broader trend of electrification in the automotive sector. As global efforts to reduce carbon emissions intensify, the demand for efficient and reliable electric vehicles has surged. This shift has brought nichrome to the forefront of EV component design, particularly in battery and powertrain systems.

In the context of electric vehicles, nichrome's unique properties make it invaluable. Its high resistance to corrosion and oxidation, coupled with its stability at high temperatures, addresses several critical challenges in EV design. These characteristics are particularly crucial in battery management systems, where temperature control and electrical resistance play vital roles in ensuring optimal performance and safety.

The technical objectives for nichrome in EV applications are multifaceted. Primarily, researchers and engineers aim to leverage nichrome's properties to enhance the efficiency and longevity of EV components. This includes improving battery thermal management systems, developing more durable electrical connectors, and creating more efficient heating elements for cabin climate control.

Another key objective is to optimize nichrome alloys specifically for EV applications. This involves fine-tuning the composition to achieve an ideal balance between electrical resistance, thermal conductivity, and durability. The goal is to create nichrome variants that can withstand the unique stresses of EV operations while contributing to overall vehicle efficiency.

Furthermore, there is a growing focus on integrating nichrome into next-generation EV technologies. This includes its potential use in solid-state batteries, where its thermal properties could play a crucial role in managing the high operating temperatures. Additionally, researchers are exploring nichrome's applications in advanced power electronics and motor designs, aiming to push the boundaries of EV performance and reliability.

As the EV market continues to expand, the demand for nichrome is expected to grow correspondingly. This presents both opportunities and challenges for the industry. On one hand, it drives innovation in nichrome production and application. On the other, it necessitates the development of sustainable sourcing and recycling methods to ensure a stable supply chain for this critical material.

EV Market Demand Analysis

The electric vehicle (EV) market has experienced unprecedented growth in recent years, driven by increasing environmental awareness, government incentives, and technological advancements. This surge in demand has created a ripple effect across the automotive supply chain, including the rising importance of nichrome in EV technology.

Global EV sales have shown remarkable growth, with annual sales surpassing 10 million units in 2022. This trend is expected to continue, with projections indicating that EVs could account for over 50% of new car sales by 2030 in major markets such as China, Europe, and the United States. The increasing adoption of EVs is not only reshaping the automotive industry but also creating new opportunities for materials and components suppliers.

Nichrome, an alloy primarily composed of nickel and chromium, is gaining significant traction in the EV market due to its unique properties. Its high electrical resistance, coupled with excellent heat and corrosion resistance, makes it an ideal material for various EV applications. The growing demand for nichrome in EVs is closely tied to the overall market expansion and the need for more efficient and durable components.

One of the primary applications of nichrome in EVs is in heating elements. As EVs lack the waste heat generated by internal combustion engines, they require dedicated heating systems for cabin comfort and battery temperature management. Nichrome-based heating elements offer rapid heat generation and uniform heat distribution, crucial for maintaining optimal battery performance and passenger comfort in various climatic conditions.

Furthermore, nichrome is finding applications in EV charging infrastructure. Fast-charging stations, which are essential for widespread EV adoption, often utilize nichrome-based heating elements to manage the thermal load during high-power charging sessions. As the demand for fast-charging stations grows, so does the need for nichrome in this sector.

The increasing electrification of vehicles has also led to a rise in the use of sensors and control systems, many of which incorporate nichrome components. These sensors play a critical role in monitoring various aspects of EV performance, including battery health, temperature, and overall system efficiency.

As the EV market continues to evolve, there is a growing emphasis on improving range and efficiency. This focus is driving innovations in lightweight materials and more efficient electrical systems, both areas where nichrome can play a significant role. The material's ability to withstand high temperatures while maintaining its electrical properties makes it valuable in the development of next-generation EV components.

In conclusion, the market demand for nichrome in EV technology is closely aligned with the overall growth of the electric vehicle sector. As EV adoption accelerates globally, the demand for nichrome is expected to rise correspondingly, driven by its critical applications in heating systems, charging infrastructure, and various other EV components.

Global EV sales have shown remarkable growth, with annual sales surpassing 10 million units in 2022. This trend is expected to continue, with projections indicating that EVs could account for over 50% of new car sales by 2030 in major markets such as China, Europe, and the United States. The increasing adoption of EVs is not only reshaping the automotive industry but also creating new opportunities for materials and components suppliers.

Nichrome, an alloy primarily composed of nickel and chromium, is gaining significant traction in the EV market due to its unique properties. Its high electrical resistance, coupled with excellent heat and corrosion resistance, makes it an ideal material for various EV applications. The growing demand for nichrome in EVs is closely tied to the overall market expansion and the need for more efficient and durable components.

One of the primary applications of nichrome in EVs is in heating elements. As EVs lack the waste heat generated by internal combustion engines, they require dedicated heating systems for cabin comfort and battery temperature management. Nichrome-based heating elements offer rapid heat generation and uniform heat distribution, crucial for maintaining optimal battery performance and passenger comfort in various climatic conditions.

Furthermore, nichrome is finding applications in EV charging infrastructure. Fast-charging stations, which are essential for widespread EV adoption, often utilize nichrome-based heating elements to manage the thermal load during high-power charging sessions. As the demand for fast-charging stations grows, so does the need for nichrome in this sector.

The increasing electrification of vehicles has also led to a rise in the use of sensors and control systems, many of which incorporate nichrome components. These sensors play a critical role in monitoring various aspects of EV performance, including battery health, temperature, and overall system efficiency.

As the EV market continues to evolve, there is a growing emphasis on improving range and efficiency. This focus is driving innovations in lightweight materials and more efficient electrical systems, both areas where nichrome can play a significant role. The material's ability to withstand high temperatures while maintaining its electrical properties makes it valuable in the development of next-generation EV components.

In conclusion, the market demand for nichrome in EV technology is closely aligned with the overall growth of the electric vehicle sector. As EV adoption accelerates globally, the demand for nichrome is expected to rise correspondingly, driven by its critical applications in heating systems, charging infrastructure, and various other EV components.

Nichrome Tech Status and Challenges

Nichrome, an alloy primarily composed of nickel and chromium, has gained significant traction in electric vehicle (EV) technology due to its unique properties. The current status of nichrome in EV applications is characterized by its widespread use in heating elements, sensors, and resistors. Its high electrical resistance, coupled with excellent heat and corrosion resistance, makes it an ideal material for various EV components.

However, the growing demand for nichrome in the EV industry has led to several challenges. One of the primary concerns is the limited availability of raw materials, particularly nickel. As EV production scales up globally, the strain on nickel resources has intensified, potentially leading to supply chain disruptions and price volatility. This situation is further exacerbated by geopolitical tensions and trade restrictions affecting key nickel-producing regions.

Another significant challenge lies in the manufacturing processes for nichrome components. As EVs require increasingly sophisticated and miniaturized parts, there is a pressing need for advanced manufacturing techniques that can produce nichrome components with higher precision and consistency. This necessitates substantial investments in research and development, as well as in upgrading existing production facilities.

The environmental impact of nichrome production and recycling presents another hurdle. While EVs are promoted as eco-friendly alternatives to conventional vehicles, the extraction and processing of nichrome's constituent metals can have significant environmental consequences. Developing more sustainable production methods and establishing efficient recycling processes for nichrome components are crucial challenges that the industry must address.

In terms of technological limitations, researchers are grappling with ways to enhance nichrome's performance under extreme conditions. As EVs push the boundaries of power and efficiency, nichrome components are subjected to higher temperatures and electrical loads. Improving the alloy's heat resistance and electrical properties without compromising its other beneficial characteristics remains a key area of focus.

Geographically, the development and production of nichrome technology for EVs are concentrated in a few key regions, primarily in East Asia, North America, and Europe. This concentration poses risks in terms of supply chain resilience and technological monopolies. Efforts to diversify the geographical distribution of nichrome technology development are underway but face obstacles related to intellectual property rights and the high costs of establishing new research and production facilities.

However, the growing demand for nichrome in the EV industry has led to several challenges. One of the primary concerns is the limited availability of raw materials, particularly nickel. As EV production scales up globally, the strain on nickel resources has intensified, potentially leading to supply chain disruptions and price volatility. This situation is further exacerbated by geopolitical tensions and trade restrictions affecting key nickel-producing regions.

Another significant challenge lies in the manufacturing processes for nichrome components. As EVs require increasingly sophisticated and miniaturized parts, there is a pressing need for advanced manufacturing techniques that can produce nichrome components with higher precision and consistency. This necessitates substantial investments in research and development, as well as in upgrading existing production facilities.

The environmental impact of nichrome production and recycling presents another hurdle. While EVs are promoted as eco-friendly alternatives to conventional vehicles, the extraction and processing of nichrome's constituent metals can have significant environmental consequences. Developing more sustainable production methods and establishing efficient recycling processes for nichrome components are crucial challenges that the industry must address.

In terms of technological limitations, researchers are grappling with ways to enhance nichrome's performance under extreme conditions. As EVs push the boundaries of power and efficiency, nichrome components are subjected to higher temperatures and electrical loads. Improving the alloy's heat resistance and electrical properties without compromising its other beneficial characteristics remains a key area of focus.

Geographically, the development and production of nichrome technology for EVs are concentrated in a few key regions, primarily in East Asia, North America, and Europe. This concentration poses risks in terms of supply chain resilience and technological monopolies. Efforts to diversify the geographical distribution of nichrome technology development are underway but face obstacles related to intellectual property rights and the high costs of establishing new research and production facilities.

Current Nichrome Solutions for EVs

01 Composition and properties of nichrome alloys

Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.- Composition and properties of nichrome alloys: Nichrome is an alloy primarily composed of nickel and chromium, with varying compositions for different applications. It is known for its high electrical resistance, heat resistance, and corrosion resistance. These properties make it suitable for use in heating elements, resistors, and other high-temperature applications.

- Nichrome in heating elements and electrical resistors: Nichrome is widely used in the manufacturing of heating elements and electrical resistors due to its high electrical resistance and heat-generating properties. It is commonly found in appliances such as hair dryers, toasters, and electric heaters. The alloy's stability at high temperatures makes it ideal for these applications.

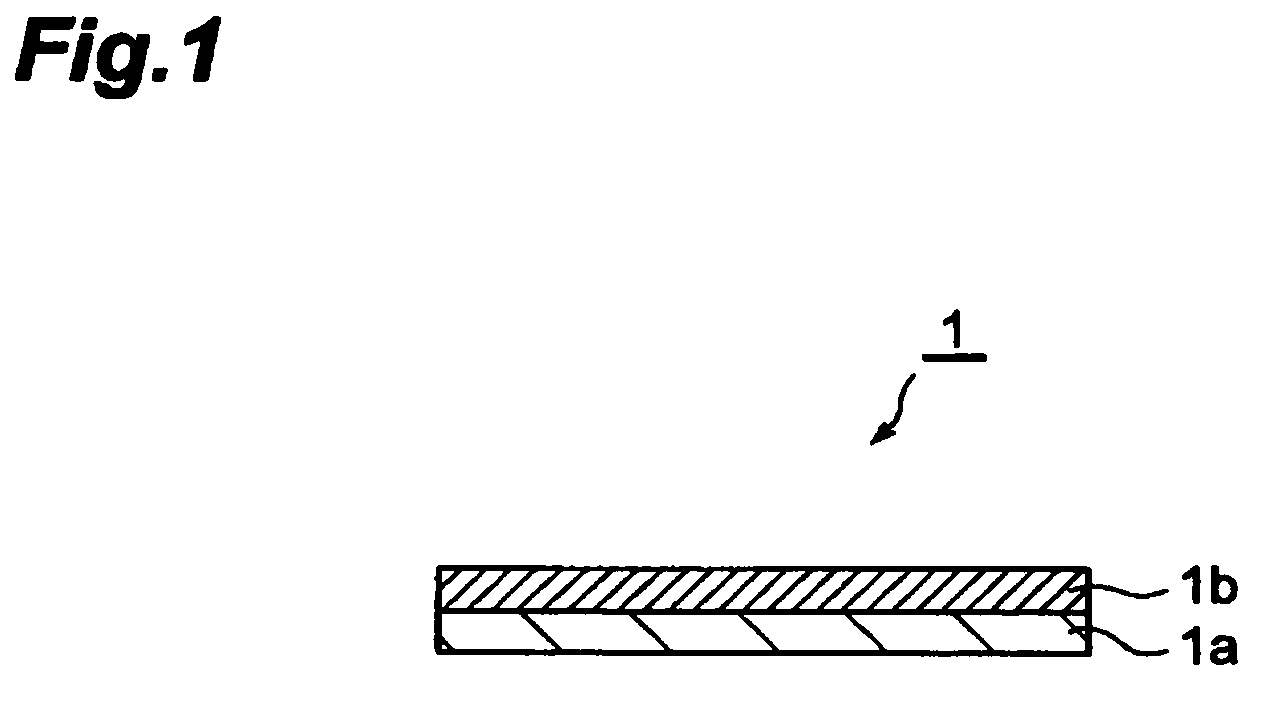

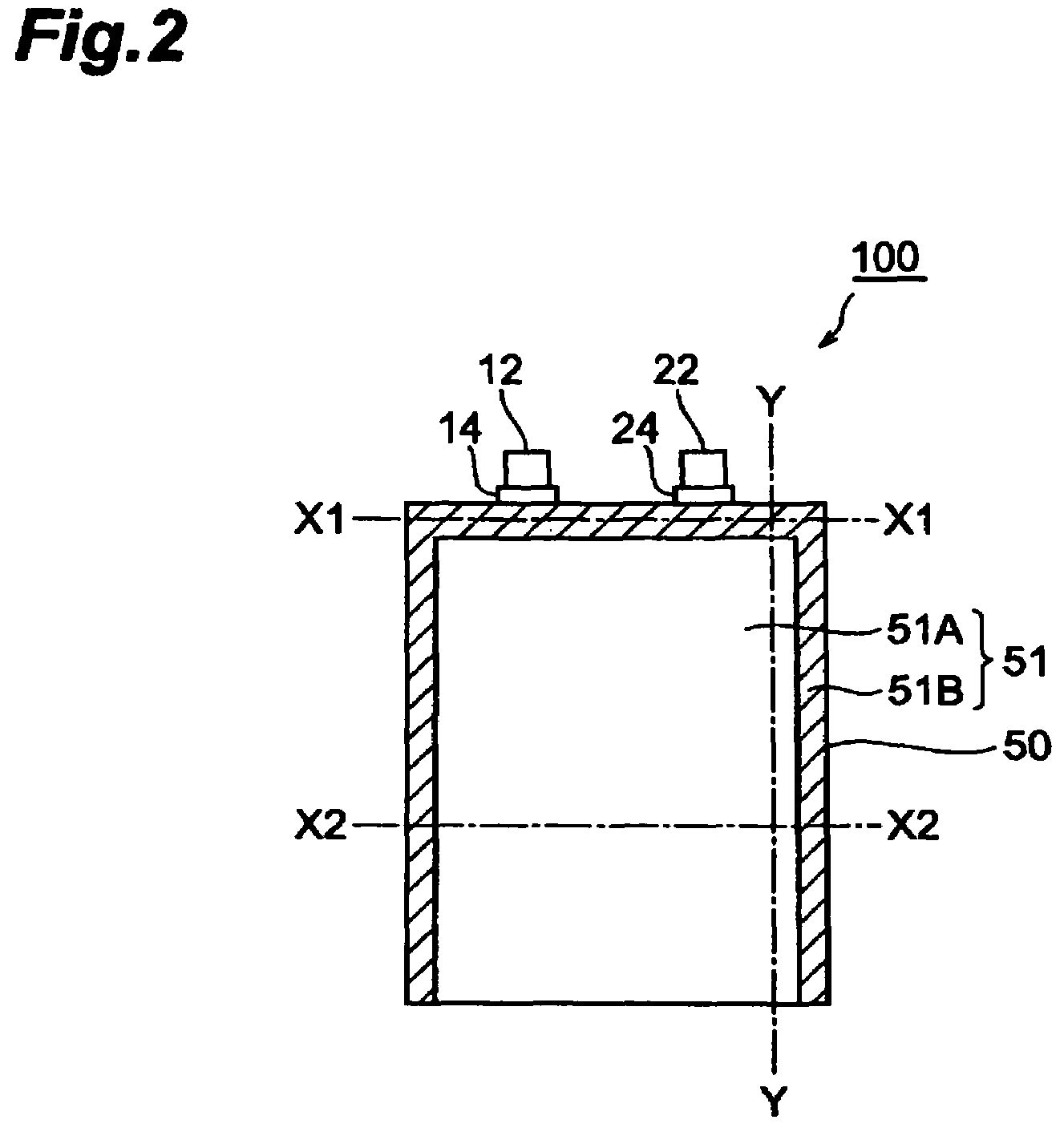

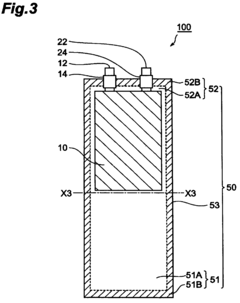

- Nichrome in thin film technology: Nichrome is utilized in thin film technology for various electronic applications. It can be deposited as a thin film on substrates to create resistive elements, sensors, and other microelectronic components. The alloy's properties allow for precise control of resistance values in miniaturized circuits.

- Nichrome in aerospace and high-temperature applications: The high temperature resistance and stability of nichrome make it suitable for aerospace and other high-temperature applications. It is used in components that require durability under extreme conditions, such as in aircraft engines, rocket nozzles, and industrial furnaces.

- Innovations in nichrome alloy compositions: Ongoing research focuses on improving nichrome alloy compositions to enhance its properties for specific applications. This includes developing new formulations with additional elements to improve oxidation resistance, mechanical strength, or electrical characteristics. These innovations aim to expand the range of applications for nichrome-based materials.

02 Manufacturing processes for nichrome components

Various manufacturing processes are employed to produce nichrome components, including wire drawing, thin film deposition, and powder metallurgy. These processes are optimized to achieve desired properties such as uniform composition, precise dimensions, and specific surface characteristics for different applications.Expand Specific Solutions03 Applications in electronic devices and sensors

Nichrome is widely used in electronic devices and sensors due to its stable electrical properties. It is employed in the fabrication of thin-film resistors, temperature sensors, and strain gauges. The material's low temperature coefficient of resistance makes it suitable for precision measurement applications.Expand Specific Solutions04 Heating element applications

Nichrome is extensively used in heating elements for various applications, including household appliances, industrial furnaces, and laboratory equipment. Its high melting point and resistance to oxidation at elevated temperatures make it an ideal material for producing durable and efficient heating elements.Expand Specific Solutions05 Surface treatment and coating techniques

Various surface treatment and coating techniques are applied to nichrome components to enhance their properties or protect them from environmental factors. These techniques include oxidation resistance coatings, insulation layers, and surface modifications to improve adhesion or electrical characteristics.Expand Specific Solutions

Key Players in Nichrome EV Tech

The nichrome market in electric vehicle technology is in a growth phase, driven by increasing EV adoption and demand for high-performance battery materials. The market size is expanding rapidly, with major players like LG Energy Solution, SK On, and Samsung SDI leading the charge. These companies are investing heavily in R&D to improve nichrome's performance and efficiency in EV applications. While the technology is relatively mature, ongoing innovations focus on enhancing energy density and thermal management. Emerging players like NIO and GEM are also making significant strides, particularly in battery recycling and sustainable production methods, indicating a competitive and dynamic landscape.

LG Energy Solution Ltd.

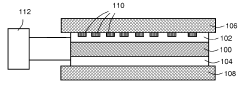

Technical Solution: LG Energy Solution has developed advanced nichrome-based heating elements for electric vehicle battery systems. Their technology utilizes a thin nichrome wire mesh embedded within the battery pack, providing efficient and uniform heating. This system enables rapid warm-up of batteries in cold conditions, improving EV performance and range. The company has also integrated smart control algorithms to optimize heating based on battery temperature and state of charge, enhancing overall energy efficiency[1][3]. Additionally, LG Energy Solution has implemented a novel coating technique for the nichrome elements, increasing their durability and resistance to corrosion in the battery environment[5].

Strengths: Efficient heating, improved cold-weather performance, smart control integration. Weaknesses: Potential for increased battery pack complexity, higher production costs.

SK On Co., Ltd.

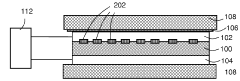

Technical Solution: SK On has developed a proprietary nichrome-based battery heating system for electric vehicles. Their technology incorporates a network of ultra-thin nichrome wires strategically placed within the battery module structure. This design allows for rapid and uniform heating of individual cells, crucial for maintaining optimal battery performance in cold climates. SK On's system also features adaptive power distribution, allocating heating energy based on real-time temperature sensors and vehicle operating conditions[2][4]. The company has further enhanced the technology by implementing a regenerative heating mode, which captures waste heat from the vehicle's powertrain to supplement the nichrome heating system, improving overall energy efficiency[6].

Strengths: Rapid heating capability, adaptive power distribution, energy efficiency. Weaknesses: Increased system complexity, potential for higher initial costs.

Core Nichrome Innovations for EVs

Electrode with conductive polymer-covered carbon nanotubes and electrochemical element employing the same

PatentActiveUS7691533B2

Innovation

- The use of conductive polymer-covered carbon nanotubes in electrodes, formed through electrolytic polymerization, which enhances the electrical double layer capacity and energy density while maintaining high-current discharge capabilities.

Electrochromic layer structure and method for the production thereof

PatentWO2011003686A1

Innovation

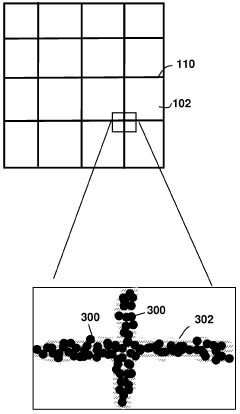

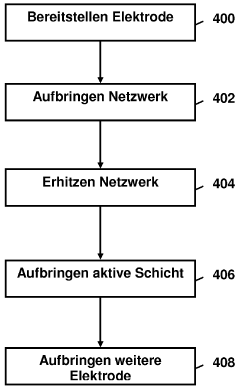

- An electrochromic layer structure with nanoparticles forming electrically conductive networks between electrodes, which reduces processing temperatures and allows for quick charge carrier exchange, combined with transparent protective layers and gaseous protective volumes to enhance durability and optical transparency.

Environmental Impact of Nichrome in EVs

The environmental impact of nichrome in electric vehicles (EVs) is a critical consideration as the automotive industry shifts towards more sustainable transportation solutions. Nichrome, an alloy primarily composed of nickel and chromium, plays a significant role in various EV components, particularly in heating elements and resistors.

One of the primary environmental benefits of using nichrome in EVs is its contribution to improved energy efficiency. The high electrical resistance and excellent heat-generating properties of nichrome allow for more efficient heating systems in electric vehicles. This efficiency translates to reduced energy consumption, which in turn leads to extended battery life and increased driving range. As a result, EVs equipped with nichrome-based heating elements can travel further on a single charge, reducing the overall carbon footprint associated with vehicle charging.

However, the production of nichrome does have environmental implications that must be considered. The mining and processing of nickel and chromium, the primary components of nichrome, can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. Additionally, the energy-intensive nature of alloy production contributes to greenhouse gas emissions during the manufacturing phase.

On the positive side, nichrome's durability and resistance to corrosion contribute to the longevity of EV components. This extended lifespan reduces the need for frequent replacements, thereby minimizing waste generation and the environmental impact associated with component production and disposal. The recyclability of nichrome also presents an opportunity for sustainable resource management, as the alloy can be recovered and reused in new applications, further reducing the demand for raw materials.

In terms of in-use emissions, nichrome-based components in EVs do not directly contribute to air pollution or greenhouse gas emissions during vehicle operation. This aligns with the zero-emission goals of electric vehicles and supports efforts to improve air quality in urban areas. However, it is important to note that the overall environmental impact of EVs, including those using nichrome components, is heavily dependent on the source of electricity used for charging. The transition to renewable energy sources for power generation is crucial to maximizing the environmental benefits of electric vehicles.

As the EV industry continues to evolve, ongoing research and development efforts are focused on optimizing the use of nichrome and exploring alternative materials that may offer even greater environmental benefits. These efforts aim to further reduce the environmental footprint of electric vehicles throughout their lifecycle, from production to end-of-life disposal or recycling.

One of the primary environmental benefits of using nichrome in EVs is its contribution to improved energy efficiency. The high electrical resistance and excellent heat-generating properties of nichrome allow for more efficient heating systems in electric vehicles. This efficiency translates to reduced energy consumption, which in turn leads to extended battery life and increased driving range. As a result, EVs equipped with nichrome-based heating elements can travel further on a single charge, reducing the overall carbon footprint associated with vehicle charging.

However, the production of nichrome does have environmental implications that must be considered. The mining and processing of nickel and chromium, the primary components of nichrome, can lead to habitat disruption, soil erosion, and water pollution if not managed responsibly. Additionally, the energy-intensive nature of alloy production contributes to greenhouse gas emissions during the manufacturing phase.

On the positive side, nichrome's durability and resistance to corrosion contribute to the longevity of EV components. This extended lifespan reduces the need for frequent replacements, thereby minimizing waste generation and the environmental impact associated with component production and disposal. The recyclability of nichrome also presents an opportunity for sustainable resource management, as the alloy can be recovered and reused in new applications, further reducing the demand for raw materials.

In terms of in-use emissions, nichrome-based components in EVs do not directly contribute to air pollution or greenhouse gas emissions during vehicle operation. This aligns with the zero-emission goals of electric vehicles and supports efforts to improve air quality in urban areas. However, it is important to note that the overall environmental impact of EVs, including those using nichrome components, is heavily dependent on the source of electricity used for charging. The transition to renewable energy sources for power generation is crucial to maximizing the environmental benefits of electric vehicles.

As the EV industry continues to evolve, ongoing research and development efforts are focused on optimizing the use of nichrome and exploring alternative materials that may offer even greater environmental benefits. These efforts aim to further reduce the environmental footprint of electric vehicles throughout their lifecycle, from production to end-of-life disposal or recycling.

Nichrome Supply Chain for EV Industry

The nichrome supply chain for the electric vehicle (EV) industry is a critical component in the production of advanced battery and heating technologies. As the demand for EVs continues to grow, the importance of a robust and efficient nichrome supply chain becomes increasingly evident.

Nichrome, an alloy primarily composed of nickel and chromium, is sourced from various regions worldwide. The primary producers of nickel include Indonesia, the Philippines, and Russia, while major chromium suppliers include South Africa, Kazakhstan, and Turkey. The extraction and processing of these raw materials form the initial stage of the nichrome supply chain.

Once extracted, the raw materials undergo refining processes to achieve the desired purity levels. This stage often involves multiple specialized facilities, as the production of high-quality nichrome requires precise control over the alloy composition. The refined nickel and chromium are then combined in specific ratios to create nichrome, typically containing about 80% nickel and 20% chromium.

The manufacturing of nichrome wire, a key component in EV heating systems and battery technologies, involves drawing the alloy into thin wires of various diameters. This process requires specialized equipment and expertise to ensure consistent quality and performance characteristics.

Distribution networks play a crucial role in the nichrome supply chain, connecting manufacturers with EV producers and their tier suppliers. These networks must be capable of handling the increasing demand while maintaining efficiency and reliability. Just-in-time inventory management systems are often employed to optimize stock levels and reduce costs.

The EV industry's reliance on nichrome has led to increased scrutiny of the supply chain's sustainability and resilience. Concerns about the environmental impact of mining operations and the geopolitical risks associated with raw material sourcing have prompted efforts to develop more sustainable and diversified supply chains.

To address these challenges, some EV manufacturers are exploring vertical integration strategies, seeking to secure direct access to raw materials or investing in nichrome production facilities. Others are focusing on developing alternative materials or technologies that could reduce dependence on nichrome, although these efforts are still in early stages.

As the EV market continues to expand, the nichrome supply chain is likely to face increasing pressure to scale up production while maintaining quality and addressing sustainability concerns. This will require ongoing innovation in extraction, processing, and manufacturing techniques, as well as strategic partnerships across the supply chain.

Nichrome, an alloy primarily composed of nickel and chromium, is sourced from various regions worldwide. The primary producers of nickel include Indonesia, the Philippines, and Russia, while major chromium suppliers include South Africa, Kazakhstan, and Turkey. The extraction and processing of these raw materials form the initial stage of the nichrome supply chain.

Once extracted, the raw materials undergo refining processes to achieve the desired purity levels. This stage often involves multiple specialized facilities, as the production of high-quality nichrome requires precise control over the alloy composition. The refined nickel and chromium are then combined in specific ratios to create nichrome, typically containing about 80% nickel and 20% chromium.

The manufacturing of nichrome wire, a key component in EV heating systems and battery technologies, involves drawing the alloy into thin wires of various diameters. This process requires specialized equipment and expertise to ensure consistent quality and performance characteristics.

Distribution networks play a crucial role in the nichrome supply chain, connecting manufacturers with EV producers and their tier suppliers. These networks must be capable of handling the increasing demand while maintaining efficiency and reliability. Just-in-time inventory management systems are often employed to optimize stock levels and reduce costs.

The EV industry's reliance on nichrome has led to increased scrutiny of the supply chain's sustainability and resilience. Concerns about the environmental impact of mining operations and the geopolitical risks associated with raw material sourcing have prompted efforts to develop more sustainable and diversified supply chains.

To address these challenges, some EV manufacturers are exploring vertical integration strategies, seeking to secure direct access to raw materials or investing in nichrome production facilities. Others are focusing on developing alternative materials or technologies that could reduce dependence on nichrome, although these efforts are still in early stages.

As the EV market continues to expand, the nichrome supply chain is likely to face increasing pressure to scale up production while maintaining quality and addressing sustainability concerns. This will require ongoing innovation in extraction, processing, and manufacturing techniques, as well as strategic partnerships across the supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!